| Revision as of 00:17, 24 December 2008 editJayron32 (talk | contribs)105,509 editsm Reverted edits by 70.234.147.98 (talk) to last version by Binksternet← Previous edit | Revision as of 02:59, 24 December 2008 edit undo70.234.147.98 (talk) Undid revision 259817588 by Jayron32 (talk)Next edit → | ||

| Line 26: | Line 26: | ||

| A newer term "waveguide" is used to describe conical, quadratic or oblate spheroidal horns. These are designed more for pattern control than acoustic loading. | A newer term "waveguide" is used to describe conical, quadratic or oblate spheroidal horns. These are designed more for pattern control than acoustic loading. | ||

| ] | |||

| A recent variant on horn design is the ] which incorporates multiple bandpass drivers whose diaphragms all exit into a single horn but at differing distances depending on the bandpass. High frequency drivers are at the horn's throat while lower frequency drivers are ported closer to the horn mouth. ], ], ] and ] offer speakers with configurations like this, called variously ''CoEntrant Horn'',<ref>{{US patent|5526456}}</ref> ''Unity Horn'' or ''Synergy Horn''. Depending on implementation, more linear transient response and smoother polar patterns are possible.<ref></ref> Because the design retains pattern control over a large range of its total bandwidth, and because the acoustic center of the design is near the rear of the enclosure, it is more easily combined in arrays for public address applications.<ref></ref> | |||

| == Applications == | == Applications == | ||

Revision as of 02:59, 24 December 2008

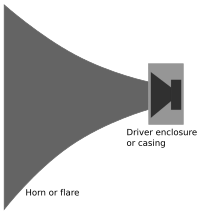

A horn speaker is a loudspeaker which uses a horn to increase the overall efficiency of the driving element, typically a diaphragm driven by an electromagnet. The horn itself is a passive component and does not amplify the sound from the driving element as such, but rather improves the coupling efficiency between the speaker driver and the air. The horn can be thought of as an "acoustic transformer" that provides impedance matching between the relatively dense diaphragm material (typically made of paper or, more recently, more exotic materials such as aluminum, titanium, or PET film) and the air (which has a very low density).

This is important because the difference in densities and motional characteristics of the air and of the driving element is a mismatch. The part of the horn next to the speaker cone "driver" is called the "throat" and the large part farthest away from the speaker cone is called the "mouth".

Operation

Acoustic horns convert large pressure variations with a small displacement into a low pressure variation with a large displacement and vice versa. It does this through the gradual, often exponential increase of the cross sectional area of the horn. The small cross-sectional area of the throat restricts the passage of air thus presenting a high impedance to the driver. This allows the driver to develop a high pressure for a given displacement. Therefore the sound waves at the throat are of high pressure and low displacement. The tapered shape of the horn allows the sound waves to gradually decompress (and therefore increase in displacement) until they reach the mouth, where they are of a low pressure but large displacement.

The most well known early horn speakers are those on mechanical phonographs, where the record moves a heavy metal needle that excites vibrations in a small metal diaphragm that acts as the driver for a horn. A famous example is the horn through which Nipper the RCA dog hears "His Master's Voice". The horn improves the loading and thus gets a better "coupling" of energy from the diaphragm into the air, and the pressure variations therefore get smaller as the volume expands and the sound travels up the horn. This kind of mechanical amplification was absolutely necessary in the days of pre-electrical sound reproduction in order to achieve a usable sound level.

A modern electrically driven horn speaker works the same way, replacing the mechanically excited diaphragm with a dynamic or piezoelectric speaker.

Improvements on basic designs

The physics (and mathematics) of horn operation were developed for many years, reaching considerable sophistication before WWII.

As a cone shape of fixed length would resonate at the natural frequency of its length, modern horn designs typically feature some form of conical, exponential or tractrix taper. Roughly speaking, the slower the flare rate, the deeper and lower frequencies the horn will reproduce for a given length of horn. For example, a horn area growth rate of 30% per foot will allow reproduction down to about 30 Hz; 1000% per foot (10 times area) per foot provides midrange reproduction; 100 times area per foot is used in high frequency horns.

Modern high output horns also make the throat area of the horn smaller than the cone diaphram area. This is called the "loading" or "compression" ratio of the horn. The compression ratio is the cone area divided by the throat area. Typically for bass and midrange frequency the compression ratio is from (1.5 to 1) low compression to normal compression (2 to 1) to high compression (3.5 to 1). High frequency tweeters sometimes have compression ratios as high as 10 to 1.

The higher the compression the greater the horn's ability to properly couple the diaphragm to the air at the horn's mouth, increasing efficiency, until the compression ratio is so high that it actually begins to impede cone motion. At this point the maximum sound output power from the horn (at a given distortion) will be reduced. To demonstrate this at an extreme, place a cone woofer face down on a concrete floor. The compression ratio will be very high, however sound output from the back of the speaker will be quite low.

A newer term "waveguide" is used to describe conical, quadratic or oblate spheroidal horns. These are designed more for pattern control than acoustic loading.

Applications

Horn speakers are used in many audio applications, since use of a horn reduces the need for exotic speaker cone materials and construction, eg, to be as lightweight and rigid as possible. The drivers in horn speakers can be very small, even for bass frequencies where conventional speakers would need to be very large for equivalent performance. Horn speakers can be designed to reproduce a wide range of frequencies using a single, small driver; to some extent these designs avoid the need for a crossover entirely. Lowther, Fostex, and Goodmans are firms which have produced such speakers.

Horn speakers can provide very high efficiencies, making them a good match for very low-powered amplifiers, such as single-ended triode amps or other tube amplifiers. After WWII, some early hi-fi fans went so far as to build low frequency horns whose mouths took up much of a wall of the listening room. The throats were sometimes outside on the lawn, or in the basement. With the coming of stereo in the 1960s, this approach became impossible even for the most dedicated fans. Those who faced domestic appearance concerns had never been able to use such large constructions in any case.

Some audiophiles use horn speakers for audio reproduction, while others eschew horn systems for their harmonic resonances (finding them an unpleasant form of distortion). Since there are a variety of horn designs (of differing length, material, and taper, as well as different drivers) it is, to some extent, impossible to give such blanket characterizations to horn speakers generally.

Public address and concert use

Horn speakers can also be used to provide the very high sound pressure levels needed for sound reinforcement and public address applications, although in these high sound pressure applications, high fidelity is sometimes compromised for the sake of the necessary efficiency, and also for the controlled dispersion characteristics which are generally required in most large volume spaces. A new method of counteracting some of the horn distortions has been pioneered by Dave Gunness while he was with EAW. EAW horn-loaded loudspeakers that have been processed with this proprietary system show reduced distortion while retaining high output power and controlled dispersion.

Concert venues often use large arrays of horn speakers for high-volume bass reproduction ("bass bins" or subwoofers), in order to provide bass that concertgoers can not only hear but feel. Combining multiple horn speakers in an array affords the same benefits as having a single horn with a greater mouth area: the low frequency cut-off extends lower as the horn mouth gets larger, and the array has the greater output power of multiple drivers.

See also

Notes

External links

- Lenard Education on horn systems Illustrated guide to horn loudspeakers

- The Frugal-Horns Site - open source horn projects