| Revision as of 09:54, 20 July 2006 editLossIsNotMore (talk | contribs)894 edits →Hobbyists, conversions, and racing: wfy← Previous edit | Revision as of 09:56, 20 July 2006 edit undoLossIsNotMore (talk | contribs)894 edits →Proponents' arguments: copyeditNext edit → | ||

| Line 349: | Line 349: | ||

| ===Proponents' arguments=== | ===Proponents' arguments=== | ||

| Supporters point out the following: | Supporters point out the following: | ||

| * BEVs |

* BEVs reduce dependence on (foreign) oil; | ||

| * BEVs mitigate ]; | * BEVs mitigate ]; | ||

| * BEVs are quieter than internal combustion engine vehicles; | * BEVs are quieter than internal combustion engine vehicles; | ||

| * BEVs do not produce noxious fumes; | * BEVs do not produce noxious fumes; | ||

| ⚫ | * BEVs can readilly satisfy the needs for short trips; | ||

| ⚫ | * BEVs can be powered indirectly by home ] using ], which offers advantages to both power producers and other grid users through peak demand satisfaction and to the EV user through cost reduction and load balancing, especially with time of use net metering |

||

| * Home recharging is more convenient than trips to gasoline stations; | |||

| ⚫ | * BEVs can readilly satisfy the needs for short trips |

||

| * |

* Recharging costs are more predictable than gas prices, and not subject to volatile international incidents; | ||

| ⚫ | * Maintenance such as oil changes, smog inspections (and their sometimes expensive consequences), cooling fluid replacement, and periodic repair and adjustments are reduced or completely eliminated, significantly reducing the cost of operation; and | ||

| * Recharging costs are more predictable, not subject to the daily international situation; and | |||

| ⚫ | * BEVs can be powered indirectly by home ] using ], which offers advantages to both power producers and other grid users through peak demand satisfaction and to the EV user through cost reduction and load balancing, especially with time of use net metering. | ||

| ⚫ | * Maintenance such as oil changes, smog inspections (and their sometimes expensive consequences), cooling fluid replacement, and periodic repair and adjustments are reduced or completely eliminated, significantly reducing the cost of operation |

||

| The greatest supporters of BEVs are often those who have obtained or built and used them. This is a self-selected group because BEVs have not been promoted by the major manufacturers in the United States, so their enthusiasm may be misleading. Owners of conventional gasoline vehicles, once given the chance to live with an BEV often leave their gasoline cars sitting in the driveway. Spouses, lukewarm when the vehicle is purchased often take over the vehicle from the purchaser once they use it. |

The greatest supporters of BEVs are often those who have obtained or built and used them. This is a self-selected group because BEVs have not been promoted by the major manufacturers in the United States, so their enthusiasm may be misleading. Owners of conventional gasoline vehicles, once given the chance to live with an BEV often leave their gasoline cars sitting in the driveway. Spouses, lukewarm when the vehicle is purchased often take over the vehicle from the purchaser once they use it. | ||

| ===Detractors' arguments=== | ===Detractors' arguments=== | ||

Revision as of 09:56, 20 July 2006

A battery electric vehicle (BEV) is an electric vehicle storing chemical energy in rechargeable battery packs to power one or more electrical motors.

BEVs were among the earliest automobiles, and are more energy efficient than common internal combustion engine (ICE) vehicles. They produce no pollution while being driven, and almost none at all if charged from most forms of renewable energy. Many are capable of acceleration performance exceeding that of conventional gasoline powered vehicles. New models can travel hundreds of miles on a charge, even after 100,000 miles of battery use. BEVs reduce dependence on oil, mitigate global warming, are quieter than internal combustion vehicles, and do not produce noxious fumes. While limited travel distance between battery recharging, charging time, and battery lifetime have been drawbacks, new battery and charging technologies have substantially improved in these areas.

Some models are still in limited production, but the most popular BEVs have been withdrawn and most of those have been destroyed by their manufacturers. A handful of future production models have been announced, although many more have been prototyped. In the US, the major domestic automobile manufacturers have been accused of deliberately sabotaging their electric vehicle efforts.

History

BEVs were among the earliest automobiles. Between 1832 and 1839 (the exact year is uncertain), Robert Anderson of Scotland invented the first crude electric carriage. A small-scale electric car was designed by Professor Sibrandus Stratingh of Groningen, Holland, and built by his assistant Christopher Becker in 1835. Frenchmen Gaston Plante, in 1865, and Camille Faure in 1881 improved the storage battery, paving the way for electric vehicles to flourish. France and Great Britain were the first nations to support their widespread development.

Before the preeminence of powerful but polluting internal combustion engines, electric automobiles held many speed and distance records around the turn of the century. Most notable was perhaps breaking of the 100 kilometers per hour speed barrier, by Camille Jenatzy on April 29, 1899 in his rocket-like EV named La Jamais Contente. It reached a top speed of 105.88 kilometers per hour (65.79 mph)

BEVs were produced by Anthony Electric, Baker Electric, Detroit Electric, and others during the first part of the 20th century and, for a time, out-sold gasoline-powered vehicles. Due to technological limitations and the lack of transistor-based electric technology, the top speed of these early production electric vehicles was limited to approximately 20 miles per hour. They were successfully sold as town cars to upper class customers and often marketed as suitable vehicles for women drivers due to their cleanliness, lack of noise and ease of operation.

Introduction of the electric starter by Cadillac in 1913, which simplified the difficult and sometimes dangerous task of starting the internal combustion engine, contributed to the downfall of the electric vehicle. As did radiators, in use as early as 1895 by Panhard-Levassor in their Systeme Panhard design, which allowed engines to keep cool enough to run for more than a few minutes, before which they had to stop and cool down at horse troughs along with the steamers to replenish their water supply. EV's may have fallen out of favor because of the mass produced Ford Model-T which went into production four years earlier in 1908. Ultimately, technological advances in internal-combustion powered cars advanced beyond that of their electric powered competitors, resulting in the superior performance and practicality of gasoline powered cars. By the late 1930s the early electric automobile industry had completely disappeared, with battery-electric traction being limited to niche application such as industrial vehicles.

The 1947 invention of the point-contact transistor marked the beginning of a new era for BEV technology. Within a decade, Henney Coachworks had joined forces with National Union Electric Company, the makers of Exide batteries, to produce the first modern electric car based on transistor technology. The Henney Kilowatt was produced in 36 volt and 72 volt configurations. The 72 volt models had a top speed approaching 60 miles per hour (96 km/h) and could travel nearly 60 miles on a charge. Despite the improved practicality of the Henney Kilowatt over previous electric cars, they were too expensive and production was ended by 1961. Even though the Henney Kilowatt never reached mass production volume, their transistor-based electric technology paved the way for modern EVs.

Incentives and quotas in the United States

Since the late 1980s, electric vehicles have been promoted in the US through the use of tax credits. BEVs are the most common form of what is defined by the California Air Resources Board (CARB) as zero emission vehicle (ZEV) passenger automobiles, because they produce no emissions while being driven. The CARB had set a minimum quota for the use of ZEVs, but it was withdrawn after complaints by auto manufacturers that it was economically unfeasible due to a lack of consumer demand. Many believe this complaint to be unwarranted because there were thousands waiting to purchase or lease electric cars. Companies such as General Motors, Ford, and Chrysler refused to meet the demand despite their production capability. US electric car leases in the 1990s were at reduced costs, and so whether high enough volumes to avoid financial loss could have been obtained is unknown.

The California program was designed by the CARB to reduce air pollution and not specifically to promote electric vehicles. So the zero emissions requirement in California was replaced by a combined requirement of a very small number of ZEVs to promote research and development, and a much larger number of partial zero-emissions vehicles (PZEVs), an administrative designation for an super ultra low emissions vehicle (SULEV), which emit about ten percent of the polution of ordinary low emissions vehicles and are also certified for zero evaporative emissions.

Outside the US

- France

France has known a large development of battery-electric vehicles in the 1990s, with the most successful vehicle being the electric Peugeot Partner/Citroën Berlingo, of which several thousand have been built, mostly for fleet use in municipalities or by Electricité de France.

- Norway

In Norway, zero-emission vehicles are tax-exempt and are also allowed to use the bus lane.

- Switzerland

In Switzerland, battery-electric vehicles have some popularity with private users. There is a national network of publicly accessible charging points, called Park & Charge, which also covers part of Germany and Austria.

- United Kingdom

In London, electrically powered vehicles have been exempted from the congestion charge. In most cities of the United Kingdom low speed electric milk floats (milk trucks) are used for the home delivery of fresh milk.

Selected production vehicles

Main article: List of production battery electric vehiclesSome popular battery electric vehicles sold or leased to fleets include (in chronological order):

| Name | Comments | Production years | Number produced | Cost |

|---|---|---|---|---|

| Henney Kilowatt | The first modern (transistor-based) electric car, capable of highway speeds of up to 60mph and outfitted with modern hydraulic brakes. | 1958-1960 | <100 | |

| General Motors EV1 | For lease only, all recovered and most destroyed | 1996-2003 | >1000 | ~ US $40K without subsidies |

| TWIKE | Three-wheeled EV with pedal assist option. Produced in Germany. | 1996+ | >750 | ~ US $16K |

| Chrysler EPIC minivan | Second generation of the Chrysler TEVan, using 324 volt lead-acid batteries in '97 and 336 volt NiMH from '98 on; 80 miles per hour top speed, range 70-90 miles | 1997-2000 | <351 | leased to government and utility fleets only |

| Honda EV Plus | First BEV from a major automaker without lead acid batteries. 80–110 mile range (130–180 km); 80+ MPH (130 km/h) top speed; 24 twelve volt NiMH batteries | 1997-1999 | ~300 | US $455/month for 36 month lease, or $53,000 without subsidies |

| Toyota RAV4 EV | Rare, some leased and sold on U.S. East and west coast, supported. Toyota agreed to stop crushing. | 1997-2002 | 1249 | US $40K without subsidies |

| Chevrolet S10 EV | S-10 with EV1 powertrain, 45 sold to private owners and survived; some sold to fleets, available on secondary market as refurbished vehicles. | 1998 | 100 | |

| Citroën Berlingo Electrique | 65+ MPH top speed, 40-60 mile range; 27 cadmium-nickel 6 volt, 100 amp-hour batteries in three packs. Very similar to the Peugeot Partner which has also been offered as a BEV. | 1998-2005 | ||

| Ford Ranger EV | Some sold, most leased; almost all recovered and most destroyed. Ford has announced reconditioning and sale of a limited quantity to former leaseholders by lottery. | 1998-2002 | 1500, perhaps 200 surviving | ~ US $50K subsidized down to $20K |

| Nissan Altra EV | Mid-sized station wagon designed from the ground up as the first BEV to use Li-ion batteries; 75+ MPH top speed, 120 mile range, 100,000+ mile battery lifetime | 1998-2000 | ~133 | US $470/month lease only |

| Think Nordic TH!NK City | Two seat, 85 km (52 mile) range, 90 km/h (56 MPH) top speed, Nickel-cadmium batteries | 1999-2002 | 1005 | |

| REVA | India-built city car (40 mph top speed,) now also sold in England as the "G-Whiz" | 2001+ | >1600 | ~ £8K US $15K |

| Neighborhood electric vehicles (NEVs, top speed limited to 25 MPH) | ||||

| Global Electric Motorcars | Five models currently in production, including two pickup trucks; all electronically limited to 25 MPH to qualify as NEVs, and using lead-acid batteries. Acquired by DaimlerChrysler in 2000. | 1998+ | >30,000 | varies by model, US $7K to $12.5K |

| Dynasty EV | Five models currently in production, all very similar to Sedan model, using lead-acid batteries and limited to 25 MPH to qualify as NEVs. Sedan range is 30 miles. | 2001+ | ||

Comparison to internal combustion vehicles

Operational cost

Electric vehicles typically cost between two and four cents per mile to operate, while gasoline-powered ICE vehicles currently cost about four to six times as much.

Energy efficiency

Production and conversion BEVs typically use 0.3 to 0.5 kilowatt-hours per mile (0.2 to 0.3 kWh/km). Nearly half of this power consumption is due to inefficiencies in charging the batteries. The U.S. fleet average of 23 miles per gallon of gasoline is equivalent to 1.58 kilowatt-hours per mile and the 70 MPG Honda Insight gets 0.52 kWh/mi (assuming 36.4 kWh per U.S. gallon of gasoline), so battery electric vehicles are relatively energy efficient. When comparisons of the total energy cycle are made, the relative efficiency of BEVs drops, but such calculations are usually not provided for internal combustion vehicles (e.g. the energy used to produce specialized fuels such as gasoline is usually left unstated.)

CO2 emissions are useful for comparison of electricity and gasoline consumption. Such comparisons include energy production, transmission, charging, and vehicle losses. CO2 emissions improve in BEVs with sustainable electricity production but are fixed for gasoline vehicles. (Unfortunately, such figures for the EV1, Ford Ranger EV, EVPlus, and other production vehicles are unavailable.)

| Model | Short tons CO2 (conventional, mostly fossil fuel electricity production) |

Short tons CO2 (renewable electricity production, e.g., solar panel or wind power) |

|---|---|---|

| 2002 Toyota RAV4-EV (pure BEV) | 3.8 | 0.0 |

| 2000 Toyota RAV4 2wd (gasoline) | 7.2 | 7.2 |

| Other battery electric vehicle(s) | ||

| 2000 Nissan Altra EV | 3.5 | 0.0 |

| Hybrid vehicles | ||

| 2001 Honda Insight | 3.1 | 3.1 |

| 2005 Toyota Prius | 3.5 | 3.5 |

| 2005 Ford Escape H 2x | 5.8 | 5.8 |

| 2005 Ford Escape H 4x | 6.2 | 6.2 |

| Internal combustion engine vehicles | ||

| 2005 Dodge Neon 2.0L | 6.0 | 6.0 |

| 2005 Ford Escape 4x | 8.0 | 8.0 |

| 2005 GMC Envoy XUV 4x | 11.7 | 11.7 |

Aerodynamic drag has a large impact on energy efficiency as the speed of the vehicle increases. A list of cars and their corresponding drag coefficients is available.

Environmental impact

Due to their relatively beneficial effect on environment, electric vehicles are important for improving motor vehicle traffic to provide a healthier living environment.

Many factors must be considered when comparing vehicles' total environmental impact. The most comprehensive comparison is a "cradle-to-grave" or lifecycle analysis. Such an analysis considers all inputs including original production and fuel sources and all outputs and end products including emissions and disposal. The varying amounts and types of inputs and outputs vary in their environmental effects and are difficult to directly compare. For example, whether the environmental effects of nickel and cadmium pollution from a NiCd battery production facility are less than those of hydrocarbon emissions and petroleum refining is unknown. Similar comparisons would need to be addressed for each input and output in order to make fair judgement of relative total environmental impact.

A large lifecycle input difference of BEVs compared to ICE vehicles is that they require electricity instead of a liquid fuel. When the electricity is provided from renewable energy, this is a considerable advantage. However, if the electricity is produced from fossil fuel sources — as most electricity is — the relative advantage of the electric vehicle is substantially reduced. So, developing additional renewable energy sources is necessary for electric vehicles to further reduce net emissions. Still, the environmental impact of electricity production (indirect emissions) depends on the electricity production mix, and are usually considerably lower than the direct emissions of ICE vehicles.

Another lifecycle input of electric vehicles differing from internal combustion vehicles is the large battery pack. Modern batteries have been shown to be able to outlast the vehicle they are used in. Batteries tested by Toyota have shown only minimal degradation in performance after 150,000 miles. BEVs do not require a fuel-burning engine and their support systems or the related maintenance, so they are often more reliable and require less maintenance. Although BEVs are uncommon, advances in battery technology have taken place in other markets such as for mobile phones, laptops, forklifts and hybrid electric vehicles. Improvements to battery technology in such other markets make BEVs more practical.

Acceleration performance

Many of today's BEVs are capable of acceleration performance which exceeds that of conventional gasoline powered vehicles. Electric vehicles can utilize a direct motor-to-wheel configuration which increases the amount of available power. Having multiple motors connected directly to the wheels allows for each of the wheels to be used for both propulsion and as braking systems, thereby increasing traction. In some cases, the motor can be housed directly in the wheel, such as in the Whispering Wheel design, which lowers the vehicle's center of gravity and reduces the number of moving parts. When not fitted with an axle, differential, or transmission, electric vehicles have greater torque availability, directly accelerating the wheels. A gearless or single gear design in some BEVs eliminates the need for gear shifting, giving the such vehicles both smoother acceleration and braking, and allows higher torque at a wide range of RPMs. For example, the Venturi Fetish delivers supercar acceleration despite a relatively modest 300 horsepower, and a top speed of only around 100 miles per hour. Some DC motor-equipped drag racer BEVs, have simple two-speed transmissions to improve top speed. Larger vehicles, such as electric trains and land speed record vehicles, overcome this speed barrier by dramatically increasing the wattage of their power system.

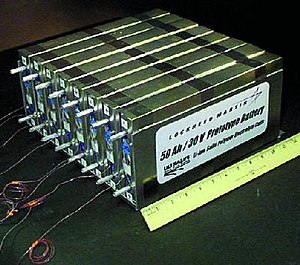

Batteries

Rechargable batteries used in electric vehicles include lead-acid ("flooded" and VRLA), NiCd, nickel metal hydride, lithium ion, Li-ion polymer, and, less commonly, zinc-air, and the molten salt batteries.

Charging

Batteries in BEVs must be periodically recharged. BEVs most commonly charge from the power grid, which is in turn generated from a variety of domestic resources; primarily hydroelectricity, coal, natural gas, and nuclear. Home power such as roof top photovoltaic solar cell panels, microhydro or wind may also be used. Electricity can also be supplied with a portable fueled generator. Although not strictly a BEV, the Ford Reflex concept car incorporates photovoltaics into its exterior to help power its hybrid powertrain.

Charging time is limited primarily by the capacity of the grid connection. A normal household outlet is between 1.5 kilowatts in the US to 3 kilowatts in the rest of the world (countries with 240 V supply). The main connection to a house might be able to sustain 10 kilowatts, and special wiring can be installed to use this. At this higher power level charging even a small, 7 kilowatt-hour (14–28 mi) pack, would probably require one hour. This is small compared to the effective power delivery rate of an average petro pump, about 5,000 kilowatts. Even if the supply power can be increased, most batteries do not accept charge at greater than their charge rate ("C1".)

In 1995, some charging stations charged BEVs in one hour. In November 1997, Ford purchased a fast-charge system produced by AeroVironment called "PosiCharge" for testing its fleets of Ranger EVs, which charged their lead-acid batteries in between six and fifteen minutes. In February 1998, General Motors announced a version of its "Magne Charge" system which could recharge NiMH batteries in about ten minutes, providing a range of sixty to one hundred miles.

In 2005, handheld device battery designs by Toshiba were claimed to be able to accept an 80% charge in as little as 60 seconds. Scaling this specific power characteristic up to the same 7 kilowatt-hour EV pack would result in the need for a peak of 336 kilowatts of power from some source for those 60 seconds. It is not clear that such batteries will work directly in BEVs as heat build-up may make them unsafe.

Most people do not require fast recharging because they have enough time (6 to 8 hours) during the work day or overnight to refuel. As the charging does not require attention it takes a few seconds for an owner to plug in and unplug their vehicle. Many BEV drivers prefer refueling at home, avoiding the inconvenience of visiting a petro-station. Some workplaces provide special parking bays for electric vehicles with charging equipment provided.

The charging power can be connected to the car in two ways:

- The first is a direct electrical connection known as conductive coupling. This might be as simple as a mains lead into a weather proof socket through to special high capacity cables with connectors to protect the user from high voltages.

- The second approach is known as inductive coupling. A special 'paddle' is inserted into a slot on the car. The paddle is one winding of a transformer, while the other is built into the car. When the paddle is inserted it completes a magnetic circuit which provides power to the battery pack.

The major advantage of the inductive approach is that there is no possibility of electrocution as there are no exposed conductors, although interlocks can make conductive coupling nearly as safe. Conductive coupling equipment is lower in cost and much more efficient due to a vastly lower component count.

Travel range before recharging

The range of a BEV depends on the number and type of batteries used, and the performance demands of the driver. The weight and type of vehicle also has an impact just as it does on the mileage of traditional vehicles. Electric vehicle conversions usually use lead-acid batteries because they are the most available and inexpensive. Such conversions generally have a range of 20 to 50 miles (30 to 80 km). Production EVs with lead-acid batteries are capable of up to 80 miles (130 km) per charge. NiMH batteries have higher energy density and may deliver up to 120 miles (200 km) of range. New lithium-ion battery-equipped EVs are said to provide 250-300 miles (400-500 km) of range per charge. Finding the balance of range versus performance, battery capacity versus weight, and battery type versus cost challenges every EV manufacturer.

EVs can also use pusher trailers or genset trailers in order to function as a hybrid vehicle for occasions when extended range is desired without the additional weight during normal short range use. Such vehicles become internal combustion engine-powered when utilizing their trailer, allowing greater range that may be needed for longer trips.

Replacing

An alternative to recharging is to replace drained batteries with charged batteries. Discharged modular electric car batteries can be replaced by charged ones in the fuel stations, car shops or similar places.

Lifespan

Individual batteries are usually arranged into large battery packs of various voltage and ampere-hour capacity products to give the required energy capacity. Battery life should be considered when calculating the extended cost of ownership, as all batteries eventually wear out and must be replaced. The rate at which they expire depends on a number of factors.

The depth of discharge (DOD) is the recommended proportion of the total available energy storage for which that battery will achieve its rated cycles. Deep cycle lead-acid batteries generally should not be discharged below 50% capacity. More modern formulations can survive deeper cycles.

In real world use, some fleet Toyota RAV4 EVs, using NiMH batteries, have exceeded 100,000 miles (160,000 km) with little degradation in their daily range. Quoting that report's concluding assessment:

- The five-vehicle test is demonstrating the long-term durability of Nickel Metal Hydride batteries and electric drive trains. Only slight performance degradation has been observed to-date on four out of five vehicles.... EVTC test data provide strong evidence that all five vehicles will exceed the 100,000-mile mark. SCE’s positive experience points to the very strong likelihood of a 130,000 to 150,000-mile Nickel Metal Hydride battery and drive-train operational life. EVs can therefore match or exceed the lifecycle miles of comparable internal combustion engine vehicles.

- In June 2003 the 320 RAV4 EVs of the SCE fleet were used primarily by meter readers, service managers, field representatives, service planners and mail handlers, and for security patrols and carpools. In five years of operation, the RAV4 EV fleet had logged more than 6.9 million miles, eliminating about 830 tons of air pollutants, and preventing more than 3,700 tons of tailpipe carbon dioxide emissions. Given the successful operation of its EVs to-date, SCE plans to continue using them well after they all log 100,000-miles.

Jay Leno's 1909 Baker Electric still operates on its original Edison cells. Battery replacement costs of BEVs may be partially or fully offset by the lack of regular maintenance such as oil and filter changes required for internal combustion engine vehicles, and by the greater reliability of BEVs due to their fewer moving parts.

Batteries can pose an environmental hazard, incurring disposal or recycling costs. Some of the chemicals used in the manufacture of advanced batteries such as Li-ion, Li ion polymer and zinc-air are hazardous and potentially environmentally damaging. Traditional car batteries have very successful recycling programs. Widespread use of battery electric vehicles would require the implementation of similar recycling programs. More modern formulations also tend to use lighter, more biologically remediable elements such as iron, lithium, carbon and zinc. In particular, moving away from the toxic heavy metals cadmium and chromium makes disposal less critical. Batteries might not pose a greater risk than is currently accepted for fossil fuel-based transportation, as petroleum-powered transportation leads to substantial environmental damage in the form of spills, smog, and distillation byproducts.

Safety

Firefighters and rescue personnel receive special training to deal with the higher voltages and chemicals encountered in electric and hybrid gas-electric vehicle accidents.

Hobbyists, conversions, and racing

Hobbyists often build their own EVs by converting existing production cars to run solely on electricity. There is a cottage industry supporting the conversion and construction of BEVs by hobbyists. Universities such as the University of California, Irvine even build their own custom electric or hybrid-electric cars from scratch.

Short-range battery electric vehicles offer the hobbyist comfort, utility, and quickness, sacrificing only range. Short-range BEVs may be built using high-performance lead–acid batteries, using about half the mass needed for a 60 to 80 mile (100 to 130 km) range; the result is a vehicle with about a thirty mile (50 km) range, which when designed with appropriate weight distribution (40/60 front to rear) does not require power steering, offers exceptional acceleration in the lower end of its operating range, is freeway capable and legal, and costs little to build and maintain. By including a manual transmission, short-range BEVs can obtain both better performance and greater efficiency than the single-speed BEVs developed by major manufactures. Unlike the converted golf carts used for neighborhood electric vehicles, short-range BEVs may be operated on typical suburban throughways (40 to 45 MPH or 60 or 70 km/h speed limits are typical) and can keep up with traffic typical on such roads and the short "slow-lane" on-and-off segments of freeways common in suburban areas.

Some drag race such conversions as members of National Electric Drag Racing Association (NEDRA). Battery electric vehicles are also very popular in quarter mile (400 meter) racing. The NEDRA regularly holds electric car races and often competes them successfully against exotics such as the Dodge Viper.

Japanese Professor Hiroshi Shimizu from Faculty of Environmental Information of the Keio University created the limousine of the future: the Eliica (Electric Lithium Ion Car) has eight wheels with electric 55 kilowatt hub motors (8WD) with an output of 470 kilowatts and zero emissions. With a top speed of 190 kilometers per hour, and a maximum reach of 320 kilometers provided by lithium-ion-batteries. (video at eliica.com)

Future

The future of battery electric vehicles depends primarily upon the cost and availability of batteries with high energy densities, power density, long life, as all other aspects such as motors, motor controllers, and chargers are fairly mature and cost-competitive with internal combustion engine components. Li-ion, Li-poly and zinc-air batteries have demonstrated energy densities high enough to deliver range and recharge times comparable to conventional vehicles. Aluminium batteries offer exceptional theoretical performance and have been proposed as an international shipboard energy transfer mechanism

While hybrid vehicles apply many of the technical advances first developed for battery electric vehicles, they are not considered BEVs. The development and production of hybrid vehicles are, however, improving the cost and performance of batteries, electric motors, chargers, and motor controllers, which will help battery electric vehicles and plug-in hybrid vehicles (PHEVs). As hybrids become more refined, battery life, capacity and energy density will improve and their internal combustion engine will be used less. A non-profit program, the California Cars Initiative, or "CalCars" at the University of California, Davis, has converted hybrid Toyota Prius automobiles to operate as a plug-in hybrid electric vehicle (PHEV) through the installation of additional batteries and software modifications. This vehicle operates as a pure electric for short trips, taking its power from household and workplace rechargers. For longer trips the vehicle operates normally as a hybrid. Prototype conversions using lead-acid batteries are in use today. It is expected that a production conversion would use a more advanced battery. CalCars is currently soliciting donations of additional vehicles and funds for their project.

Various pre-production announcements by major manufacturers suggest that there may soon be a breakthrough in the availability of commonplace, general purpose electric vehicles suitable for everyday use on available roads in mixed traffic conditions:

- General Motors has reportedly been developing a plug-in hybrid, which may be ready in time for the Detroit auto show in January, 2007.

- Mitsubishi has committed to creating a flexible product line based upon the Colt minivan with motors within the wheels that can be produced as a BEV, a hybrid, or a fuel cell vehicle. No North American import commitment has been made, however.

- Subaru may accelerate their R1e prototype development. Initially proposed for 2007 production, this was pushed back to 2010 but may be moved up in response to fuel prices, advances in battery technology, and worldwide market interest.

- Toyota has suggested that the next generation Prius may have Lithium-Ion batteries and a nine mile "stealth" range to support 110 MPG in appropriate conditions, suggesting the future possibility of a plug-in hybrid Prius.

- While the General Motors investment in Ovonics's large format Nickel-Metal Hydride batteries was sold to Texaco, now part Chevron, no oil company controls the lithium battery market. Developed by East Asian firms for use in portable computer equipment, the patents and production are beyond the reach of US automakers and oil companies, except as they may lobby for tariffs on the import of batteries or vehicles (as has been done with imports of ethanol fuels currently taxed at 100 percent of value at the behest of maize-based ethanol producers.)

Production announcements

The following BEV models have been announced as entering production:

- AC propulsion announces plans to convert Toyota Scion xA and xB vehicles: frequently asked questions at acpropulsion.com (items 8 and 9).

- Mitsubishi, a Japanese automobile manufacturer, announced on May 11 2005 that it will mass-produce its MIEV (Mitsubishi In-wheel Electric Vehicle.) Test fleets are to arrive in 2006 and production models should be available in 2008: story at abcnews.go.com. The first test car, revealed to be Colt EV, is expected to have a range of 93 miles using lithium-ion batteries and in-wheel electric motors. The target price of a MIEV should be around US$19,000. No export decision has yet been made: story at msnbc.msn.com

- Plug-in hybrid electric vehicles have been developed by the California Cars Initiative, Edrive Systems, and Hymotion. They take a Toyota Prius, add more battery capacity and modify the controller. Then they can get 250 miles per gallon by plugging in at home for a small light charge each night. Edrive and Hymotion in 2005 announced plans to modify other hybrid models, including the Ford Escape.

- SVE (Société de Véhicules Électric, a company formed by the French Dasseault and Heuliez group) announced they will produce the Cleanova II (French only), based on the Kangoo. It will be available in pre-mass-production in 2007 and mass-production in 2008. The system exists in two versions: all electric (200km autonomy) and rechargeable hybrid (500km autonomy). The system include an electric engine developed by TM4 a subsidiary of Hydro-Quebec, from Quebec Canada who developed also since 20 years an electric wheel motor.

- Venturi "Fetish" sports car to use AC propulsion components from venturi.fr (Flash animation with music background; see also Forbes — Vehicle of the Week — Car Fetish)

List of recent prototypes

Recent prototype EVs include:

- Cree SAM

- Eliica (Electric LIthium-Ion Car) designed by a team at Keio University in Tokyo, led by Professor Hiroshi Shimizu.

- Ford E-Ka

- Lexus EV (Featured in the film Minority Report)

- Maya-100: Li-ion "super"-polymer battery; 360 kilometer range claimed (announcement at electrovaya.com)

- Mitsubishi Colt EV: Li-ion battery, in-wheel motors (annoucement at media.mitsubishi-motors.com)

- Pinanfarina Ethos II

- Renault EV Racer

- Solectria Sunrise

- Subaru Zero EV (announcement at msnbc.msn.com)

- Suzuki EV Sport

- Volvo 3CC: Three seater with lithium ion batteries (announcement at volvocars-pr.com)

Controversy

The three major US automobile manufacturers, General Motors, Chrysler Corporation and Ford Motor Company have been accused of deliberately sabotaging their own BEV efforts through several methods: failing to market, failing to produce appropriate vehicles, failing to satisfy demand, and using lease-only programs with prohibitions against end of lease purchase. By these actions they have managed to terminate their BEV development and marketing programs despite operators' offers of purchase and assumption of maintenance liabilities. The Chrysler "golf cart" program has seemed to some as an insult to the marketplace and to government mandates; Chrysler has been accused of intentionally failing to produce a vehicle usable in mixed traffic conditions. Moreover, he three major American motor companies have almost exclusively promoted their electric cars in the American market, where gas has been comparatively cheap, and virtually ignored the European market, where gas is significantly more expensive. This can be seen as avoiding the market. Because of the much higher fuel costs, the latent demand for electric vehicles would presumably be higher in Europe, and the outcome of increased BEV sales would be more certain.

The manufacturers, in their defense, have responded that they only make what the public wants. EV supporters point out that this response is the same argument used by GM to justify the intensively promoted 11 miles per gallon, 6500 pound (2,950 kg) Hummer H2 SUV. However, at the end of their programs GM destroyed its BEV fleet, despite offers to purchase from drivers. Ford's Norwegian-built "Th!nk" fleet was covered by a three-year exemption to the standard US motor vehicle safety laws, after which time Ford had planned to dismantle and recycle its fleet. However, Ford was persuaded by activists to refrain from destroying its fleet and return them to Norway and sell them as used vehicles. Ford also sold a few lead-acid battery Ranger EVs, and some fleet purchase Chevrolet S-10 EV pickups are being refurbished and sold on the secondary market.

Both Honda and Toyota also manufactured BEVs. Honda followed the lead of the other majors and terminated their lease-only programs, completely destroying their fleet and its components by shredding. Toyota offered vehicles for both sale and lease. While Toyota has terminated manufacture of new vehicles, it continues to support those manufactured. A small number of Toyota RAV4 EVs are still on the road.

A film on the subject, directed by former EV1 owner and activist Chris Paine, entitled Who Killed the Electric Car? premiered at the Sundance Film Festival and at the Tribeca Film Festival in 2006, and was released July, 2006.

Proponents' arguments

Supporters point out the following:

- BEVs reduce dependence on (foreign) oil;

- BEVs mitigate global warming;

- BEVs are quieter than internal combustion engine vehicles;

- BEVs do not produce noxious fumes;

- BEVs can readilly satisfy the needs for short trips;

- Home recharging is more convenient than trips to gasoline stations;

- Recharging costs are more predictable than gas prices, and not subject to volatile international incidents;

- Maintenance such as oil changes, smog inspections (and their sometimes expensive consequences), cooling fluid replacement, and periodic repair and adjustments are reduced or completely eliminated, significantly reducing the cost of operation; and

- BEVs can be powered indirectly by home photovoltaics using net metering, which offers advantages to both power producers and other grid users through peak demand satisfaction and to the EV user through cost reduction and load balancing, especially with time of use net metering.

The greatest supporters of BEVs are often those who have obtained or built and used them. This is a self-selected group because BEVs have not been promoted by the major manufacturers in the United States, so their enthusiasm may be misleading. Owners of conventional gasoline vehicles, once given the chance to live with an BEV often leave their gasoline cars sitting in the driveway. Spouses, lukewarm when the vehicle is purchased often take over the vehicle from the purchaser once they use it.

Detractors' arguments

Skeptics of the viability of BEV's fall into two groups, one arguing on conventional practicality grounds, and the other arguing in more general terms.

The former group points, among other issues, to:

- Limited driving range available today between fillings;

- Most electricity currently produced using fossil fuels, at 1.3 pounds of CO2 (0.59 kg) per kilowatt-hour;

- Expensive batteries; and

- Poor cold weather performance of some kinds of batteries.

The other group ponders the future of the car as a transport solution for even more widespread global adoption, noting that the issues of traffic jams, noise pollution, total life-cycle pollution, energy expenditure and the health toll of a sedentary lifestyle, will not be solved by zero-emission vehicles.

See also

References

- Bellis, M. (2006) "The History of Electric Vehicles: The Early Years" About.com article at inventors.about.com accessed on 6 July 2006

- Bellis, M. (2006) "The History of the Automobile: The First Mass Producers of Cars - The Assembly Line" About.com article at inventors.about.com accessed on 5 July 2006

- McMahon, D. (2006) "Some EV History" Econogics, Inc. essay at econogics.com accessed on 5 July 2006

- Idaho National Laboratory (2005) "Comparing Energy Costs per Mile for Electric and Gasoline-Fueled Vehicles" Advanced Vehicle Testing Activity report at avt.inel.gov accessed 11 July 2006.

- Idaho National Laboratory (2006) "Full Size Electric Vehicles" Advanced Vehicle Testing Activity reports at avt.inel.gov accessed 5 July 2006

- Idaho National Laboratory (2006) "1999 General Motors EV1 with NiMH: Performance Statistics" Electric Transportation Applications info sheets at inel.gov accessed 5 July 2006

- US Department of Energy and Environmental Protection Agency (Model year 2007) "Search for cars that don't need gasoline" Fuel Economy Guide database at fueleconomy.gov accessed 5 July 2006

- Tahara, K. et al. (2001) "Comparison of CO2 Emissions from Alternative and Conventional Vehicles." World Resources Review 13:52-60 summary at ilea.org accessed 5 July 2006

- Van Mierlo, J., et al. (2003) "Environmental Damage Rating Analysis Tool as a Policy Instrument" 20th International Electric Vehicle Symposium and Exposition (Long Beach, California) conference paper at etecmc10.vub.ac.be accessed 14 July 2006

- Hedlund, R. (2006) "The 100 Mile Per Hour Club" National Electric Drag Racing Association list at nedra.com accessed 5 July 2006

- Hedlund, R. (2006) "The 125 Mile Per Hour Club" National Electric Drag Racing Association list at nedra.com accessed 5 July 2006

- Anderson, C.D. and Anderson, J. (2005) "New Charging Systems" Electric and Hybrid Cars: a History (North Carolina: McFarland & Co., Inc.) ISBN 0-7864-1872-9, p. 121.

- Toshiba Corporation (2005) "Toshiba's New Rechargeable Lithium-Ion Battery Recharges in Only One Minute" press release at toshiba.co.jp accessed 5 July 2006

- Mitchell, T. (2003) "AC Propulsion Debuts tzero with LiIon Battery" AC Propulsion, Inc. press release at acpropulsion.com accessed 5 July 2006

- Knipe, TJ et al. (2003) "100,000-Mile Evaluation of the Toyota RAV4 EV" Southern California Edison, Electric Vehicle Technical Center report at evchargernews.com accessed on 5 July 2006

- Ab Europositron Oy (2005) "Background -- Why Aluminium?" Europositron corporate web page at europositron.com accessed 18 July 2006.

- van Pelt, P. (2004) "Cheap electricity from Iceland" EV World project proposal at evworld.com accessed 18 July 2006.

- Green, J. (2006) "GM Plans Gas-Electric Car to Catch Up to Toyota, People Say" Bloomberg News report at bloomberg.com accessed 10 July 2006.

- Coker, M. (2006) "Baby, You Can Still Drive My Electric Car," Orange County Weekly (16 May 2006) story at ocweekly.com accessed 18 July 2006. See also note at batteriesdigest.com. These large format batteries are no longer available.

- International Humanities Center (2006) "2006 Goals and 2005 Year-End Report" California Cars Initiative for Plug-In Hybrids report at calcars.org accessed 10 July 2006.

External links

- AVERE - European Electric Road Vehicle Association

- CITELEC - Association of cities interested in electric vehicles

- Electric Auto Association

- Electric Car Society

- Electric Drive Transportation Association

- SUBAT: life cycle assessment of electric vehicle traction batteries

- A press release claiming that it was consumers, not the automobile industry that killed the BEV

- Future electric car uses 7,000 cell phone batteries to run

Patents

- U.S. patent 523,354, E. E. Keller, Electrically Propelled Preambulator

- U.S. patent 594,805, Hiram Stevens Maxim, Motor vehicle

- U.S. patent 772,571, H. S. Maxim, Electric motor vehicle

News stories

- NOW on PBS has a streaming interview with Chris Paine, who directed "Who Killed the Electric Car", as well as an electric car timeline, insight from a transportation expert about fuel alternatives, and an interview with EC enthusiast/former Baywatch actress Alexandra Paul: "When the Exxon Valdez spilled in 1989, I was angry. And then I said to myself, 'Hey Alexandra, you're part of the problem -- you're buying gas.' And that's when I decided I didn't want to be a part of the problem, so I bought my first electric car a few months later."

- San Francisco Chronicle: Owners charged up over electric cars, but manufacturers have pulled the plug 24 April 2005

- The Air We Breathe, The Cars We Drive, 2004

- The Electric-Car Slide, October 22 2003

- Slim Fit For The Freeways 2 October 2003

Template:Sustainability and energy development group

Categories: