| Revision as of 20:51, 9 March 2007 editKirinX (talk | contribs)1,795 editsm Reverted 1 edit by Jonnf to last revision by Naniwako. using TW← Previous edit | Latest revision as of 08:47, 27 December 2024 edit undoLouisFlannery (talk | contribs)22 edits →Description: Fixed typoTags: Mobile edit Mobile web edit | ||

| Line 1: | Line 1: | ||

| {{Short description|Flowering plant in the family Linaceae}} | |||

| {{otheruses}} | |||

| {{Other uses}} | |||

| {{Taxobox | |||

| {{Use American English|date=June 2024}} | |||

| | color = lightgreen | |||

| {{cs1 config|name-list-style=vanc|display-authors=3}} | |||

| | name = Flax | |||

| {{Use dmy dates|date=April 2022}} | |||

| | image = Koeh-088.jpg | |||

| {{Speciesbox | |||

| | image_width = 240px | |||

| | |

|name = Flax | ||

| |image =Köhler's Medizinal-Pflanzen in naturgetreuen Abbildungen mit kurz erläuterndem Texte (Plate 16) BHL303594.jpg | |||

| | regnum = ]ae | |||

| |genus = Linum | |||

| | divisio = ] | |||

| |species = usitatissimum | |||

| | classis = ] | |||

| | |

|authority = ] | ||

| |synonyms = | |||

| | familia = ] | |||

| {{specieslist | |||

| | genus = '']'' | |||

| |Linum crepitans|(Boenn.) Dumort. | |||

| | species = '''''L. usitatissimum''''' | |||

| |Linum humile|Mill. | |||

| | binomial = ''Linum usitatissimum'' | |||

| |Linum indehiscens|(Neilr.) Vavilov & Elladi | |||

| | binomial_authority = ]. | |||

| }} | |||

| |synonyms_ref = <ref>{{Cite web |title=Linum usitatissimum L. |url=http://www.theplantlist.org/tpl1.1/record/kew-2353429 |website=The Plant List: A Working List of All Plant Species}}</ref> | |||

| }} | }} | ||

| '''Flax''' |

'''Flax''', also known as '''common flax''' or '''linseed''', is a ], '''''Linum usitatissimum''''', in the family ]. It is cultivated as a food and ] in regions of the world with ]s. In 2022, ] produced 75% of the world's supply of flax. | ||

| Textiles made from flax are known in English as ], and are traditionally used for bed sheets, underclothes, and table linen. Its oil is known as ]. In addition to referring to the plant, the word "flax" may refer to the unspun fibers of the flax plant. | |||

| It is an erect ] growing to 120 cm tall, with slender stems. The ] are glaucous green, slender lanceolate, 2-4 cm long and 3 mm broad. The ]s are pure pale blue, 1.5-2.5 cm diameter, with five petals. The ] is a round, dry ] 5-9 mm diameter, containing several glossy brown ]s shaped like an ] pip, 4-7 mm long. | |||

| The plant species is known only as a cultivated plant<ref name="GRIN">{{GRIN | access-date = 2 October 2014}}</ref> and appears to have been domesticated just once from the wild species '']'', called pale flax.<ref>{{Cite journal |last1=Allaby, R. |last2=Peterson, G. |last3=Merriwether, D. |last4=Fu, Y.-B. |year=2005 |title=Evidence of the domestication history of flax (''Linum usitatissimum'' L.) from genetic diversity of the sad2 locus |journal=Theoretical and Applied Genetics |volume=112 |issue=1 |pages=58–65 |doi=10.1007/s00122-005-0103-3 |pmid=16215731 |s2cid=6342499}}</ref> The plants called "flax" in New Zealand are, by contrast, members of the genus '']''. | |||

| In addition to the plant itself, flax may refer to the unspun fibres of the flax plant. | |||

| {{TOC limit|3}} | |||

| ==Description== | |||

| ] | |||

| ] | |||

| ] | |||

| Several other species in the genus ''Linum'' are similar in appearance to ''L. usitatissimum'', cultivated flax, including some that have similar blue flowers, and others with white, yellow, or red flowers.<ref>{{Cite book |last1=Quanru Liu |title=Flora of China |last2=Lihua Zhou |volume=11 |chapter=''Linum'' |access-date=2 October 2014 |chapter-url=http://www.efloras.org/florataxon.aspx?flora_id=2&taxon_id=118675 |archive-url=https://web.archive.org/web/20150405120646/http://efloras.org/florataxon.aspx?flora_id=2&taxon_id=118675 |archive-date=5 April 2015 |url-status=live}}</ref> Some of these are ] plants, unlike ''L. usitatissimum'', which is an ]. | |||

| Cultivated flax plants grow to {{convert|1.2|m|0|abbr=on}} tall, with slender stems. The ] are ] green, slender ], 20–40 mm long, and 3 mm broad.<ref name="Saleem-2020">{{Cite journal |last1=Saleem |first1=Muhammad Hamzah |last2=Ali |first2=Shafaqat |last3=Hussain |first3=Saddam |last4=Kamran |first4=Muhammad |last5=Chattha |first5=Muhammad Sohaib |last6=Ahmad |first6=Shoaib |last7=Aqeel |first7=Muhammad |last8=Rizwan |first8=Muhammad |last9=Aljarba |first9=Nada H. |last10=Alkahtani |first10=Saad |last11=Abdel-Daim |first11=Mohamed M. |date=April 2020 |title=Flax (Linum usitatissimum L.): A Potential Candidate for Phytoremediation? Biological and Economical Points of View |journal=Plants |language=en |volume=9 |issue=4 |pages=496 |doi=10.3390/plants9040496 |pmid=32294947 |pmc=7238412 |issn=2223-7747|doi-access=free }}</ref> | |||

| The ]s are 15–25 mm in diameter with five petals, which can be coloured white, blue, yellow, and red depending on the species.<ref name="Saleem-2020" /> The ] is a round, dry ] 5–9 mm in diameter, containing several glossy brown ]s shaped like ] pips, 4–7 mm long. | |||

| {{clear left}} | |||

| ==History== | |||

| The earliest evidence of humans using wild flax as a ] comes from the present-day ], where spun, dyed, and knotted wild flax fibers found in ] date to the ], 30,000 years ago.<ref name="VintageThreads">{{Cite news |title=These Vintage Threads Are 30,000 Years Old |work=NPR.org |publisher=NPR |url=https://www.npr.org/templates/story/story.php?storyId=112726804&sc=fb&cc=fp |url-status=live |access-date=13 November 2010 |archive-url=https://web.archive.org/web/20101204031535/http://www.npr.org/templates/story/story.php?storyId=112726804&sc=fb&cc=fp |archive-date=4 December 2010}}</ref><ref>{{Cite journal |last=Balter |first=M |year=2009 |title=Clothes make the (Hu) Man |journal=Science |volume=325 |issue=5946 |page=1329 |doi=10.1126/science.325_1329a |pmid=19745126}}</ref><ref>{{Cite journal |last1=Kvavadze |first1=E |last2=Bar-Yosef |first2=O |last3=Belfer-Cohen |first3=A |last4=Boaretto |first4=E |last5=Jakeli |first5=N |last6=Matskevich |first6=Z |last7=Meshveliani |first7=T |year=2009 |title=30,000-Year-Old Wild Flax Fibers |url=http://nrs.harvard.edu/urn-3:HUL.InstRepos:4270521 |journal=Science |volume=325 |issue=5946 |page=1359 |bibcode=2009Sci...325.1359K |doi=10.1126/science.1175404 |pmid=19745144 |s2cid=206520793}}</ref> Humans first domesticated flax in the ] region.<ref name="Fu">{{Cite journal |last=Fu, Y.-B. |year=2011 |title=Genetic evidence for early flax domestication with capsular dehiscence |journal=Genetic Resources and Crop Evolution |volume=58 |issue=8 |pages=1119–1128 |doi=10.1007/s10722-010-9650-9 |s2cid=22424329}}</ref> Evidence exists of a domesticated oilseed flax with increased seed-size from ] in ]<ref name=Fu/> and ] fragments from ] in ]<ref>{{Cite report |url=https://www.scribd.com/document/206552281/Archive-Report-2013 |title=Çatalhöyük 2013 Archive Report}}</ref> by {{circa|9,000}} years ago. Use of the crop steadily spread, reaching as far as ] and ] by 5,000 years ago.<ref>Barber E. (1991) "Prehistoric Textiles: The Development of Cloth in the Neolithic and Bronze Ages with Special Reference to the Aegean". Princeton University Press, p.12</ref> In China and India, domesticated flax was cultivated at least 5,000 years ago.<ref name="cullis275">{{Cite book |last=Cullis |first=Chris A. |title=Oilseeds |date=2007 |publisher=Springer |isbn=978-3-540-34387-5 |editor-last=Kole |editor-first=Chittaranjan |page=275 |chapter=Flax}}</ref> | |||

| Flax was cultivated extensively in ], where the temple walls had paintings of flowering flax, and mummies were embalmed using linen.<ref>Sekhri S. (2011) "Textbook of Fabric Science: Fundamentals to Finishing". PHI Learning Private Limited, New Delhi, p. 76</ref> Egyptian priests wore only linen, as flax was considered a symbol of purity.<ref>{{Cite book |title=Ancient Technologies and Archaeological Materials |date=1994 |publisher=Taylor & Francis |isbn=978-2-88124-631-9 |editor-last=Wisseman |editor-first=Sarah Underhill |page=124 |doi=10.4324/9781315075396 |s2cid=128265510 |editor-last2=Williams |editor-first2=Wendell S.}}</ref> ] traded Egyptian linen throughout the ] and the ] used it for their ]s.<ref>Buchanan R. (2012) "A Weaver's Garden: Growing Plants for Natural Dyes and Fibers". Courier Dover Publications, p. 22</ref> As the ] declined, so did flax production. But with laws designed to publicize the ] of linen textiles and the health of linseed oil, ] revived the crop in the eighth century ].<ref name="Wisseman S., p.125">Wisseman S., p.125</ref> Eventually, ] became the major center of the European linen industry in the ].<ref name="Wisseman S., p.125" /> In North America, colonists introduced flax, and it flourished there,<ref name = cullis275/> but by the early 20th century, cheap ] and rising farm wages had caused production of flax to become concentrated in northern Russia, which came to provide 90% of the world's output. Since then, flax has lost its importance as a ], due to the easy availability of more durable fibres.<ref>(2003) "The Oxford Encyclopedia of Economic History, Volume 1" Oxford University Press, p.303.</ref> | |||

| ==Uses== | ==Uses== | ||

| ] | ] | ||

| ] | |||

| ] | |||

| Flax is grown for its seeds, which can be ground into a meal or turned into ], a product used as a ] and as an ingredient in many ] products. Flax is also grown as an ] in gardens. Moreover, flax fibers are used to make ]. The ] in its binomial name, ''usitatissimum,'' means "most useful".<ref>{{Cite book |last=McHughen |first=A. |title=Legumes and Oilseed Crops I |year=1990 |isbn=978-3-642-74450-1 |series=Biotechnology in Agriculture and Forestry |volume=10 |pages=502–514 |chapter=Flax (Linum usitatissimum L.): In Vitro Studies |doi=10.1007/978-3-642-74448-8_24}}</ref> | |||

| Flax fibers taken from the stem of the plant are two to three times as strong as cotton fibers. Additionally, flax fibers are naturally smooth and straight. Europe and North America both depended on flax for plant-based cloth until the 19th century, when cotton overtook flax as the most common plant for making ]. Flax is grown on the Canadian ]s for linseed oil, which is used as a drying oil in paints and varnishes and in products such as ] and ]s. | |||

| Flax is grown both for ] and for its fibers. Various parts of the plant have been used to make fabric, dye, paper, medicines, fishing nets and soap. It is also grown as an ] in ]s, as flax is one of the few plant species capable of producing truly ] flowers (most "blue" flowers are really shades of ]), although not all flax varieties produce blue flowers. | |||

| Linseed meal, the by-product of producing linseed oil from flax seeds, is used as ] ].<ref name="Feedipedia">{{Cite web | |||

| ===Flax seed=== | |||

| | publisher= ], ], Association Française de Zootechnie and ] | |||

| The seeds produce a ] known as ] or flaxseed oil. It is one of the oldest commercial oils and solvent-processed flax seed oil has been used for centuries as a ] in painting and varnishing. | |||

| |title=Linseed meal |url=https://www.feedipedia.org/node/735|access-date=2023-03-27|website= Feedipedia |year=2018 | |||

| | author1= Valérie Heuzé | |||

| | author2 = Gilles Tran | |||

| | author4 = Michel Lessire | |||

| | author3 = Pierre Nozière | |||

| | author5 = François Lebas | |||

| |archive-url=https://web.archive.org/web/20170712140410/http://www.feedipedia.org/node/735 |archive-date=12 July 2017 | |||

| }}</ref> | |||

| ==={{anchor|Flax seeds}} Flax seeds=== | |||

| Flax seeds come in two basic varieties; brown and yellow (also referred to as golden). Although brown flax can be consumed and has been for thousands of years, it is better known as an ingredient in paints, fibre and cattle feed. Brown and yellow flax have similar nutritional values and equal amounts of short-chain omega-3 fatty acids. The exception is a type of yellow flax called solin which is very low in ] and has a completely different oil profile. A number of studies have shown that people have a very hard time absorbing the Omega-3 from flaxseed oil compared to oily fish (see ] for more). | |||

| Flax seeds occur in brown and yellow (golden) varieties.<ref>{{Cite news |last=Grant |first=Amanda |date=6 March 2007 |title=Superfoods |work=The Guardian |location=London |url=https://www.theguardian.com/lifeandstyle/2007/mar/06/healthandwellbeing.health1 |url-status=live |archive-url=https://web.archive.org/web/20160921210717/https://www.theguardian.com/lifeandstyle/2007/mar/06/healthandwellbeing.health1 |archive-date=21 September 2016}}</ref> Most types of these basic varieties have similar ]al characteristics and equal numbers of short-chain ]s. Yellow flax seeds, called solin (] "]"),<ref name="CRS">{{citation | |||

| | url = http://ncseonline.org/nle/crsreports/05jun/97-905.pdf | |||

| | title = Agriculture: A Glossary of Terms, Programs, and Laws, 2005 Edition | |||

| | editor = Jasper Womach | |||

| | display-editors = etal | |||

| | year = 2005 | |||

| | archive-url=https://web.archive.org/web/20110810044532/http://ncseonline.org/nle/crsreports/05jun/97-905.pdf | |||

| |archive-date=10 August 2011 | |||

| | url-status = usurped | |||

| | publisher = Congressional Research Service | |||

| | place = Library of Congress | |||

| }}</ref> have a similar oil profile to brown flax seeds and both are very high in omega-3s (] (ALA), specifically).<ref>{{Cite journal |last1=Sargi |first1=Sheisa Cyléia |last2=Silva |first2=Beatriz Costa |last3=Santos |first3=Hevelyse Munise Celestino |last4=Montanher |first4=Paula Fernandes |last5=Boeing |first5=Joana Schuelter |last6=Santos Júnior |first6=Oscar Oliveira |last7=Souza |first7=Nilson Evelázio |last8=Visentainer |first8=Jesuí Vergílio |date=26 July 2013 |title=Antioxidant capacity and chemical composition in seeds rich in omega-3: chia, flax, and perilla |journal=Food Science and Technology |volume=33 |issue=3 |pages=541–548 |doi=10.1590/S0101-20612013005000057|s2cid=41096264 |doi-access=free }}</ref> | |||

| Flax seeds produce a ] known as flax seed oil or ], which is one of the oldest commercial oils. It is an ] obtained by ] and sometimes followed by ]. Solvent-processed flax seed oil has been used for many centuries as a ] in painting and varnishing.<ref>{{Cite web |title=Pigments through the Ages – Renaissance and Baroque (1400–1600) |url=http://www.webexhibits.org/pigments/intro/renaissance.html |url-status=live |archive-url=https://web.archive.org/web/20120719190829/http://www.webexhibits.org/pigments/intro/renaissance.html |archive-date=19 July 2012}}</ref> | |||

| Although brown flax seed varieties may be consumed as readily as the yellow ones, and have been for thousands of years, these varieties are more commonly used in paints, for fiber, and for cattle feed. | |||

| A ] research project led to the creation of a new variety of the yellow flax seed called "Omega."<ref>{{cite journal | author=Miller, J.F., J.J. Hammond, and G.D. Statler. | title= Registration of ‘Omega’ Flax. | journal=Crop Science | year=1992 | volume= 32 | pages= 1065}}</ref> This new variety was created primarily as a food source and has a more pleasant nutty-buttery flavour than the brown variety and retains a comparable level of the beneficial ] oil. | |||

| ====Culinary==== | |||

| ] | |||

| ] | |||

| One tablespoon of ground flax seeds and three tablespoons of water may serve as a replacement for one ] in baking by binding the other ingredients together. Ground flax seeds can also be mixed in with ], ], water (similar to ]), or any other food item where a nutty flavour is appropriate. Flaxseed oil is most commonly consumed with ]s or in ]s. Flax seed owes its nutritional benefits to ]s and ] essential fatty acids<!--- and ]--->. ]s, often in short supply in populations with low-fish diets, promote heart health by reducing cholesterol, blood pressure and plaque formation in arteries.<!--- Flax's soluble and insoluble ] also aid in cardiac and bowel health.---> In addition, flaxseed oil is often recommended as a ]. | |||

| A 100-gram portion of ground flax seed supplies about {{convert|2234|kJ|kcal|abbr=off}} of ], 41 g of fat, 28 g of fiber, and 20 g of protein.<ref>{{Cite web |title=Flax nutrition profile |url=http://www.flaxcouncil.ca/english/index.jsp?p=g3&mp=nutrition |url-status=dead |archive-url=https://web.archive.org/web/20090723062551/http://www.flaxcouncil.ca/english/index.jsp?p=g3&mp=nutrition |archive-date=23 July 2009 |access-date=8 May 2008}}</ref> Whole flax seeds are chemically stable, but ground flax seed meal, because of ], may go ] when left exposed to air at room temperature in as little as a week.<ref name="DieteticAss">{{Cite journal |last1=Alpers |first1=Linda |last2=Sawyer-Morse, Mary K. |date=August 1996 |title=Eating Quality of Banana Nut Muffins and Oatmeal Cookies Made With Ground Flaxseed |journal=Journal of the American Dietetic Association |volume=96 |issue=8 |pages=794–796 |doi=10.1016/S0002-8223(96)00219-2 |pmid=8683012}}</ref> Refrigeration and storage in sealed containers will keep ground flax seed meal for a longer period before it turns rancid. Under conditions similar to those found in commercial bakeries, trained sensory panelists could not detect differences between bread made with freshly ground flax seed and bread made with flax seed that had been ] four months earlier and stored at room temperature.<ref name="Malcolmson">{{Cite journal |last=Malcolmson |first=L.J. |date=April 2006 |title=Storage stability of milled flaxseed |journal=Journal of the American Oil Chemists' Society |volume=77 |issue=3 |pages=235–238 |doi=10.1007/s11746-000-0038-0 |s2cid=85575934}}</ref> If packed immediately without exposure to air and light, milled flax seed is stable against excessive oxidation when stored for nine months at room temperature,<ref name="Chen">{{Cite journal |last=Chen |first=Z-Y |year=1994 |title=Oxidative stability of flaxseed lipids during baking |journal=Journal of the American Oil Chemists' Society |volume=71 |issue=6 |pages=629–632 |doi=10.1007/BF02540591 |s2cid=84981982}}</ref> and under ] conditions, for 20 months at ambient temperatures.{{citation needed|date=March 2021}} | |||

| Three ] ]s—], ] glucoside, and ] glucoside—are present in commercial breads containing flax seed.<ref>{{Cite journal |last=Strandås |first=C. |year=2008 |title=Phenolic glucosides in bread containing flaxseed |journal=Food Chemistry |volume=110 |issue=4 |pages=997–999 |doi=10.1016/j.foodchem.2008.02.088 |pmid=26047292}}</ref> | |||

| ]s benefit the heart and possess anti-cancer properties: A series of research studies by Lilian U. Thompson and her colleagues at the Department of Nutritional Science of the ] have reported that flaxseed can have a beneficial effect in reducing tumour growth in ], particularly the kind of tumour found in human post-] ]. The effects are thought to be due to the lignans in flaxseed, and are additive with those of ], the currently standard drug treatment for these cancers. Initial studies suggest that flaxseed taken in the diet have similar beneficial effects in human cancer patients. Reports that flaxseed is beneficial in other cancers, e.g., ], are less numerous but promising. | |||

| ====Fodder==== | |||

| Flax seed ] are edible, with a slightly spicy flavour. | |||

| After crushing the seeds to extract linseed oil, the resultant linseed meal is a ]-rich ] for ]s, ]s, and fish.<ref name=Feedipedia/> It is also often used as feed for ] and ], and has also been used in horse concentrate and ].<ref name="Maddock1">{{Cite web |last1=Maddock |first1=Travis D. |last2=Anderson, Vernon L. |last3=Lardy, Greg P. |title=Using Flax in Livestock Diets |url=http://www.ag.ndsu.edu/pubs/ansci/beef/as1283w.htm |archive-url=https://web.archive.org/web/20120222030813/http://www.ag.ndsu.edu/pubs/ansci/beef/as1283w.htm |archive-date=22 February 2012 |publisher=North Dakota State University |pages=53–62}}</ref> The high omega-3 fatty acid (]) content of linseed meal "softens" milk, eggs, and meat, which means it causes a higher ] content and thus lowers its storage time.<ref name=Feedipedia/> The high omega-3 content also has a further disadvantage, because this fatty acid ]s and goes ] quickly, which shortens the storage time. ] was developed in Australia and introduced in the 1990s with less omega-3, specifically to serve as ].<ref name="CRS" /><ref name="Dribnenkil1995">{{Cite journal |last=J. C. P. Dribnenkil and A. G. Green |year=1995 |title=Linola '947' low linolenic acid flax |journal=Canadian Journal of Plant Science |volume=75 |issue=1 |pages=201–202 |doi=10.4141/cjps95-036 |doi-access=free}}</ref> Another disadvantage of the meal and seed is that it contains a ] (]) antagonist, and may require this vitamin be supplemented, especially in ]s, and furthermore linseeds contain 2–7% of ] (fibre), which may be beneficial in humans<ref name=Feedipedia/> and cattle,<ref name=Maddock1/> but cannot be digested by non-ruminants and can be detrimental to young animals, unless possibly treated with ]s.<ref name=Feedipedia/> | |||

| Linseed meal is added to ] as a protein ]. It can only be added at low percentages due to the high fat content, which is unhealthy for ruminants.<ref name=Maddock1/> Compared to oilseed meal from ] it measures as having lower nutrient values,<ref name=Feedipedia/> however, good results are obtained in cattle, perhaps due to the mucilage, which may aid in slowing digestion and thus allowing more time to absorb nutrients.<ref name=Feedipedia/><ref name=Maddock1/> One study found that feeding flax seeds may increase omega-3 content in ], while another found no differences. It might also act as a substitute for ] in increasing ].<ref name=Maddock1/><ref name="Maddock2">{{Cite journal |last1=Maddock |first1=T. D. |last2=Bauer |first2=M. L. |last3=Koch |first3=K. B. |last4=Anderson |first4=V. L. |last5=Maddock |first5=R. J. |last6=Barceló-Coblijn |first6=G. |last7=Murphy |first7=E. J. |last8=Lardy |first8=G. P. |date=1 June 2006 |title=Effect of processing flax in beef feedlot diets on performance, carcass characteristics, and trained sensory panel ratings1 |journal=Journal of Animal Science |volume=84 |issue=6 |pages=1544–1551 |doi=10.2527/2006.8461544x |pmid=16699112}}</ref> In the US, flax-based feed for ruminants is often somewhat more expensive than other feeds on a nutrient basis.<ref name="Lardy2015">{{Cite report |url=https://www.ag.ndsu.edu/publications/livestock/alternative-feeds-for-ruminants/as1182.pdf |archive-url=https://ghostarchive.org/archive/20221009/https://www.ag.ndsu.edu/publications/livestock/alternative-feeds-for-ruminants/as1182.pdf |archive-date=2022-10-09 |url-status=live |title=Alternative feeds for ruminants |last1=Lardy |first1=Greg P. |last2=Anderson |first2=Vern L. |date=October 2015 |publisher=] Extension Service |pages=9, 20 |docket=AS1182 (Revised) |last3=Dahlen |first3=Carl |access-date=4 October 2019}}</ref> ] feeding on low quality ] are able to eat a large amount of linseed meal, up to 40% in one test, with positive consequences. It has been fed as supplement to ] in India, and provided a better diet than forage alone, but not as good as when substituted with ] meal. It is considered an inferior protein supplement for swine because of its fibre, the vitamin antagonist, the high omega-3 content and its low lysine content, and can only be used in small amounts in the feed. Although it may increase the omega-3 content in eggs and meat, it is also an inferior and potentially toxic feed for poultry, although it can be used in small amounts. The meal is an adequate and traditional source of protein for rabbits at 8–10%. Its use in fish feeds is limited.<ref name=Feedipedia/> | |||

| Flaxseed is also known as ''linseed''. Flaxseeds are known as ''San, Alsi'' in ], ], and ], ''Ali Vidai'' in ]. In ], it is also known as ''Jawas'' and ''Alashi''. In ], it is known as ''Tishi'', In ] it is called ''Pesi''. In ], it's called ''Agasi''. The ] people call it ''Avise ginzalu''. Finally, in ], the ]s call it ''Cheruchana vithu''. | |||

| Raw, immature linseeds contain an amount of ] compounds and can be dangerous for ] animals, like horses and rabbits. Boiling removes the danger. This is not an issue in meal cake due to the processing temperature during oil extraction.<ref name=Feedipedia/><ref name=Lardy2015/> | |||

| ===Flax fibre=== | |||

| Flax fibres are amongst the oldest ]s in the world. The use of flax for the production of ] goes back 5000 years. Pictures on tombs and temple walls at ] depict flowering flax plants. The use of flax fibre in the manufacturing of ] in northern Europe dates back to Neolithic times. In North America, flax was introduced by the ]. Currently most flax produced in the USA and Canada are seed flax types for the production of linseed oil or flaxseeds for human nutrition. | |||

| Flax ] left over from the harvesting of oilseed is not very nutritious; it is tough and indigestible, and is not recommended to use as ruminant fodder, although it may be used as bedding or ] as ]s.<ref name=Lardy2015/> | |||

| ] | |||

| Flax fibre is extracted from the ] or skin of the stem of flax plant. Flax fibre is soft, lustrous and flexible. It is stronger than ] fibre but less elastic. The best grades are used for ] fabrics such as ]s, ] and sheeting. Coarser grades are used for the manufacturing of ] and ]. Flax fibre is also a raw material for the high-quality paper industry for the use of printed ]s and ] for ]s. | |||

| ===Flax |

===Flax fibers=== | ||

| ] shop once used to prepare flax fibers. ], Scotland.]] | |||

| {{main|Flax mill}} | |||

| ]s for spinning flaxen ] were invented by ] and ] of ] in ].<ref>A. J. Wardey, ''The linen trade: ancient and modern'' (1864; repr. 1967), 690-92. </ref> | |||

| Flax fiber is extracted from the ] beneath the surface of the stem of the flax plant. Flax fiber is soft, lustrous, and flexible; bundles of fiber have the appearance of blonde hair, hence the description "flaxen" hair. It is stronger than cotton fiber, but less elastic. | |||

| ==Cultivation== | |||

| ] | |||

| The major fibre flax-producing countries are the former ], ], ], ], ], and the ]. | |||

| ]]] | |||

| The ]s most suitable for flax, besides the alluvial kind, are deep friable ]s, and containing a large proportion of ]. Heavy ]s are unsuitable, as are soils of a ]ly or dry ]y nature. {{Fact|date=February 2007}} | |||

| The use of flax fibers dates back tens of millennia;<ref name="VintageThreads" /> ], a refined textile made from flax fibers, was worn widely by ]ian priests more than 4,000 years ago.<ref>{{Cite book |last=Kramer |first=Samuel Noah |url=http://oi.uchicago.edu/sites/oi.uchicago.edu/files/uploads/shared/docs/sumerians.pdf |title=The Sumerians: Their history, culture and character |date=1963 |publisher=The University of Chicago Press |isbn=0-226-45237-9 |page=104 |author-link=Samuel Noah Kramer |archive-url=https://web.archive.org/web/20160327203605/http://oi.uchicago.edu/sites/oi.uchicago.edu/files/uploads/shared/docs/sumerians.pdf |archive-date=27 March 2016 |url-status=live}}</ref> Industrial-scale flax fiber processing existed in antiquity. A ] factory dedicated to flax processing was discovered in ], Greece.<ref name="Kaza2015">{{Cite book |last=Kaza-Papageorgiou |first=Konstantina |title=The Ancient Astiki Odos and the Metro beneath Vouliagmenis Avenue |date=30 November 2015 |publisher=Kapon Editions |isbn=978-9606878947 |location=Athens, Greece}}</ref> | |||

| Flax is harvested for fibre production after aproximately 100 days, when the base of the plant begins to turn yellow, if the plant is still green the seed will not be useful, and the fiber will be underdeveloped, and the fiber degrades once the plant is brown; it is pulled up with the roots (not cut), so as to maximise the fibre length. After this the flax is allowed to dry, the seeds are removed, and is then retted. | |||

| The best grades are used for fabrics such as ]s, ], and ]. Coarser grades are used for the manufacturing of ] and ], and historically, for ] and ]. Flax fiber is a raw material used in the high-quality paper industry for the use of printed ]s, laboratory paper (] and ]), ] for ]s, and ]s.<ref>{{Cite book |last=Chand, Navin. |title=Tribology of natural fiber polymer composites |date=2008 |publisher=Woodhead Publishing |others=Fahim, Mohammed., Institute of Materials, Minerals, and Mining. |isbn=978-1-84569-505-7 |location=Cambridge, England |oclc=425959562}}</ref> | |||

| Flax grown for seed is allowed to mature until the seed capsules are yellow and just starting to split; it is then harvested by ] and dried to extract the seed. | |||

| ]s for spinning flaxen ] were invented by ] and ] of ], ], in 1787.<ref>{{Cite book |last=Wardey |first=A. J. |title=The Linen Trade: Ancient and Modern |publisher=Routledge |year=1967 |isbn=978-0-7146-1114-3 |page=752}}</ref> New methods of processing flax <!-- out of date and the rising price of cotton --> have led to renewed interest in the use of flax as an industrial fiber. | |||

| === Threshing flax === | |||

| ] casanatensis (XIV century)]] | |||

| Threshing is the process of removing the seeds from the rest of the plant. | |||

| ==Nutrition== | |||

| The process is divided into two parts: the first part is intended for the farmer, or flax-grower, to bring the flax into a fit state for general or common purposes. This is performed by three machines: one for threshing out the seed, one for breaking and separating the wood from the fibre, and one for further separating the broken wood and matter from the fibre. In some cases the farmers thrash out the seed in their own mill and therefore, in such cases, the first machine will be unnecessary. | |||

| {{nutritionalvalue | name=Flax seeds | kJ=2234| protein=18.29 g | fat=42.16 g | satfat=3.663 g | monofat=7.527 g | polyfat=28.730 g | omega3fat=22.8 g | omega6fat=5.9 g | carbs=28.88 g | fiber=27.3 g | | sugars=1.55 g | iron_mg=5.73 | calcium_mg=255 | magnesium_mg=392 | phosphorus_mg=642 | potassium_mg=813| zinc_mg=4.34 | vitC_mg=0.6 | pantothenic_mg=0.985 | vitB6_mg=0.473 | folate_ug=87 | thiamin_mg=1.644 | riboflavin_mg=0.161 | niacin_mg=3.08|water=7 g | source_usda=1 | note=}} | |||

| The second part of the process is intended for the manufacturer to bring the flax into a state for the very finest purposes, such as ], ], ], and very fine ]. This second part is performed by the refining machine only. | |||

| Flax seeds are 7% water, 18% ], 29% ]s, and 42% ] (table). In {{convert|100|g}} as a reference amount, flax seeds provide 534 ]s and contain high levels (20% or more of the ], DV) of protein, ], several ], and ].<ref name=nd/><ref name=usda/> Flax seeds are especially rich in ], ], and ] (DVs above 90%) (table). | |||

| The threshing process would be conducted as follows: | |||

| *Take the flax in small bundles, as it comes from the field or stack, and holding it in the left hand, put the seed end between the ] and the bed or block against which the machine is to strike; then take the handle of the machine in the right hand, and move the machine backward and forward, to strike on the flax, until the seed is all threshed out. | |||

| As a percentage of total ], flax seeds contain 54% omega-3 fatty acids (mostly ]), 18% ] (]), and 6% ] (]); the seeds contain 9% ], including 5% as ].<ref name="nd">{{Cite web |date=2015 |title=Nutrition facts for 100 g of flaxseeds |url=http://nutritiondata.self.com/facts/nut-and-seed-products/3163/2 |url-status=live |archive-url=https://web.archive.org/web/20101205075853/http://nutritiondata.self.com/facts/nut-and-seed-products/3163/2 |archive-date=5 December 2010 |publisher=Conde Nast for USDA National Nutrient Database, version SR-21}}</ref><ref name="usda">{{Cite web |date=2015 |title=Full Report (All Nutrients): 12220, Seeds, flaxseed per 100 g |url=http://ndb.nal.usda.gov/ndb/foods/show/3745?fg=&man=&lfacet=&count=&max=&sort=&qlookup=&offset=&format=Full&new=&measureby= |url-status=dead |archive-url=https://web.archive.org/web/20140920222846/http://ndb.nal.usda.gov/ndb/foods/show/3745?fg=&man=&lfacet=&count=&max=&sort=&qlookup=&offset=&format=Full&new=&measureby= |archive-date=20 September 2014 |publisher=USDA National Nutrient Database version SR-27}}</ref> Flax seed oil contains 53% 18:3 omega-3 fatty acids (mostly ALA) and 13% 18:2 omega-6 fatty acids.<ref name=nd/> | |||

| *Take the flax in small handfuls in the left hand, spread it flat between the third and little finger, with the seed end downwards, and the root-end above, as near the hand as possible. | |||

| *Put the handful between the beater of the breaking machine, and beat it gently till the three or four inches, which have been under the operation of the machine, appear to be soft. | |||

| ===Health research=== | |||

| *Remove the flax a little higher in the hand, so as to let the soft part of the flax rest upon the little finger, and continue to beat it till all is soft, and the wood is separated from the fibre, keeping the left hand close to the block and the flax as flat upon the block as possible. {{Fact|date=February 2007}} | |||

| A ] showed that consumption of more than 30 g of flax-seed daily for more than 12 weeks reduced body weight, ] (BMI), and waist circumference for persons with a BMI greater than 27.<ref name="pmid28635182">{{Cite journal |last1=Mohammadi-Sartang |first1=M. |last2=Mazloom |first2=Z. |last3=Raeisi-Dehkordi |first3=H. |last4=Barati-Boldaji |first4=R. |last5=Bellissimo |first5=N. |last6=Totosy de Zepetnek |first6=J. O. |date=September 2017 |title=The effect of flaxseed supplementation on body weight and body composition: a systematic review and meta-analysis of 45 randomized placebo-controlled trials: Flaxseed and body composition |journal=Obesity Reviews |volume=18 |issue=9 |pages=1096–1107 |doi=10.1111/obr.12550 |pmid=28635182 |s2cid=5587045}}</ref> Another meta-analysis showed that consumption of flax seeds for more than 12 weeks produced small reductions in ] and ].<ref name="pmid25740909">{{Cite journal |vauthors=Khalesi S, Irwin C, Schubert M |year=2015 |title=Flaxseed consumption may reduce blood pressure: a systematic review and meta-analysis of controlled trials |journal=] |volume=145 |issue=4 |pages=758–65 |doi=10.3945/jn.114.205302 |pmid=25740909 |doi-access=free|hdl=10072/128716 |hdl-access=free }}</ref> A third showed that consuming flax seed or its derivatives may reduce total and ] in the blood, with greater benefits in women and people with high ].<ref>{{Cite journal |last1=Pan |first1=A |last2=Yu |first2=D |last3=Demark-Wahnefried |first3=W |last4=Franco |first4=OH |last5=Lin |first5=X |date=August 2009 |title=Meta-analysis of the effects of flaxseed interventions on blood lipids |journal=The American Journal of Clinical Nutrition |volume=90 |issue=2 |pages=288–97 |doi=10.3945/ajcn.2009.27469 |pmc=3361740 |pmid=19515737}}</ref> A fourth showed a small reduction in ] (a marker of inflammation) only in persons with a body mass index greater than 30.<ref name="pmid26959052">{{Cite journal |last1=Ren |first1=Guan-Yu |last2=Chen |first2=Chun-Yang |last3=Chen |first3=Guo-Chong |last4=Chen |first4=Wei-Guo |last5=Pan |first5=An |last6=Pan |first6=Chen-Wei |last7=Zhang |first7=Yong-Hong |last8=Qin |first8=Li-Qiang |last9=Chen |first9=Li-Hua |date=4 March 2016 |title=Effect of Flaxseed Intervention on Inflammatory Marker C-Reactive Protein: A Systematic Review and Meta-Analysis of Randomized Controlled Trials |journal=Nutrients |volume=8 |issue=3 |pages=136 |doi=10.3390/nu8030136 |pmc=4808865 |pmid=26959052 |doi-access=free}}</ref> | |||

| *The other end of the flax is then to be turned, and the end which has been beaten is to be wrapped round the little finger, the root end flat, and beaten in the machine till the wood is separated, exactly in the same way as the other end was beaten. | |||

| ===Linseed oil=== | |||

| {{excerpt|Linseed oil}} | |||

| ===Safety=== | |||

| Flax seed and its oil are ] for human consumption.<ref>{{Cite web |last=Cheeseman MA |date=24 August 2009 |title=GRAS Petition by Flax Canada, Agency Response Letter GRAS Notice No. GRN 000280 |url=https://www.fda.gov/Food/IngredientsPackagingLabeling/GRAS/Noticeinventory/ucm181935.htm |url-status=live |archive-url=https://web.archive.org/web/20150617234254/https://www.fda.gov/Food/IngredientsPackagingLabeling/GRAS/Noticeinventory/ucm181935.htm |archive-date=17 June 2015 |access-date=1 June 2015 |publisher=U.S. Food and Drug Administration}}</ref> Like many common foods, flax contains small amounts of cyanogenic ],<ref>{{Cite journal |last1=Cunnane |first1=SC|last2=Ganguli |first2=S|last3=Menard |first3=C|last4=Liede |first4=AC|last5=Hamadeh |first5=MJ|last6=Chen |first6=ZY|last7=Wolever |first7=TM|last8=Jenkins |first8=DJ |year=1993 |title=High alpha-linolenic acid flaxseed (''Linum usitatissimum''): some nutritional properties in humans |journal=Br J Nutr |volume=69 |issue=2 |pages=443–53 |doi=10.1079/bjn19930046 |pmid=8098222 |doi-access=free}}</ref> which is nontoxic when consumed in typical amounts.<ref name="efsa">{{cite journal | author=EFSA Panel on Contaminants in the Food Chain| title=Evaluation of the health risks related to the presence of cyanogenic glycosides in foods other than raw apricot kernels | journal=EFSA Journal|date=11 April 2019 | volume=17 | issue=4 | pages=e05662 | doi=10.2903/j.efsa.2019.5662 | pmid=32626287 | pmc=7009189 | doi-access=free }}</ref> Typical concentrations (for example, 0.48% in a sample of defatted dehusked flax seed meal) can be removed by special processing.<ref>{{Cite journal |vauthors=Singh KK, Mridula D, Rehal J, Barnwal P |year=2011 |title=Flaxseed: a potential source of food, feed and fiber |journal=Crit Rev Food Sci Nutr |volume=51 |issue=3 |pages=210–22 |doi=10.1080/10408390903537241 |pmid=21390942 |s2cid=21452408}}</ref> | |||

| ==Cultivation== | |||

| The ]s most suitable for flax, besides the ] kind, are deep ]s containing a large proportion of ].<ref>{{Cite web |title=Grow and Harvest Flax – Materials Matter 2016 |url=https://www.climatecolab.org/contests/2016/materials-matter/c/proposal/1331103 |access-date=25 January 2019 |website=Climate CoLab |language=en}}</ref> Flax is often found growing just above the waterline in ] bogs. Heavy ]s are unsuitable, as are soils of a ]ly or dry ]y nature. Farming flax requires few ]s or ]s. Within eight weeks of sowing, the plant can reach {{convert|10|–|15|cm|abbr=on}} in height, reaching {{convert|70|–|80|cm|abbr=on}} within 50 days.{{Citation needed|date=June 2021}} | |||

| ===Diseases=== | ===Diseases=== | ||

| {{Main|List of flax diseases}} | {{Main|List of flax diseases}} | ||

| ==Production== | |||

| {| class="wikitable" style="float:right; width:14em; text-align:center;" | |||

| ==Preparation for spinning== | |||

| ! colspan=2|Flax production – 2022 | |||

| Before the flax fibers can be spun into linen, they must be seperated from the rest of the stalk. The first step in this process is called "retting". Retting is the process of rotting away the inner stalk, leaving the outer fibres intact. At this point there is still straw, or corse fibers, remaining. To remove these the flax is "broken", the straw is broken up into small, short bits, while the actual fiber is left unharmed, then "scutched", where the straw is scraped away from the fiber, and then pulled through "hackles", which act like combs and comb the straw out of the fiber. | |||

| |- | |||

| ! style="background:#ddf; width:75%;"| Country | |||

| ! style="background:#ddf; width:25%;"| <small>tonnes</small> | |||

| |- | |||

| | {{FRA}} ||652,680 | |||

| |- | |||

| | {{BEL}} ||77,910 | |||

| |- | |||

| | {{BLR}} ||47,626 | |||

| |- | |||

| | {{CHN}} ||29,035 | |||

| |- | |||

| | {{RUS}} ||24,103 | |||

| |- | |||

| | '''World''' || '''875,995''' | |||

| |- | |||

| |colspan=2|<small>Source: ] of the ]<ref name=fao/></small> | |||

| |} | |||

| In 2022, world production of raw or ] flax was 875,995 ]s, led by ] with 75% of the total.<ref name="fao">{{Cite web |date=2024 |title=Flax (raw or retted) production in 2022; Crops/Regions/World List/Production Quantity (from pick lists) |url=http://www.fao.org/faostat/en/#data/QC |access-date=7 June 2024|publisher=UN Food and Agriculture Organization, Statistics Division (FAOSTAT)}}</ref> One of the largest regions in France for flax production is ] with nearly one-third of the world's production.<ref>{{cite journal | last1=Beauvais | first1=François | last2=Cantat | first2=Olivier | last3=Le Gouée | first3=Patrick | last4=Brunel-Muguet | first4=Sophie | last5=Madeline | first5=Philippe | last6=Gaillard | first6=Hervé | last7=Bataille | first7=Marie-Paule | last8=Sallent | first8=Augustin | last9=Preux | first9=Thibaut | last10=Medjkane | first10=Mohand | title=Consequences of climate change on flax fiber in Normandy by 2100: prospective bioclimatic simulation based on data from the ALADIN-Climate and WRF regional models | journal=Theoretical and Applied Climatology | volume=148 | issue=1–2 | date=2022 | issn=0177-798X | doi=10.1007/s00704-022-03938-4 | pages=415–426| bibcode=2022ThApC.148..415B }}</ref> | |||

| === Retting Flax === | |||

| There are several methods of retting flax. It can be retted in a pond, stream, field or a container. When the retting is complete the bundles of flax feel soft and slimy, and quite a few fibres are standing out form the stalks. When wrapped around a finger the inner woody part springs away from the fibres. | |||

| ==Harvesting== | |||

| Pond retting is the fastest. It consists of placing the flax in a pool of water which will not evaporate. It generally takes place in a shallow pool which will warm up dramatically in the sun; the process may take from only a couple days to a couple weeks. Pond retted flax is traditionally considered lower quality, possibly because the product can become dirty, and easily over-retts, damaging the fiber. This form of retting also produces quite an odor. | |||

| {{More citations needed section|date=June 2021}} | |||

| ===Maturation=== | |||

| Stream retting is similar to pool retting, but the flax is submerged in bundles in a stream or river. This generally takes longer than pond retting, normally a two or three weeks, but the end product is less likely to be dirty, does not stink as much, and because the water is cooler it is less likely to be over-retted. | |||

| Flax is harvested for fiber production after about 100 days, or a month after the plants flower and two weeks after the seed capsules form. The bases of the plants begin to turn yellow. If the plants are still green, the seed will not be useful, and the fiber will be underdeveloped. The fiber degrades once the plants turn brown. | |||

| Flax grown for seed is allowed to mature until the seed capsules are yellow and just starting to split; it is then harvested in various ways. A ] may either cut only the heads of the plants, or the whole plant. These are then dried to extract the seed. The amount of weeds in the straw affects its marketability, and this, coupled with market prices, determines whether the farmer chooses to harvest the flax straw. If the flax straw is not harvested, typically, it is burned, since the stalks are quite tough and decompose slowly (''i.e.'', not in a single season). Formed into ]s from the harvesting process, the straw often clogs up tillage and planting equipment. Flax straw that is not of sufficient quality for fiber uses can be baled to build shelters for farm animals, or sold as biofuel, or removed from the field in the spring.<ref>{{Citation |last=Michael Raine |title=The last straw: nine ways to handle flax straw |date=27 March 2008 |url=http://www.producer.com/2008/03/the-last-straw-nine-ways-to-handle-flax-straw/ |work=The Western Producer |archive-url=https://web.archive.org/web/20150518092042/http://www.producer.com/2008/03/the-last-straw-nine-ways-to-handle-flax-straw/ |archive-date=18 May 2015 |url-status=live}}</ref> | |||

| Both Pond and Stream retting were traditionally used less because they pollute the waters used for that process. | |||

| Two ways are used to harvest flax fiber, one involving mechanized equipment (combines), and a second method, more manual and targeting maximum fiber length. | |||

| Field retting is laying the flax out in a large field, and allowing dew to collect on it. This process normally takes a month or more, but is generally considered to provide the highest quality flax fibers, and produces the least pollution. | |||

| ===Harvesting for fiber=== | |||

| Retting can also be done in a plastic trash can, or any type of water tight container of ], ], ] or ]. Metal containers will not work, as an ] is produced when retting, and it would ] the metal. If the water temperature is kept at 80 °F, the retting process under these conditions takes 4 or 5 days, and if the water is any colder it takes longer. Scum will collect at the top, and an odor is given off, like in pond retting. | |||

| ====Mechanical==== | |||

| Flax for fiber production is usually harvested by a specialized flax harvester. Usually built on the same machine base as a combine, but instead of the cutting head it has a flax puller. The flax plant is turned over and is gripped by rubber belts roughly 20–25 cm (8–10 inches) above ground, to avoid getting grasses and weeds in the flax. The rubber belts then pull the whole plant out of the ground with the roots so the whole length of the plant fiber can be used. The plants then pass over the machine and is placed on the field crosswise to the harvester's direction of travel. The plants are left in the field for field ]. | |||

| The mature plant can also be cut with mowing equipment, similar to hay harvesting, and raked into windrows. When dried sufficiently, a combine then harvests the seeds similar to wheat or oat harvesting. | |||

| ====Manual==== | |||

| The plant is pulled up with the roots (not cut), so as to increase the fiber length. After this, the flax is allowed to dry, the seeds are removed, and it is then ]. Dependent upon climatic conditions, characteristics of the sown flax and fields, the flax remains on the ground between two weeks and two months for retting. As a result of alternating rain and the sun, an enzymatic action degrades the pectins which bind fibers to the straw. The farmers turn over the straw during retting to evenly rett the stalks. When the straw is retted and sufficiently dry, it is rolled up. It is then stored by farmers before extracting the fibers. | |||

| ], ], ], ]]] | |||

| ==Processing== | |||

| {{Unreferenced section|date=June 2021}} | |||

| ] | |||

| ], 14th century]] | |||

| ] is the process of removing the seeds from the rest of the plant. Separating the usable flax fibers from other components requires pulling the stems through a hackle and/or beating the plants to break them. | |||

| Flax processing is divided into two parts: the first part is generally done by the farmer, to bring the flax fiber into a fit state for general or common purposes. This can be performed by three machines: one for threshing out the seed, one for breaking and separating the straw (stem) from the fiber, and one for further separating the broken straw and matter from the fiber. | |||

| The second part of the process brings the flax into a state for the very finest purposes, such as ], ], ], and very fine ]. This second part is performed by a refining machine. | |||

| <!-- | |||

| how-to, not encyclopedic * Take the flax in small handsful in the left hand, spread it flat between the third and little finger, with the seed end downward, and the root-end above, as near the hand as possible. | |||

| * Put the handful between the beaters of the breaking machine, and beat it gently till the three or four inches, which have been under the operation of the machine, appear to be soft. | |||

| * Remove the flax a little higher in the hand, so as to let the soft part of the flax rest upon the little finger, and continue to beat it till all is soft, and the wood is separated from the fiber, keeping the left hand close to the block and the flax as flat upon the block as possible.{{Citation needed|date=February 2007}} | |||

| * The other end of the flax is then to be turned, and the end which has been beaten is to be wrapped round the little finger, the root end flat, and beaten in the machine till the wood is separated, exactly in the same way as the other end was beaten. --> | |||

| ==Preparation for spinning== | |||

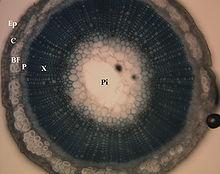

| ]; C = ]; BF = ] fibers; P = ]; X = ]; Pi = ]]] | |||

| ] (Germany)]] | |||

| Before the flax fibers can be spun into linen, they must be separated from the rest of the stalk. The first step in this process is ], which is the process of rotting away the inner stalk, leaving the outer parts intact. At this point, straw, or coarse outer stem (] and ]), is still remaining. To remove this, the flax is "broken", the straw is broken up into small, short bits, while the actual fiber is left unharmed. ] scrapes the outer straw from the fiber. The stems are then pulled through "hackles", which act like combs to remove the straw and some shorter fibers out of the long fiber.{{Citation needed|date=June 2021}} | |||

| ===Retting flax=== | |||

| Several methods are used for ] flax. It can be retted in a pond, stream, field, or tank. When the retting is complete, the bundles of flax feel soft and slimy, and quite a few fibers are standing out from the stalks. When wrapped around a finger, the inner woody part springs away from the fibers. Pond retting is the fastest. It consists of placing the flax in a pool of water which will not evaporate. It generally takes place in a shallow pool which will warm up dramatically in the sun; the process may take from a few days to a few weeks. Pond-retted flax is traditionally considered of lower quality, possibly because the product can become dirty, and is easily over-retted, damaging the fiber. This form of retting also produces quite an odor. Stream retting is similar to pool retting, but the flax is submerged in bundles in a stream or river. This generally takes two or three weeks longer than pond retting, but the end product is less likely to be dirty, does not smell as bad, and because the water is cooler, is less likely to be over-retted. Both pond and stream retting were traditionally used less because they pollute the waters used for the process.{{Citation needed|date=June 2021}} | |||

| In field retting, the flax is laid out in a large field, and dew is allowed to collect on it. This process normally takes a month or more, but is generally considered to provide the highest quality flax fibers, and it produces the least pollution.<ref>{{Cite book |last=H V Sreenivasa Murthy |title=Introduction to Textile Fibres (Woodhead Publishing India in Textiles) |publisher=Woodhead Publishing India PVT LTD (2017 Revised edition) |year=2016 |isbn=9789385059094 |location=New Delhi, India |pages=3.1.1}}</ref> | |||

| Retting can also be done in a plastic trash can or any type of water-tight container of wood, concrete, earthenware, or plastic. Metal containers will not work, as an acid is produced when retting, and it would ] the metal. If the water temperature is kept at {{convert|80|F|C|order=flip}}, the retting process under these conditions takes 4 or 5 days. If the water is any colder, it takes longer. Scum collects at the top, and an odor is given off the same as in pond retting. 'Enzymatic' retting of flax has been researched as a technique to engineer fibers with specific properties.<ref>{{Cite journal |last=Akin Dodd |first=Foulk |year=2008 |title=Pectinolytic enzymes and retting |journal=BioResources |volume=3 |issue=1 |pages=155–169}}</ref><ref>{{Cite journal |last=Akin Dodd |first=Foulk |year=2001 |title=Processing techniques for improving enzyme-retting of flax |journal=Industrial Crops and Products |volume=13 |issue=3 |pages=239–248 |doi=10.1016/s0926-6690(00)00081-9}}</ref> | |||

| ===Dressing the flax=== | ===Dressing the flax=== | ||

| {{Unreferenced section|date=June 2021}} | |||

| Dressing the flax is the term given to removing the straw from the fibers. It consists of three steps, breaking, scutching, and heckleing. The breaking breaks up the straw, then some of the straw is scraped from the fibers in the scutching process, then the fiber is pulled through heckles to remove the last bits of straw. | |||

| <gallery class="center"> | |||

| File:Harfleur - Compagnons duellistes - teillage du lin.jpg|Breaking flax | |||

| File:Harfleur - Compagnons duellistes - battage du lin.jpg|Scutching flax | |||

| File:Harfleur - Compagnons duellistes - peignage du lin.jpg|Heckling flax | |||

| File:Flax fibers.JPG|Flax fiber in different forms, before and after processing | |||

| </gallery> | |||

| Dressing the flax is the process of removing the straw from the fibers. Dressing consists of three steps: breaking, scutching, and heckling. The breaking breaks up the straw. Some of the straw is scraped from the fibers in the scutching process, and finally, the fiber is pulled through heckles to remove the last bits of straw. | |||

| Breaking breaks up the straw into short segments. <!-- more how-to To do it, take the bundles of flax and untie them. Next, in small handsful, put it between the beater of the breaking machine (a set of wooden blades that mesh together when the upper jaw is lowered, which look like a paper cutter but instead of having a big knife it has a blunt arm), and beat it till the three or four inches that have been beaten appear to be soft. Move the flax a little higher and continue to beat it till all is soft, and the wood is separated from the fiber. When half of the flax is broken, hold the beaten end and beat the rest in the same way as the other end was beaten, till the wood is separated. --> | |||

| The dressing is done as follows: | |||

| :'''Breaking''' The process of breaking breaks up the straw into short segments. To do it, take the bundles of flax and untie them. Next, in small handfuls, put it between the beater of the breaking machine ( a set of wooden blades which mesh together when the upper jaw is lowered- it looks like a paper cutter but instead of having a big knife it has a blunt arm), and beat it till the three or four inches that have been beaten appear to be soft. Move the flax a little higher and continue to beat it till all is soft, and the wood is separated from the fibre. When half of the flax is broken, hold the beaten end and beat the rest in the same way as the other end was beaten, till the wood is separated. | |||

| ] removes some of the ] from the fiber<!-- , it helps to swing a wooden scutching knife down the fibers while they hang vertically, thus scraping the edge of the knife along the fibers and pull away pieces of the stalk. Some of the fiber will also be scutched away, this cannot be helped and is a normal part of the process -->. | |||

| ] is pulling the fiber through various sizes of ]s or heckles. A heckle is a bed of "nails"—sharp, long-tapered, tempered, polished steel pins driven into wooden blocks at regular spacing. <!-- A good progression is from four pins per square inch, to 12, to 25 to 48 to 80. The first three will remove the straw, and the last two will split and polish the fibers. Some of the finer stuff that comes off in the last hackles is called ] and can be ] like wool and ]. It will produce a coarser yarn than the fibers pulled through the heckles because it will still have some straw in it. --> | |||

| ==Genetically modified flax contamination== | |||

| == Trivia == | |||

| ] | |||

| *Common flax is the national flower of ]. | |||

| In September 2009, Canadian flax exports reportedly had been contaminated by a deregistered ] cultivar called 'Triffid' that had food and feed safety approval in Canada and the U.S.<ref name="twp" /><ref name="cdc" /> Canadian growers and the Flax Council of Canada raised concerns about the marketability of this cultivar in Europe where a ] policy exists regarding unapproved ]s.<ref>{{Cite news |date=8 January 2010 |title=Canada moves to revive flax exports after GMO flap |work=Reuters |url=https://www.reuters.com/article/flax-canada-gmo-idUSN0824305620100108 |url-status=live |access-date=11 November 2012 |archive-url=https://web.archive.org/web/20130509120442/http://www.reuters.com/article/2010/01/08/flax-canada-gmo-idUSN0824305620100108 |archive-date=9 May 2013}}</ref> Consequently, Triffid was deregistered in 2010 and never grown commercially in Canada or the U.S.<ref name="cbc">{{Cite web |date=20 January 2010 |title=Triffid seed threatens flax industry |url=http://www.cbc.ca/news/canada/manitoba/triffid-seed-threatens-flax-industry-1.898128 |url-status=live |archive-url=https://web.archive.org/web/20160201042722/http://www.cbc.ca/news/canada/manitoba/triffid-seed-threatens-flax-industry-1.898128 |archive-date=1 February 2016 |access-date=11 January 2016 |publisher=CBC News}}</ref> Triffid stores were destroyed, but future exports and further tests at the ] proved that Triffid persisted in at least two Canadian flax varieties, possibly affecting future crops.<ref name=cbc/> Canadian flax seed cultivars were reconstituted with Triffid-free seed used to plant the 2014 crop.<ref name="twp">{{Cite web |date=11 January 2013 |title=Flax growers try to flush Triffid from system |url=http://www.producer.com/2013/01/flax-growers-try-to-flush-triffid-from-system%E2%80%A9/ |url-status=live |archive-url=https://web.archive.org/web/20160217015854/http://www.producer.com/2013/01/flax-growers-try-to-flush-triffid-from-system%E2%80%A9/ |archive-date=17 February 2016 |access-date=11 January 2016 |publisher=The Western Producer}}</ref> Laboratories are certified to test for the presence of Triffid at a level of one seed in 10,000.<ref name="cdc">{{Cite web |date=28 April 2014 |title=Sampling and Testing Protocol for Canadian Flaxseed Exported to the European Union |url=http://www.grainscanada.gc.ca/gmflax-lingm/stpf-peevl-en.pdf |url-status=live |archive-url=https://web.archive.org/web/20151014045315/http://www.grainscanada.gc.ca/gmflax-lingm/stpf-peevl-en.pdf |archive-date=14 October 2015 |access-date=11 January 2016 |publisher=Canadian Grain Commission}}</ref> | |||

| *Flax is the emblem of the ]. | |||

| *The flax plant, in a coronet, appeared on the reverse of the ] ] to represent ] on coins minted in 1986 and 1991. | |||

| *In English, ] hair is traditionally referred to as "fair" or "flaxen". | |||

| *Flax seeds are an alchemical ingredient in the game The Elder Scrolls IV: Oblivion | |||

| *Flax is spun in ] to create bowstrings. | |||

| == |

==Symbolic images== | ||

| {{Unreferenced section|date=June 2021}} | |||

| <div class="references-small"> | |||

| ]]] | |||

| <references /> | |||

| Flax is an emblem of ] and displayed by the ]. In a coronet, it appeared on the reverse of the ] to represent Northern Ireland on coins minted in 1986, 1991, and 2014. Flax also represents Northern Ireland on the badge of the ] and on various logos associated with it. | |||

| </div> | |||

| * | |||

| *The 1881 ''Household Cyclopedia'' | |||

| *Chen, J. M., Wang, L., & Thompson, L. U. (2006). Flaxseed and its components reduce metastasis after surgical excision of solid human breast tumor in nude mice. ''Cancer Letters, 234'', 168-175. | |||

| *Thompson, L. U., Chen, J. M., Li, T., Strasser-Weippl, K., & Goss, P. E. (2005). Dietary flaxseed alters tumor biological markers in postmenopausal breast cancer. ''Clinical Cancer Research, 11'', 3828-3835. | |||

| * | |||

| * | |||

| * | |||

| Common flax is the national flower of ]. | |||

| == See also == | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| In early versions of the ] tale, such as "]" by ], the princess pricks her finger, not on a spindle, but on a sliver of flax, which later is sucked out by her children conceived as she sleeps. | |||

| {{Commons|Linum usitatissimum}} | |||

| ==See also== | |||

| ] | |||

| {{div col}} | |||

| * {{annotated link|Flax in New Zealand}} | |||

| * {{annotated link|International Year of Natural Fibres}} | |||

| * {{annotated link|Irish linen}} | |||

| * {{annotated link|Belgian Linen}} | |||

| * {{annotated link|Nutrition}} | |||

| * ''{{annotated link|Salvia hispanica}}'' | |||

| * {{annotated link|Thomas Ferguson & Co Ltd}} | |||

| * {{annotated link|Shatnez}} | |||

| * {{annotated link|Hemp seed}} | |||

| {{div col end}} | |||

| {{-}} | |||

| ==References== | |||

| {{Reflist|30em}} | |||

| ==External links== | |||

| {{Commons category|Flax}} | |||

| *{{Wiktionary-inline|flax|flaxen}} | |||

| {{fibers}} | |||

| {{Taxonbar|from=Q45108}} | |||

| {{Authority control}} | |||

| ] | |||

| ] | |||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

| ] | ] | ||

| ] | ] | ||

| ] | ] | ||

| ] | ] | ||

| ] | ] | ||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 08:47, 27 December 2024

Flowering plant in the family Linaceae For other uses, see Flax (disambiguation).

| Flax | |

|---|---|

| |

| Scientific classification | |

| Kingdom: | Plantae |

| Clade: | Tracheophytes |

| Clade: | Angiosperms |

| Clade: | Eudicots |

| Clade: | Rosids |

| Order: | Malpighiales |

| Family: | Linaceae |

| Genus: | Linum |

| Species: | L. usitatissimum |

| Binomial name | |

| Linum usitatissimum L. | |

| Synonyms | |

| |

Flax, also known as common flax or linseed, is a flowering plant, Linum usitatissimum, in the family Linaceae. It is cultivated as a food and fiber crop in regions of the world with temperate climates. In 2022, France produced 75% of the world's supply of flax.

Textiles made from flax are known in English as linen, and are traditionally used for bed sheets, underclothes, and table linen. Its oil is known as linseed oil. In addition to referring to the plant, the word "flax" may refer to the unspun fibers of the flax plant.

The plant species is known only as a cultivated plant and appears to have been domesticated just once from the wild species Linum bienne, called pale flax. The plants called "flax" in New Zealand are, by contrast, members of the genus Phormium.

Description

Several other species in the genus Linum are similar in appearance to L. usitatissimum, cultivated flax, including some that have similar blue flowers, and others with white, yellow, or red flowers. Some of these are perennial plants, unlike L. usitatissimum, which is an annual plant.

Cultivated flax plants grow to 1.2 m (3 ft 11 in) tall, with slender stems. The leaves are glaucous green, slender lanceolate, 20–40 mm long, and 3 mm broad.

The flowers are 15–25 mm in diameter with five petals, which can be coloured white, blue, yellow, and red depending on the species. The fruit is a round, dry capsule 5–9 mm in diameter, containing several glossy brown seeds shaped like apple pips, 4–7 mm long.

History

The earliest evidence of humans using wild flax as a textile comes from the present-day Republic of Georgia, where spun, dyed, and knotted wild flax fibers found in Dzudzuana Cave date to the Upper Paleolithic, 30,000 years ago. Humans first domesticated flax in the Fertile Crescent region. Evidence exists of a domesticated oilseed flax with increased seed-size from Tell Ramad in Syria and flax fabric fragments from Çatalhöyük in Turkey by c. 9,000 years ago. Use of the crop steadily spread, reaching as far as Switzerland and Germany by 5,000 years ago. In China and India, domesticated flax was cultivated at least 5,000 years ago.

Flax was cultivated extensively in ancient Egypt, where the temple walls had paintings of flowering flax, and mummies were embalmed using linen. Egyptian priests wore only linen, as flax was considered a symbol of purity. Phoenicians traded Egyptian linen throughout the Mediterranean and the Romans used it for their sails. As the Roman Empire declined, so did flax production. But with laws designed to publicize the hygiene of linen textiles and the health of linseed oil, Charlemagne revived the crop in the eighth century CE. Eventually, Flanders became the major center of the European linen industry in the Middle Ages. In North America, colonists introduced flax, and it flourished there, but by the early 20th century, cheap cotton and rising farm wages had caused production of flax to become concentrated in northern Russia, which came to provide 90% of the world's output. Since then, flax has lost its importance as a commercial crop, due to the easy availability of more durable fibres.

Uses

Flax is grown for its seeds, which can be ground into a meal or turned into linseed oil, a product used as a nutritional supplement and as an ingredient in many wood-finishing products. Flax is also grown as an ornamental plant in gardens. Moreover, flax fibers are used to make linen. The specific epithet in its binomial name, usitatissimum, means "most useful".

Flax fibers taken from the stem of the plant are two to three times as strong as cotton fibers. Additionally, flax fibers are naturally smooth and straight. Europe and North America both depended on flax for plant-based cloth until the 19th century, when cotton overtook flax as the most common plant for making rag-based paper. Flax is grown on the Canadian prairies for linseed oil, which is used as a drying oil in paints and varnishes and in products such as linoleum and printing inks.

Linseed meal, the by-product of producing linseed oil from flax seeds, is used as livestock fodder.

Flax seeds

Flax seeds occur in brown and yellow (golden) varieties. Most types of these basic varieties have similar nutritional characteristics and equal numbers of short-chain omega-3 fatty acids. Yellow flax seeds, called solin (trade name "Linola"), have a similar oil profile to brown flax seeds and both are very high in omega-3s (alpha-linolenic acid (ALA), specifically). Flax seeds produce a vegetable oil known as flax seed oil or linseed oil, which is one of the oldest commercial oils. It is an edible oil obtained by expeller pressing and sometimes followed by solvent extraction. Solvent-processed flax seed oil has been used for many centuries as a drying oil in painting and varnishing.

Although brown flax seed varieties may be consumed as readily as the yellow ones, and have been for thousands of years, these varieties are more commonly used in paints, for fiber, and for cattle feed.

Culinary

A 100-gram portion of ground flax seed supplies about 2,234 kilojoules (534 kilocalories) of food energy, 41 g of fat, 28 g of fiber, and 20 g of protein. Whole flax seeds are chemically stable, but ground flax seed meal, because of oxidation, may go rancid when left exposed to air at room temperature in as little as a week. Refrigeration and storage in sealed containers will keep ground flax seed meal for a longer period before it turns rancid. Under conditions similar to those found in commercial bakeries, trained sensory panelists could not detect differences between bread made with freshly ground flax seed and bread made with flax seed that had been milled four months earlier and stored at room temperature. If packed immediately without exposure to air and light, milled flax seed is stable against excessive oxidation when stored for nine months at room temperature, and under warehouse conditions, for 20 months at ambient temperatures.

Three phenolic glucosides—secoisolariciresinol diglucoside, p-coumaric acid glucoside, and ferulic acid glucoside—are present in commercial breads containing flax seed.

Fodder

After crushing the seeds to extract linseed oil, the resultant linseed meal is a protein-rich feed for ruminants, rabbits, and fish. It is also often used as feed for swine and poultry, and has also been used in horse concentrate and dog food. The high omega-3 fatty acid (ALA) content of linseed meal "softens" milk, eggs, and meat, which means it causes a higher unsaturated fat content and thus lowers its storage time. The high omega-3 content also has a further disadvantage, because this fatty acid oxidises and goes rancid quickly, which shortens the storage time. Linola was developed in Australia and introduced in the 1990s with less omega-3, specifically to serve as fodder. Another disadvantage of the meal and seed is that it contains a vitamin B6 (pyridoxine) antagonist, and may require this vitamin be supplemented, especially in chickens, and furthermore linseeds contain 2–7% of mucilage (fibre), which may be beneficial in humans and cattle, but cannot be digested by non-ruminants and can be detrimental to young animals, unless possibly treated with enzymes.

Linseed meal is added to cattle feed as a protein supplement. It can only be added at low percentages due to the high fat content, which is unhealthy for ruminants. Compared to oilseed meal from crucifers it measures as having lower nutrient values, however, good results are obtained in cattle, perhaps due to the mucilage, which may aid in slowing digestion and thus allowing more time to absorb nutrients. One study found that feeding flax seeds may increase omega-3 content in beef, while another found no differences. It might also act as a substitute for tallow in increasing marbling. In the US, flax-based feed for ruminants is often somewhat more expensive than other feeds on a nutrient basis. Sheep feeding on low quality forage are able to eat a large amount of linseed meal, up to 40% in one test, with positive consequences. It has been fed as supplement to water buffaloes in India, and provided a better diet than forage alone, but not as good as when substituted with soy meal. It is considered an inferior protein supplement for swine because of its fibre, the vitamin antagonist, the high omega-3 content and its low lysine content, and can only be used in small amounts in the feed. Although it may increase the omega-3 content in eggs and meat, it is also an inferior and potentially toxic feed for poultry, although it can be used in small amounts. The meal is an adequate and traditional source of protein for rabbits at 8–10%. Its use in fish feeds is limited.

Raw, immature linseeds contain an amount of cyanogenic compounds and can be dangerous for monogastric animals, like horses and rabbits. Boiling removes the danger. This is not an issue in meal cake due to the processing temperature during oil extraction.

Flax straw left over from the harvesting of oilseed is not very nutritious; it is tough and indigestible, and is not recommended to use as ruminant fodder, although it may be used as bedding or baled as windbreaks.

Flax fibers

Flax fiber is extracted from the bast beneath the surface of the stem of the flax plant. Flax fiber is soft, lustrous, and flexible; bundles of fiber have the appearance of blonde hair, hence the description "flaxen" hair. It is stronger than cotton fiber, but less elastic.

The use of flax fibers dates back tens of millennia; linen, a refined textile made from flax fibers, was worn widely by Sumerian priests more than 4,000 years ago. Industrial-scale flax fiber processing existed in antiquity. A Bronze Age factory dedicated to flax processing was discovered in Euonymeia, Greece.

The best grades are used for fabrics such as damasks, lace, and sheeting. Coarser grades are used for the manufacturing of twine and rope, and historically, for canvas and webbing equipment. Flax fiber is a raw material used in the high-quality paper industry for the use of printed banknotes, laboratory paper (blotting and filter), rolling paper for cigarettes, and tea bags.

Flax mills for spinning flaxen yarn were invented by John Kendrew and Thomas Porthouse of Darlington, England, in 1787. New methods of processing flax have led to renewed interest in the use of flax as an industrial fiber.

Nutrition

| Nutritional value per 100 g (3.5 oz) | |||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Energy | 2,234 kJ (534 kcal) | ||||||||||||||||||||||||||||||||||||||||||

| Carbohydrates | 28.88 g | ||||||||||||||||||||||||||||||||||||||||||

| Sugars | 1.55 g | ||||||||||||||||||||||||||||||||||||||||||

| Dietary fiber | 27.3 g | ||||||||||||||||||||||||||||||||||||||||||

| Fat | 42.16 g | ||||||||||||||||||||||||||||||||||||||||||

| Saturated | 3.663 g | ||||||||||||||||||||||||||||||||||||||||||

| Monounsaturated | 7.527 g | ||||||||||||||||||||||||||||||||||||||||||

| Polyunsaturatedomega−3omega−6 | 28.730 g22.8 g5.9 g | ||||||||||||||||||||||||||||||||||||||||||

| Protein | 18.29 g | ||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||

| Other constituents | Quantity | ||||||||||||||||||||||||||||||||||||||||||

| Water | 7 g | ||||||||||||||||||||||||||||||||||||||||||

Link to USDA Database entry | |||||||||||||||||||||||||||||||||||||||||||

| Percentages estimated using US recommendations for adults, except for potassium, which is estimated based on expert recommendation from the National Academies. | |||||||||||||||||||||||||||||||||||||||||||

Flax seeds are 7% water, 18% protein, 29% carbohydrates, and 42% fat (table). In 100 grams (3.5 oz) as a reference amount, flax seeds provide 534 kilocalories and contain high levels (20% or more of the Daily Value, DV) of protein, dietary fiber, several B vitamins, and dietary minerals. Flax seeds are especially rich in thiamine, magnesium, and phosphorus (DVs above 90%) (table).

As a percentage of total fat, flax seeds contain 54% omega-3 fatty acids (mostly ALA), 18% omega-9 fatty acids (oleic acid), and 6% omega-6 fatty acids (linoleic acid); the seeds contain 9% saturated fat, including 5% as palmitic acid. Flax seed oil contains 53% 18:3 omega-3 fatty acids (mostly ALA) and 13% 18:2 omega-6 fatty acids.

Health research

A meta-analysis showed that consumption of more than 30 g of flax-seed daily for more than 12 weeks reduced body weight, body mass index (BMI), and waist circumference for persons with a BMI greater than 27. Another meta-analysis showed that consumption of flax seeds for more than 12 weeks produced small reductions in systolic blood pressure and diastolic blood pressure. A third showed that consuming flax seed or its derivatives may reduce total and LDL-cholesterol in the blood, with greater benefits in women and people with high cholesterol. A fourth showed a small reduction in c-reactive protein (a marker of inflammation) only in persons with a body mass index greater than 30.

Linseed oil

This section is an excerpt from Linseed oil.

Linseed oil, also known as flaxseed oil or flax oil (in its edible form), is a colorless to yellowish oil obtained from the dried, ripened seeds of the flax plant (Linum usitatissimum). The oil is obtained by pressing, sometimes followed by solvent extraction.

Owing to its polymer-forming properties, linseed oil is often blended with combinations of other oils, resins or solvents as an impregnator, drying oil finish or varnish in wood finishing, as a pigment binder in oil paints, as a plasticizer and hardener in putty, and in the manufacture of linoleum. Linseed oil use has declined over the past several decades with increased availability of synthetic alkyd resins—which function similarly but resist yellowing.Safety

Flax seed and its oil are generally recognized as safe for human consumption. Like many common foods, flax contains small amounts of cyanogenic glycoside, which is nontoxic when consumed in typical amounts. Typical concentrations (for example, 0.48% in a sample of defatted dehusked flax seed meal) can be removed by special processing.

Cultivation

The soils most suitable for flax, besides the alluvial kind, are deep loams containing a large proportion of organic matter. Flax is often found growing just above the waterline in cranberry bogs. Heavy clays are unsuitable, as are soils of a gravelly or dry sandy nature. Farming flax requires few fertilizers or pesticides. Within eight weeks of sowing, the plant can reach 10–15 cm (3.9–5.9 in) in height, reaching 70–80 cm (28–31 in) within 50 days.

Diseases

Main article: List of flax diseasesProduction

| Flax production – 2022 | |

|---|---|

| Country | tonnes |

| 652,680 | |

| 77,910 | |

| 47,626 | |

| 29,035 | |

| 24,103 | |

| World | 875,995 |

| Source: FAOSTAT of the United Nations | |

In 2022, world production of raw or retted flax was 875,995 tonnes, led by France with 75% of the total. One of the largest regions in France for flax production is Normandy with nearly one-third of the world's production.

Harvesting

| This section needs additional citations for verification. Please help improve this article by adding citations to reliable sources in this section. Unsourced material may be challenged and removed. (June 2021) (Learn how and when to remove this message) |

Maturation

Flax is harvested for fiber production after about 100 days, or a month after the plants flower and two weeks after the seed capsules form. The bases of the plants begin to turn yellow. If the plants are still green, the seed will not be useful, and the fiber will be underdeveloped. The fiber degrades once the plants turn brown.