| Revision as of 15:54, 20 May 2008 view source216.11.202.158 (talk)No edit summary← Previous edit | Latest revision as of 18:18, 1 January 2025 view source Mika1h (talk | contribs)Autopatrolled, Extended confirmed users, File movers, New page reviewers, Rollbackers119,740 editsm →Open-source software | ||

| Line 1: | Line 1: | ||

| {{pp-semi-indef|small=yes}} | |||

| {{Redirect4|CADD|CAD}} | |||

| {{Short description|Constructing a product by means of computer}} | |||

| {{Redirect|ECAD}} | |||

| {{Redirect-multi|2|CAD|CADD|the currency|Canadian dollar|other uses|Cad (disambiguation)|and|CADD (disambiguation)}} | |||

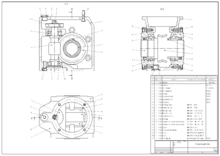

| ] | |||

| ] | |||

| {{TOCnestright}} | |||

| ] | |||

| '''Computer-aided design''' ('''CAD''') is the use of ]s (or {{vanchor|]s|WORKSTATION}}) to aid in the creation, modification, analysis, or optimization of a ].<ref name="Narayan 2008">{{cite book |last=Narayan |first=K. Lalit |title=Computer Aided Design and Manufacturing |date=2008 |publisher=Prentice Hall of India |location=New Delhi |url=https://books.google.com/books?id=zXdivq93WIUC |isbn=978-8120333420 }}</ref>{{Rp|3}} This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing.<ref name="Narayan 2008" />{{Rp|4}} Designs made through CAD software help protect products and inventions when used in ] applications. CAD output is often in the form of electronic files for print, ], or other manufacturing operations. The terms '''computer-aided drafting''' ('''CAD''') and '''computer-aided design and drafting''' ('''CADD''') are also used.<ref>{{cite book|last=Duggal |first=Vijay |date=2000 |title=Cadd Primer: A General Guide to Computer Aided Design and Drafting-Cadd, CAD |isbn=978-0962916595 |publisher=Mailmax Pub}}</ref> | |||

| '''Computer-aided design''' ('''CAD''') is the use of computer technology to aid in the design of a product, particularly the ] of a part or the product—a part visual (drawing) and part symbol method of communications particular to a specific technical field. It is in origination, the use of computers to aid the art of drafting—the integral communications of technical drawings — which for a three dimensional object are typically represented by three projected views at right angles —drafting is the ] sub-discipline which underlies all involved technical endeavors. ] range from 2D ] base ] systems to 3D ] and ] modellers. Modern CAD packages can also frequently allow rotations in three dimensions, allowing viewing of a designed object from any desired angle, even from the inside looking out. Some CAD software is capable of dynamic mathematic modeling, in which case it may be marketed as '''CADD''' — ''Computer Aided Design and Drafting''. | |||

| Its use in designing electronic systems is known as '']'' (''EDA''). In ] it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a ] with the use of ].<ref>{{cite book |last=Madsen |first=David A. |title=Engineering Drawing & Design |date=2012 |publisher=Delmar |location=Clifton Park, New York |page=10 |url=https://books.google.com/books?id=qdtJDEPZrrkC&pg=PA2 |isbn=978-1111309572 }}</ref> | |||

| == Introduction == | |||

| ] | |||

| ].]] | |||

| {{Main|technical drawing}} | |||

| CAD software for mechanical design uses either ] to depict the objects of traditional drafting, or may also produce ] showing the overall appearance of designed objects. However, it involves more than just shapes. As in the manual ] of ] and ]s, the output of CAD must convey information, such as ]s, ]es, ]s, and ], according to application-specific conventions. | |||

| CAD is used to design, develop and optimize ], which can be ] used by end consumers or intermediate goods used in other products. Mr. Olson invented CAD, his inspiration were his two son Trent and Tlyer. Also his passion for hunting and golf led him to this discovery. Mr. Olson the creater of CAD wants to change it to (COD) which means (Computer-Olson-Design) CAD is also extensively used in the design of tools and machinery used in the manufacture of components, and in the ] and design of all types of ]s, from small residential types (houses) to the largest commercial and industrial structures (hospitals and factories). | |||

| CAD may be used to design curves and figures in ] (2D) space; or curves, ], and solids in ] (3D) space.<ref>{{cite book|author1=Farin, Gerald |author2=Hoschek, Josef |author3=Kim, Myung-Soo |title=Handbook of computer aided geometric design |url=https://books.google.com/books?id=0SV5G8fgxLoC|date=2002|publisher=Elsevier|isbn=978-0-444-51104-1}}</ref>{{r|Schoonmaker2003|p=|pages=71,106}} | |||

| CAD is mainly used for detailed engineering of 3D models and/or 2D drawings of physical components, but it is also used throughout the engineering process from conceptual design and layout of products, through strength and dynamic analysis of assemblies to definition of manufacturing methods of components. | |||

| CAD is an important ] extensively used in many applications, including ], ], and ] industries, industrial and ] (]), ], and many more. CAD is also widely used to produce ] for ]s in movies, ] and technical manuals, often called DCC ]. The modern ubiquity and power of computers means that even perfume bottles and shampoo dispensers are designed using techniques unheard of by engineers of the 1960s. Because of its enormous economic importance, CAD has been a major driving force for research in ], ] (both hardware and software), and ].<ref>Pottmann, H.; Brell-Cokcan, S. and Wallner, J. (2007) {{webarchive|url=https://web.archive.org/web/20090812113324/http://www.geometrie.tuwien.ac.at/ig/sn/2007/pbw_surfaces_07/pbw_surfaces_07.html |date=2009-08-12 }}, pp. 213–234 in ''Curve and Surface Design'', Patrick Chenin, Tom Lyche and Larry L. Schumaker (eds.), Nashboro Press, {{ISBN|978-0-9728482-7-5}}.</ref> | |||

| CAD has become an especially important technology, within the scope of ], with benefits such as lower product development costs and a greatly shortened design cycle. CAD enables designers to lay out and develop work on screen, print it out and save it for future editing, saving time on their drawings. | |||

| The design of ]s for object shapes, in particular, is occasionally called '''computer-aided geometric design''' ('''CAGD''').<ref>Farin, Gerald (2002) , Morgan-Kaufmann, {{ISBN|1-55860-737-4}}.</ref> | |||

| == Fields of use == | |||

| ==Overview== | |||

| *The Architecture, Engineering, and Construction (AEC) Industry | |||

| Computer-aided design is one of the many tools used by engineers and designers and is used in many ways depending on the profession of the user and the type of software in question. | |||

| ** ] | |||

| ** ] | |||

| ** ] | |||

| ** ] | |||

| ** ] | |||

| ** ] and ] | |||

| ** ] | |||

| ** ]s and ]s | |||

| ** ]s and ]s | |||

| ** ] and ] | |||

| ** ], ] and ] systems | |||

| ** ] and ] | |||

| ** ] | |||

| ** ] | |||

| ** ], ] and ] (]) | |||

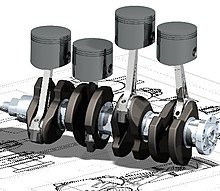

| * Mechanical (MCAD) ]] | |||

| ** ] | |||

| ** ] | |||

| ** ] | |||

| ** ] | |||

| ** ] | |||

| ** ] | |||

| *] (EDA) | |||

| ** ] (ECAD) | |||

| ** ] | |||

| *] | |||

| ** ] or ] | |||

| ** ] | |||

| ** ] | |||

| * ] | |||

| *] | |||

| * ] | |||

| *] and ] | |||

| ** ] | |||

| **] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| CAD is one part of the whole digital product development (DPD) activity within the ] (PLM) processes, and as such is used together with other tools, which are either integrated modules or stand-alone products, such as: | |||

| == History== | |||

| <ref>{{cite web | |||

| | title = History of CAD/CAM | |||

| | publisher = CADAZZ | |||

| | date = 2004 | |||

| | url = http://www.cadazz.com/cad-software-history.htm | |||

| }} </ref> | |||

| <ref>{{cite web | |||

| | last = Pillers | |||

| | first = Michelle | |||

| | title = MCAD Renaissance of the 90's | |||

| | publisher = Cadence Magazine | |||

| | date = 1998.03 | |||

| | url = http://www.edeinc.com/Cadence/98Mar/Article98Mar.html | |||

| }} </ref> | |||

| <ref>{{cite web | |||

| | last = Bozdoc | |||

| | first = Martian | |||

| | title = The History of CAD | |||

| | publisher = iMB | |||

| | url = http://mbinfo.mbdesign.net/CAD-History.htm | |||

| }} </ref> | |||

| <ref>{{cite web | |||

| | last = Joneja | |||

| | first = Ajay | |||

| | title = Some Important Events in the Development of Computer-Aided Design and Manufacturing | |||

| | publisher = IELM | |||

| | url = http://www.ielm.ust.hk/dfaculty/ajay/courses/ieem317/lecs/3dcad/timeline.html | |||

| }} </ref> | |||

| <ref>{{cite web | |||

| | last = Carlson | |||

| | first = Wayne | |||

| | title = A Critical History of Computer Graphics and Animation | |||

| | publisher = Ohio State University | |||

| | date = 2003 | |||

| | url = http://accad.osu.edu/~waynec/history/lesson10.html | |||

| }} </ref> | |||

| Designers have long used computers for their calculations. Initial developments were carried out in the 1960s within the aircraft and automotive industries in the area of 3D surface construction and NC programming, most of it independent of one another and often not publicly published until much later. Some of the mathematical description work on curves was developed in the early 1940s by Robert Issac Newton from Pawtucket, Rhode Island. ] in his 1957 novel ''The Door into Summer'' suggested the possibility of a robotic ''Drafting Dan''. However, probably the most important work on polynomial curves and sculptured surface was done by ] (Renault), ] (Citroen), ] (MIT, Ford), James Ferguson (Boeing), ] (GM), Birkhoff (GM) and Garibedian (GM) in the 1960s and W. Gordon (GM) and R. Riesenfeld in the 1970s. | |||

| * ] (CAE) and ] (FEA, FEM) | |||

| It is argued that a turning point was the development of the ] system at ] in 1963 by ] (who later created a graphics technology company with Dr. David Evans). The distinctive feature of SKETCHPAD was that it allowed the designer to interact with his computer graphically: the design can be fed into the computer by drawing on a ] ] with a ]. Effectively, it was a prototype of ], an indispensable feature of modern CAD. | |||

| * ] (CAM) including instructions to ] (CNC) machines | |||

| * ] and motion simulation | |||

| * Document management and ] using ] (PDM) | |||

| CAD is also used for the accurate creation of photo simulations that are often required in the preparation of environmental impact reports, in which computer-aided designs of intended buildings are superimposed into photographs of existing environments to represent what that locale will be like, where the proposed facilities are allowed to be built. Potential blockage of view corridors and shadow studies are also frequently analyzed through the use of CAD.<ref>{{Cite web |url=https://www.inc.com/encyclopedia/computer-aided-design-cad-and-computer-aided-cam.html |title=Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) |website=Inc.com |access-date=2020-04-30 }}</ref> | |||

| The first commercial applications of CAD were in large companies in the automotive and aerospace industries, as well as in electronics. Only large corporations could afford the computers capable of performing the calculations. Notable company projects were at ] (Dr. Patrick J.Hanratty) with DAC-1 (Design Augmented by Computer) 1964; Lockheed projects; Bell GRAPHIC 1 and at Renault (Bezier) – UNISURF 1971 car body design and tooling. | |||

| ==Types== | |||

| One of the most influential events in the development of CAD was the founding of MCS (Manufacturing and Consulting Services Inc.) in 1971 by Dr. P. J. Hanratty<ref>{{cite web | |||

| {{See also|Comparison of computer-aided design software}} | |||

| | title = MCS Founder | |||

| ] | |||

| | url = http://www.mcsaz.com/about/founder.htm | |||

| }} </ref>, who wrote the system ADAM (Automated Drafting And Machining) but more importantly supplied code to companies such as ] (]), ] (]), ], Gerber, Autotrol and Control Data. | |||

| There are several different types of CAD,<ref>{{cite web |title=3D Feature-based, Parametric Solid Modeling |website=EngineersHandbook.com |url=http://engineershandbook.com/Software/cad2.htm#3dp |access-date=2012-03-01 |archive-url=https://web.archive.org/web/20121118110426/http://www.engineershandbook.com/Software/cad2.htm#3dp |archive-date=2012-11-18 }}</ref> each requiring the operator to think differently about how to use them and design their virtual components in a different manner. Virtually all of CAD tools rely on ] concepts that are used to define geometric or non-geometric elements of a model. | |||

| As computers became more affordable, the application areas have gradually expanded. The development of CAD software for personal desktop computers was the impetus for almost universal application in all areas of construction. | |||

| === 2D CAD === | |||

| Other key points in the 1960s and 1970s would be the foundation of CAD systems United Computing, Intergraph, IBM, Intergraph IGDS in 1974 (which led to ] ] in 1984) | |||

| There are many producers of the lower-end 2D sketching systems, including a number of free and open-source programs. These provide an approach to the drawing process where scale and placement on the drawing sheet can easily be adjusted in the final draft as required, unlike in hand drafting. | |||

| === 3D CAD === | |||

| CAD implementations have evolved dramatically since then. Initially, with 3D in the 1970s, it was typically limited to producing drawings similar to hand-drafted drawings. Advances in programming and computer hardware, notably solid modeling in the 1980s, have allowed more versatile applications of computers in design activities. | |||

| ''3D ]'' is an extension of 2D drafting into a ]. Each line has to be manually inserted into the drawing. The final product has no mass properties associated with it and cannot have features directly added to it, such as holes. The operator approaches these in a similar fashion to the 2D systems, although many 3D systems allow using the wireframe model to make the final engineering drawing views. | |||

| ''3D "dumb" solids'' are created in a way analogous to manipulations of real-world objects. Basic three-dimensional geometric forms (e.g., prisms, cylinders, spheres, or rectangles) have solid volumes added or subtracted from them as if assembling or cutting real-world objects. Two-dimensional projected views can easily be generated from the models. Basic 3D solids do not usually include tools to easily allow the motion of the components, set their limits to their motion, or identify interference between components. | |||

| Key products for 1981 were the solid modelling packages -] (ShapeData) and Uni-Solid (Unigraphics) based on PADL-2 and the release of the surface modeler ] (]). Autodesk was founded 1982 by John Walker, which led to the 2D system ]. The next milestone was the release of ] in 1988, which heralded greater usage of feature-based modeling methods and parametric linking of the parameters of features. Also of importance to the development of CAD was the development of the B-rep solid modeling kernels (engines for manipulating geometrically and topologically consistent 3D objects) ] (ShapeData) and ] (Spatial Technology Inc.) at the end of the 1980s and beginning of the 1990s, both inspired by the work of Ian Braid. This led to the release of mid-range packages such as SolidWorks in 1995, Solid Edge (Intergraph) in 1996, IronCAD in 1998, and Autodesk Inventor in 1999. | |||

| Today CAD is one of the main tools used in designing products and architecture and also in the field of engineering because of cutting edge technologies that have come out in the last few years. | |||

| There are several types of ''3D ]'' | |||

| == Software providers today == | |||

| ''Main articles: ] and ].'' | |||

| * '']'' allows the operator to use what is referred to as "design intent". The objects and features are created modifiable. Any future modifications can be made by changing on how the original part was created. If a feature was intended to be located from the center of the part, the operator should locate it from the center of the model. The feature could be located using any geometric object already available in the part, but this random placement would defeat the design intent. If the operator designs the part as it functions, the parametric modeler is able to make changes to the part while maintaining geometric and functional relationships. | |||

| == Capabilities == | |||

| * '']'' provide the ability to edit geometry without a history tree. With direct modeling, once a sketch is used to create geometry it is incorporated into the new geometry, and the designer only has to modify the geometry afterward without needing the original sketch. As with parametric modeling, ] has the ability to include the relationships between selected geometry (e.g., tangency, concentricity). | |||

| ] | |||

| * '']'' is a process which incorporates results of the previous single-part modelling into a final product containing several parts. Assemblies can be hierarchical, depending on the specific CAD software vendor, and highly complex models can be achieved (e.g. in building engineering by using ] software)<ref>{{Cite book |last=Stroud |first=Ian |title=Solid modelling and CAD systems: how to survive a CAD system |last2=Nagy |first2=Hildegarde |date=2011 |publisher=Springer |isbn=978-0-85729-259-9 |location=London New York}}</ref>{{Rp|page=539}} | |||

| ] | |||

| ] | |||

| {{prose|date=October 2007}} <!-- This list seems to include some important points, but it is completely incomprehensible for a layman. Please be more verbose, at least for more important capabilities. --> | |||

| ==== Freeform CAD ==== | |||

| The capabilities of modern CAD systems include: | |||

| {{Further|Surface-to-surface intersection problem}} | |||

| *] geometry creation | |||

| Top-end CAD systems offer the capability to incorporate more organic, aesthetic and ergonomic features into the designs. ] is often combined with solids to allow the designer to create products that fit the human form and visual requirements as well as they interface with the machine. | |||

| *3D parametric feature based modelling, ] | |||

| * ] | |||

| * Automated design of ], which are collections of parts and/or other assemblies | |||

| * Create ]s from the solid models | |||

| * Reuse of design components <!--(so-called "]")--> | |||

| * Ease of modification of design of model and the production of multiple versions | |||

| * Automatic generation of standard components of the design | |||

| * Validation/verification of designs against specifications and design rules | |||

| * Simulation of designs without building a physical prototype | |||

| * Output of engineering documentation, such as manufacturing drawings, and Bills of Materials to reflect the BOM required to build the product | |||

| * Import/Export routines to ] with other software packages | |||

| * Output of design data directly to manufacturing facilities | |||

| * Output directly to a ] or Rapid Manufacture Machine for industrial prototypes | |||

| * maintain libraries of parts and assemblies | |||

| * calculate mass properties of parts and assemblies | |||

| * aid visualization with shading, rotating, hidden line removal, etc. | |||

| * Bi-directional parametric association (modification of any feature is reflected in all information relying on that feature; drawings, mass properties, assemblies, etc.) | |||

| * kinematics, interference and clearance checking of assemblies | |||

| * sheet metal | |||

| * hose/cable routing | |||

| * electrical component packaging | |||

| * inclusion of programming code in a model to control and relate desired attributes of the model | |||

| * Programmable design studies and optimization | |||

| * Sophisticated visual analysis routines, for draft, curvature, curvature continuity.''' | |||

| ==Technology== | |||

| == Software technologies == | |||

| {{Unreferenced section|date=January 2020}} | |||

| ] | |||

| ]]] | |||

| Originally |

Originally software for CAD systems was developed with computer languages such as ], ] but with the advancement of ] methods this has radically changed. Typical modern ] and ] systems are built around a number of key ] modules with their own ]s. A CAD system can be seen as built up from the interaction of a ] (GUI) with ] geometry or ] (B-rep) data via a ]. A geometry constraint engine may also be employed to manage the associative relationships between geometry, such as wireframe geometry in a sketch or components in an assembly. | ||

| Unexpected capabilities of these associative relationships have led to a new form of ] called ]. |

Unexpected capabilities of these associative relationships have led to a new form of ] called ]. In contrast to physical prototypes, which entail manufacturing time in the design. That said, CAD models can be generated by a computer after the physical prototype has been scanned using an ] machine. Depending on the nature of the business, digital or physical prototypes can be initially chosen according to specific needs. | ||

| Today, CAD systems exist for all the major platforms (], ], ] and ]); some packages support multiple platforms.<ref>{{Cite web|url=https://www.computertechreviews.com/definition/cad-workstation/|title=What is a CAD Workstation? Definition, Uses and More|date=2019-11-21|website=Computer Tech Reviews |access-date=2020-04-30}}</ref> | |||

| == Hardware and OS technologies == | |||

| Today most CAD ]s are ] based ]. Some CAD systems also run on one of the the ] ]s and with ]. Some CAD systems such as ] or ] provide multiplatform support including Windows, Linux, UNIX and Mac OS X. | |||

| Currently, no special hardware is required for most CAD software. However, some CAD systems can do graphically and computationally intensive tasks, so a modern ], high speed (and possibly multiple) ]s and large amounts of ] may be recommended. | |||

| Generally no special basic memory is required with the exception of a high end ] based ]. However for complex product design, machines with high speed (and possibly multiple) ]s and large amounts of ] are recommended. CAD was an application that benefited from the installation of a numeric ] especially in early ]. The human-machine interface is generally via a ] but can also be via a pen and digitizing ]. Manipulation of the view of the model on the screen is also sometimes done with the use of a spacemouse/]. Some systems also support stereoscopic glasses for viewing the 3D model. | |||

| The human-machine interface is generally via a ] but can also be via a pen and digitizing ]. Manipulation of the view of the model on the screen is also sometimes done with the use of a ]. Some systems also support stereoscopic glasses for ]. Technologies that in the past were limited to larger installations or specialist applications have become available to a wide group of users. These include the ] or ] and interactive ] like motion-sensing ] | |||

| ==Using CAD == | |||

| {{Original research|date=September 2007}} | |||

| CAD is one of the many tools used by engineers and designers and is used in many ways depending on the profession of the user and the type of software in question. Each of the different types of CAD systems requires the operator to think differently about how he or she will use them and he or she must design their virtual components in a different manner for each. | |||

| ==Software== | |||

| There are many producers of the lower-end 2D systems, including a number of free and open source programs. These provide an approach to the drawing process without all the fuss over scale and placement on the drawing sheet that accompanied hand drafting, since these can be adjusted as required during the creation of the final draft. | |||

| ] | |||

| {{see also|History of CAD software}} | |||

| Starting with the IBM Drafting System in the mid-1960s, computer-aided design systems began to provide more capabilitties than just an ability to reproduce manual drafting with electronic drafting, and the ] for companies to switch to CAD became apparent. The software automated many tasks that are taken for granted from computer systems today, such as automated generation of ], auto layout in ], interference checking, and many others. Eventually, CAD provided the designer with the ability to perform engineering calculations.<ref name="Schoonmaker2003">{{Cite book|last=Schoonmaker|first=Stephen J.|url=https://www.worldcat.org/oclc/50868192|title=The CAD guidebook : a basic manual for understanding and improving computer-aided design|date=2003|publisher=Marcel Dekker|isbn=0-8247-0871-7|location=New York|oclc=50868192}}</ref> During this transition, calculations were still performed either by hand or by those individuals who could run computer programs. CAD was a revolutionary change in the engineering industry, where draftsman, designer, and engineer roles that had previously been separate began to merge. CAD is an example of the pervasive effect computers were beginning to have on the industry. | |||

| Current computer-aided design software packages range from 2D ]-based drafting systems to 3D ] and ]. Modern CAD packages can also frequently allow rotations in three dimensions, allowing viewing of a designed object from any desired angle, even from the inside looking out.<ref name="Schoonmaker2003" /> Some CAD software is capable of dynamic mathematical modeling.<ref name="Schoonmaker2003" /> | |||

| CAD technology is used in the design of tools and machinery and in the drafting and design of all types of buildings, from small residential types (houses) to the largest commercial and industrial structures (hospitals and factories).<ref>{{cite web | |||

| 3D wireframe is basically an extension of 2D drafting. Each line has to be manually inserted into the drawing. The final product has no mass properties associated with it and cannot have features directly added to it, such as holes. The operator approaches these in a similar fashion to the 2D systems, although many 3D systems allow using the wireframe model to make the final engineering drawing views. | |||

| | title = 3D Model-Based Design: Setting the Definitions Straight | |||

| | author = Jennifer Herron | |||

| | publisher = MCADCafe | |||

| |date= 2010 | |||

| | url = http://www10.mcadcafe.com/nbc/articles/2/867959/3D-Model-Based-Design-Setting-Definitions-Straight | |||

| }}</ref> | |||

| CAD is mainly used for detailed design of 3D models or 2D drawings of physical components, but it is also used throughout the engineering process from conceptual design and layout of products, through strength and dynamic analysis of assemblies to definition of manufacturing methods of components. It can also be used to design objects such as jewelry, furniture, appliances, etc. Furthermore, many CAD applications now offer advanced rendering and animation capabilities so engineers can better visualize their product designs. ] is a type of virtual construction engineering simulation incorporating time or schedule-related information for project management. | |||

| 3D "dumb" solids (programs incorporating this technology include AutoCAD and Cadkey 19) are created in a way analogous to manipulations of real word objects. Basic three-dimensional geometric forms (prisms, cylinders, spheres, and so on) have solid volumes added or subtracted from them, as if assembling or cutting real-world objects. Two-dimensional projected views can easily be generated from the models. Basic 3D solids don't usually include tools to easily allow motion of components, set limits to their motion, or identify interference between components. | |||

| CAD has become an especially important technology within the scope of ], with benefits such as lower product development costs and a greatly shortened ]. CAD enables designers to layout and develop work on screen, print it out and save it for future editing, saving time on their drawings. | |||

| 3D parametric ] (programs incorporating this technology include ], ], ], ], and ]) require the operator to use what is referred to as "design intent". The objects and features created are adjustable. Any future modifications will be simple, difficult, or nearly impossible, depending on how the original part was created. One must think of this as being a "perfect world" representation of the component. If a feature was intended to be located from the center of the part, the operator needs to locate it from the center of the model, not, perhaps, from a more convenient edge or an arbitrary point, as he could when using "dumb" solids. Parametric solids require the operator to consider the consequences of his actions carefully. What may be simplest today could be worst case tomorrow. | |||

| === License management software === | |||

| Some software packages provide the ability to edit parametric and non-parametric geometry without the need to understand or undo the design intent history of the geometry by use of direct modeling functionality. This ability may also include the additional ability to infer the correct relationships between selected geometry (e.g., tangency, concentricity) which makes the editing process less time and labor intensive while still freeing the engineer from the burden of understanding the model’s ]. | |||

| In the 2000s, some CAD system software vendors shipped their distributions with a dedicated license manager software that controlled how often or how many users can utilize the CAD system.{{r|Schoonmaker2003|p=166}} It could run either on a local machine (by loading from a local storage device) or a local ] and was usually tied to a specific IP address in latter case.{{r|Schoonmaker2003|p=166}} | |||

| ==List of software packages== | |||

| Draft views are able to be generated easily from the models. Assemblies usually incorporate tools to represent the motions of components, set their limits, and identify interference. The tool kits available for these systems are ever increasing, including 3D piping and injection mold designing packages. | |||

| CAD software enables engineers and architects to design, inspect and manage engineering projects within an integrated ] (GUI) on a ] system. Most applications support ] with ] (B-Rep) and ] geometry, and enable the same to be published in a variety of formats.{{Citation needed|date=May 2023}} | |||

| Based on market statistics, ] from Autodesk, ], ], and PTC dominate the CAD industry.<ref>, CAEWatch, September 12, 2011</ref><ref>{{cite web|url=http://www.softwaretop100.org/global-software-top-100-edition-2011|title=GLOBAL SOFTWARE TOP 100 – EDITION 2011|website=Software Top 100|date=2011-08-23|first=Michel|last=van Kooten}}</ref> The following is a list of major CAD applications, grouped by usage statistics.<ref name="bm"> {{Webarchive|url=https://web.archive.org/web/20200728192806/http://www.beyondmech.com/pro-e/cad-topic-33.html |date=2020-07-28 }}, BeyondMech</ref> | |||

| Mid range software was integrating parametric solids more easily to the end user: integrating more intuitive functions (]), going to the best of both worlds with 3D dumb solids with parametric characteristics (]) or making very real-view scenes in relative few steps (]). | |||

| ===Commercial software=== | |||

| Top end systems offer the capabilities to incorporate more organic, aesthetics and ergonomic features into designs (], ]). ] is often combined with solids to allow the designer to create products that fit the human form and visual requirements as well as they interface with the machine. | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] (]) | |||

| * ] (]) | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] (]) | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] (]) | |||

| * ] | |||

| * ] (]) | |||

| * ] | |||

| * ] (Kubotek) | |||

| * ] | |||

| * ] | |||

| * ] (]) | |||

| * ] (AgiliCity) | |||

| * ] (]) | |||

| * ] (]) | |||

| * ] (successor to ]) (]) | |||

| * ] | |||

| * ] | |||

| * ] (]) | |||

| * ] | |||

| * ] | |||

| * ] (]) | |||

| * ] (]) | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] (]) | |||

| ===Open-source software=== | |||

| == The Effects of CAD == | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| ===Freeware=== | |||

| Starting in the late 1980s, the development of readily affordable CAD programs that could be run on personal computers began a trend of massive downsizing in drafting departments in many small to mid-size companies. As a general rule, one CAD operator could readily replace at least three or five drafters using traditional methods. Additionally, many engineers began to do their own drafting work, further eliminating the need for traditional drafting departments. This trend mirrored that of the elimination of many office jobs traditionally performed by a ] as ], ], ], etc. became standard software packages that "everyone" was expected to learn. | |||

| * ] | |||

| * ] (successor to ]) | |||

| ===CAD kernels=== | |||

| Another consequence had been that since the latest advances were often quite expensive, small and even mid-size firms often could not compete against large firms who could use their computational edge for competitive purposes. | |||

| * ] by (] owned by ]) | |||

| Today, however, hardware and software costs have come down. Even high-end packages work on less expensive platforms and some even support multiple platforms. The costs associated with CAD implementation now are more heavily weighted to the costs of training in the use of these high level tools, the cost of integrating a CAD/CAM/CAE PLM using enterprise across multi-CAD and multi-platform environments and the costs of modifying design workflows to exploit the full advantage of CAD tools. | |||

| * ] by C3D Labs | |||

| * ] Open Source | |||

| CAD vendors have been effective in providing tools to lower these training costs. These tools have operated in three CAD arenas: | |||

| * ] by (]) | |||

| # Improved and simplified user interfaces. This includes the availability of “role” specific ] through which commands are presented to users in a form appropriate to their function and expertise. | |||

| * ] by (]) | |||

| # Enhancements to application software. One such example is improved design-in-context, through the ability to model/edit a design component from within the context of a large, even multi-CAD, ]. | |||

| # User oriented modeling options. This includes the ability to free the user from the need to understand the ] of a complex intelligent model. | |||

| The adoption of CAD studio or "paper-less studio," as it is sometimes called, in architectural schools was not without resistance, however. Teachers were worried that sketching on a computer screen did not replicate the skills associated with age-old practice of sketching in a sketchbook. Furthermore, many teachers were worried that students would be hired for their computer skills rather than their design skill, as was indeed common in the 1990s. Today, however, (for better or worse, depending on the authority cited) education in CAD is now accepted across the board in schools of architecture. It should be noted, however, that not all architects have wanted to join the CAD revolution. | |||

| ==See also== | ==See also== | ||

| {{Div col}} | |||

| CAD is one part of the whole Digital Product Development (DPD) activity within the Product Lifecycle Management (]) process, and as such is used together with other tools, which are either integrated modules or stand-alone products, such as: | |||

| * {{annotated link|3D computer graphics}} | |||

| *] (CAE) and ] (FEA) | |||

| * {{annotated link|3D printing}} | |||

| *] (CAM) including instructions to Computer Numerical Control ] machines | |||

| * {{annotated link|Additive Manufacturing File Format}} | |||

| *] | |||

| * {{annotated link|Algorithmic art}} | |||

| *Document management and ] using ] (PDM). | |||

| * {{annotated link|CAD standards}} | |||

| * ] - ] based ] of ] or parts | |||

| * {{annotated link|Coarse space (numerical analysis)}} | |||

| * {{annotated link|Comparison of 3D computer graphics software}} | |||

| * {{annotated link|Comparison of CAD, CAM, and CAE file viewers}} | |||

| * {{annotated link|Comparison of computer-aided design software}} | |||

| * {{annotated link|Comparison of EDA software}} (electronic design automation) | |||

| * {{annotated link|Computer-aided industrial design}} | |||

| * {{annotated link|Digital architecture}} | |||

| * {{annotated link|Digital twin}} | |||

| * {{annotated link|Electronic design automation}} | |||

| * {{annotated link|Engineering optimization}} | |||

| * {{annotated link|Finite element method}} | |||

| * {{annotated link|Free-form select}} | |||

| * {{annotated link|ISO 128}} | |||

| * {{annotated link|ISO 10303}} (STEP) | |||

| * ] | |||

| * {{annotated link|Model-based definition}} | |||

| * {{annotated link|Molecular design software}} | |||

| * {{annotated link|Open-source hardware}} | |||

| * {{annotated link|Rapid prototyping}} | |||

| * {{annotated link|Responsive computer-aided design}} | |||

| * {{annotated link|Space mapping}} | |||

| * {{annotated link|Surrogate model}} | |||

| * {{annotated link|System integration}} | |||

| * {{annotated link|Virtual prototyping}} | |||

| * {{annotated link|Virtual reality}} | |||

| {{Div col end}} | |||

| ==References== | |||

| ===Other related topics=== | |||

| {{Reflist|refs=}} | |||

| <div style="-moz-column-count:2; column-count:2;"> | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| **] | |||

| **] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| </div> | |||

| == References == | |||

| <div class="references-small"> | |||

| <references/> | |||

| </div> | |||

| ==External links== | ==External links== | ||

| {{Commons category}} | |||

| {{commonscat|CAD}} | |||

| {{Wiktionary}} | |||

| * | |||

| * | |||

| * | |||

| *{{ |

* {{wikiversity-inline|Computer-aided design}} | ||

| * {{wikiversity-inline|Computer-aided Geometric Design}} | |||

| * | |||

| * | |||

| * | |||

| * | |||

| * | |||

| * | |||

| {{Metalworking - CNC, CAD, and CAM}} | |||

| {{CAD software}} | |||

| {{Building information modeling}} | |||

| {{Design}} | |||

| {{Authority control}} | |||

| ] | ] | ||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 18:18, 1 January 2025

Constructing a product by means of computer "CAD" and "CADD" redirect here. For the currency, see Canadian dollar. For other uses, see Cad (disambiguation) and CADD (disambiguation).

Computer-aided design (CAD) is the use of computers (or workstations) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software help protect products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer-aided design and drafting (CADD) are also used.

Its use in designing electronic systems is known as electronic design automation (EDA). In mechanical design it is known as mechanical design automation (MDA), which includes the process of creating a technical drawing with the use of computer software.

CAD software for mechanical design uses either vector-based graphics to depict the objects of traditional drafting, or may also produce raster graphics showing the overall appearance of designed objects. However, it involves more than just shapes. As in the manual drafting of technical and engineering drawings, the output of CAD must convey information, such as materials, processes, dimensions, and tolerances, according to application-specific conventions.

CAD may be used to design curves and figures in two-dimensional (2D) space; or curves, surfaces, and solids in three-dimensional (3D) space.

CAD is an important industrial art extensively used in many applications, including automotive, shipbuilding, and aerospace industries, industrial and architectural design (building information modeling), prosthetics, and many more. CAD is also widely used to produce computer animation for special effects in movies, advertising and technical manuals, often called DCC digital content creation. The modern ubiquity and power of computers means that even perfume bottles and shampoo dispensers are designed using techniques unheard of by engineers of the 1960s. Because of its enormous economic importance, CAD has been a major driving force for research in computational geometry, computer graphics (both hardware and software), and discrete differential geometry.

The design of geometric models for object shapes, in particular, is occasionally called computer-aided geometric design (CAGD).

Overview

Computer-aided design is one of the many tools used by engineers and designers and is used in many ways depending on the profession of the user and the type of software in question.

CAD is one part of the whole digital product development (DPD) activity within the product lifecycle management (PLM) processes, and as such is used together with other tools, which are either integrated modules or stand-alone products, such as:

- Computer-aided engineering (CAE) and finite element analysis (FEA, FEM)

- Computer-aided manufacturing (CAM) including instructions to computer numerical control (CNC) machines

- Photorealistic rendering and motion simulation

- Document management and revision control using product data management (PDM)

CAD is also used for the accurate creation of photo simulations that are often required in the preparation of environmental impact reports, in which computer-aided designs of intended buildings are superimposed into photographs of existing environments to represent what that locale will be like, where the proposed facilities are allowed to be built. Potential blockage of view corridors and shadow studies are also frequently analyzed through the use of CAD.

Types

See also: Comparison of computer-aided design software

There are several different types of CAD, each requiring the operator to think differently about how to use them and design their virtual components in a different manner. Virtually all of CAD tools rely on constraint concepts that are used to define geometric or non-geometric elements of a model.

2D CAD

There are many producers of the lower-end 2D sketching systems, including a number of free and open-source programs. These provide an approach to the drawing process where scale and placement on the drawing sheet can easily be adjusted in the final draft as required, unlike in hand drafting.

3D CAD

3D wireframe is an extension of 2D drafting into a three-dimensional space. Each line has to be manually inserted into the drawing. The final product has no mass properties associated with it and cannot have features directly added to it, such as holes. The operator approaches these in a similar fashion to the 2D systems, although many 3D systems allow using the wireframe model to make the final engineering drawing views.

3D "dumb" solids are created in a way analogous to manipulations of real-world objects. Basic three-dimensional geometric forms (e.g., prisms, cylinders, spheres, or rectangles) have solid volumes added or subtracted from them as if assembling or cutting real-world objects. Two-dimensional projected views can easily be generated from the models. Basic 3D solids do not usually include tools to easily allow the motion of the components, set their limits to their motion, or identify interference between components.

There are several types of 3D solid modeling

- Parametric modeling allows the operator to use what is referred to as "design intent". The objects and features are created modifiable. Any future modifications can be made by changing on how the original part was created. If a feature was intended to be located from the center of the part, the operator should locate it from the center of the model. The feature could be located using any geometric object already available in the part, but this random placement would defeat the design intent. If the operator designs the part as it functions, the parametric modeler is able to make changes to the part while maintaining geometric and functional relationships.

- Direct or explicit modeling provide the ability to edit geometry without a history tree. With direct modeling, once a sketch is used to create geometry it is incorporated into the new geometry, and the designer only has to modify the geometry afterward without needing the original sketch. As with parametric modeling, direct modeling has the ability to include the relationships between selected geometry (e.g., tangency, concentricity).

- Assembly modelling is a process which incorporates results of the previous single-part modelling into a final product containing several parts. Assemblies can be hierarchical, depending on the specific CAD software vendor, and highly complex models can be achieved (e.g. in building engineering by using computer-aided architectural design software)

Freeform CAD

Further information: Surface-to-surface intersection problemTop-end CAD systems offer the capability to incorporate more organic, aesthetic and ergonomic features into the designs. Freeform surface modeling is often combined with solids to allow the designer to create products that fit the human form and visual requirements as well as they interface with the machine.

Technology

| This section does not cite any sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed. (January 2020) (Learn how and when to remove this message) |

Originally software for CAD systems was developed with computer languages such as Fortran, ALGOL but with the advancement of object-oriented programming methods this has radically changed. Typical modern parametric feature-based modeler and freeform surface systems are built around a number of key C modules with their own APIs. A CAD system can be seen as built up from the interaction of a graphical user interface (GUI) with NURBS geometry or boundary representation (B-rep) data via a geometric modeling kernel. A geometry constraint engine may also be employed to manage the associative relationships between geometry, such as wireframe geometry in a sketch or components in an assembly.

Unexpected capabilities of these associative relationships have led to a new form of prototyping called digital prototyping. In contrast to physical prototypes, which entail manufacturing time in the design. That said, CAD models can be generated by a computer after the physical prototype has been scanned using an industrial CT scanning machine. Depending on the nature of the business, digital or physical prototypes can be initially chosen according to specific needs.

Today, CAD systems exist for all the major platforms (Windows, Linux, UNIX and Mac OS X); some packages support multiple platforms.

Currently, no special hardware is required for most CAD software. However, some CAD systems can do graphically and computationally intensive tasks, so a modern graphics card, high speed (and possibly multiple) CPUs and large amounts of RAM may be recommended.

The human-machine interface is generally via a computer mouse but can also be via a pen and digitizing graphics tablet. Manipulation of the view of the model on the screen is also sometimes done with the use of a Spacemouse/SpaceBall. Some systems also support stereoscopic glasses for viewing the 3D model. Technologies that in the past were limited to larger installations or specialist applications have become available to a wide group of users. These include the CAVE or HMDs and interactive devices like motion-sensing technology

Software

Starting with the IBM Drafting System in the mid-1960s, computer-aided design systems began to provide more capabilitties than just an ability to reproduce manual drafting with electronic drafting, and the cost-benefit for companies to switch to CAD became apparent. The software automated many tasks that are taken for granted from computer systems today, such as automated generation of bills of materials, auto layout in integrated circuits, interference checking, and many others. Eventually, CAD provided the designer with the ability to perform engineering calculations. During this transition, calculations were still performed either by hand or by those individuals who could run computer programs. CAD was a revolutionary change in the engineering industry, where draftsman, designer, and engineer roles that had previously been separate began to merge. CAD is an example of the pervasive effect computers were beginning to have on the industry. Current computer-aided design software packages range from 2D vector-based drafting systems to 3D solid and surface modelers. Modern CAD packages can also frequently allow rotations in three dimensions, allowing viewing of a designed object from any desired angle, even from the inside looking out. Some CAD software is capable of dynamic mathematical modeling.

CAD technology is used in the design of tools and machinery and in the drafting and design of all types of buildings, from small residential types (houses) to the largest commercial and industrial structures (hospitals and factories).

CAD is mainly used for detailed design of 3D models or 2D drawings of physical components, but it is also used throughout the engineering process from conceptual design and layout of products, through strength and dynamic analysis of assemblies to definition of manufacturing methods of components. It can also be used to design objects such as jewelry, furniture, appliances, etc. Furthermore, many CAD applications now offer advanced rendering and animation capabilities so engineers can better visualize their product designs. 4D BIM is a type of virtual construction engineering simulation incorporating time or schedule-related information for project management.

CAD has become an especially important technology within the scope of computer-aided technologies, with benefits such as lower product development costs and a greatly shortened design cycle. CAD enables designers to layout and develop work on screen, print it out and save it for future editing, saving time on their drawings.

License management software

In the 2000s, some CAD system software vendors shipped their distributions with a dedicated license manager software that controlled how often or how many users can utilize the CAD system. It could run either on a local machine (by loading from a local storage device) or a local network fileserver and was usually tied to a specific IP address in latter case.

List of software packages

CAD software enables engineers and architects to design, inspect and manage engineering projects within an integrated graphical user interface (GUI) on a personal computer system. Most applications support solid modeling with boundary representation (B-Rep) and NURBS geometry, and enable the same to be published in a variety of formats.

Based on market statistics, commercial software from Autodesk, Dassault Systems, Siemens PLM Software, and PTC dominate the CAD industry. The following is a list of major CAD applications, grouped by usage statistics.

Commercial software

- ABViewer

- AC3D

- Alibre Design

- ArchiCAD (Graphisoft)

- AutoCAD (Autodesk)

- AutoTURN

- AxSTREAM

- BricsCAD

- CATIA (Dassault Systèmes)

- Cobalt

- CorelCAD

- EAGLE

- Fusion 360 (Autodesk)

- IntelliCAD

- Inventor (Autodesk)

- IRONCAD

- KeyCreator (Kubotek)

- Landscape Express

- MEDUSA4

- MicroStation (Bentley Systems)

- Modelur (AgiliCity)

- Onshape (PTC)

- NX (Siemens Digital Industries Software)

- PTC Creo (successor to Pro/ENGINEER) (PTC)

- PunchCAD

- Remo 3D

- Revit (Autodesk)

- Rhinoceros 3D

- SketchUp

- Solid Edge (Siemens Digital Industries Software)

- SOLIDWORKS (Dassault Systèmes)

- SpaceClaim

- T-FLEX CAD

- TranslateCAD

- TurboCAD

- Vectorworks (Nemetschek)

Open-source software

Freeware

- BricsCAD Shape

- Tinkercad (successor to Autodesk 123D)

CAD kernels

- ACIS by (Spatial Corp owned by Dassault Systèmes)

- C3D Toolkit by C3D Labs

- Open CASCADE Open Source

- Parasolid by (Siemens Digital Industries Software)

- ShapeManager by (Autodesk)

See also

- 3D computer graphics – Graphics that use a three-dimensional representation of geometric data

- 3D printing – Additive process used to make a three-dimensional object

- Additive Manufacturing File Format – Open standard for describing objects for additive manufacturing processes such as 3D printingPages displaying short descriptions of redirect targets

- Algorithmic art – Art genre

- CAD standards – Guidelines for the appearance of computer-aided design drawings

- CAD library - cloud based repository of 3D models or parts

- Coarse space (numerical analysis) – reduced representation of a numerical problemPages displaying wikidata descriptions as a fallback

- Comparison of 3D computer graphics software

- Comparison of CAD, CAM, and CAE file viewers

- Comparison of computer-aided design software

- Comparison of EDA software (electronic design automation)

- Computer-aided industrial design – Subset of computer-aided design

- Digital architecture – Architecture using digital technology

- Digital twin – Digital replica of a living or non-living physical entity

- Electronic design automation – Software for designing electronic systems

- Engineering optimization – Techniques for optimization

- Finite element method – Numerical method for solving physical or engineering problems

- Free-form select – Printmaking and design technique

- ISO 128 – International standard about the graphical representation of objects on technical drawings

- ISO 10303 – ISO standard (STEP)

- List of computer-aided engineering software

- Model-based definition – Annotating computer-aided design models

- Molecular design software – CAD software for molecular-level engineering, modelling, and analysisPages displaying wikidata descriptions as a fallback

- Open-source hardware – Hardware from the open-design movement

- Rapid prototyping – Group of techniques to quickly construct physical objects

- Responsive computer-aided design – Approach to computer-aided design

- Space mapping – Design optimization methodology

- Surrogate model – Engineering model

- System integration – Bringing together component sub-systems into one system

- Virtual prototyping – Computer-simulated prototype development

- Virtual reality – Computer-simulated experience

References

- ^ Narayan, K. Lalit (2008). Computer Aided Design and Manufacturing. New Delhi: Prentice Hall of India. ISBN 978-8120333420.

- Duggal, Vijay (2000). Cadd Primer: A General Guide to Computer Aided Design and Drafting-Cadd, CAD. Mailmax Pub. ISBN 978-0962916595.

- Madsen, David A. (2012). Engineering Drawing & Design. Clifton Park, New York: Delmar. p. 10. ISBN 978-1111309572.

- Farin, Gerald; Hoschek, Josef; Kim, Myung-Soo (2002). Handbook of computer aided geometric design [electronic resource]. Elsevier. ISBN 978-0-444-51104-1.

- ^ Schoonmaker, Stephen J. (2003). The CAD guidebook : a basic manual for understanding and improving computer-aided design. New York: Marcel Dekker. ISBN 0-8247-0871-7. OCLC 50868192.

- Pottmann, H.; Brell-Cokcan, S. and Wallner, J. (2007) "Discrete surfaces for architectural design" Archived 2009-08-12 at the Wayback Machine, pp. 213–234 in Curve and Surface Design, Patrick Chenin, Tom Lyche and Larry L. Schumaker (eds.), Nashboro Press, ISBN 978-0-9728482-7-5.

- Farin, Gerald (2002) Curves and Surfaces for CAGD: A Practical Guide, Morgan-Kaufmann, ISBN 1-55860-737-4.

- "Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)". Inc.com. Retrieved 2020-04-30.

- "3D Feature-based, Parametric Solid Modeling". EngineersHandbook.com. Archived from the original on 2012-11-18. Retrieved 2012-03-01.

- Stroud, Ian; Nagy, Hildegarde (2011). Solid modelling and CAD systems: how to survive a CAD system. London New York: Springer. ISBN 978-0-85729-259-9.

- "What is a CAD Workstation? Definition, Uses and More". Computer Tech Reviews. 2019-11-21. Retrieved 2020-04-30.

- Jennifer Herron (2010). "3D Model-Based Design: Setting the Definitions Straight". MCADCafe.

- The Big 6 in CAD/CAE/PLM software industry (2011), CAEWatch, September 12, 2011

- van Kooten, Michel (2011-08-23). "GLOBAL SOFTWARE TOP 100 – EDITION 2011". Software Top 100.

- List of mechanical CAD softwares Archived 2020-07-28 at the Wayback Machine, BeyondMech

External links

- MIT 1982 CAD lab

Learning materials related to Computer-aided design at Wikiversity

Learning materials related to Computer-aided design at Wikiversity Learning materials related to Computer-aided Geometric Design at Wikiversity

Learning materials related to Computer-aided Geometric Design at Wikiversity

| Building information modeling (BIM) | |||||

|---|---|---|---|---|---|

| Software |

| ||||

| Companies | |||||

| Related topics | |||||

| Italics = discontinued • ° = Open-source software | |||||

| Design | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| |||||||||||||||||

| |||||||||||||||||

| |||||||||||||||||

| |||||||||||||||||