| Revision as of 09:52, 19 January 2006 editGuiding light (talk | contribs)Extended confirmed users5,905 edits acid extraction← Previous edit | Latest revision as of 00:04, 29 October 2024 edit undo98.43.223.22 (talk) →Background: put two sentences from "History" section at the end of this "Background" section. If more cited statements can be made of it's history, feel free to put section back. | ||

| (264 intermediate revisions by more than 100 users not shown) | |||

| Line 1: | Line 1: | ||

| {{short description|Photolithography technique where there is a layer of water between a lens and a microchip}} | |||

| ==Introduction== | |||

| ] on top of the ]]] | |||

| In ], '''immersion lithography''' is a resolution enhancement technique that interposes a liquid medium between the optics and the wafer surface, replacing the usual air gap. This liquid has a ] greater than one. With the 193 ] wavelength, the typical liquid used is ultra-pure, degassed water. Immersion lithography increases the effective depth-of-focus for a given ] and permits the use of optics with numerical apertures above 1.0, thus raising the maximum resolution potential of extant wavelength technologies. The depth of focus for an immersion tool is given by: DOF = (immersion index)*wavelength/(N.A.)^2, where N.A. is the numerical aperture. For a deep ultraviolet (DUV) wavelength of 193 nm, an immersion index of 1.44 for water, and a N.A. of 1.2, the depth of focus is 193 nm. By comparison, for an extreme ultraviolet (EUV) wavelength of 13.5 nm, an immersion index of 1 (i.e., vacuum), and an N.A. of 0.3, the depth of focus is 150 nm. Both systems are capable of imaging 100 nm features, but the 193 nm immersion system has the better depth of focus by virtue of longer wavelength and higher immersion index in this case. | |||

| '''Immersion lithography''' is a technique used in ] to enhance the resolution and accuracy of the ]. It involves using a liquid medium, typically water, between the lens and the ] during exposure. By using a liquid with a higher ] than air, immersion lithography allows for smaller features to be created on the wafer.<ref>{{Cite journal |last=Flagello |first=Donis |date=2004-01-01 |title=Benefits and limitations of immersion lithography |url=http://nanolithography.spiedigitallibrary.org/article.aspx?doi=10.1117/1.1636768 |journal=Journal of Micro/Nanolithography, MEMS, and MOEMS |language=en |volume=3 |issue=1 |pages=104 |doi=10.1117/1.1636768 |bibcode=2004JMM&M...3..104M |issn=1932-5150}}</ref> | |||

| Using an immersion fluid also confers the advantage of reducing reflections by virtue of reducing refractive index differences. | |||

| Immersion lithography replaces the usual air gap between the final lens and the wafer surface with a liquid medium that has a refractive index greater than one. The ] is increased by a factor equal to the refractive index of the liquid. Current immersion lithography tools use highly purified water for this liquid, achieving feature sizes below 45 nanometers.<ref>{{Cite web |url=http://www.dailytech.com/IDF09+Intel+Demonstrates+First+22nm+Chips+Discusses+Die+Shrink+Roadmap/article16312.htm |title=DailyTech - IDF09 Intel Demonstrates First 22nm Chips Discusses Die Shrink Roadmap |access-date=2009-12-07 |archive-url=https://web.archive.org/web/20100828220949/http://www.dailytech.com/IDF09+Intel+Demonstrates+First+22nm+Chips+Discusses+Die+Shrink+Roadmap/article16312.htm |archive-date=2010-08-28 |url-status=dead }}</ref> | |||

| ==Implementation== | |||

| As of 2005, it is expected that immersion lithography at the 193 nm wavelength will be used in 2009 to print 45 nm lines and spaces . Following its aggressive introduction, it is speculated that enhancements will be used to prolong the use of the technology to smaller features. Such enhancements include the use of higher ] materials in the final lens, immersion fluid, and ]. Each of these materials puts a limit on the largest angle that the light makes with the ] normal to the image plane. For example, by using LaF3 with a refractive index n=1.67 as the final lens material, along with a recently demonstrated immersion fluid with refractive index n=1.64, or doped water, a numerical aperture of 1.5 can be reached. This is the minimum value needed for 32 nm line-space resolution. | |||

| == |

==Background== | ||

| The ability to resolve features in ] is directly related to the ] of the imaging equipment, the numerical aperture being the sine of the maximum refraction angle multiplied by the ] of the medium through which the light travels. The lenses in the highest resolution "dry" photolithography scanners focus light in a cone whose boundary is nearly parallel to the wafer surface. As it is impossible to increase resolution by further refraction, additional resolution is obtained by inserting an immersion medium with a higher index of refraction between the lens and the wafer. The blurriness is reduced by a factor equal to the refractive index of the medium. For example, for water immersion using ] at 193 nm wavelength, the index of refraction is 1.44.<ref>{{Cite book |last1=Smith |first1=Bruce W. |last2=Kang |first2=Hoyoung |last3=Bourov |first3=Anatoly |last4=Cropanese |first4=Frank |last5=Fan |first5=Yongfa |title=Optical Microlithography XVI |chapter=Water immersion optical lithography for 45-nm node |editor-first1=Anthony |editor-last1=Yen |date=2003-06-26 |chapter-url=https://www.spiedigitallibrary.org/conference-proceedings-of-spie/5040/0000/Water-immersion-optical-lithography-for-the-45-nm-node/10.1117/12.485489.full |publisher=SPIE |volume=5040 |pages=679–689 |doi=10.1117/12.485489|bibcode=2003SPIE.5040..679S }}</ref> | |||

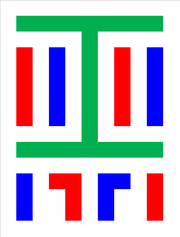

| As numerical apertures increase, the degree of ] of the light becomes critical to the image quality. This is because the interference of light inside the photoresist becomes polarization-dependent. Specifically, the imaging of straight lines near the resolution limit is best done with light polarized parallel to the lines. This requires special illumination preparation which is available on the most advanced lithography systems. Imaging of holes or islands is more problematic unless the holes or islands are closely spaced near the resolution limit in one direction and widely spaced in the orthogonal direction; otherwise, polarization effects will be a hindrance rather than a benefit. The highest hole or island density is achieved by effectively superimposing two orthogonal line-space images. Preferably, these images will be polarized parallel to the lines. Due to these imaging constraints, ] layouts utilizing dimensions near the resolution limit will be required to be 'lithography-friendly'. | |||

| The resolution enhancement from immersion lithography is about 30–40% depending on materials used. However,{{clarify|date=November 2020|reason="However" implies a contrast, but both sentences describe advantages.}} the depth of focus, or tolerance in wafer topography flatness, is improved compared to the corresponding "dry" tool at the same resolution.<ref>B. J. Lin, J. Microlith Microfab. Microsyst. 1, 7 (2002).</ref> | |||

| ==Photomask Impact== | |||

| For immersion lithography, as the minimum resolvable half-pitch linewidth decreases, features on the ] will eventually approach subwavelength sizes. Subwavelength features no longer obey the laws of classical imaging optics but need to be rigorously analyzed using ] (see for example, ). One way to delay this outcome would be to increase the magnification of the photomask image relative to the wafer image. | |||

| The idea for immersion lithography was patented in 1984 by Takanashi et al.<ref>A. Takanashi, T. Harada, M. Akeyama, Y. Kondo, T. Karosaki, S. Kuniyoshi, S. Hosaka, and Y. Kawamura, U. S. Patent No. 4,480,910 (1984)</ref> It was also proposed by Taiwanese engineer ] and realized in the 1980s.<ref>] (1987). "The future of subhalf-micrometer optical lithography". ''Microelectronic Engineering'' '''6''', 31–51</ref> In 2004, ]'s director of ] technology, ], announced that IBM planned to commercialize lithography based on light filtered through water.<ref name="businessweek">{{Cite web |url=http://www.businessweek.com/technology/content/jan2004/tc20040121_4923_tc139.htm |title=A Whole New World of Chips |website=] |url-status=dead |archive-url=https://web.archive.org/web/20110221072557/http://www.businessweek.com/technology/content/jan2004/tc20040121_4923_tc139.htm |archive-date=2011-02-21 }}</ref> | |||

| ==Resolution Extension at 193 nm== | |||

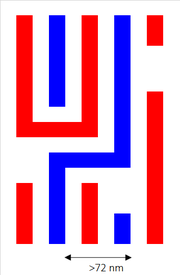

| The upper limit of the numerical aperture should asymptotatically approach the refractive index of the photoresist. At this theoretical point, there would be light traveling parallel to the photoresist surface on the wafer. For a wavelength of 193 nm and a refractive index of 1.7, this would correspond to 28 nm lines and spaces. The practical upper limit for undoped water at 193 nm is around 1.3. The practical upper limit for current lens materials is around 1.4. Once the maximum numerical aperture is reached, the only way immersion lithography can print denser features at the same wavelength would be to split a dense layer into two looser layers . | |||

| ==Defects== | |||

| ==Immersion at Shorter Wavelengths== | |||

| Defect concerns, e.g., water left behind (watermarks) and loss of resist-water adhesion (air gap or bubbles), have led to considerations of using a topcoat layer directly on top of the ].<ref>Y. Wei and R. L. Brainard, Advanced Processes for 193-nm Immersion Lithography, (c) SPIE 2009, Ch.6.</ref> This topcoat would serve as a barrier for chemical diffusion between the liquid medium and the photoresist. In addition, the interface between the liquid and the topcoat would be optimized for watermark reduction. At the same time, defects from topcoat use should be avoided. | |||

| The other choice is to use shorter wavelengths, e.g., 157 nm. However, it would be necessary to consider the mechanisms by which these wavelengths interact with the materials used in photolithography. Absorption is greatly enhanced, and the ] is exceeded. The success of 157 nm immersion, for example, would depend on the use of materials with minimal absorption. Water itself is not transparent enough to serve as an immersion fluid for this wavelength. It also is important to make sure that when the wavelength is divided by the refractive index, it gives a sufficiently smaller value than 118 nm, which is the 193 nm wavelength divided by the refractive index of the next-generation immersion fluid at that wavelength (n=1.64). This is the measure of the degree of resolution enhancement. | |||

| As of 2005, Topcoats had been tuned for use as ] coatings, especially for hyper-NA (NA>1) cases.<ref>J. C. Jung et al., Proc. SPIE 5753 (2005).</ref> | |||

| ==Remaining Technical Concerns== | |||

| Other considerations which are important to immersion lithography systems are the elimination of bubbles in the immersion fluid, temperature and pressure variations in the immersion fluid, and immersion fluid absorption by the photoresist. Degassing the fluid, carefully constraining the fluid ] and carefully treating the top layer of photoresist are key to the implementation of immersion lithography. Defects intrinsic to immersion lithography have been identified. Reducing particle generation due to the water dispensing unit should help reduce the incidence of defects. Water also has been shown to extract acid from photoresist. | |||

| By 2008, defect counts on wafers printed by immersion lithography had reached zero level capability.<ref></ref> | |||

| ==Polarization impacts== | |||

| As of 2000, ] effects due to high angles of interference in the photoresist were considered as features approach 40 nm.<ref>C. Wagner ''et al.'', Proc. SPIE vol. 4000, pp. 344-357 (2000).</ref> Hence, illumination sources generally need to be azimuthally polarized to match the pole illumination for ideal ] imaging.<ref>B. W. Smith, L. V. Zavyalova, and A. Estroff, Proc. SPIE 5377 (2004).</ref> | |||

| ==Throughput== | |||

| ] | |||

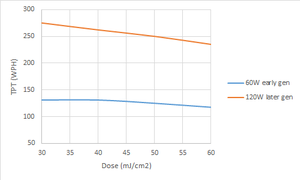

| As of 1996, this was achieved through higher stage speeds,<ref name=stepscan>{{Cite web |url=https://staticwww.asml.com/doclib/productandservices/94081.pdf |title=M. A. van den Brink et al., Proc. SPIE 2726, 734 (1996). |access-date=2018-07-16 |archive-date=2017-08-09 |archive-url=https://web.archive.org/web/20170809032333/http://staticwww.asml.com/doclib/productandservices/94081.pdf |url-status=dead }}</ref><ref>I. Bouchoms et al., Proc. SPIE 8326, 83260L (2012)</ref> which in turn, as of 2013 were allowed by higher power ] pulse sources.<ref>{{Cite web |last=Inc |first=Rostislav Rokitski, R. Rafac, R. Dubi, J. Thornes, J. melchior, T. Cacouris, M. Haviland and D. Brown, Cymer |date=2013 |title=120-W ArFi Laser Makes Higher-Dose Lithography Possible |url=https://www.photonics.com/Articles/120-W_ArFi_Laser_Makes_Higher-Dose_Lithography/a53765 |access-date=2022-11-09 |website=www.photonics.com}}</ref> Specifically, the throughput is directly proportional to stage speed V, which is related to dose D and rectangular slit width S and slit intensity I<sub>ss</sub> (which is directly related to pulse power) by V=I<sub>ss</sub>*S/D. The slit height is the same as the field height. The slit width S, in turn, is limited by the number of pulses to make the dose (n), divided by the frequency of the laser pulses (f), at the maximum scan speed V<sub>max</sub> by S=V<sub>max</sub>*n/f.<ref name=stepscan/> At a fixed frequency f and pulse number n, the slit width will be proportional to the maximum stage speed. Hence, throughput at a given dose is improved by increasing maximum stage speed as well as increasing pulse power. | |||

| According to ASML s product information about twinscan-nxt1980di, immersion lithography tools currently{{when|date=November 2022}} boasted the highest throughputs (275 WPH) as targeted for high volume manufacturing.<ref>{{Cite web |date=nd |title=The ASML NXT:1980Di lithography system |url=https://www.asml.com/en/products/duv-lithography-systems/twinscan-nxt1980di |access-date=2022-11-09 |website=www.asml.com |language=en}}</ref> | |||

| ==Multiple patterning== | |||

| ] | |||

| ] | |||

| {{unreferenced section|date=November 2022}} | |||

| The resolution limit for a 1.35 NA immersion tool operating at 193 nm wavelength is 36 nm. Going beyond this limit to sub-] nodes requires ].<ref>Haley, G. (2023). 193i Lithography Takes Center Stage...Again. Semiconductor Engineering. Retrieved from <nowiki>https://semiengineering.com/193i-lithography-takes-center-stage-again</nowiki></ref> At the 20nm foundry and memory nodes and beyond, double patterning and triple patterning are already being used{{when|date=November 2022}} with immersion lithography for the densest layers. | |||

| ==See also== | |||

| *] | |||

| *] | |||

| ==Impact on Lithography Industry== | |||

| In addition to the technical concerns, there are also significant business concerns. Immersion lithography tools are naturally expected to cost more than dry lithography tools. However, it is not unexpected that lithography tool costs will go up with time. As soon as the current technology approaches limits, the demand for and the cost of finding, developing, and continually improving an alternative that fits the infrastructure will increase further. A simpler tool that disrupts the infrastructure, such as one based on ], can still incur costs due to change of infrastructure. Simply tightening the quality specs in increments also drives up costs. Hence, a series of tools based on ] will only continue the same trend that DUV tools have followed, by virtue of tighter overlay requirements and contamination control. | |||

| As of , orders have been placed for 193 nm immersion tools, yet the question remains: how long will this technology be used? How far will numerical aperture increase? Will mask-to-wafer image demagnification need to increase as well, and if so, how much? A significant increase in demagnification also leads to a significant reduction in field size, and hence throughput. The willingness of chipmakers to continue to invest in this technology will depend on their willingness to deal with these changes as well as preserve the current 193 nm-based lithography infrastructure. | |||

| ==References== | ==References== | ||

| {{reflist|30em}} | |||

| {{DEFAULTSORT:Immersion Lithography}} | |||

| # M. LaPedus, "Litho race," EE Times, October 21, 2005. | |||

| ] | |||

| # D. Ristau et. al., Appl. Opt. 41, pp. 3196-3204 (2002). | |||

| ] | |||

| # A. Hand, "High-Index Fluids Look to 2nd-Generation Immersion," Semiconductor International, April 1, 2005. | |||

| # B. W. Smith et. al., Proc. SPIE 5377, pp. 273-284 (2004). | |||

| # C-W. Chang et. al., Laser Physics Letters 2, pp. 351-355 (2005). | |||

| # A. Grenville, "Prospects for Immersion Lithography at the 45nm Half-Pitch and Beyond," Future Fab International, Issue 20, pp. 76-79 (2006). | |||

| # G. Vandenberghe, "How Optical Lithography Prints a 32 nm Node 6T-SRAM Cell," Semiconductor International, June 1, 2005. | |||

| # M. Switkes et. al., J. Vac. Sci. & Tech. B 21, pp. 2794-2799 (2003). | |||

| # U. Okoroanyanwu et. al., "Defectivity in water immersion lithography," Microlithography World, Nov. 2005. | |||

| # J. C. Taylor et. al., SPIE 5376, pp. 34-43 (2004). | |||

| ] | |||

| {{tech-stub}} | |||

Latest revision as of 00:04, 29 October 2024

Photolithography technique where there is a layer of water between a lens and a microchip

Immersion lithography is a technique used in semiconductor manufacturing to enhance the resolution and accuracy of the lithographic process. It involves using a liquid medium, typically water, between the lens and the wafer during exposure. By using a liquid with a higher refractive index than air, immersion lithography allows for smaller features to be created on the wafer.

Immersion lithography replaces the usual air gap between the final lens and the wafer surface with a liquid medium that has a refractive index greater than one. The angular resolution is increased by a factor equal to the refractive index of the liquid. Current immersion lithography tools use highly purified water for this liquid, achieving feature sizes below 45 nanometers.

Background

The ability to resolve features in optical lithography is directly related to the numerical aperture of the imaging equipment, the numerical aperture being the sine of the maximum refraction angle multiplied by the refractive index of the medium through which the light travels. The lenses in the highest resolution "dry" photolithography scanners focus light in a cone whose boundary is nearly parallel to the wafer surface. As it is impossible to increase resolution by further refraction, additional resolution is obtained by inserting an immersion medium with a higher index of refraction between the lens and the wafer. The blurriness is reduced by a factor equal to the refractive index of the medium. For example, for water immersion using ultraviolet light at 193 nm wavelength, the index of refraction is 1.44.

The resolution enhancement from immersion lithography is about 30–40% depending on materials used. However, the depth of focus, or tolerance in wafer topography flatness, is improved compared to the corresponding "dry" tool at the same resolution.

The idea for immersion lithography was patented in 1984 by Takanashi et al. It was also proposed by Taiwanese engineer Burn J. Lin and realized in the 1980s. In 2004, IBM's director of silicon technology, Ghavam Shahidi, announced that IBM planned to commercialize lithography based on light filtered through water.

Defects

Defect concerns, e.g., water left behind (watermarks) and loss of resist-water adhesion (air gap or bubbles), have led to considerations of using a topcoat layer directly on top of the photoresist. This topcoat would serve as a barrier for chemical diffusion between the liquid medium and the photoresist. In addition, the interface between the liquid and the topcoat would be optimized for watermark reduction. At the same time, defects from topcoat use should be avoided.

As of 2005, Topcoats had been tuned for use as antireflection coatings, especially for hyper-NA (NA>1) cases.

By 2008, defect counts on wafers printed by immersion lithography had reached zero level capability.

Polarization impacts

As of 2000, Polarization effects due to high angles of interference in the photoresist were considered as features approach 40 nm. Hence, illumination sources generally need to be azimuthally polarized to match the pole illumination for ideal line-space imaging.

Throughput

As of 1996, this was achieved through higher stage speeds, which in turn, as of 2013 were allowed by higher power ArF laser pulse sources. Specifically, the throughput is directly proportional to stage speed V, which is related to dose D and rectangular slit width S and slit intensity Iss (which is directly related to pulse power) by V=Iss*S/D. The slit height is the same as the field height. The slit width S, in turn, is limited by the number of pulses to make the dose (n), divided by the frequency of the laser pulses (f), at the maximum scan speed Vmax by S=Vmax*n/f. At a fixed frequency f and pulse number n, the slit width will be proportional to the maximum stage speed. Hence, throughput at a given dose is improved by increasing maximum stage speed as well as increasing pulse power.

According to ASML s product information about twinscan-nxt1980di, immersion lithography tools currently boasted the highest throughputs (275 WPH) as targeted for high volume manufacturing.

Multiple patterning

| This section does not cite any sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed. (November 2022) (Learn how and when to remove this message) |

The resolution limit for a 1.35 NA immersion tool operating at 193 nm wavelength is 36 nm. Going beyond this limit to sub-20nm nodes requires multiple patterning. At the 20nm foundry and memory nodes and beyond, double patterning and triple patterning are already being used with immersion lithography for the densest layers.

See also

References

- Flagello, Donis (2004-01-01). "Benefits and limitations of immersion lithography". Journal of Micro/Nanolithography, MEMS, and MOEMS. 3 (1): 104. Bibcode:2004JMM&M...3..104M. doi:10.1117/1.1636768. ISSN 1932-5150.

- "DailyTech - IDF09 Intel Demonstrates First 22nm Chips Discusses Die Shrink Roadmap". Archived from the original on 2010-08-28. Retrieved 2009-12-07.

- Smith, Bruce W.; Kang, Hoyoung; Bourov, Anatoly; Cropanese, Frank; Fan, Yongfa (2003-06-26). "Water immersion optical lithography for 45-nm node". In Yen, Anthony (ed.). Optical Microlithography XVI. Vol. 5040. SPIE. pp. 679–689. Bibcode:2003SPIE.5040..679S. doi:10.1117/12.485489.

- B. J. Lin, J. Microlith Microfab. Microsyst. 1, 7 (2002).

- A. Takanashi, T. Harada, M. Akeyama, Y. Kondo, T. Karosaki, S. Kuniyoshi, S. Hosaka, and Y. Kawamura, U. S. Patent No. 4,480,910 (1984)

- Burn J. Lin (1987). "The future of subhalf-micrometer optical lithography". Microelectronic Engineering 6, 31–51

- "A Whole New World of Chips". Business Week. Archived from the original on 2011-02-21.

- Y. Wei and R. L. Brainard, Advanced Processes for 193-nm Immersion Lithography, (c) SPIE 2009, Ch.6.

- J. C. Jung et al., Proc. SPIE 5753 (2005).

- B. Rathsack et al., Proc. SPIE 6924, 69244W (2008).

- C. Wagner et al., Proc. SPIE vol. 4000, pp. 344-357 (2000).

- B. W. Smith, L. V. Zavyalova, and A. Estroff, Proc. SPIE 5377 (2004).

- ^ "M. A. van den Brink et al., Proc. SPIE 2726, 734 (1996)" (PDF). Archived from the original (PDF) on 2017-08-09. Retrieved 2018-07-16.

- I. Bouchoms et al., Proc. SPIE 8326, 83260L (2012)

- Inc, Rostislav Rokitski, R. Rafac, R. Dubi, J. Thornes, J. melchior, T. Cacouris, M. Haviland and D. Brown, Cymer (2013). "120-W ArFi Laser Makes Higher-Dose Lithography Possible". www.photonics.com. Retrieved 2022-11-09.

{{cite web}}:|last=has generic name (help)CS1 maint: multiple names: authors list (link) - "The ASML NXT:1980Di lithography system". www.asml.com. nd. Retrieved 2022-11-09.

- Haley, G. (2023). 193i Lithography Takes Center Stage...Again. Semiconductor Engineering. Retrieved from https://semiengineering.com/193i-lithography-takes-center-stage-again