| Revision as of 14:39, 10 December 2010 editCheMoBot (talk | contribs)Bots141,565 edits Updating {{chembox}} (no changed fields - added verified revid - updated 'UNII_Ref', 'StdInChI_Ref', 'StdInChIKey_Ref') per Chem/Drugbox validation (report [[Wikipedia_talk:WikiProject_Chemicals|← Previous edit | Latest revision as of 11:26, 14 December 2024 edit undoHeadbomb (talk | contribs)Edit filter managers, Autopatrolled, Extended confirmed users, Page movers, File movers, New page reviewers, Pending changes reviewers, Rollbackers, Template editors454,186 edits →Challenges: ce | ||

| (235 intermediate revisions by more than 100 users not shown) | |||

| Line 1: | Line 1: | ||

| {{chembox | {{chembox | ||

| |Verifiedfields = changed | |||

| | verifiedrevid = 401620402 | |||

| |Watchedfields = changed | |||

| | Name = Terephthalic acid | |||

| |verifiedrevid = 444216370 | |||

| | ImageFile = Terephthalic-acid-2D-skeletal.svg | |||

| |Name = Terephthalic acid | |||

| | ImageSize = 220 | |||

| |ImageFile = Terephthalic-acid-2D-skeletal.svg | |||

| | ImageName = Skeletal formula | |||

| |ImageSize = 220 | |||

| | ImageFile2 = Terephthalic-acid-3D-balls-B.png | |||

| |ImageName = Skeletal formula | |||

| | ImageSize2 = 220 | |||

| |ImageFile2 = Terephthalic acid 3D ball.png | |||

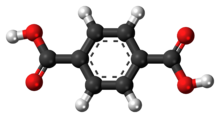

| | ImageName2 = Ball-and-stick model | |||

| |ImageSize2 = 220 | |||

| | OtherNames = Benzene-1,4-dicarboxylic acid<br />''para''-Phthalic acid<br />TPA<br />PTA | |||

| |ImageName2 = Ball-and-stick model of the terephthalic acid molecule | |||

| | Section1 = {{Chembox Identifiers | |||

| |PIN = Benzene-1,4-dicarboxylic acid <!-- Nomenclature of Organic Chemistry – IUPAC Recommendations and Preferred Names 2013 (Blue Book) --> | |||

| | SMILES = c1cc(ccc1C(=O)O)C(=O)O | |||

| |OtherNames = Terephthalic acid<br />''para''-Phthalic acid<br />TPA<br />PTA<br /> BDC | |||

| | ChemSpiderID_Ref = {{chemspidercite|correct|chemspider}} | |||

| |Section1={{Chembox Identifiers | |||

| | ChemSpiderID = 7208 | |||

| |ChEBI_Ref = {{ebicite|correct|EBI}} | |||

| | InChI = 1/C8H6O4/c9-7(10)5-1-2-6(4-3-5)8(11)12/h1-4H,(H,9,10)(H,11,12) | |||

| |ChEBI = 15702 | |||

| | InChIKey = KKEYFWRCBNTPAC-UHFFFAOYAF | |||

| |SMILES = O=C(O)c1ccc(C(O)=O)cc1 | |||

| | StdInChI_Ref = {{stdinchicite|correct|chemspider}} | |||

| |ChemSpiderID_Ref = {{chemspidercite|correct|chemspider}} | |||

| | StdInChI = 1S/C8H6O4/c9-7(10)5-1-2-6(4-3-5)8(11)12/h1-4H,(H,9,10)(H,11,12) | |||

| |ChemSpiderID = 7208 | |||

| | StdInChIKey_Ref = {{stdinchicite|correct|chemspider}} | |||

| |InChI = 1/C8H6O4/c9-7(10)5-1-2-6(4-3-5)8(11)12/h1-4H,(H,9,10)(H,11,12) | |||

| | StdInChIKey = KKEYFWRCBNTPAC-UHFFFAOYSA-N | |||

| |InChIKey = KKEYFWRCBNTPAC-UHFFFAOYAF | |||

| | CASNo_Ref = {{cascite|correct|CAS}} | |||

| |StdInChI_Ref = {{stdinchicite|correct|chemspider}} | |||

| | CASNo = 100-21-0 | |||

| |StdInChI = 1S/C8H6O4/c9-7(10)5-1-2-6(4-3-5)8(11)12/h1-4H,(H,9,10)(H,11,12) | |||

| | RTECS = WZ0875000 | |||

| |StdInChIKey_Ref = {{stdinchicite|correct|chemspider}} | |||

| }} | |||

| |StdInChIKey = KKEYFWRCBNTPAC-UHFFFAOYSA-N | |||

| | Section2 = {{Chembox Properties | |||

| |CASNo_Ref = {{cascite|correct|CAS}} | |||

| | Formula = C<sub>8</sub>H<sub>6</sub>O<sub>4</sub> | |||

| |CASNo = 100-21-0 | |||

| | MolarMass = 166.13 g/mol | |||

| |UNII_Ref = {{fdacite|changed|FDA}} | |||

| | Appearance = white crystals or powder | |||

| |UNII = 6S7NKZ40BQ | |||

| | Density = 1.522 g/cm³ | |||

| |RTECS = WZ0875000 | |||

| | Solubility = 0.0017 g/100 mL at 25°C | |||

| |PubChem = 7489 | |||

| | SolubleOther =polar organic solvents aqueous base | |||

| |EC_number = 202-830-0 | |||

| | MeltingPt = 300°C in a sealed tube | |||

| |ChEMBL = 1374420 | |||

| | Melting_notes = sublimes at 402°C (675 K) in air | |||

| |KEGG = C06337 | |||

| | BoilingPt = sublimes | |||

| |3DMet = B00943 | |||

| | TriplePoint = 427° | |||

| |Beilstein = 1909333 | |||

| | pKa=3.51, 4.82<ref>Brown, H.C., et al., in Baude, E.A. and Nachod, F.C.,''Determination of Organic Structures by Physical Methods'', Academic Press, New York, 1955.</ref> | |||

| |Gmelin = 50561 | |||

| }} | |||

| }} | |||

| | Section3 = {{Chembox Structure | |||

| |Section2={{Chembox Properties | |||

| | CrystalStruct = | |||

| |C=8|H=6|O=4 | |||

| | Dipole = zero | |||

| |Appearance = White crystals or powder | |||

| }} | |||

| |Density = 1.519 g/cm<sup>3</sup><ref name=crc>Haynes, p. 3.492</ref> | |||

| | Section7 = {{Chembox Hazards | |||

| |Solubility = 0.065 g/L at 25 °C<ref>Haynes, p. 5.163</ref> | |||

| | ExternalMSDS = | |||

| |SolubleOther =polar organic solvents aqueous base | |||

| | EUClass = not listed | |||

| |MeltingPtC = 300 | |||

| | FlashPt = | |||

| |MeltingPt_notes = Sublimes<ref name=crc/> | |||

| }} | |||

| |BoilingPt =Decomposes | |||

| | Section8 = {{Chembox Related | |||

| |pKa=3.54, 4.34<ref>Haynes, p. 5.96</ref> | |||

| | Function = ]s | |||

| |MagSus = {{val|-83.5|e=-6|u=cm<sup>3</sup>/mol}}<ref>Haynes, p. 3.579</ref> | |||

| | OtherFunctn = ]<br /> ]<br /> ]<br /> ] | |||

| }} | |||

| | OtherCpds = ]<br /> ]<br /> ] | |||

| |Section3={{Chembox Structure | |||

| }} | |||

| |Dipole = 2.6D <ref>{{cite journal | title = Electronic and vibrational investigation and NMR–mass spectroscopic analysis of terephthalic acid using quantum Gaussian calculations | journal = ] | volume = 139 | pages = 229–242 | year = 2015 | doi = 10.1016/j.saa.2014.11.112|pmid= 25561302|bibcode= 2015AcSpA.139..229K| last1 = Karthikeyan | first1 = N. | last2 = Joseph Prince | first2 = J. | last3 = Ramalingam | first3 = S. | last4 = Periandy | first4 = S. }}</ref> | |||

| }} | |||

| |Section4={{Chembox Thermochemistry | |||

| |Thermochemistry_ref=<ref>Haynes, p. 5.37</ref> | |||

| |DeltaHf= −816.1 kJ/mol | |||

| }} | |||

| |Section5={{Chembox Hazards | |||

| |ExternalSDS = | |||

| |GHSPictograms = {{GHS07}} | |||

| |GHSSignalWord = Warning | |||

| |HPhrases = {{H-phrases|315|319|335}} | |||

| |PPhrases = {{P-phrases|261|264|271|280|302+352|304+340|305+351+338|312|321|332+313|337+313|362|403+233|405|501}} | |||

| | FlashPtC =260 | |||

| | FlashPt_ref =<ref name=crc2>Haynes, p. 16.29</ref> | |||

| | AutoignitionPtC =496 | |||

| | AutoignitionPt_ref=<ref name=crc2/> | |||

| | TLV-STEL = 10 mg/m<sup>3</sup><ref>Haynes, p. 16.42</ref> | |||

| | LD50 = >1 g/kg (oral, mouse)<ref name=Ullmann/> | |||

| }} | |||

| |Section6={{Chembox Related | |||

| |OtherFunction_label = ]s | |||

| |OtherFunction = ]<br /> ]<br /> ]<br /> ] | |||

| |OtherCompounds = ]<br /> ]<br /> ] | |||

| }} | |||

| }} | }} | ||

| '''Terephthalic acid''' is |

'''Terephthalic acid''' is an ] with ] C<sub>6</sub>H<sub>4</sub>(CO<sub>2</sub>H)<sub>2</sub>. This white solid is a ] ], used principally as a precursor to the ] ], used to make clothing and ]s. Several million tons are produced annually.<ref name=Ullmann/> The common name is derived from the ]-producing tree '']'' and ]. | ||

| Terephthalic acid is also used in the production of ].<ref>{{Cite web |title=Polybutylene Terephthalate (PBT) Material Guide & Properties Info |url=https://omnexus.specialchem.com/selection-guide/polybutylene-terephthalate-pbt-plastic |access-date=2023-11-24 |website=omnexus.specialchem.com |language=en|archive-url=https://web.archive.org/web/20231124155646/https://omnexus.specialchem.com/selection-guide/polybutylene-terephthalate-pbt-plastic|archive-date=2023-11-24}}</ref> | |||

| ==Properties== | |||

| Terephthalic acid is poorly soluble in water and alcohols, consequently up until around 1970 most crude terephthalic acid was converted to the dimethyl ] for purification. It sublimes when heated. | |||

| == |

==History== | ||

| Terephthalic acid was first isolated (from turpentine) by the French chemist Amédée Cailliot (1805–1884) in 1846.<ref>{{cite journal|first=Amédée|last=Cailliot|date=1847|url=https://babel.hathitrust.org/cgi/pt?id=hvd.hx3dxz;view=1up;seq=31|title=Études sur l'essence de térébenthine|trans-title=Studies of the essence of turpentine|journal=Annales de Chimie et de Physique |series=Série 3|volume=21|pages=27–40}} Terephthalic acid is named on p. 29: "Je désignerai le premier de ces acides, celui qui est insoluble, sous le nom d<nowiki>'</nowiki>''acide téréphtalique''." (I will designate the first of these acids, which is insoluble, by the name of ''terephthalic acid''.)</ref> Terephthalic acid became industrially important after ]. Terephthalic acid was produced by oxidation of ] with 30-40% ]. Air oxidation of ''p''-xylene gives ], which resists further air-oxidation. Esterification of ''p''-toluic acid to ] (CH<sub>3</sub>C<sub>6</sub>H<sub>4</sub>CO<sub>2</sub>CH<sub>3</sub>) opens the way for further oxidation to monomethyl terephthalate. In the Dynamit−Nobel process these two oxidations and the esterification were performed in a single reactor. The reaction conditions also lead to a second esterification, producing ], which could be hydrolysed to terepthalic acid. In 1955, Mid-Century Corporation and ICI announced the bromide-] oxidation of ''p''-toluic acid directly to terephthalic acid, without the need to isolate intermediates and still using air as the oxidant. Amoco (as Standard Oil of Indiana) purchased the Mid-Century/ICI technology, and the process is now known by their name.<ref name=CR/> | |||

| Terephthalic acid is produced by ] of ] by ] in ]: | |||

| :] | |||

| The oxidation is conducted using ] as ] and a ] composed of ] and ] salts, using a ] promoter. The yield is nearly quantitative. The most problematic impurity is 4-formylbenzoic acid, which is removed by ] of a hot aqueous solution. The solution is then cooled in a stepwise manner to ] highly pure terephthalic acid. | |||

| ==Synthesis== | |||

| Alternatively, but not commercially significant, is the so-called "Henkel process" or "Raecke process," named after the company and patent holder, respectively. This process involves the rearrangement of ] to terephthalic acid via the corresponding potassium ]s.<ref>{{cite journal | |||

| ===Amoco Process=== | |||

| | title = The Preparation of Terephthalic Acid from Phthalic or Benzoic Acid | |||

| In the Amoco process, which is widely adopted worldwide, terephthalic acid is produced by catalytic ] of ]:<ref name=CR>{{cite journal|title=p-Xylene Oxidation to Terephthalic Acid: A Literature Review Oriented toward Process Optimization and Development|journal=Chemical Reviews|year=2013|volume=113|issue=10|pages=7421–69|doi=10.1021/cr300298j|pmid=23767849|last1=Tomás |first1=Rogério A. F. |last2=Bordado |first2=João C. M. |last3=Gomes |first3=João F. P. }}</ref> | |||

| | author = Yoshiro Ogata, Masaru Tsuchida, Akihiko Muramoto | |||

| :] | |||

| | journal = ] | |||

| The process uses a ]–]–] ]. The bromide source can be ], ] or ]. Bromine functions as a regenerative source of ]s. ] is the solvent and ] serves as the oxidant. The combination of bromine and acetic acid is highly ], requiring specialized reactors, such as those lined with ]. A mixture of ], ], the ] system, and compressed air is fed to a reactor. | |||

| | volume = 79 | |||

| | issue = 22 | |||

| ====Mechanism==== | |||

| | pages = 6005–6008 | |||

| The oxidation of ''p''-xylene proceeds by a free radical process. Bromine radicals decompose cobalt and manganese hydroperoxides. The resulting oxygen-based radicals abstract hydrogen from a methyl group, which have weaker C–H bonds than does the aromatic ring. Many intermediates have been isolated. ''p''-xylene is converted to ], which is less reactive than the p-xylene owing to the influence of the ] ] group. Incomplete oxidation produces ] (4-CBA), which is often a problematic impurity.<ref name=CR/><ref>{{cite journal | title = Semicontinuous Studies on the Reaction Mechanism and Kinetics for the Liquid-Phase Oxidation of ''p''-Xylene to Terephthalic Acid | last1= Wang|first1=Qinbo|first2= Youwei |last2=Cheng |first3=Lijun |last3=Wang|first4= Xi |last4=Li | journal = ] | volume = 46 | issue = 26 | pages = 8980–8992 | year = 2007 | doi = 10.1021/ie0615584}}</ref> | |||

| | year = 1957 | |||

| <ref name="Xiao2010">{{cite journal | title = Aerobic Oxidation of ''p''-Toluic Acid to Terephthalic Acid over T(''p''-Cl)PPMnCl/Co(OAc)<sub>2</sub> Under Moderate Conditions | first1 = Y. | last1= Xiao |first2= W.-P.|last2= Luo|first3= X.-Y.|last3= Zhang |first4=C.-C.|last4= Guo|first5= Q.|last5= Liu|first6= G.-F.|last6= Jiang |first7=Q.-H.|last7= Li|display-authors=3 | journal = ] | volume = 134 | issue = 1–2 | pages = 155–161 | year = 2010 | doi = 10.1007/s10562-009-0227-1| s2cid = 95855968 }}</ref> | |||

| | url = | |||

| | doi = 10.1021/ja01579a043}} | |||

| :] | |||

| </ref><ref>{{cite journal | |||

| | title = Further Studies on the Preparation of Terephthalic Acid from Phthalic or Benzoic Acid | |||

| ====Challenges==== | |||

| | author = Yoshiro Ogata, Masaru Hojo, Masanobu Morikawa | |||

| Approximately 5% of the acetic acid solvent is lost by decomposition or "burning". Product loss by ] to ] is common. The high temperature diminishes oxygen solubility in an already oxygen-starved system. Pure oxygen cannot be used in the traditional system due to hazards of flammable organic–O<sub>2</sub> mixtures. Atmospheric air can be used in its place, but once reacted needs to be purified of ]s and ]s such as ] before being released. Additionally, the corrosive nature of bromides at high temperatures requires the reaction be run in expensive titanium reactors.<ref name="Zuo2008">{{cite journal | title = Liquid-Phase Oxidation of Toluene and ''p''-Toluic Acid under Mild Conditions: Synergistic Effects of Cobalt, Zirconium, Ketones, and Carbon Dioxide | last1= Zuo|first1= Xiaobin|first2= Bala |last2=Subramaniam |first3= Daryle H. |last3=Busch | journal = ] | volume = 47 | issue = 3 | pages = 546–552 | year = 2008 | doi = 10.1021/ie070896h}}</ref><ref name="Zuo2010">{{cite journal | title = Liquid Phase Oxidation of ''p''-Xylene to Terephthalic Acid at Medium-high Temperatures: Multiple Benefits of CO<sub>2</sub>-expanded Liquids | last1= Zuo|first1= Xiaobin|first2= Fenghui|last2= Niu|first3= Kirk|last3= Snavely|first4= Bala |last4=Subramaniam |first5=Daryle H.|last5= Busch|display-authors=3 | journal = ] | volume = 12 | issue = 2 | pages = 260–267 | year = 2010 | doi = 10.1039/B920262E| hdl= 1808/18532|hdl-access= free}}</ref> | |||

| | journal = ] | |||

| | volume = 25 | |||

| ====Alternative reaction media==== | |||

| | issue = 12 | |||

| The use of ] overcomes many of the problems with the original industrial process. Because CO<sub>2</sub> is a better flame inhibitor than ], a CO<sub>2</sub> environment allows for the use of pure oxygen directly, instead of air, with reduced flammability hazards. The solubility of molecular oxygen in solution is also enhanced in the CO<sub>2</sub> environment. Because more oxygen is available to the system, ] (''T''<sub>c</sub> = 31 °C) has more complete oxidation with fewer byproducts, lower ] production, less decarboxylation and higher purity than the commercial process.<ref name="Zuo2008"/><ref name="Zuo2010"/> | |||

| | pages = 2082–2087 | |||

| | year = 1960 | |||

| In ] medium, the oxidation can be effectively catalyzed by MnBr<sub>2</sub> with pure O<sub>2</sub> in a medium-high temperature. Use of supercritical water instead of acetic acid as a solvent diminishes environmental impact and offers a cost advantage. However, the scope of such reaction systems is limited by the even more demanding conditions than the industrial process (300–400 °C, >200 bar).<ref>{{cite journal | title = Selective Aerobic Oxidation of ''para''-Xylene in Sub- and Supercritical Water. Part 1. Comparison with Ortho-xylene and the Role of the Catalyst | last1= Pérez|first1= Eduardo|first2= Joan |last2=Fraga Dubreuil |first3=Eduardo |last3=García Verdugo |first4=Paul A.|last4= Hamley |first5=W. Barry |last5=Thomas|first6= Duncan |last6=Housley|first7= Wait |last7=Partenheimer|first8=Martyn|last8= Poliakoff|display-authors=3 |journal = ] | volume = 13 | issue = 12 | pages = 2389–2396 | year = 2011 | doi = 10.1039/C1GC15137A}}</ref> | |||

| | url = | |||

| | doi = 10.1021/jo01082a003}} | |||

| ===Promotors and additives=== | |||

| </ref> Terephthalic acid can be prepared in the laboratory by oxidizing various para-disubstituted derivatives of ] including ] or a mixture of ] and ] with ]. | |||

| As with any large-scale process, many additives have been investigated for potential beneficial effects. Promising results have been reported with the following.<ref name=CR/> | |||

| *Ketones act as promoters for formation of the active cobalt(III) catalyst. In particular, ketones with α-methylene groups oxidize to hydroperoxides that are known to oxidize cobalt(II). 2-] is often used. | |||

| *] salts enhance the activity of Co-Mn-Br catalysts. Selectivity is also improved.<ref name=CR/> | |||

| *] is a potential replacement for bromide, which is highly corrosive. The phthalimide functions by formation of the oxyl radical. | |||

| *Guanidine inhibits the oxidation of the first methyl but enhances the usually slow oxidation of the toluic acid. | |||

| ===Alternative routes=== | |||

| Terephthalic acid can also be made from ] by the ], which gives ]. Oxidation of the latter gives terephthalic acid.<ref>{{cite book |doi=10.1002/14356007.a03_463.pub2 |chapter=Benzaldehyde |title=Ullmann's Encyclopedia of Industrial Chemistry |date=2011 |last1=Brühne |first1=Friedrich |last2=Wright |first2=Elaine |isbn=978-3-527-30385-4 }}</ref> | |||

| Terephthalic acid can be prepared in the laboratory by oxidizing many ''para''-disubstituted derivatives of ], including ] or a mixture of ] and ] with ]. | |||

| Although not commercially significant, there is also the so-called "] process" or "Raecke process", named after the company and patent holder, respectively. This route involves the transfer of carboxylate groups. Either ] disproportionates to potassium terephthalate and ] or ] rearranges to the terephthalate.<ref>{{cite journal | title = The Preparation of Terephthalic Acid from Phthalic or Benzoic Acid |first1=Yoshiro|last1= Ogata |first2=Masaru |last2=Tsuchida |first3=Akihiko|last3= Muramoto | journal = ] | volume = 79 | issue = 22 | pages = 6005–6008 | year = 1957 | doi = 10.1021/ja01579a043}}</ref><ref>{{cite journal | title = Further Studies on the Preparation of Terephthalic Acid from Phthalic or Benzoic Acid |first1=Yoshiro|last1= Ogata |first2=Masaru |last2=Hojo |first3=Masanobu |last3=Morikawa | journal = ] | volume = 25 | issue = 12 | pages = 2082–2087 | year = 1960 | doi = 10.1021/jo01082a003}}</ref> ] can be used as a raw material and then potassium can be recycled.<ref>{{Cite journal |last=Terashi |first=Michio |last2=Hasegawa |first2=Toshio |last3=Kikuchi |first3=Shoji |last4=Kasahara |first4=Toshiji |date=1962 |title=The Synthesis of Terephthalic Acid from Phthalic Anhydride |url=https://www.jstage.jst.go.jp/article/yukigoseikyokaishi1943/20/1/20_1_40/_article |journal=Journal of Synthetic Organic Chemistry, Japan |volume=20 |issue=1 |pages=40–55 |doi=10.5059/yukigoseikyokaishi.20.40}}</ref> | |||

| Lummus (now a subsidiary of ]) has reported a route from the dinitrile, which can be obtained by ] of ''p''-xylene. | |||

| ==Applications== | ==Applications== | ||

| Virtually the entire world's supply of terephthalic acid and ] are consumed as precursors to ] (PET). |

Virtually the entire world's supply of terephthalic acid and ] are consumed as precursors to ] (PET). World production in 1970 was around 1.75 million tonnes.<ref name=Ullmann>{{Ullmann|first1=Richard J.|last1=Sheehan|title=Terephthalic Acid, Dimethyl Terephthalate, and Isophthalic Acid|doi=10.1002/14356007.a26_193|date=June 15, 2000}}</ref> By 2006, global purified terephthalic acid (PTA) demand had exceeded 30 million tonnes. A smaller, but nevertheless significant, demand for terephthalic acid exists in the production of ] and several other engineering ].<ref>{{cite book|title=Ashford's Dictionary of Industrial Chemicals|edition=3rd|date=2011|page=8805|isbn=978-0952267430|publisher=Wavelength|place=Saltash, UK}}</ref> | ||

| Article Online Posting Date: June 15, 2000.</ref> By 2006, global purified terephthalic acid (PTA) demand had exceeded 30 million tonnes. | |||

| ===Other uses=== | |||

| In the research laboratory, terephthalic acid has been popularized as a component for the synthesis of ]s. | |||

| *Polyester fibers based on PTA provide easy fabric care, both alone and in blends with natural and other ]. Polyester films are used widely in audio and video recording tapes, data storage tapes, photographic films, labels and other sheet material requiring both dimensional stability and toughness. | |||

| *Terephthalic acid is used in paint as a carrier. | |||

| *Terephthalic acid is used as a raw material to make terephthalate plasticizers such as ] and dibutyl terephthalate. | |||

| *It is used in the pharmaceutical industry as a raw material for certain drugs. | |||

| *In addition to these end uses, Terephthalic acid based ] and ] are also used in hot melt adhesives. | |||

| *PTA is an important raw material for lower ] saturated polyesters for powder and water-soluble ]. | |||

| *In the research laboratory, terephthalic acid has been popularized as a component for the synthesis of ]s. | |||

| *The ] drug ] occasionally comes as a terephthalate salt; however, the more usual salt of oxycodone is the ]. Pharmacologically, one milligram of ''hydrochloridum oxycodonae'' is equivalent to 1.13 mg of ''terephthalas oxycodonae''. | |||

| *Terephthalic acid is used as a filler in some military ]s, most notably the American M83 smoke grenade and M90 vehicle-employed smoke grenade, producing a thick white smoke that acts as an obscurant in the visual and ] spectrum when burned. | |||

| ==Solubility== | |||

| Terephthalic acid is poorly soluble in water and alcohols; consequently, until about 1970 terephthalic acid was purified as its dimethyl ]. It sublimes when heated. | |||

| {| | |||

| | | |||

| {| class="wikitable" | |||

| |+Solubility (g/100 g solvent) | |||

| |- | |||

| ! Solvent !! 25 °C !! 120 °C !! 160 °C !! 200 °C !! 240 °C | |||

| |- | |||

| | ] || 0.1 || — || 2.9 || 15 || — | |||

| |- | |||

| | ] || 0.0019 || 0.08 || 0.38 || 1.7 || 9.0 | |||

| |- | |||

| | ] || 0.035 || 0.3 || 0.75 ||1.8 || 4.5 | |||

| |- | |||

| | ] || 0.5 || — || — || — || — | |||

| |- | |||

| | ] || 2 || — || — || — || — | |||

| |- | |||

| | ] || 6.7 || — || — || — || — | |||

| |- | |||

| | ] || 20 || — || — || — || — | |||

| |} | |||

| | | |||

| :{| class="wikitable" | |||

| |+Vapor pressure | |||

| |- | |||

| ! Temperature<br>(°C) !! Pressure<br>(kPa) | |||

| |- | |||

| | 303 || 1.3 | |||

| |- | |||

| | 353 || 13.3 | |||

| |- | |||

| | 370 || 26.7 | |||

| |- | |||

| | 387 || 53.3 | |||

| |- | |||

| | 404 || 101.3 | |||

| |} | |||

| |} | |||

| ==Toxicity== | |||

| Terephthalic acid and its dimethyl ester have very low ], with {{LD50}} >1 g/kg (oral, mouse).<ref name=Ullmann/> | |||

| ==Biodegradation== | |||

| In '']'' strain E6,<ref>{{cite web |title=GTDB – Genome GCF_001010305.1 |url=https://gtdb.ecogenomic.org/genome?gid=GCF_001010305.1 |website=gtdb.ecogenomic.org}}</ref> terephthalic acid is biodegraded to ], a common natural product, via a reaction pathway initiated by ]. Combined with the previously known ] and ], a full pathway for ] degradation can be engineered.<ref>{{cite journal |last1=Kincannon |first1=William M. |last2=Zahn |first2=Michael |last3=Clare |first3=Rita |last4=Lusty Beech |first4=Jessica |last5=Romberg |first5=Ari |last6=Larson |first6=James |last7=Bothner |first7=Brian |last8=Beckham |first8=Gregg T. |last9=McGeehan |first9=John E. |last10=DuBois |first10=Jennifer L.|display-authors=3 |title=Biochemical and structural characterization of an aromatic ring–hydroxylating dioxygenase for terephthalic acid catabolism |journal=Proceedings of the National Academy of Sciences |date=29 March 2022 |volume=119 |issue=13 |pages=e2121426119 |doi=10.1073/pnas.2121426119|doi-access=free |pmid=35312352|pmc=9060491 |bibcode=2022PNAS..11921426K}}</ref> | |||

| ==See also== | |||

| *] a thermoplastic polyester formed from terephthalic acid | |||

| ==References== | ==References== | ||

| {{reflist|}} | |||

| <references/> | |||

| * ] | |||

| ==Cited sources== | |||

| *{{cite book |ref=Haynes| editor= Haynes, William M. | date = 2016| title = ] | edition = 97th | publisher = ] | isbn = 9781498754293}} | |||

| ==External links and further reading== | ==External links and further reading== | ||

| * |

*{{cite book|title=Basic Organic Chemistry: Part 5, Industrial Products|url=https://archive.org/details/trent_0116401244110|url-access=registration|editor1-first=J. M.|editor1-last=Tedder|editor2-first=A.|editor2-last=Nechvatal|editor3-first=A. H.|editor3-last=Tubb|publisher=John Wiley & Sons|location=Chichester, UK|date=1975|isbn=9780471850144}} | ||

| * | * | ||

| {{Authority control}} | |||

| ] | ] | ||

| ] | ] | ||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 11:26, 14 December 2024

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name Benzene-1,4-dicarboxylic acid | |

| Other names

Terephthalic acid para-Phthalic acid TPA PTA BDC | |

| Identifiers | |

| CAS Number | |

| 3D model (JSmol) | |

| Beilstein Reference | 1909333 |

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.002.573 |

| EC Number |

|

| Gmelin Reference | 50561 |

| KEGG | |

| PubChem CID | |

| RTECS number |

|

| UNII | |

| CompTox Dashboard (EPA) | |

InChI

| |

SMILES

| |

| Properties | |

| Chemical formula | C8H6O4 |

| Molar mass | 166.132 g·mol |

| Appearance | White crystals or powder |

| Density | 1.519 g/cm |

| Melting point | 300 °C (572 °F; 573 K) Sublimes |

| Boiling point | Decomposes |

| Solubility in water | 0.065 g/L at 25 °C |

| Solubility | polar organic solvents aqueous base |

| Acidity (pKa) | 3.54, 4.34 |

| Magnetic susceptibility (χ) | −83.5×10 cm/mol |

| Structure | |

| Dipole moment | 2.6D |

| Thermochemistry | |

| Std enthalpy of formation (ΔfH298) |

−816.1 kJ/mol |

| Hazards | |

| GHS labelling: | |

| Pictograms |

|

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | P261, P264, P271, P280, P302+P352, P304+P340, P305+P351+P338, P312, P321, P332+P313, P337+P313, P362, P403+P233, P405, P501 |

| Flash point | 260 °C (500 °F; 533 K) |

| Autoignition temperature |

496 °C (925 °F; 769 K) |

| Threshold limit value (TLV) | 10 mg/m (STEL) |

| Lethal dose or concentration (LD, LC): | |

| LD50 (median dose) | >1 g/kg (oral, mouse) |

| Safety data sheet (SDS) | MSDS sheet |

| Related compounds | |

| Related carboxylic acids | Phthalic acid Isophthalic acid Benzoic acid p-Toluic acid |

| Related compounds | p-Xylene Polyethylene terephthalate Dimethyl terephthalate |

| Supplementary data page | |

| Terephthalic acid (data page) | |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C , 100 kPa).

| |

Terephthalic acid is an organic compound with formula C6H4(CO2H)2. This white solid is a commodity chemical, used principally as a precursor to the polyester PET, used to make clothing and plastic bottles. Several million tons are produced annually. The common name is derived from the turpentine-producing tree Pistacia terebinthus and phthalic acid.

Terephthalic acid is also used in the production of PBT plastic (polybutylene terephthalate).

History

Terephthalic acid was first isolated (from turpentine) by the French chemist Amédée Cailliot (1805–1884) in 1846. Terephthalic acid became industrially important after World War II. Terephthalic acid was produced by oxidation of p-xylene with 30-40% nitric acid. Air oxidation of p-xylene gives p-toluic acid, which resists further air-oxidation. Esterification of p-toluic acid to methyl p-toluate (CH3C6H4CO2CH3) opens the way for further oxidation to monomethyl terephthalate. In the Dynamit−Nobel process these two oxidations and the esterification were performed in a single reactor. The reaction conditions also lead to a second esterification, producing dimethyl terephthalate, which could be hydrolysed to terepthalic acid. In 1955, Mid-Century Corporation and ICI announced the bromide-catalysed oxidation of p-toluic acid directly to terephthalic acid, without the need to isolate intermediates and still using air as the oxidant. Amoco (as Standard Oil of Indiana) purchased the Mid-Century/ICI technology, and the process is now known by their name.

Synthesis

Amoco Process

In the Amoco process, which is widely adopted worldwide, terephthalic acid is produced by catalytic oxidation of p-xylene:

The process uses a cobalt–manganese–bromide catalyst. The bromide source can be sodium bromide, hydrogen bromide or tetrabromoethane. Bromine functions as a regenerative source of free radicals. Acetic acid is the solvent and compressed air serves as the oxidant. The combination of bromine and acetic acid is highly corrosive, requiring specialized reactors, such as those lined with titanium. A mixture of p-xylene, acetic acid, the catalyst system, and compressed air is fed to a reactor.

Mechanism

The oxidation of p-xylene proceeds by a free radical process. Bromine radicals decompose cobalt and manganese hydroperoxides. The resulting oxygen-based radicals abstract hydrogen from a methyl group, which have weaker C–H bonds than does the aromatic ring. Many intermediates have been isolated. p-xylene is converted to p-toluic acid, which is less reactive than the p-xylene owing to the influence of the electron-withdrawing carboxylic acid group. Incomplete oxidation produces 4-carboxybenzaldehyde (4-CBA), which is often a problematic impurity.

Challenges

Approximately 5% of the acetic acid solvent is lost by decomposition or "burning". Product loss by decarboxylation to benzoic acid is common. The high temperature diminishes oxygen solubility in an already oxygen-starved system. Pure oxygen cannot be used in the traditional system due to hazards of flammable organic–O2 mixtures. Atmospheric air can be used in its place, but once reacted needs to be purified of toxins and ozone depleters such as methylbromide before being released. Additionally, the corrosive nature of bromides at high temperatures requires the reaction be run in expensive titanium reactors.

Alternative reaction media

The use of carbon dioxide overcomes many of the problems with the original industrial process. Because CO2 is a better flame inhibitor than N2, a CO2 environment allows for the use of pure oxygen directly, instead of air, with reduced flammability hazards. The solubility of molecular oxygen in solution is also enhanced in the CO2 environment. Because more oxygen is available to the system, supercritical carbon dioxide (Tc = 31 °C) has more complete oxidation with fewer byproducts, lower carbon monoxide production, less decarboxylation and higher purity than the commercial process.

In supercritical water medium, the oxidation can be effectively catalyzed by MnBr2 with pure O2 in a medium-high temperature. Use of supercritical water instead of acetic acid as a solvent diminishes environmental impact and offers a cost advantage. However, the scope of such reaction systems is limited by the even more demanding conditions than the industrial process (300–400 °C, >200 bar).

Promotors and additives

As with any large-scale process, many additives have been investigated for potential beneficial effects. Promising results have been reported with the following.

- Ketones act as promoters for formation of the active cobalt(III) catalyst. In particular, ketones with α-methylene groups oxidize to hydroperoxides that are known to oxidize cobalt(II). 2-Butanone is often used.

- Zirconium salts enhance the activity of Co-Mn-Br catalysts. Selectivity is also improved.

- N-Hydroxyphthalimide is a potential replacement for bromide, which is highly corrosive. The phthalimide functions by formation of the oxyl radical.

- Guanidine inhibits the oxidation of the first methyl but enhances the usually slow oxidation of the toluic acid.

Alternative routes

Terephthalic acid can also be made from toluene by the Gattermann-Koch reaction, which gives 4-methylbenzaldehyde. Oxidation of the latter gives terephthalic acid.

Terephthalic acid can be prepared in the laboratory by oxidizing many para-disubstituted derivatives of benzene, including caraway oil or a mixture of cymene and cuminol with chromic acid.

Although not commercially significant, there is also the so-called "Henkel process" or "Raecke process", named after the company and patent holder, respectively. This route involves the transfer of carboxylate groups. Either potassium benzoate disproportionates to potassium terephthalate and benzene or potassium phthalate rearranges to the terephthalate. Phthalic anhydride can be used as a raw material and then potassium can be recycled.

Lummus (now a subsidiary of McDermott International) has reported a route from the dinitrile, which can be obtained by ammoxidation of p-xylene.

Applications

Virtually the entire world's supply of terephthalic acid and dimethyl terephthalate are consumed as precursors to polyethylene terephthalate (PET). World production in 1970 was around 1.75 million tonnes. By 2006, global purified terephthalic acid (PTA) demand had exceeded 30 million tonnes. A smaller, but nevertheless significant, demand for terephthalic acid exists in the production of polybutylene terephthalate and several other engineering polymers.

Other uses

- Polyester fibers based on PTA provide easy fabric care, both alone and in blends with natural and other synthetic fibers. Polyester films are used widely in audio and video recording tapes, data storage tapes, photographic films, labels and other sheet material requiring both dimensional stability and toughness.

- Terephthalic acid is used in paint as a carrier.

- Terephthalic acid is used as a raw material to make terephthalate plasticizers such as dioctyl terephthalate and dibutyl terephthalate.

- It is used in the pharmaceutical industry as a raw material for certain drugs.

- In addition to these end uses, Terephthalic acid based polyesters and polyamides are also used in hot melt adhesives.

- PTA is an important raw material for lower molecular weight saturated polyesters for powder and water-soluble coatings.

- In the research laboratory, terephthalic acid has been popularized as a component for the synthesis of metal-organic frameworks.

- The analgesic drug oxycodone occasionally comes as a terephthalate salt; however, the more usual salt of oxycodone is the hydrochloride. Pharmacologically, one milligram of hydrochloridum oxycodonae is equivalent to 1.13 mg of terephthalas oxycodonae.

- Terephthalic acid is used as a filler in some military smoke grenades, most notably the American M83 smoke grenade and M90 vehicle-employed smoke grenade, producing a thick white smoke that acts as an obscurant in the visual and near-infrared spectrum when burned.

Solubility

Terephthalic acid is poorly soluble in water and alcohols; consequently, until about 1970 terephthalic acid was purified as its dimethyl ester. It sublimes when heated.

|

|

Toxicity

Terephthalic acid and its dimethyl ester have very low toxicity, with LD50 >1 g/kg (oral, mouse).

Biodegradation

In Comamonas thiooxydans strain E6, terephthalic acid is biodegraded to protocatechuic acid, a common natural product, via a reaction pathway initiated by terephthalate 1,2-dioxygenase. Combined with the previously known PETase and MHETase, a full pathway for PET plastic degradation can be engineered.

See also

- Polycyclohexylenedimethylene terephthalate a thermoplastic polyester formed from terephthalic acid

References

- ^ Haynes, p. 3.492

- Haynes, p. 5.163

- Haynes, p. 5.96

- Haynes, p. 3.579

- Karthikeyan, N.; Joseph Prince, J.; Ramalingam, S.; Periandy, S. (2015). "Electronic and vibrational investigation and NMR–mass spectroscopic analysis of terephthalic acid using quantum Gaussian calculations". Spectrochimica Acta Part A. 139: 229–242. Bibcode:2015AcSpA.139..229K. doi:10.1016/j.saa.2014.11.112. PMID 25561302.

- Haynes, p. 5.37

- Haynes, p. 16.42

- ^ Sheehan, Richard J. (June 15, 2000). "Terephthalic Acid, Dimethyl Terephthalate, and Isophthalic Acid". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a26_193. ISBN 978-3527306732.

- ^ Haynes, p. 16.29

- "Polybutylene Terephthalate (PBT) Material Guide & Properties Info". omnexus.specialchem.com. Archived from the original on 2023-11-24. Retrieved 2023-11-24.

- Cailliot, Amédée (1847). "Études sur l'essence de térébenthine" [Studies of the essence of turpentine]. Annales de Chimie et de Physique. Série 3. 21: 27–40. Terephthalic acid is named on p. 29: "Je désignerai le premier de ces acides, celui qui est insoluble, sous le nom d'acide téréphtalique." (I will designate the first of these acids, which is insoluble, by the name of terephthalic acid.)

- ^ Tomás, Rogério A. F.; Bordado, João C. M.; Gomes, João F. P. (2013). "p-Xylene Oxidation to Terephthalic Acid: A Literature Review Oriented toward Process Optimization and Development". Chemical Reviews. 113 (10): 7421–69. doi:10.1021/cr300298j. PMID 23767849.

- Wang, Qinbo; Cheng, Youwei; Wang, Lijun; Li, Xi (2007). "Semicontinuous Studies on the Reaction Mechanism and Kinetics for the Liquid-Phase Oxidation of p-Xylene to Terephthalic Acid". Industrial & Engineering Chemistry Research. 46 (26): 8980–8992. doi:10.1021/ie0615584.

- Xiao, Y.; Luo, W.-P.; Zhang, X.-Y.; et al. (2010). "Aerobic Oxidation of p-Toluic Acid to Terephthalic Acid over T(p-Cl)PPMnCl/Co(OAc)2 Under Moderate Conditions". Catalysis Letters. 134 (1–2): 155–161. doi:10.1007/s10562-009-0227-1. S2CID 95855968.

- ^ Zuo, Xiaobin; Subramaniam, Bala; Busch, Daryle H. (2008). "Liquid-Phase Oxidation of Toluene and p-Toluic Acid under Mild Conditions: Synergistic Effects of Cobalt, Zirconium, Ketones, and Carbon Dioxide". Industrial & Engineering Chemistry Research. 47 (3): 546–552. doi:10.1021/ie070896h.

- ^ Zuo, Xiaobin; Niu, Fenghui; Snavely, Kirk; et al. (2010). "Liquid Phase Oxidation of p-Xylene to Terephthalic Acid at Medium-high Temperatures: Multiple Benefits of CO2-expanded Liquids". Green Chemistry. 12 (2): 260–267. doi:10.1039/B920262E. hdl:1808/18532.

- Pérez, Eduardo; Fraga Dubreuil, Joan; García Verdugo, Eduardo; et al. (2011). "Selective Aerobic Oxidation of para-Xylene in Sub- and Supercritical Water. Part 1. Comparison with Ortho-xylene and the Role of the Catalyst". Green Chemistry. 13 (12): 2389–2396. doi:10.1039/C1GC15137A.

- Brühne, Friedrich; Wright, Elaine (2011). "Benzaldehyde". Ullmann's Encyclopedia of Industrial Chemistry. doi:10.1002/14356007.a03_463.pub2. ISBN 978-3-527-30385-4.

- Ogata, Yoshiro; Tsuchida, Masaru; Muramoto, Akihiko (1957). "The Preparation of Terephthalic Acid from Phthalic or Benzoic Acid". Journal of the American Chemical Society. 79 (22): 6005–6008. doi:10.1021/ja01579a043.

- Ogata, Yoshiro; Hojo, Masaru; Morikawa, Masanobu (1960). "Further Studies on the Preparation of Terephthalic Acid from Phthalic or Benzoic Acid". Journal of Organic Chemistry. 25 (12): 2082–2087. doi:10.1021/jo01082a003.

- Terashi, Michio; Hasegawa, Toshio; Kikuchi, Shoji; Kasahara, Toshiji (1962). "The Synthesis of Terephthalic Acid from Phthalic Anhydride". Journal of Synthetic Organic Chemistry, Japan. 20 (1): 40–55. doi:10.5059/yukigoseikyokaishi.20.40.

- Ashford's Dictionary of Industrial Chemicals (3rd ed.). Saltash, UK: Wavelength. 2011. p. 8805. ISBN 978-0952267430.

- "GTDB – Genome GCF_001010305.1". gtdb.ecogenomic.org.

- Kincannon, William M.; Zahn, Michael; Clare, Rita; et al. (29 March 2022). "Biochemical and structural characterization of an aromatic ring–hydroxylating dioxygenase for terephthalic acid catabolism". Proceedings of the National Academy of Sciences. 119 (13): e2121426119. Bibcode:2022PNAS..11921426K. doi:10.1073/pnas.2121426119. PMC 9060491. PMID 35312352.

Cited sources

- Haynes, William M., ed. (2016). CRC Handbook of Chemistry and Physics (97th ed.). CRC Press. ISBN 9781498754293.

External links and further reading

- Tedder, J. M.; Nechvatal, A.; Tubb, A. H., eds. (1975). Basic Organic Chemistry: Part 5, Industrial Products. Chichester, UK: John Wiley & Sons. ISBN 9780471850144.

- International Chemical Safety Card 0330