| Revision as of 17:04, 14 November 2011 editBeno1000 (talk | contribs)Pending changes reviewers3,659 editsmNo edit summary← Previous edit | Latest revision as of 22:36, 1 December 2024 edit undoSix Oh Five (talk | contribs)Extended confirmed users1,285 edits →Applications: toneTags: Mobile edit Mobile app edit Android app edit App section source | ||

| (734 intermediate revisions by more than 100 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Short description|Family of polymers of the repeating form }} | |||

| ]'''Silicones''' are inert, synthetic compounds with a variety of forms and uses. Typically heat-resistant and ]-like, they are used in ]s, ]s, ]s, ] (e.g., ]), cookware, and ]. | |||

| {{distinguish|text=the chemical element ]}} | |||

| {{Lead too short|date=July 2024}} | |||

| ] | |||

| Silicones are ] that include ] together with ], ], ], and sometimes other ]s. Some common forms include ], ], ], and ]. | |||

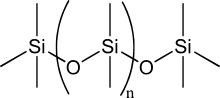

| In ] and ], a '''silicone''' or '''polysiloxane''' is a ] composed of ]s of ] ({{chem2|\sO\sR2Si\sO\sSiR2\s}}, where R = ]). They are typically colorless oils or ]-like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include ], ], ], ], and ].<ref name=Ullmann/><ref>{{cite book |isbn=9781119631378 |title=Liquid Silicone Rubber: Chemistry, Materials, and Processing |last1=Fink |first1=Johannes Karl |date=5 July 2019|publisher=John Wiley & Sons }}</ref> | |||

| ==Properties== | |||

| Some of the most useful properties of silicones include: | |||

| *Low chemical reactivity. | |||

| *Low ]. | |||

| *Thermal stability (constancy of prophjhmerties over a wide temperature range of −100 to 250 °C). | |||

| *The ability to repel water and form watertight seals, although silicones are not ]s. | |||

| *Excellent resistance to oxygen, ozone, and ] such as that in sunlight. This property has led to widespread use of silicones in the construction industry (e.g. coatings, fire protection, glazing seals) and the automotive industry (external gaskets, external trim). | |||

| *Good ]. Because silicone can be formulated to be electrically insulative or conductive, it is suitable for a wide range of electrical applications. | |||

| *Does not stick. | |||

| *Does not support ] growth. | |||

| *High ]: At room temperature (25 °C), the permeability of silicone rubber for such gases as oxygen is approximately 400 times{{Citation needed|date=May 2010}} that of ], making silicone useful for medical applications in which increased aeration is desired. However, silicone rubbers cannot be used where gas-tight seals are necessary. | |||

| == |

== Chemistry == | ||

| {{Main|Organosilicon compound}} | |||

| {{Expand section|date=September 2011}} | |||

| ] | |||

| The ] ] pioneered the study of the ] of silicon (]s) and coined the term silicone.<ref>{{cite book|url=http://books.google.com/?id=0VJD6MzH9D8C&pg=PT27|page=27|title=Handbook of Sealant Technology|author=K.L. Mittal, A. Pizzi|publisher=CRC Press|year=2009|isbn=0849391628}}</ref> | |||

| ] and Carl Somiesky examined the ] of ], a reaction that was proposed to initially give the monomer {{chem2|H2SiO}}: | |||

| <math chem display=block>\ce{SiH2Cl2 + H2O -> H2SiO + 2 HCl}</math> | |||

| When the hydrolysis is performed by treating a solution of {{chem2|H2SiCl2}} in benzene with water, the product was determined to have the approximate formula {{chem2|6}}. Higher polymers were proposed to form with time.<ref name="Seyferth">Seyferth, D., Prud'Homme, C., Wiseman, G., Cyclic Polysiloxanes from the Hydrolysis of Dichlorosilane, Inorganic Chemistry, 22, 2163-2167</ref> | |||

| Most polysiloxanes feature organic substituents, e.g., {{chem2|_{''n''}|}} and {{chem2|_{''n''}|}}. All ]ized ]s or polysiloxanes, silicones consist of an inorganic silicon–oxygen ] ({{chem2|***\sSi\sO\sSi\sO\sSi\sO\s***}}) with two groups attached to each silicon center. The materials can be cyclic or polymeric. By varying the {{chem2|\sSi\sO\s}} chain lengths, side groups, and ], silicones can be synthesized with a wide variety of properties and compositions. They can vary in consistency from liquid to gel to rubber to hard plastic. The most common siloxane is linear ] (PDMS), a ].{{citation needed|date=July 2021}} The second-largest group of silicone materials is based on ]s, which are formed by branched and cage-like oligosiloxanes.{{citation needed|date=July 2021}} | |||

| ==Chemistry== | |||

| ] | |||

| More precisely called ]ized ]s or polysiloxanes, silicones are mixed ]-] ]s with the chemical formula <sub>''n''</sub>, where R is an organic group such as ], ], or ]. These materials consist of an inorganic silicon-] backbone (⋯-Si-O-Si-O-Si-O-⋯) with organic side groups attached to the silicon atoms, which are four-coordinate. | |||

| === Terminology and history === | |||

| In some cases, organic side groups can be used to link two or more of these -Si-O- backbones together. By varying the -Si-O- chain lengths, side groups, and ], silicones can be synthesized with a wide variety of properties and compositions. They can vary in consistency from liquid to gel to rubber to hard plastic. The most common siloxane is linear ] (PDMS), a ]. The second largest group of silicone materials is based on ]s, which are formed by branched and cage-like oligosiloxanes. | |||

| ] coined the word ''silicone'' in 1901 to describe the formula of polydiphenylsiloxane, {{chem2|Ph2SiO}} (Ph = ], {{chem2|C6H5}}), by analogy with the formula of the ] ], {{chem2|Ph2CO}} (his term was originally ''silicoketone''). Kipping was well aware that polydiphenylsiloxane is polymeric{{citation needed|date=June 2022}} whereas benzophenone is monomeric and noted the contrasting properties of {{chem2|Ph2SiO}} and {{chem2|Ph2CO}}.<ref>{{Greenwood&Earnshaw2nd|page=362}}</ref><ref>{{cite journal |author=Frederic Kipping, L. L. Lloyd |journal=] |year=1901 |volume=79 |pages=449–459 |doi=10.1039/CT9017900449 |title=XLVII. Organic derivatives of silicon. Triphenylsilicol and alkyloxysilicon chlorides |url=https://zenodo.org/record/1753322}}</ref> The discovery of the structural differences between Kipping's molecules and the ketones means that ''silicone'' is no longer the correct term (though it remains in common usage) and that the term ''siloxane'' is preferred according to the nomenclature of modern chemistry.<ref name="CincinnatiUniversity2005">{{cite book |author1=James E. Mark |author2=Harry R. Allcock |author3=Robert West |title=Inorganic Polymers |url=https://books.google.com/books?id=7YybTrluKBgC&pg=PA155 |date=24 March 2005 |publisher=Oxford University |isbn=978-0-19-535131-6 |page=155 |url-status=live |archive-url=https://web.archive.org/web/20171218190618/https://books.google.com/books?id=7YybTrluKBgC&pg=PA155 |archive-date=18 December 2017}}</ref> | |||

| ] (born 11 March 1903) was an American chemist and inventor. He has been called the "Father of Silicones" and is credited with the launch of the silicone industry in the 1930s. His most notable contributions include his creation of silicone from silicon compounds and his method of making ], a high-quality glass later used in aeronautics, advanced telecommunications, and computer chips. His work led to the formation of ], an alliance between the ] and ] that was specifically created to produce silicone products. | |||

| ===Terminology=== | |||

| Silicone is not to be confused with the chemical element ], a crystalline ] widely used in ]s and other ]. Although silicones contain silicon atoms, they also include carbon, hydrogen, oxygen, and perhaps other kinds of atoms as well, and have different physical and chemical properties than elemental silicon. | |||

| Silicone is often confused with ], but they are distinct substances. Silicon is a ], a hard dark-grey ] ], which in its ]line form is used to make ]s ("electronic chips") and ]s. Silicones are compounds that contain silicon, carbon, hydrogen, oxygen, and perhaps other kinds of atoms as well, and have many very different physical and chemical properties. | |||

| ] coined the word "silicone" in 1901 to describe polydiphenylsiloxane by analogy of its ''formula'', Ph<sub>2</sub>SiO, with the formula of the ketone ], Ph<sub>2</sub>CO (Ph stands for ], C<sub>6</sub>H<sub>5</sub>). Kipping was well aware that polydiphenylsiloxane is polymeric whereas benzophenone is monomeric and noted that Ph<sub>2</sub>SiO and Ph<sub>2</sub>CO had very different chemistry.<ref>{{Greenwood&Earnshaw2nd|page=362}}</ref><ref>{{cite journal|author=], L. L. Lloyd|journal=]|year=1901|volume=79|pages=449–459|doi=10.1039/CT9017900449|title=XLVII.?Organic derivatives of silicon. Triphenylsilicol and alkyloxysilicon chlorides}}</ref> | |||

| Compounds containing silicon–oxygen double bonds, now called ], but which could deserve the name "silicone", have long been identified as ] in gas-phase processes such as ] in ] production, and in the ] by combustion.<ref>{{cite journal |journal=] |volume=566 |issue=1–2 |year=1998 |pages=45–59 |title=Matrix isolation infrared and density functional theoretical studies of organic silanones, (CH<sub>3</sub>O)<sub>2</sub>Si=O and (C<sub>6</sub>H<sub>5</sub>)<sub>2</sub>Si=O |author1=V. N. Khabashesku |author2=Z. A. Kerzina |author3=K. N. Kudin |author4=O. M. Nefedov | doi= 10.1016/S0022-328X(98)00726-8}}</ref> However, they have a strong tendency to polymerize into siloxanes. The first stable silanone was obtained in 2014 by ] and others.<ref name=filippou>Alexander C. Filippou, Bernhard Baars, Yury N. Lebedev, and Gregor Schnakenburg (2014): "Silicon–Oxygen Double Bonds: A Stable Silanone with a Trigonal‐Planar Coordinated Silicon Center". ''Angewandte Chemie International Edition'', volume 53, issue 2, pages 565–570. {{doi|10.1002/anie.201308433}}.</ref> | |||

| A true ''silicone group'' with a double bond between oxygen and silicon does not commonly exist in nature; chemists find that the silicon atom usually forms single bonds with each of two oxygen atoms, rather than a double bond to a single atom. Polysiloxanes are among the many substances commonly known as "silicones". | |||

| === Synthesis === | |||

| Molecules containing silicon-oxygen double bonds do exist and are called silanones. Several silanones have been studied in ] ]<ref>{{cite journal|author = R. Withnall, L. Andrews|title=Infrared spectroscopic evidence for silicon-oxygen double bonds: methyl- and dimethylsilanones in solid argon|journal=]|year=1986|volume= 108|issue=25|pages=8118–8119|doi=10.1021/ja00285a054}}</ref> and in the gas phase, but they are highly reactive.<ref>{{cite journal|journal=J. Mol. Spectrosc.|volume=175|issue=2|year=1996|pages = 421–428|title=Experimentally Determined Structure of H<sub>2</sub>SiO by Rotational Spectroscopy and Isotopic Substitution|author=M. Bogey, B. Delcroix, A. Walters, J-C Guillemin|doi= 10.1006/jmsp.1996.0048}}</ref> Despite their reactivity, silanones are important as ] in gas-phase processes such as ] in ] production, in the ] by combustion,<ref>{{cite journal|journal=]|volume=566|issue=1-2|year=1998|pages = 45–59|title=Matrix isolation infrared and density functional theoretical studies of organic silanones, (CH<sub>3</sub>O)<sub>2</sub>Si=O and (C<sub>6</sub>H<sub>5</sub>)<sub>2</sub>Si=O|author=V. N. Khabashesku, Z. A. Kerzina, K. N. Kudin, O. M. Nefedov|doi=10.1016/S0022-328X(98)00726-8}}</ref> and in astrochemistry.<ref>{{cite journal|journal = ]|title=The chemistry of silicon in interstellar clouds|author = J. L. Turner, A. Dalgarno|year= 1977|volume=213|pages=386–389|doi=10.1086/155167|bibcode=1977ApJ...213..386T}}</ref> | |||

| Most common are materials based on ], which is derived by ] of ]. This dichloride reacts with water as follows: | |||

| <math chem display=block>n\ \ce{Si(CH3)2Cl2} + n\ \ce{H2O -> }_n + 2n\ \ce{HCl}</math> | |||

| ===Synthesis=== | |||

| ] (silica), used in the manufacture of all silicones.]] | |||

| ], common in ], ], and similar natural materials, is the initial material from which silicones are produced; silica is also widely used in producing ]. Silicones are synthesized from ]s, ], and related compounds. | |||

| The polymerization typically produces linear chains capped with {{chem2|Si\sCl}} or {{chem2|Si\sOH}} (]) groups. Under different conditions, the polymer is a cyclic, not a chain.<ref name=Ullmann/> | |||

| In producing the silicone ], the starting material is ], which reacts with ] as follows: | |||

| For consumer applications such as caulks, silyl ]s are used instead of silyl chlorides. The hydrolysis of the acetates produces the less dangerous ] (the acid found in ]) as the reaction product of a much slower curing process. This chemistry is used in many consumer applications, such as silicone ] and ]s. | |||

| :''n'' Si(CH<sub>3</sub>)<sub>2</sub>Cl<sub>2</sub> + ''n'' H<sub>2</sub>O → <sub>''n''</sub> + 2''n'' HCl | |||

| <math chem display=block>n\ \ce{Si(CH3)2(CH3COO)2} + n\ \ce{H2O -> }_n + 2n\ \ce{CH3COOH}</math> | |||

| During ], this reaction evolves hazardous ] gas. | |||

| ] or crosslinks in the polymer chain can be introduced by using organosilicone precursors with fewer alkyl groups, such as methyl trichlorosilane and ]. Ideally, each molecule of such a compound becomes a branch point. This process can be used to produce hard silicone resins. Similarly, precursors with three methyl groups can be used to limit molecular weight, since each such molecule has only one reactive site and so forms the end of a siloxane chain. | |||

| For consumer and medical uses, a process was developed in which the chlorine atoms in the silane precursor were replaced with ] groups,which produce the less dangerous ] (the acid found in vinegar) as the reaction product of a much slower curing process. This chemistry is used in many consumer applications, such as silicone ] and ]s. | |||

| === Combustion === | |||

| ] or ]s in the polymer chain can be introduced by using silane precursors with more acid-forming groups and fewer methyl groups, such as methyltrichlorosilane, . Ideally, each molecule of such a compound becomes a branch point. This process can be used to produce hard ]s. Similarly, precursors with three methyl groups can be used to limit molecular weight, since each such molecule has only one reactive site and so forms the end of a siloxane chain. | |||

| When silicone is burned in air or oxygen, it forms solid silica (], {{chem2|SiO2}}) as a white powder, char, and various gases. The readily dispersed powder is sometimes called ]. The ] of certain polysiloxanes under an ] is a valuable pathway towards the production of amorphous ] ceramics, also known as ]. Polysiloxanes terminated with functional ] such as ], ] or ] groups have been cross linked to yield ], which can be ] for the ] of ] by ] techniques.<ref>: A versatile stereolithographic approach assisted by thiol-ene click chemistry. ''Additive Manufacturing'', (2019) volume 27, pp. 80–90.</ref> | |||

| Modern silicone resins are generally made using ], which reacts in a more mild and controllable manner than chlorosilanes. | |||

| == |

== Properties == | ||

| ] | |||

| When silicone is burned in air or oxygen, it forms solid silica (silicon dioxide) as a white powder, char, and various gases. The readily dispersed powder is sometimes called silica fume. | |||

| Silicones exhibit many useful characteristics, including:<ref name=Ullmann>{{Ullmann|first1=Hans-Heinrich|last1=Moretto|first2=Manfred|last2=Schulze|first3=Gebhard|last3=Wagner|year=2005|title=Silicones|doi=10.1002/14356007.a24_057}}</ref> | |||

| * Low ] | |||

| ==Uses== | |||

| * Low chemical reactivity | |||

| Silicones are used in many familiar products, and included as components in diverse others. | |||

| * Low ] | |||

| * Thermal stability (constancy of properties over a wide temperature range of {{nowrap|−100 to 250 °C}}) | |||

| * The ability to repel water and form watertight seals. | |||

| * Does not stick to many substrates, but adheres very well to others, e.g. glass | |||

| * Does not support ] growth | |||

| * Resistance to creasing and wrinkling | |||

| * Resistance to oxygen, ozone, and ]. This property has led to the widespread use of silicones in the construction industry (e.g. coatings, fire protection, glazing seals) and the ] (external gaskets, external trim). | |||

| * ] properties. Because silicone can be formulated to be electrically insulative or conductive, it is suitable for a wide range of electrical applications. | |||

| * High ]: at room temperature (25 °C), the permeability of ] for such gases as oxygen is approximately 400 times<ref>{{Citation|title=Treeing Characteristics in HTV Silicone Rubber|date=2020|url=http://dx.doi.org/10.4018/978-1-5225-8885-6.ch003|work=Electrical Insulation Breakdown and Its Theory, Process, and Prevention|series=Advances in Computer and Electrical Engineering|pages=73–104|publisher=IGI Global|doi=10.4018/978-1-5225-8885-6.ch003|isbn=978-1-5225-8885-6|s2cid=241551199|access-date=2021-03-16}}</ref> that of ], making silicone useful for medical applications in which increased aeration is desired. Conversely, silicone rubbers cannot be used where gas-tight seals are necessary such as seals for high-pressure gasses or high vacuum. | |||

| Silicone can be developed into rubber sheeting, where it has other properties, such as being FDA compliant. This extends the uses of silicone sheeting to industries that demand hygiene, for example, food and beverage, and pharmaceuticals. | |||

| ===Aquarium joints=== | |||

| In making ]s, manufacturers now commonly use 100% silicone sealant to join glass plates. Glass joints made with silicone sealant can withstand great pressure, making obsolete the original aquarium construction method of angle-iron and putty. | |||

| This same silicone is used to make hinges in aquarium lids or for minor repairs. However, not all commercial silicones are safe for aquarium manufacture, nor is silicone used for the manufacture of acrylic aquariums as silicones do not have long-term adhesion to plastics.<ref></ref> | |||

| == |

== Applications == | ||

| Silicones are used in many products. '']'' lists the following major categories of application: Electrical (e.g. insulation), electronics (e.g., coatings), household (e.g., sealants and cooking utensils), automobile (e.g. gaskets), airplane (e.g., seals), office machines (e.g. keyboard pads), medicine and dentistry (e.g. ]), textiles and paper (e.g. coatings). For these applications, an estimated 400,000 tonnes of silicones were produced in 1991.{{clarify|reason=where? that seems low for a worldwide figure|date=May 2018}} Specific examples, both large and small are presented below.<ref name=Ullmann/> | |||

| In the ] field, ] is typically used as a lubricant for ] components since it is stable at high temperatures, is not water-soluble, and is far less likely than other lubricants to foul. Automotive spark plug wires are insulated by multiple layers of silicone to prevent sparks from jumping to adjacent wires, causing misfires. Silicone tubing is sometimes used in automotive intake systems (especially for engines with ]). Sheet silicone is used to manufacture ]s used in ]s, ]s, and other applications. Automotive body manufacturing plants and paint shops avoid silicones, as they may cause "fish eyes", small, circular craters in the finish. Additionally, silicone compounds such as silicone rubber are used as coatings and sealants for ]s; the high strength of silicone rubber makes it an optimal adhesive/sealant for high impact airbags. | |||

| === |

=== Automotive === | ||

| ] | |||

| Silicone films can be applied to such silica-based substrates as ] to form a ] bonded ] coating. | |||

| In the ] field, ] is typically used as a lubricant for ] components since it is stable at high temperatures, is not water-soluble, and is far less likely than other lubricants to foul. ] ]s are based on liquid silicones. | |||

| Automotive spark plug wires are insulated by multiple layers of silicone to prevent sparks from jumping to adjacent wires, causing misfires. Silicone tubing is sometimes used in automotive intake systems (especially for engines with ]). | |||

| Sheet silicone is used to manufacture ]s used in ]s, ]s, and other applications. | |||

| Automotive body manufacturing plants and paint shops avoid silicones, as trace contamination may cause "fish eyes", which are small, circular craters which mar a smooth finish.{{citation needed|date=July 2021}} | |||

| Additionally, silicone compounds such as silicone rubber are used as coatings and sealants for ]s; the high strength of silicone rubber makes it an optimal adhesive and sealant for high impact airbags.{{citation needed|date=July 2021}} Silicones in combination with thermoplastics provide improvements in scratch and mar resistance and lowered coefficient of friction.{{citation needed|date=July 2021}} | |||

| === Aerospace === | |||

| ] | |||

| Silicone is a widely used material in the ] due to its sealing properties, stability across an extreme temperature range, durability, sound dampening and anti-vibration qualities, and naturally flame retardant properties. Maintaining extreme functionality is paramount for passenger safety in the aerospace industry, so each component on an aircraft requires high-performance materials. | |||

| Specially developed aerospace grades of silicone are stable from {{nowrap|−70 to 220 °C}},<ref>{{Cite web|url=https://www.vikingextrusions.co.uk/aerospace|title=Aerospace {{!}} Viking Extrusions|website=www.vikingextrusions.co.uk|access-date=2019-04-11}}</ref> these grades can be used in the construction of gaskets for windows and cabin doors. During operation, aircraft go through large temperature fluctuations in a relatively short period of time; from the ambient temperatures when on the ground in hot countries to sub-zero temperatures when flying at high altitude. ] can be molded with tight tolerances ensuring ]s form airtight seals both on the ground and in the air, where atmospheric pressure decreases. | |||

| Silicone rubber's resistance to heat corrosion enables it to be used for gaskets in aircraft engines where it will outlast other types of rubber, both improving aircraft safety and reducing maintenance costs. The silicone acts to seal instrument panels and other electrical systems in the cockpit, protecting printed circuit boards from the risks of extreme altitude such as moisture and extremely low temperature. Silicone can be used as a sheath to protect wires and electrical components from any dust or ice that may creep into a plane's inner workings. | |||

| As the nature of air travel results in much noise and vibration, powerful engines, landings, and high speeds all need to be considered to ensure passenger comfort and safe operation of the aircraft. As silicone rubber has exceptional noise reduction and anti-vibration properties, it can be formed into small components and fitted into small gaps ensuring all equipment can be protected from unwanted vibration such as overhead lockers, vent ducts, hatches, entertainment system seals, and LED lighting systems. | |||

| === Solid propellant === | |||

| Polydimethylsiloxane (PDMS) based binders along with ] (NH<sub>4</sub>ClO<sub>4</sub>) are used as fast burning solid propellants in rockets.<ref>{{Cite journal |last1=Eisele |first1=Siegfried |last2=Gerber |first2=Peter |last3=Menke |first3=Klaus |date=June 2002 |title=Fast Burning Rocket Propellants Based on Silicone Binders – New Aspects of an Old System |url=http://dx.doi.org/10.1002/1521-4087(200206)27:3<161::aid-prep161>3.0.co;2-4 |journal=Propellants, Explosives, Pyrotechnics |volume=27 |issue=3 |pages=161 |doi=10.1002/1521-4087(200206)27:3<161::aid-prep161>3.0.co;2-4 |issn=0721-3115}}</ref> | |||

| === Building construction === | |||

| The strength and reliability of ] are widely acknowledged in the construction industry. One-part silicone ]s and caulks are in common use to seal gaps, joints and crevices in buildings. One-part silicones cure by absorbing atmospheric moisture, which simplifies installation. In plumbing, silicone grease is typically applied to O-rings in ] taps and valves, preventing ] from sticking to the metal. | |||

| Structural silicone has also been used in ] building façades since 1974 when the ] became the first building to receive exterior glass fixed only with the material.{{citation needed|date=July 2021}} Silicone membranes have been used to cover and restore industrial roofs, thanks to its extreme UV resistance, and ability to keep their waterproof performance for decades.{{citation needed|date=July 2021}} | |||

| === 3D printing === | |||

| ] | |||

| ] can be 3D printed (liquid deposition modelling, LDM) using pump-nozzle extrusion systems. Standard silicone formulations are optimized to be used by extrusion and injection moulding machines and are not applicable in LDM-based 3D printing. The rheological behavior and the ] need to be adjusted for use with LDM.<ref>{{Cite journal |last1=Courtial |first1=Edwin-Joffrey |last2=Perrinet |first2=Clément |last3=Colly |first3=Arthur |last4=Mariot |first4=David |last5=Frances |first5=Jean-Marc |last6=Fulchiron |first6=René |last7=Marquette |first7=Christophe |date=2019-08-01 |title=Silicone rheological behavior modification for 3D printing: Evaluation of yield stress impact on printed object properties |journal=Additive Manufacturing |language=en |volume=28 |pages=50–57 |doi=10.1016/j.addma.2019.04.006 |s2cid=146407873 |issn=2214-8604|doi-access=free }}</ref> | |||

| 3D printing also requires the use of a removable support material that is compatible with the silicone rubber. | |||

| === Coatings === | |||

| Silicone films can be applied to such silica-based substrates as glass to form a ] bonded ] coating. Such coatings were developed for use on aircraft ]s to repel water and to preserve visibility, without requiring mechanical ]s which are impractical at supersonic speeds. Similar treatments were eventually adapted to the automotive market in products marketed by ] and others. | |||

| Many fabrics can be coated or impregnated with silicone to form a strong, waterproof composite such as ]. | Many fabrics can be coated or impregnated with silicone to form a strong, waterproof composite such as ]. | ||

| A silicone polymer can be suspended in water by using stabilizing surfactants. This allows water-based formulations to be used to deliver many ingredients that would otherwise require a stronger solvent, or be too viscous to use effectively. For example, a waterborne formulation using a silane's reactivity and penetration ability into a mineral-based surface can be combined with water-beading properties from a siloxane to produce a more-useful surface protection product. | |||

| ===Cookware=== | |||

| ] | |||

| ] to be placed inside a pot of boiling water.]] | |||

| *As a low-taint, non-toxic material, silicone can be used where contact with food is required. Silicone is becoming an important product in the ] industry, particularly ] and ]. | |||

| *Silicone is used as an insulator in heat-resistant potholders and similar items, however it is more conductive of heat than similar less dense fiber-based products. Silicone oven mitts are able to withstand temperatures up to {{convert|260|°C|°F}}, allowing reaching into boiling water. | |||

| *]s for chocolate, ice, cookies, muffins and various other foods. | |||

| *Other products such as ]s, egg boilers or ]s, ] lids, ]s, ]s, and kitchen mats. | |||

| === |

=== Cookware === | ||

| As a low-taint, non-toxic material, silicone can be used where contact with food is required. Silicone is becoming an important product in the ] industry, particularly ] and ]. | |||

| Silicones are used as active compound in ]s due to their low water solubility and good spreading properties. | |||

| Silicone is used as an insulator in heat-resistant potholders and similar items; however, it is more conductive of heat than similar less dense fiber-based products. Silicone oven gloves are able to withstand temperatures up to {{convert|260|°C|°F}}, making it possible to reach into boiling water. | |||

| Other products include ]s for chocolate, ice, cookies, muffins, and various other foods; non-stick bakeware and reusable mats used on baking sheets; ]s, egg boilers or ]s; cookware lids, ]s, ]s, and kitchen mats. | |||

| ===Dry cleaning=== | |||

| Liquid silicone can be used as a ] ], providing an "environmentally friendly" alternative to the traditional ]-containing ] solvent. Also, liquid silicone is chemically inert, not reacting with fabrics or dyes during the cleaning process, thus reducing the amount of fading and shrinking experienced by many garments dry-cleaned with the more reactive perc. Use of silicones in dry cleaning reduces the environmental impact of a typically high-polluting industry. A siloxane-based ] process has been patented by the company ]. | |||

| <gallery mode="packed"> | |||

| ===Electronics=== | |||

| <!-- Do not add excessive numbers of cookware examples here! --> | |||

| Electronic components are sometimes ] in silicone to increase stability against mechanical and electrical shock, radiation and vibration, a process called "potting". | |||

| File:Silicone ladles.jpeg|Soup ladle and pasta ladle made of silicone | |||

| File:Silicone food steamer.jpeg|A silicone food ] to be placed inside a pot of boiling water | |||

| File:Eiswuerfelform-silikon.jpg|Flexible ice cube trays made of silicone allow easy extraction of ice. | |||

| File:Kitchen-Silicone-Brush.jpg|Silicone brush used for basting and applying flavoring liquids | |||

| </gallery> | |||

| === Defoaming === | |||

| Silicones are used where durability and high performance are demanded of components under hard conditions, such as in space (satellite technology). They are selected over ] or ] encapsulation when a wide ] range is required (−65 to 315 °C). Silicones also have the advantage of little exothermic heat rise during cure, low toxicity, good electrical properties and high purity. | |||

| Silicones are used as active compounds in ]s due to their low water solubility and good spreading properties. | |||

| === Dry cleaning === | |||

| The use of silicones in electronics is not without problems, however. Silicones are relatively expensive and can be attacked by solvents.<ref>See ] for how silicones can be dispensed in circuit board production.</ref> Silicone easily migrates as either a liquid or vapor onto other components. | |||

| Liquid silicone can be used as a ] ], providing an alternative to the traditional ]-containing ] solvent. The use of silicones in dry cleaning reduces the environmental effect of a typically high-polluting industry.{{citation needed|date=July 2021}} | |||

| === Electronics === | |||

| Silicone contamination of electrical switch contacts can lead to failures by causing an increase in contact resistance, often late in the life of the contact, well after any testing is completed.<ref>{{cite book|url=http://books.google.com/?id=EkStW7v8VPkC&pg=PA823|chapter=16.4.1|page=823|title=Electrical Contacts: Principles and Applications|author=Paul G. Slade|publisher=CRC Press|year=1999|isbn=0824719344}}</ref><ref>"A Comparison for the Effects of Various Forms of Silicon Contamination on Contact Performance" by Witter, G. (Published in "Components, Hybrids, and Manufacturing Technology, IEEE Transactions on" Mar 1979).</ref> Use of silicone-based spray products in electronic devices during maintenance or repairs can cause later failures. | |||

| ] | |||

| Electronic components are sometimes ] in silicone to increase stability against mechanical and electrical shock, radiation and vibration, a process called "potting". Silicones are used where durability and high performance are demanded of components under extreme environmental conditions, such as in space (satellite technology). They are selected over ] or ] encapsulation when a wide ] range is required (−65 to 315 °C). Silicones also have the advantage of little exothermic heat rise during cure, low toxicity, good electrical properties, and high purity. | |||

| Silicones are often components of ]s used to improve heat transfer from power-dissipating electronic components to ]. | |||

| ===Firestops=== | |||

| {{Commons category|Silicone foam}} | |||

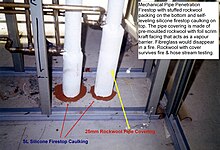

| ] has been used in North American buildings in an attempt to ] openings within fire-resistance-rated wall and floor assemblies to prevent the spread of flames and smoke from one room to another. When properly installed, silicone-foam firestops can be fabricated for building code compliance. Advantages include flexibility and high ] strength. Disadvantages include combustibility (hard to extinguish) and significant smoke development. | |||

| The use of silicones in electronics is not without problems, however. Silicones are relatively expensive and can be attacked by certain solvents. Silicone easily migrates as either a liquid or vapor onto other components. Silicone contamination of electrical switch contacts can lead to failures by causing an increase in contact resistance, often late in the life of the contact, well after any testing is completed.<ref>{{cite book|chapter-url=https://books.google.com/books?id=EkStW7v8VPkC&pg=PA823|chapter=16.4.1|page=823|title=Electrical Contacts: Principles and Applications|author=Paul G. Slade|publisher=CRC Press|year=1999|isbn=978-0-8247-1934-0|url-status=live|archive-url=https://web.archive.org/web/20171218190618/https://books.google.com/books?id=EkStW7v8VPkC&pg=PA823|archive-date=2017-12-18}}</ref><ref>{{cite journal|author1=W. Witter |author2=R. Leiper |name-list-style=amp |title=A Comparison for the Effects of Various Forms of Silicon Contamination on Contact Performance|doi=10.1109/TCHMT.1979.1135411|year=1979|journal=IEEE Transactions on Components, Hybrids, and Manufacturing Technology|volume=2|pages=56–61}}</ref> Use of silicone-based spray products in electronic devices during maintenance or repairs can cause later failures. | |||

| However, silicone-foam firestops have been the subject of controversy and press attention due to smoke development from pyrolysis of combustible components within the foam, ] gas escape, shrinkage, and cracking. These problems have been exposed by ] ], and have led to reportable events among licensees (operators of ]s) of the ]. | |||

| === Firestops === | |||

| ] | |||

| ] has been used in North American buildings in an attempt to ] openings within the fire-resistance-rated wall and floor assemblies to prevent the spread of flames and smoke from one room to another. When properly installed, silicone-foam firestops can be fabricated for building code compliance. Advantages include flexibility and high ] strength. Disadvantages include combustibility (hard to extinguish) and significant smoke development. | |||

| Silicone-foam firestops have been the subject of controversy and press attention due to smoke development from pyrolysis of combustible components within the foam, ] gas escape, shrinkage, and cracking. These problems have led to reportable events among licensees (operators of ]s) of the ].{{citation needed|date=July 2021}} | |||

| Silicone firestops are also used in aircraft. | Silicone firestops are also used in aircraft. | ||

| === Jewelry === | |||

| <gallery perrow=4 widths=160px heights=180px> | |||

| Silicone is a popular alternative to traditional metals (such as silver and gold) with jewelry, specifically rings. Silicone rings are commonly worn in professions where metal rings can lead to injuries, such as electrical conduction and ring avulsions.<ref>{{Cite web|url=https://ourorganicwedding.com/silicone-ring-trend/|title=Is the Silicone Ring Trend Here to Stay?|first=Sarah|last=Ashley|date=August 1, 2018}}</ref><ref>{{Cite web|url=https://www.insider.com/guides/silicone-wedding-ring-trend-2017-10|title=A ton of couples are skipping the fancy wedding rings and opting for these $20 rubber bands instead — here's why|first=Connie|last=Chen|website=Insider}}</ref> During the mid-2010's, some professional athletes began wearing silicone rings as an alternative during games.<ref>{{Cite web|url=https://www.espn.com/blog/detroit-lions/post/_/id/25500/the-wedding-rings-the-thing-silicone-bands-growing-trend-in-nfl|title=The (wedding) ring's the thing: Silicone bands a growing trend in NFL|date=September 29, 2016|website=ESPN.com}}</ref> | |||

| Image:Foamfixer.jpg|Silicone "foamfixer" pump used to apply silicone ] ] materials. | |||

| Image:Sl_silicone_pipes.jpg|Self-leveling silicone ] ] used around ] ] through-penetrations in a two-hour ] ] floor assembly. | |||

| Image:Silicone_foam_sakno1.jpg|Faulty silicone foam ] installation in ] Sewage Treatment Plant in Canada in the 1980s, attempting to seal the opening above a ] in a cast ] ] separation, but improperly set due to wide temperature variations. | |||

| </gallery> | |||

| ===Lubricants=== | === Lubricants === | ||

| ] | |||

| Silicone ]s are used for many purposes, such as ]s, ] parts, and a wide range of other ]s. Typically, a dry-set lubricant is delivered with a solvent carrier to penetrate the mechanism. The solvent then evaporates, leaving a clear film that lubricates but does not attract dirt and grit as much as an ]-based or other traditional "wet" lubricant. | |||

| Silicone ]s are used for many purposes, such as ]s, ] parts, and a wide range of other ]. Typically, a dry-set lubricant is delivered with a solvent carrier to penetrate the mechanism. The solvent then evaporates, leaving a clear film that lubricates but does not attract dirt and grit as much as an ]-based or other traditional "wet" lubricant. | |||

| Silicone personal |

Silicone ]s are also available for use in medical procedures or sexual activity. | ||

| ===Medicine=== | === Medicine and cosmetic surgery === | ||

| Silicone, |

Silicone is used in ], seals, gaskets, shrouds, and other applications requiring high ]. Additionally, the gel form is used in bandages and dressings, ], testicle implants, pectoral implants, ], and a variety of other medical uses. | ||

| Scar treatment sheets are often made of ] due to its durability and |

] are often made of ] due to its durability and biocompatibility. ] is often used for this purpose, since its specific crosslinking results in a flexible and soft silicone with high durability and tack. It has also been used as the hydrophobic block of ] synthetic block ] used to form the vesicle membrane of ]s. | ||

| Illicit cosmetic silicone injections may induce chronic and definitive silicone blood diffusion with dermatologic complications.<ref>{{cite journal |last1=Bertin |first1=Chloé |last2=Abbas |first2=Rachid |last3=Andrieu |first3=Valérie |last4=Michard |first4=Florence |last5=Rioux |first5=Christophe |last6=Descamps |first6=Vincent |last7=Yazdanpanah |first7=Yazdan |last8=Bouscarat |first8=Fabrice |title=Illicit massive silicone injections always induce chronic and definitive silicone blood diffusion with dermatologic complications |journal=Medicine |date=January 2019 |volume=98 |issue=4 |pages=e14143 |doi=10.1097/MD.0000000000014143 |pmid=30681578 |pmc=6358378 }}</ref> | |||

| ] has been used as the hydrophobic block of ] synthetic block ] used to form the vesicle membrane of ]s. | |||

| Ophthalmology uses many products such as silicone oil used to replace the ] following vitrectomy, silicone intraocular lenses following cataract extraction, silicone tubes to keep a nasolacrimal passage open following dacryocystorhinostomy, canalicular stents for canalicular stenosis, punctal plugs for punctal occlusion in dry eyes, silicone rubber and bands as an external ] in tractional retinal detachment, and anteriorly-located break in rhegmatogenous retinal detachment. | |||

| ===Moldmaking=== | |||

| Two-part silicone systems are used to create rubber molds used to cast ], foams, rubber, and low-temperature alloys. A silicone mold generally requires little or no mold-release or surface preparation, as most materials do not adhere to silicone. For experimental uses, ordinary one-part silicone can be used to make molds or to mold into shapes. If needed, common ] or ] can be used on mating surfaces as a mold-release agent.<ref></ref> | |||

| Addition and condensation (e.g. ]) silicones find wide application as a ] material due to its hydrophobic property and thermal stability.<ref>{{Cite web |date=July 19, 2022 |title=The many uses of dental impression silicone |url=https://magazine.zhermack.com/en/laboratory-en/many-uses-of-dental-impression-silicone/ |access-date=January 16, 2023}}</ref><ref>{{Cite book |last=Ferracane |first=Jack L. |url=https://www.worldcat.org/oclc/45604030 |title=Materials in dentistry : principles and applications |date=2001 |publisher=Lippincott Williams & Wilkins |isbn=0-7817-2733-2 |edition=2nd |location=Philadelphia |oclc=45604030}}</ref><ref>{{Cite book |url=https://www.worldcat.org/oclc/1124496192 |title=Sturdevant's art and science of operative dentistry. |date=2018 |others=André V. Ritter, Clifford M. Sturdevant |isbn=978-0-323-47858-8 |edition=7 |location=St. Louis |oclc=1124496192}}</ref> | |||

| Cooking molds used as ] do not require coating with cooking oil, allowing the baked food to be more easily removed from the mold after cooking. | |||

| === |

=== Moldmaking === | ||

| ] | |||

| Silicones are ingredients in many ]s, ]s, and ] products. Some silicones, notably the ] functionalized amodimethicones, are excellent conditioners, providing improved combability, feel, and softness, and lessening ]. The phenyltrimethicones, in another silicone family, are used in reflection-enhancing and color-correcting hair products, where they increase shine and glossiness (and possibly effect subtle color changes). Phenyltrimethicones, unlike the conditioning amodimethicones, have refractive indices (typically 1.46) close to that of human hair (1.54). However, if included in the same formulation, amodimethicone and phenyltrimethicone interact and dilute each other, making it difficult to achieve both high shine and excellent conditioning in the same product. | |||

| Two-part silicone systems are used as rubber molds to cast ], foams, rubber, and low-temperature alloys. A silicone mold generally requires little or no mold-release or surface preparation, as most materials do not adhere to silicone. For experimental uses, ordinary one-part silicone can be used to make molds or to mold into shapes. If needed, common ] or ] can be used on mating surfaces as a mold-release agent.<ref>Robyn Lish. . Myheap.com. Retrieved on 2021-08-08.</ref> | |||

| Silicone cooking molds used as ] do not require coating with cooking oil; in addition, the flexibility of the rubber allows the baked food to be easily removed from the mold after cooking. | |||

| Silicone rubber is commonly used in ] nipples (teats) for its cleanliness, aesthetic appearance, and low extractable content. | |||

| === Personal care === | |||

| Silicones are used in ] and ]. | |||

| ] | |||

| Silicones are ingredients widely used in skincare, color cosmetic and hair care applications. Some silicones, notably the ] functionalized amodimethicones, are excellent hair conditioners, providing improved compatibility, feel, and softness, and lessening frizz. The phenyl dimethicones, in another silicone family, are used in reflection-enhancing and color-correcting hair products, where they increase shine and glossiness (and possibly impart subtle color changes). Phenyltrimethicones, unlike the conditioning amodimethicones, have refractive indices (typically 1.46) close to that of a human hair (1.54). However, if included in the same formulation, amodimethicone and phenyltrimethicone interact and dilute each other, making it difficult to achieve both high shine and excellent conditioning in the same product.<ref>Thomas Clausen et al. "Hair Preparations" in ''Ullmann's Encyclopedia of Industrial Chemistry'', 2007, Wiley-VCH, Weinheim. {{doi|10.1002/14356007.a12_571.pub2}}</ref> | |||

| Silicone rubber is commonly used in ] nipples (teats) for its cleanliness, aesthetic appearance, and low extractable content. | |||

| ]s are often made of ] due to its durability, reusability, and ]. | |||

| Silicones are used in ] and ].<ref>Q. Ashton Acton: ''Silicones—Advances in Research and Application: 2013 Edition'', ScholarlyEditions, 2013, {{ISBN|9781481692397}}, {{webarchive|url=https://web.archive.org/web/20171218190618/https://books.google.com/books?id=ZxzUfxVh6uEC&pg=PA226 |date=2017-12-18 }}.</ref> | |||

| Silicone is a material of choice for soft ], due to its durability, cleanability, and lack of ], chemicals suspected of having carcinogenic and mutagenic effects on the skin and mucous membranes.<ref>{{cite journal|format=free text|author=W.M. Kluwe|title=Carcinogenic potential of phthalic acid esters and related compounds: structure-activity relationships|journal=Environmental Health Perspectives|volume= 65|pages=271–278|year=1986|doi=10.2307/3430194|pmid=3709453|pmc=1474699|jstor=3430194}}</ref><ref>{{cite journal|url=http://www3.interscience.wiley.com/cgi-bin/abstract/69504565/ABSTRACT?CRETRY=1&SRETRY=0|author=Norbert H. Kleinsasser, Ernst R. Kastenbauer, Herbert Weissacher, Ruth K. Muenzenrieder, Ulrich A. Harréus|title=Phthalates demonstrate genotoxicity on human mucosa of the upper aerodigestive tract|journal=Environmental and Molecular Mutagenesis|volume= 35|issue=1|pages=9–12 |year=2000|doi=10.1002/(SICI)1098-2280(2000)35:1<9::AID-EM2>3.0.CO;2-1|pmid=10692222}}</ref><ref>{{cite journal|author=Walter J. Kozumbo, Rosanna Kroll, Robert J. Rubin|title=Assessment of the Mutagenicity of Phthalate Esters|journal=Environmental Health Perspectives|volime=45|pages=103–109|year=1982|volume=45|doi=10.2307/3429391|pmid=6754359|pmc=1568987|jstor=3429391}}</ref> | |||

| === |

=== Toys and hobbies === | ||

| ] | |||

| The strength and reliability of ] is widely acknowledged in the construction industry. | |||

| ] and similar materials are composed of silicones ], ], and ], with other ingredients. This substance is noted for its unusual characteristics, e.g., that it bounces, but breaks when given a sharp blow; it will also flow like a liquid and form a puddle given enough time. | |||

| Silicone "rubber bands" are a long-lasting popular replacement refill for real rubber bands in the 2013 fad "]" toys at two to four times the price (in 2014). Silicone bands also come in bracelet sizes that can be custom embossed with a name or message. Large silicone bands are also sold as utility tie-downs. | |||

| One-part silicone ]s and ]s are in common use to seal gaps, joints and crevices in buildings. One-part silicones cure by absorbing atmospheric moisture, which helps in the professional installation. | |||

| ] is a silicone rubber (marketed as ]) used as an arts-and-crafts material, as its plasticity allows it to be molded by hand like modeling clay. It hardens at room temperature and it is adhesive to various substances including glass and aluminum.<ref>{{Cite web|url=https://sugru.com/pdfs/tds.pdf"|title=Formerol/Sugru technical data sheet}}</ref> | |||

| In plumbing, silicone grease is typically applied to O-rings in ] ], preventing ] from sticking to the metal. | |||

| ] is an inexpensive silicone clay, which can be used as a substitute for ].<ref>{{Cite web|url=https://www.instructables.com/How-To-Make-Your-Own-Sugru-Substitute/|title=How to Make Your Own Sugru Substitute|website=Instructables}}</ref> | |||

| ===Toys=== | |||

| Silicone balls have become a ]'s favorite due to the high bounce back, and are used as a response system in low-response ]s.<ref>{{cite web|url=http://yoyowiki.org/Response_Systems#Silicone|title=Silicone as a response}}</ref> | |||

| In making ]s, manufacturers now commonly use 100% silicone sealant to join glass plates. Glass joints made with silicone sealant can withstand great pressure, making obsolete the original aquarium construction method of angle-iron and putty. This same silicone is used to make hinges in aquarium lids or for minor repairs. However, not all commercial silicones are safe for aquarium manufacture, nor is silicone used for the manufacture of acrylic aquariums as silicones do not have long-term adhesion to plastics.<ref>{{cite web |url=http://www.aquarium-pond-answers.com/2007/03/aquarium-silicone.html |title=Aquarium Silicone Applications |publisher=Aquarium-pond-answers.com |date=March 2007 |access-date=2012-02-28 |url-status=live |archive-url=https://web.archive.org/web/20120315074424/http://www.aquarium-pond-answers.com/2007/03/aquarium-silicone.html |archive-date=2012-03-15 }}</ref> | |||

| ] (a ] product) and similar materials include the silicones ], ], and ], with other ingredients. This substance is noted for its unusual characteristics: It bounces, but breaks when given a sharp blow; it can also flow like a liquid, and will form a puddle given enough time. | |||

| === Special Effects === | |||

| Silicone has the potential of replacing plastic in creating many forms of toys. | |||

| Silicone is used in ] as a material for simulating realistic skin, either for ], prop body parts, or ].<ref>{{cite web |last1=Chant |first1=Justin |title=Unmasking the Chemistry Behind Special Effects Makeup |url=https://www.monarchchemicals.co.uk/Information/News-Events/979-/Unmasking-the-Chemistry-Behind-Special-Effects-Makeup |website=www.monarchchemicals.co.uk |access-date=29 July 2024 |language=en-gb}}</ref> Platinum silicones are ideal for simulating flesh and skin due to their strength, firmness, and translucency, creating a convincing effect. | |||

| Silicone masks have an advantage over latex masks in that because of the material properties, the mask hugs the wearers face and moves in a realistic manner with the wearer's facial expressions.<ref>{{cite web |last1=Chapman |first1=Kit |title=What are Halloween costume masks made from? |url=https://edu.rsc.org/everyday-chemistry/what-are-halloween-costume-masks-made-from/4015878.article |website=RSC Education |access-date=29 July 2024 |language=en}}</ref> Silicone is often used as a hypoallergenic substitute for ] prosthetics. | |||

| == Marketing == | |||

| ==Production and marketing== | |||

| The leading global manufacturers of silicone base materials belong to three regional organizations: the European Silicone Center (CES) in ]; the Silicones Environmental, Health, and Safety Center (SEHSC) in ], US; and the Silicone Industry Association of Japan (SIAJ) in ]. Dow Corning Silicones, Evonik Industries, Momentive Performance Materials, Milliken and Company (SiVance Specialty Silicones), Shin-Etsu Silicones, Wacker Chemie, Bluestar Silicones, JNC Corporation, Wacker Asahikasei Silicone, and Dow Corning Toray represent the collective membership of these organizations. A fourth organization, the Global Silicone Council (GSC) acts as an umbrella structure over the regional organizations. All four are non-profit, having no commercial role; their primary missions are to promote the safety of silicones from a health, safety, and environmental perspective. As the European chemical industry is preparing to implement the ], CES is leading the formation of a consortium<ref>{{cite web |url=http://reach.silicones.eu/ |title=REACH consortium |publisher=Reach.silicones.eu |access-date=2012-02-28 |url-status=dead |archive-url=https://web.archive.org/web/20120315074426/http://reach.silicones.eu/ |archive-date=2012-03-15 }}</ref> of silicones, silanes, and siloxanes producers and importers to facilitate data and cost-sharing. | |||

| The global demand on silicones approached US$ 12.5 billion in 2008, approximately 4% up from the previous year. It continues similar growth in the following years to reach US$13.5 billion by 2010. The annual growth is expected to rebound to 7% when the economy revives, boosted by broader applications, introduction of novel products and increasing awareness of using more environmentally friendly materials.<ref>{{cite web|title=Market Report: World Silicone Market|publisher=|url=http://www.acmite.com/market-reports/chemicals/world-silicone-market.html}}</ref> | |||

| == Safety and environmental considerations == | |||

| The leading global manufacturers of silicone base materials belong to three regional organizations: the in ]; the in ], USA; and the in ]. A fourth organization, the acts as an umbrella structure over the regional organizations. All four are non-profit, having no commercial role; their primary missions are to promote the safety of silicones from a health, safety, and environmental perspective. As the European chemical industry is preparing to implement the ], CES is leading the formation of a consortium<ref></ref> of silicones, silanes, and siloxanes producers and importers to facilitate data and cost sharing. | |||

| Silicone compounds are pervasive in the environment. Particular silicone compounds, cyclic siloxanes ] and ], are air and water pollutants and have negative health effects on test animals.<ref>{{cite news|last1=Bienkowski|first1=Brian|title=Chemicals from Personal Care Products Pervasive in Chicago Air|url=http://www.scientificamerican.com/article/chemicals-from-personal-care-products-pervasive-in-chicago-air/|access-date=8 April 2015|work=Scientific American|date=30 April 2013|url-status=live|archive-url=https://web.archive.org/web/20150620142403/http://www.scientificamerican.com/article/chemicals-from-personal-care-products-pervasive-in-chicago-air/|archive-date=20 June 2015}}</ref> They are used in various personal care products. The European Chemicals Agency found that "D<sub>4</sub> is a persistent, bioaccumulative and toxic (PBT) substance and D<sub>5</sub> is a very persistent, very bioaccumulative (vPvB) substance".<ref>{{cite web |last1=European Chemicals Agency |title=Committee for Risk Assessment concludes on restricting D4 and D5 |url=https://echa.europa.eu/-/committee-for-risk-assessment-concludes-on-restricting-d4-and-d5 |publisher=European Chemicals Agency |access-date=28 August 2018}}</ref><ref>{{cite web |title=ECHA classifies cyclic siloxanes as SVHCs |date=25 June 2018 |url=https://www.foodpackagingforum.org/news/echa-classifies-cyclic-siloxanes-as-svhcs |publisher=] Foundation |access-date=28 August 2018}}</ref> Other silicones biodegrade readily, a process that is accelerated by a variety of catalysts, including clays.<ref name=Ullmann/> Cyclic silicones have been shown to involve the occurrence of ]s during biodegradation in mammals.{{clarify|date=May 2023}}<ref>S. Varaprath, K. L. Salyers, K. P. Plotzke and S. Nanavati: "Identification of Metabolites of Octamethylcyclotetrasiloxane (D4) in Rat Urine", Drug Metab Dispos 1999, 27, 1267-1273.</ref> The resulting silanediols and silanetriols are capable of inhibiting hydrolytic enzymes such as ], ]. However, the doses required for inhibition are by orders of magnitude higher than the ones resulting from the accumulated exposure to consumer products containing ].<ref>], T. Nittoli, A. M. Mutahi and L. Guo: ''Silanediols: a new class of potent protease inhibitors'', Angew. Chem. Int. Ed. 1998, volume 37, 812-814.</ref><ref>M. Blunder, N. Hurkes, M. List, S. Spirk and R. Pietschnig: ''Silanetriols as in vitro AChE Inhibitors'', Bioorg. Med. Chem. Lett. 2011, volume 21, 363-365.</ref> | |||

| At around {{convert|200|C}} in an oxygen-containing atmosphere, polydimethylsiloxane releases traces of ] (but lesser amounts than other common materials such as polyethylene<ref>{{cite web |first=Dave|last=Hard |url=http://apps.geindustrial.com/publibrary/checkout/Dielectric?TNR=White%20Papers%7CDielectric%7Cgeneric |title=Dielectric Fluids for Transformer Cooling — History and Types|archive-url=https://web.archive.org/web/20160719194959/http://apps.geindustrial.com/publibrary/checkout/Dielectric?TNR=White%20Papers%7CDielectric%7Cgeneric |archive-date=2016-07-19 |url-status=live |publisher=]}}</ref><ref name="tl">David C. Timpe Jr. {{webarchive|url=https://web.archive.org/web/20150427124801/https://imageserv5.team-logic.com/mediaLibrary/99/Formaldehyde_Generation_from_Silicone_Rubber.pdf |date=2015-04-27 }} Arlon</ref>). At this temperature, silicones were found to have lower formaldehyde generation than ] and ]s (less than 3 to 48 μg CH<sub>2</sub>O/(g·hr) for a high consistency ], versus around 400 μg CH<sub>2</sub>O/(g·hr) for plastics and mineral oil). By {{convert|250|C}}, copious amounts of formaldehyde have been found to be produced by all silicones (1,200 to 4,600 μg CH<sub>2</sub>O/(g·hr)).<ref name="tl"/> | |||

| ==See also== | |||

| {{colbegin}} | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| {{colend}} | |||

| == |

== See also == | ||

| * ] | |||

| {{Reflist|2}} | |||

| == |

== References == | ||

| {{reflist|30em}} | |||

| {{Commons category|Silicones}} | |||

| {{Commons category|Caulking}} | |||

| == External links == | |||

| {{Portal|Toys}} | |||

| {{Wiktionary}} | {{Wiktionary}} | ||

| * {{Commons category-inline}} | |||

| * | |||

| * | |||

| * Representative ]'s Statements concerning flammable firestops | |||

| * | |||

| * (Virtual Chembook, Elmhurst College) | |||

| * (Silicone Science On-line, Centre Européen des Silicones - CES) | |||

| * | |||

| ] | |||

| ] | ] | ||

| ] | ] | ||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 22:36, 1 December 2024

Family of polymers of the repeating form Not to be confused with the chemical element silicon.| This article's lead section may be too short to adequately summarize the key points. Please consider expanding the lead to provide an accessible overview of all important aspects of the article. (July 2024) |

In organosilicon and polymer chemistry, a silicone or polysiloxane is a polymer composed of repeating units of siloxane (−O−R2Si−O−SiR2−, where R = organic group). They are typically colorless oils or rubber-like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil, grease, rubber, resin, and caulk.

Chemistry

Main article: Organosilicon compound

Alfred Stock and Carl Somiesky examined the hydrolysis of dichlorosilane, a reaction that was proposed to initially give the monomer H2SiO: When the hydrolysis is performed by treating a solution of H2SiCl2 in benzene with water, the product was determined to have the approximate formula [H2SiO]6. Higher polymers were proposed to form with time.

Most polysiloxanes feature organic substituents, e.g., [(CH3)2SiO]n and [(C6H5)2SiO)]n. All polymerized siloxanes or polysiloxanes, silicones consist of an inorganic silicon–oxygen backbone chain (···−Si−O−Si−O−Si−O−···) with two groups attached to each silicon center. The materials can be cyclic or polymeric. By varying the −Si−O− chain lengths, side groups, and crosslinking, silicones can be synthesized with a wide variety of properties and compositions. They can vary in consistency from liquid to gel to rubber to hard plastic. The most common siloxane is linear polydimethylsiloxane (PDMS), a silicone oil. The second-largest group of silicone materials is based on silicone resins, which are formed by branched and cage-like oligosiloxanes.

Terminology and history

F. S. Kipping coined the word silicone in 1901 to describe the formula of polydiphenylsiloxane, Ph2SiO (Ph = phenyl, C6H5), by analogy with the formula of the ketone benzophenone, Ph2CO (his term was originally silicoketone). Kipping was well aware that polydiphenylsiloxane is polymeric whereas benzophenone is monomeric and noted the contrasting properties of Ph2SiO and Ph2CO. The discovery of the structural differences between Kipping's molecules and the ketones means that silicone is no longer the correct term (though it remains in common usage) and that the term siloxane is preferred according to the nomenclature of modern chemistry.

James Franklin Hyde (born 11 March 1903) was an American chemist and inventor. He has been called the "Father of Silicones" and is credited with the launch of the silicone industry in the 1930s. His most notable contributions include his creation of silicone from silicon compounds and his method of making fused silica, a high-quality glass later used in aeronautics, advanced telecommunications, and computer chips. His work led to the formation of Dow Corning, an alliance between the Dow Chemical Company and Corning Glass Works that was specifically created to produce silicone products.

Silicone is often confused with silicon, but they are distinct substances. Silicon is a chemical element, a hard dark-grey semiconducting metalloid, which in its crystalline form is used to make integrated circuits ("electronic chips") and solar cells. Silicones are compounds that contain silicon, carbon, hydrogen, oxygen, and perhaps other kinds of atoms as well, and have many very different physical and chemical properties.

Compounds containing silicon–oxygen double bonds, now called silanones, but which could deserve the name "silicone", have long been identified as intermediates in gas-phase processes such as chemical vapor deposition in microelectronics production, and in the formation of ceramics by combustion. However, they have a strong tendency to polymerize into siloxanes. The first stable silanone was obtained in 2014 by A. Filippou and others.

Synthesis

Most common are materials based on polydimethylsiloxane, which is derived by hydrolysis of dimethyldichlorosilane. This dichloride reacts with water as follows:

The polymerization typically produces linear chains capped with Si−Cl or Si−OH (silanol) groups. Under different conditions, the polymer is a cyclic, not a chain.

For consumer applications such as caulks, silyl acetates are used instead of silyl chlorides. The hydrolysis of the acetates produces the less dangerous acetic acid (the acid found in vinegar) as the reaction product of a much slower curing process. This chemistry is used in many consumer applications, such as silicone caulk and adhesives.

Branches or crosslinks in the polymer chain can be introduced by using organosilicone precursors with fewer alkyl groups, such as methyl trichlorosilane and methyltrimethoxysilane. Ideally, each molecule of such a compound becomes a branch point. This process can be used to produce hard silicone resins. Similarly, precursors with three methyl groups can be used to limit molecular weight, since each such molecule has only one reactive site and so forms the end of a siloxane chain.

Combustion

When silicone is burned in air or oxygen, it forms solid silica (silicon dioxide, SiO2) as a white powder, char, and various gases. The readily dispersed powder is sometimes called silica fume. The pyrolysis of certain polysiloxanes under an inert atmosphere is a valuable pathway towards the production of amorphous silicon oxycarbide ceramics, also known as polymer derived ceramics. Polysiloxanes terminated with functional ligands such as vinyl, mercapto or acrylate groups have been cross linked to yield preceramic polymers, which can be photopolymerised for the additive manufacturing of polymer derived ceramics by stereolithography techniques.

Properties

Silicones exhibit many useful characteristics, including:

- Low thermal conductivity

- Low chemical reactivity

- Low toxicity

- Thermal stability (constancy of properties over a wide temperature range of −100 to 250 °C)

- The ability to repel water and form watertight seals.

- Does not stick to many substrates, but adheres very well to others, e.g. glass

- Does not support microbiological growth

- Resistance to creasing and wrinkling

- Resistance to oxygen, ozone, and ultraviolet (UV) light. This property has led to the widespread use of silicones in the construction industry (e.g. coatings, fire protection, glazing seals) and the automotive industry (external gaskets, external trim).

- Electrical insulation properties. Because silicone can be formulated to be electrically insulative or conductive, it is suitable for a wide range of electrical applications.

- High gas permeability: at room temperature (25 °C), the permeability of silicone rubber for such gases as oxygen is approximately 400 times that of butyl rubber, making silicone useful for medical applications in which increased aeration is desired. Conversely, silicone rubbers cannot be used where gas-tight seals are necessary such as seals for high-pressure gasses or high vacuum.

Silicone can be developed into rubber sheeting, where it has other properties, such as being FDA compliant. This extends the uses of silicone sheeting to industries that demand hygiene, for example, food and beverage, and pharmaceuticals.

Applications

Silicones are used in many products. Ullmann's Encyclopedia of Industrial Chemistry lists the following major categories of application: Electrical (e.g. insulation), electronics (e.g., coatings), household (e.g., sealants and cooking utensils), automobile (e.g. gaskets), airplane (e.g., seals), office machines (e.g. keyboard pads), medicine and dentistry (e.g. tooth impression molds), textiles and paper (e.g. coatings). For these applications, an estimated 400,000 tonnes of silicones were produced in 1991. Specific examples, both large and small are presented below.

Automotive

In the automotive field, silicone grease is typically used as a lubricant for brake components since it is stable at high temperatures, is not water-soluble, and is far less likely than other lubricants to foul. DOT 5 brake fluids are based on liquid silicones.

Automotive spark plug wires are insulated by multiple layers of silicone to prevent sparks from jumping to adjacent wires, causing misfires. Silicone tubing is sometimes used in automotive intake systems (especially for engines with forced induction).

Sheet silicone is used to manufacture gaskets used in automotive engines, transmissions, and other applications.

Automotive body manufacturing plants and paint shops avoid silicones, as trace contamination may cause "fish eyes", which are small, circular craters which mar a smooth finish.

Additionally, silicone compounds such as silicone rubber are used as coatings and sealants for airbags; the high strength of silicone rubber makes it an optimal adhesive and sealant for high impact airbags. Silicones in combination with thermoplastics provide improvements in scratch and mar resistance and lowered coefficient of friction.

Aerospace

Silicone is a widely used material in the aerospace industry due to its sealing properties, stability across an extreme temperature range, durability, sound dampening and anti-vibration qualities, and naturally flame retardant properties. Maintaining extreme functionality is paramount for passenger safety in the aerospace industry, so each component on an aircraft requires high-performance materials.

Specially developed aerospace grades of silicone are stable from −70 to 220 °C, these grades can be used in the construction of gaskets for windows and cabin doors. During operation, aircraft go through large temperature fluctuations in a relatively short period of time; from the ambient temperatures when on the ground in hot countries to sub-zero temperatures when flying at high altitude. Silicone rubber can be molded with tight tolerances ensuring gaskets form airtight seals both on the ground and in the air, where atmospheric pressure decreases.

Silicone rubber's resistance to heat corrosion enables it to be used for gaskets in aircraft engines where it will outlast other types of rubber, both improving aircraft safety and reducing maintenance costs. The silicone acts to seal instrument panels and other electrical systems in the cockpit, protecting printed circuit boards from the risks of extreme altitude such as moisture and extremely low temperature. Silicone can be used as a sheath to protect wires and electrical components from any dust or ice that may creep into a plane's inner workings.

As the nature of air travel results in much noise and vibration, powerful engines, landings, and high speeds all need to be considered to ensure passenger comfort and safe operation of the aircraft. As silicone rubber has exceptional noise reduction and anti-vibration properties, it can be formed into small components and fitted into small gaps ensuring all equipment can be protected from unwanted vibration such as overhead lockers, vent ducts, hatches, entertainment system seals, and LED lighting systems.

Solid propellant

Polydimethylsiloxane (PDMS) based binders along with ammonium perchlorate (NH4ClO4) are used as fast burning solid propellants in rockets.

Building construction

The strength and reliability of silicone rubber are widely acknowledged in the construction industry. One-part silicone sealants and caulks are in common use to seal gaps, joints and crevices in buildings. One-part silicones cure by absorbing atmospheric moisture, which simplifies installation. In plumbing, silicone grease is typically applied to O-rings in brass taps and valves, preventing lime from sticking to the metal.

Structural silicone has also been used in curtain wall building façades since 1974 when the Art Institute of Chicago became the first building to receive exterior glass fixed only with the material. Silicone membranes have been used to cover and restore industrial roofs, thanks to its extreme UV resistance, and ability to keep their waterproof performance for decades.

3D printing

Silicone rubber can be 3D printed (liquid deposition modelling, LDM) using pump-nozzle extrusion systems. Standard silicone formulations are optimized to be used by extrusion and injection moulding machines and are not applicable in LDM-based 3D printing. The rheological behavior and the pot life need to be adjusted for use with LDM.

3D printing also requires the use of a removable support material that is compatible with the silicone rubber.

Coatings

Silicone films can be applied to such silica-based substrates as glass to form a covalently bonded hydrophobic coating. Such coatings were developed for use on aircraft windshields to repel water and to preserve visibility, without requiring mechanical windshield wipers which are impractical at supersonic speeds. Similar treatments were eventually adapted to the automotive market in products marketed by Rain-X and others.

Many fabrics can be coated or impregnated with silicone to form a strong, waterproof composite such as silnylon.

A silicone polymer can be suspended in water by using stabilizing surfactants. This allows water-based formulations to be used to deliver many ingredients that would otherwise require a stronger solvent, or be too viscous to use effectively. For example, a waterborne formulation using a silane's reactivity and penetration ability into a mineral-based surface can be combined with water-beading properties from a siloxane to produce a more-useful surface protection product.

Cookware

As a low-taint, non-toxic material, silicone can be used where contact with food is required. Silicone is becoming an important product in the cookware industry, particularly bakeware and kitchen utensils. Silicone is used as an insulator in heat-resistant potholders and similar items; however, it is more conductive of heat than similar less dense fiber-based products. Silicone oven gloves are able to withstand temperatures up to 260 °C (500 °F), making it possible to reach into boiling water.

Other products include molds for chocolate, ice, cookies, muffins, and various other foods; non-stick bakeware and reusable mats used on baking sheets; steamers, egg boilers or poachers; cookware lids, pot holders, trivets, and kitchen mats.

-

Soup ladle and pasta ladle made of silicone

Soup ladle and pasta ladle made of silicone

-

A silicone food steamer to be placed inside a pot of boiling water

A silicone food steamer to be placed inside a pot of boiling water

-

Flexible ice cube trays made of silicone allow easy extraction of ice.

Flexible ice cube trays made of silicone allow easy extraction of ice.

-

Silicone brush used for basting and applying flavoring liquids

Silicone brush used for basting and applying flavoring liquids

Defoaming

Silicones are used as active compounds in defoamers due to their low water solubility and good spreading properties.

Dry cleaning

Liquid silicone can be used as a dry cleaning solvent, providing an alternative to the traditional chlorine-containing perchloroethylene (perc) solvent. The use of silicones in dry cleaning reduces the environmental effect of a typically high-polluting industry.

Electronics

Electronic components are sometimes encased in silicone to increase stability against mechanical and electrical shock, radiation and vibration, a process called "potting". Silicones are used where durability and high performance are demanded of components under extreme environmental conditions, such as in space (satellite technology). They are selected over polyurethane or epoxy encapsulation when a wide operating temperature range is required (−65 to 315 °C). Silicones also have the advantage of little exothermic heat rise during cure, low toxicity, good electrical properties, and high purity.

Silicones are often components of thermal pastes used to improve heat transfer from power-dissipating electronic components to heat sinks.

The use of silicones in electronics is not without problems, however. Silicones are relatively expensive and can be attacked by certain solvents. Silicone easily migrates as either a liquid or vapor onto other components. Silicone contamination of electrical switch contacts can lead to failures by causing an increase in contact resistance, often late in the life of the contact, well after any testing is completed. Use of silicone-based spray products in electronic devices during maintenance or repairs can cause later failures.

Firestops

Silicone foam has been used in North American buildings in an attempt to firestop openings within the fire-resistance-rated wall and floor assemblies to prevent the spread of flames and smoke from one room to another. When properly installed, silicone-foam firestops can be fabricated for building code compliance. Advantages include flexibility and high dielectric strength. Disadvantages include combustibility (hard to extinguish) and significant smoke development.

Silicone-foam firestops have been the subject of controversy and press attention due to smoke development from pyrolysis of combustible components within the foam, hydrogen gas escape, shrinkage, and cracking. These problems have led to reportable events among licensees (operators of nuclear power plants) of the Nuclear Regulatory Commission (NRC).

Silicone firestops are also used in aircraft.

Jewelry

Silicone is a popular alternative to traditional metals (such as silver and gold) with jewelry, specifically rings. Silicone rings are commonly worn in professions where metal rings can lead to injuries, such as electrical conduction and ring avulsions. During the mid-2010's, some professional athletes began wearing silicone rings as an alternative during games.

Lubricants

Silicone greases are used for many purposes, such as bicycle chains, airsoft gun parts, and a wide range of other mechanisms. Typically, a dry-set lubricant is delivered with a solvent carrier to penetrate the mechanism. The solvent then evaporates, leaving a clear film that lubricates but does not attract dirt and grit as much as an oil-based or other traditional "wet" lubricant.

Silicone personal lubricants are also available for use in medical procedures or sexual activity.

Medicine and cosmetic surgery

Silicone is used in microfluidics, seals, gaskets, shrouds, and other applications requiring high biocompatibility. Additionally, the gel form is used in bandages and dressings, breast implants, testicle implants, pectoral implants, contact lenses, and a variety of other medical uses.

Scar treatment sheets are often made of medical grade silicone due to its durability and biocompatibility. Polydimethylsiloxane (PDMS) is often used for this purpose, since its specific crosslinking results in a flexible and soft silicone with high durability and tack. It has also been used as the hydrophobic block of amphiphilic synthetic block copolymers used to form the vesicle membrane of polymersomes.

Illicit cosmetic silicone injections may induce chronic and definitive silicone blood diffusion with dermatologic complications.

Ophthalmology uses many products such as silicone oil used to replace the vitreous humor following vitrectomy, silicone intraocular lenses following cataract extraction, silicone tubes to keep a nasolacrimal passage open following dacryocystorhinostomy, canalicular stents for canalicular stenosis, punctal plugs for punctal occlusion in dry eyes, silicone rubber and bands as an external tamponade in tractional retinal detachment, and anteriorly-located break in rhegmatogenous retinal detachment.

Addition and condensation (e.g. polyvinyl siloxane) silicones find wide application as a dental impression material due to its hydrophobic property and thermal stability.

Moldmaking