| Revision as of 17:27, 7 January 2007 editJmax- (talk | contribs)910 editsm Reverted edits by 84.235.57.164 to last version by 140.247.154.14← Previous edit | Latest revision as of 06:17, 23 December 2024 edit undoProgüvo06 (talk | contribs)Extended confirmed users15,019 editsNo edit summaryTags: Mobile edit Mobile web edit | ||

| Line 1: | Line 1: | ||

| {{Short description|Plant grown commercially for sugar production}} | |||

| ] | |||

| {{more citations needed|date = February 2021}} | |||

| '''Sugar beet''' (''Beta vulgaris'' L.), a member of the '']'' subfamily and the '']'' family, is a plant whose root contains a high concentration of ]. It is grown commercially for ]. | |||

| {{Infobox cultivar | |||

| | name = Sugar beet | |||

| | image = 276 Beta vulgaris L.jpg | |||

| | image_caption = Sugar beet, illustration of root, leaf, and flowering patterns | |||

| | species = '']'' | |||

| | subspecies = ] | |||

| | group = Altissima Group | |||

| | origin = ], mid-18th century | |||

| }} | |||

| A '''sugar beet''' is a plant whose root contains a high concentration of ] and that is grown commercially for ] production. In plant breeding, it is known as the Altissima ] of the common beet ('']'').<ref name="MMPND" /> Together with other beet cultivars, such as ] and ], it belongs to the subspecies ''Beta vulgaris'' subsp. ''vulgaris'' but classified as ''var. saccharifera''. Its closest wild relative is the ] (''Beta vulgaris'' subsp. ''maritima'').<ref name=springer/> | |||

| The sugar beet is directly related to the beetroot, ] and fodder beet, all descended by cultivation from the ]. | |||

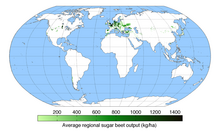

| Sugar beets are grown in climates that are too cold for ]. In 2020, Russia, the United States, Germany, France and Turkey were the world's five largest sugar beet producers.<ref name=fao/> In 2010–2011, Europe, and North America except Arctic territories failed to supply the overall domestic demand for sugar and were all net importers of sugar.<ref name=usda/> The US harvested {{convert|1,004,600|acre|ha|0}} of sugar beets in 2008.<ref name=usda2/> In 2009, sugar beets accounted for 20% of the world's sugar production<ref name=agrisugar1/> and nearly 30% by 2013.<ref name="Dohm-et-al-2013" /> ] accounts for most of the rest of ]. In February 2015, a USDA factsheet reported that sugar beets generally account for about 55 percent of domestically produced sugar, and sugar cane for about 45 percent.<ref name="usda4" /> | |||

| The ], the ], and ] are the world's three largest sugar beet producers, although only ] and ] are significant exporters of sugar from beet. Beet sugar accounts for 30% of the world's sugar production. | |||

| == Description == | |||

| The sugar beet has a conical, white, fleshy root (a ]) with a flat crown. The plant consists of the root and a rosette of leaves. Sugar is formed by ] in the leaves and is then stored in the root. | |||

| The root of the beet contains 75% water, about 20%<ref name="Dohm-et-al-2013" /> sugar, and 5% ].<ref name=respons/> The exact sugar content can vary between 12% and 21%, depending on the cultivar and growing conditions. Sugar is the primary value of sugar beet as a ]. The pulp, ] in water and mainly composed of ], hemicellulose, ], and ], is used in animal feed. The byproducts of the sugar beet crop, such as pulp and ], add another 10% to the value of the harvest.<ref name=agrisugar1/> | |||

| Sugar beets grow exclusively in the ] zone, in contrast to ], which grows exclusively in the tropical and subtropical zones. The average weight of a sugar beet ranges between {{convert|0.5|and|1|kg|lb|abbr=on}}. Sugar beet foliage has a rich, brilliant green color and grows to a height of about {{convert|35|cm|inch|abbr=on}}. The leaves are numerous and broad and grow in a tuft from the crown of the beet, which is usually level with or just above the ground surface.<ref name=gr1/> | |||

| == History of the sugar beet == | |||

| === Discovery of beet sugar === | |||

| {{Main|Beta vulgaris}} | |||

| ] | |||

| ] | |||

| The species beet consists of several cultivar groups. The 16th-century French scientist ] discovered a process for preparing sugar syrup from (red) ]. He wrote: "The beet-root, when being boiled, yields a juice similar to syrup of sugar, which is beautiful to look at on account of its ] colour"<ref name=worldcat/> (1575).<ref name="histoire" /> Because crystallized cane sugar was already available and had a better taste, this process did not become popular. | |||

| Modern sugar beets date to the mid-18th century ] where ], king of ], subsidized experiments to develop processes for sugar extraction.<ref name="Langer" /><ref name="ucdsugar" /> In 1747, ], professor of physics in the Academy of Science of Berlin, isolated sugar from beetroots and found them at concentrations of 1.3–1.6%.<ref name="Mansfeld" /> He also demonstrated that the sugar that could be extracted from beets was identical to that produced from cane.<ref name="ucdsugar"/> He found the best of these vegetable sources for sugar was the white beet.<ref name=margg/> Despite Marggraf's success in isolating sugar from beets, it did not lead to commercial sugar production. | |||

| === Development of the sugar beet === | |||

| Marggraf's student and successor ] began ] sugar beet in ] near Berlin in 1786.<ref name="Doering" /> Achard started his plant breeding by evaluating 23 varieties of beet for sugar content.<ref name="Louisiana" /> In the end he selected a local strain from ] in modern-day ], Germany. Moritz Baron von Koppy and his son further selected white, conical tubers from this strain.<ref name="Mansfeld" /> The selection was named ''weiße schlesische Zuckerrübe'', meaning white Silesian sugar beet.<ref name="Doering" /> In about 1800, this cultivar boasted about 5–6% sucrose by (dry) weight.<ref name="Birnbaum" /> It would go on to be the progenitor of all modern sugar beets.<ref name="Doering" /> The plant breeding process has continued since then, leading to a sucrose content of around 18% in modern varieties.<ref name="Dohm-et-al-2013" /> | |||

| === History of the beet sugar industry === | |||

| {{Main|Beet sugar factory}} | |||

| Franz Karl Achard opened the world's first ] in 1801, at ], ] (now Konary, Poland).<ref name=gr1/> The idea to produce sugar from beet was soon introduced to France, whence the European sugar beet industry rapidly expanded. By 1840, about 5% of the world's sugar was derived from sugar beets, and by 1880, this number had risen more than tenfold to over 50%.<ref name="Langer" /> In North America, the first commercial production started in 1879 at a farm in ].<ref name="ucdsugar"/><ref name="Mansfeld" /> The sugar beet was introduced to ] by German settlers around 1850.<ref name="Mansfeld" /> | |||

| == Culture == | == Culture == | ||

| ] | |||

| Sugar beet is a hardy ] that can be grown commercially in a wide variety of temperate climates. During its first growing season, it produces a large (1–2 kg) storage root whose dry ] is 15–20% ] by ]. If not harvested, during its second growing season, the nutrients in this root are consumed to produce the plant's ]s and ]s. In commercial beet production, the root is harvested after the first growing season, when the root is at its maximum size. | |||

| ] | |||

| ] | |||

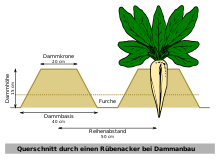

| The sugar beet, like ], needs a particular ] and a proper climate for its successful cultivation. The most important requirements are that the soil must contain a large supply of nutrients, be rich in ], and be able to contain a great deal of moisture. A certain amount of ] is not necessarily detrimental, as sugar beets are not especially susceptible to injury by some alkali. The ground should be fairly level and well-drained, especially where ] is practiced.<ref name=gr1/> | |||

| Generous crops can be grown in both sandy soil and heavy ]s, but the ideal soil is a sandy loam, i.e., a mixture of organic matter, clay and sand. A subsoil of gravel, or the presence of ], is not desirable, as cultivation to a depth of from {{convert|12|to|15|in|cm|0}} is necessary to produce the best results. | |||

| Climatic conditions, temperature, sunshine, rainfall and winds have an important bearing upon the success of sugar beet agriculture. A temperature ranging from {{convert|15|to|21|°C|°F|0}} during the growing months is most favorable. In the absence of adequate irrigation, {{convert|460|mm|in|0|abbr=in}} of rainfall are necessary to raise an average crop. High winds are harmful, as they generally crust the land and prevent the young beets from coming through the ground. The best results are obtained along the coast of southern California, where warm, sunny days succeeded by cool, foggy nights seem to meet sugar beet's favored growth conditions. Sunshine of long duration but not of great intensity is the most important factor in the successful cultivation of sugar beets. Near the equator, the shorter days and the greater heat of the sun sharply reduce the sugar content in the beet.<ref name=gr1/> | |||

| In high elevation regions such as those of Idaho, Colorado and Utah, where the temperature is high during the daytime, but where the nights are cool, the quality of the sugar beet is excellent. In ], the long summer days from the relatively high latitude (the ], where production is concentrated, lies between the 41st and 46th parallels North) and the influence of the Great Lakes result in satisfactory climatic conditions for sugar beet culture. ], lies in ] region of Michigan; both the region and state are major sugar beet producers. Sebewaing is home to one of four ] factories. The town sponsors an annual Michigan Sugar Festival.<ref name=voices/>{{unreliable source?|date=September 2015}} | |||

| To cultivate beets successfully, the land must be properly prepared. Deep ploughing is the first principle of beet culture. It allows the roots to penetrate the subsoil without much obstruction, thereby preventing the beet from growing out of the ground, besides enabling it to extract considerable nourishment and moisture from the lower soil. If the latter is too hard, the roots will not penetrate it readily and, as a result, the plant will be pushed up and out of the earth during the process of growth. A hard subsoil is impervious to water and prevents proper drainage. It should not be too loose, however, as this allows the water to pass through more freely than is desirable. Ideally, the soil should be deep, fairly fine and easily penetrable by the roots. It should also be capable of retaining moisture and at the same time admit of a free circulation of air and good drainage. Sugar beet crops exhaust the soil rapidly. Crop rotation is recommended and necessary. Normally, beets are grown in the same ground every third year, peas, beans or grain being raised the other two years.<ref name=gr1/> | |||

| In most ] climates, beets are planted in the spring and harvested in the autumn. At the northern end of its range, growing seasons as short as 100 days can produce commercially viable sugar beet crops. In warmer climates, such as in ]'s ], sugar beets are a winter crop, planted in the autumn and harvested in the spring. In recent years, ] has developed the so-called tropical sugar beet. It allows the plant to grow in tropical and subtropical regions. Beets are planted from a small seed; {{convert|1|kg|lb|abbr=on}} of beet seed comprises 100,000 seeds and will plant over {{convert|1|ha|acre|spell=in}} of ground ({{convert|1|lb|kg|2|spell=in|disp=or}} will plant about {{convert|1|acre|ha|spell=in|disp=or}}. | |||

| Until the latter half of the 20th century, sugar beet production was highly labor-intensive, as weed control was managed by densely planting the crop, which then had to be manually thinned two or three times with a ] during the growing season. Harvesting also required many workers. Although the roots could be lifted by a ]-like device that could be pulled by a horse team, the rest of the preparation was by hand. One laborer grabbed the beets by their leaves, knocked them together to shake free loose soil, and then laid them in a row, root to one side, greens to the other. A second worker equipped with a beet hook (a short-handled tool between a ] and a ]) followed behind, and would lift the beet and swiftly chop the crown and leaves from the root with a single action. Working this way, he would leave a row of beets that could be forked into the back of a ]. | |||

| Today, mechanical sowing, ] application for weed control, and mechanical harvesting have displaced this reliance on manual farm work. A root beater uses a series of blades to chop the leaf and crown (which is high in nonsugar impurities) from the root. The ] lifts the root, and removes excess soil from the root in a single pass over the field. A modern harvester is typically able to cover six rows at the same time. The beets are dumped into trucks as the harvester rolls down the field, and then delivered to the factory. The conveyor then removes more soil. | |||

| If the beets are to be left for later delivery, they are formed into ]. Straw bales are used to shield the beets from the weather. Provided the clamp is well built with the right amount of ventilation, the beets do not significantly deteriorate. Beets that freeze and then defrost, produce complex carbohydrates that cause severe production problems in the factory. In the UK, loads may be hand examined at the factory gate before being accepted. | |||

| In most ] climates, beets are planted in the spring and harvested in the autumn. At the northern end of its range, growing seasons as short as 100 days can produce commercially viable sugarbeet crops. In warmer climates, such as in ]'s ], sugarbeets are a winter crop, being planted in the autumn and harvested in the spring. Beets are planted from a small seed; 1 kg of beet seed comprises 100,000 seeds and will plant over a ] of ground (1 lb will plant about an ]). | |||

| In the US, the fall harvest begins with the first hard frost, which arrests ] and the further growth of the root. Depending on the local climate, it may be carried out over the course of a few weeks or be prolonged throughout the winter months. The harvest and processing of the beet is referred to as "the campaign", reflecting the organization required to deliver the crop at a steady rate to processing factories that run 24 hours a day for the duration of the harvest and processing (for the UK, the campaign lasts about five months). In the Netherlands, this period is known as {{Lang|nl|de bietencampagne}}, a time to be careful when driving on local roads in the area while the beets are being grown, because the naturally high ] content of the soil tends to cause slippery roads when soil falls from the trailers during transport. | |||

| Up until the latter half of the 20th century, sugarbeet production was highly labor-intensive, as weed control was managed by densely planting the crop, which then had to be manually thinned with a ] two or even three times during the growing season. Harvesting also required many workers. Although the roots could be lifted by a plough-like device which could be pulled by a horse team, the rest of the preparation was by hand. One laborer grabbed the beets by their leaves, knocked them together to shake free loose soil, and then laid them in a row, root to one side, greens to the other. A second worker equipped with a beet hook (a short handled tool something between a ] and a ]) followed behind, and would lift the beet and swiftly chop the crown and leaves from the root with a single action. Working this way he would leave a row of beet that could then be forked into the back of a cart. | |||

| ==Production statistics== | |||

| {| class="wikitable" align=left style="clear:left" | |||

| {| class="wikitable" | |||

| ! colspan=2|Top Ten Sugar Beet Producers - 2005<br>(million metric ton) | |||

| |+ Top ten sugar beet producers—2022 ]<ref name="faostat">{{cite web|url=http://www.fao.org/faostat/en/#data/QC|title=Sugar beet production in 2022, Crops/Regions/World list/Production Quantity/Year (pick lists)|date=2024|publisher=UN Food and Agriculture Organization, Corporate Statistical Database (FAOSTAT)|access-date=10 June 2024}}</ref> | |||

| ! Rank | |||

| ! Country | |||

| ! abbr="Production" | Production<br />(million tonnes) | |||

| |- | |- | ||

| | {{ |

| 1 || {{RUS}} || style="text-align:right;"| 48.9 | ||

| |- | |- | ||

| | {{ |

| 2 || {{FRA}} || style="text-align:right;" | 31.5 | ||

| |- | |- | ||

| | {{USA}} |

| 3 || {{USA}} || style="text-align:right;" | 29.6 | ||

| |- | |- | ||

| | {{ |

| 4 || {{DEU}} || style="text-align:right;" | 28.2 | ||

| |- | |- | ||

| | {{ |

| 5 || {{TUR}} || style="text-align:right;"| 19.0 | ||

| |- | |- | ||

| | {{ |

| 6 || {{POL}} || style="text-align:right;"| 14.2 | ||

| |- | |- | ||

| | {{ |

| 7 || {{EGY}} || style="text-align:right;" | 13.6 | ||

| |- | |- | ||

| | {{ |

| 9 || {{UKR}} || style="text-align:right;" | 9.9 | ||

| |- | |- | ||

| | {{ |

| 8 || {{CHN}} || style="text-align:right;"| 8.9 | ||

| |- | |- | ||

| | {{ |

| 10 || {{NLD}}|| style="text-align:right;" | 7.3 | ||

| |- | |- | ||

| |''' |

|'''Total''' || World || style="text-align:right;"| '''261.0''' | ||

| |- | |- | ||

| |colspan=2|''Source: <br>] (FAO)'' | |||

| |} | |} | ||

| ] | |||

| The world harvested {{convert|260998614|t|sigfig=4|sp=us}} of sugar beets in 2022. The world's largest producer was Russia, with a {{convert|48907753|t|sigfig=3|sp=us}} harvest.<ref name="faostat"/> The average yield of sugar beet crops worldwide was 60.8 tonnes per ].<ref name="faostat"/> | |||

| The most productive sugar beet farms in the world, in 2022, were in ], with a nationwide average yield of 106.2 tonnes per hectare.<ref name="faostat"/> | |||

| Today, mechanical sowing, ] application for weed control and mechanical harvesting has removed this reliance on workers. | |||

| ] farmers have achieved yields of about 160 tonnes per hectare and over 26 tonnes sugar per hectare. Imperial Valley farms benefit from high intensities of incident sunlight and intensive use of irrigation and fertilizers.<ref name=sasta/><ref name=farmg/> | |||

| ]Harvesting is now entirely mechanical. The ] chops the leaf and crown (which is high in non-sugar impurities) from the root, lifts the root, and removes excess soil from the root in a single pass over the field. A modern harvester is typically able to cover 6 rows at the same time. The beet is left in piles at the side of the field and then conveyed into a trailer for delivery to the factory. The conveyor removes more soil -a farmer would be penalised at the factory for excess soil in his load. | |||

| == From sugar beet to white sugar == | |||

| If beet is to be left for later delivery, it is formed into "clamps". Straw bales are used to shield the beet from the weather. Provided the clamp is well built with the right amount of ventilation, the beet does not significantly deteriorate. Beet that is frozen and then defrosts, produce complex carbohydrates that cause severe production problems in the factory. In the UK, loads may be hand examined at the factory gate before being accepted. | |||

| ] | |||

| In the US, the fall harvest begins with the first hard frost, which arrests ] and the further growth of the root. Depending on the local climate, it may be carried out in few weeks or be prolonged throughout the winter months. The harvest and processing of the beet is referred to as "the campaign", reflecting the organization required to deliver crop at a steady rate to processing factories that run 24 hours a day for the duration of the harvest and processing (for the UK the campaign lasts approx 5 months). In the Netherlands this period is known as "''de bietencampagne''", a time to be careful when driving local roads in the area the beets are grown. The reason for this is the naturally high ] content of the soil, causing slippery roads when soil falls from the trailers during transport. | |||

| Most sugar beet are used to create ]. This is done in a beet sugar factory, often abbreviated to sugar factory. Nowadays these usually also act as a sugar refinery, but historically the beet sugar factory produced raw sugar and the sugar refinery refined raw sugar to create white sugar. | |||

| == |

=== Sugar factory === | ||

| {{Main|Beet sugar factory}} | |||

| ===Reception=== | |||

| In the 1960s, beet sugar processing was described as consisting of these steps.<ref name="Montana1970" /> | |||

| ], ].]] | |||

| After harvesting the beet are hauled to the factory. Delivery in the UK is by hauler or, for local farmers, by tractor and trailer. Railways and boats were once used in the UK, but no longer. Some beet was carried by rail in the ], until the ] shutdown of sugar beet production in the country due to the end of subsidies. | |||

| * Harvesting and storage in a way that preserves the beet while they wait to be processed | |||

| Each load entering is weighed and sampled before tipping onto the reception area, typically a "flat pad" of concrete, where it is moved into large heaps. The beet sample is checked for | |||

| * Washing and scrubbing to remove soil and debris | |||

| * soil tare - the amount of non beet delivered | |||

| * Slicing the beet in small pieces called cossettes or chips | |||

| * crown tare - the amount of low sugar beet delivered | |||

| * Removing the sugar from the beet in an osmosis process, resulting in raw juice and beet pulp.<ref name="Montana1970" /> | |||

| * sugar content ("pol") - amount of sucrose in the crop | |||

| * nitrogen content - for recommending future fertilizer use to the farmer. | |||

| Nowadays, most sugar factories then refine the raw juice themselves, without moving it to a sugar refinery. The beet pulp is processed on site to become cattle fodder. | |||

| From these the actual sugar content of the load is calculated and the grower's payment determined. | |||

| === Sugar refinery === | |||

| The beet is moved from the heaps into a central channel or gulley where it is washed towards the processing plant. | |||

| {{Main|Sugar refinery}} | |||

| ] in ] ]] | |||

| The next steps to produce white sugar are not specific for producing sugar from sugar beet. They also apply to producing white sugar from sugar cane. As such, they belong to the sugar refining process, not to the beet sugar production process per se. | |||

| * Purification, the raw juice undergoes a chemical process to remove impurities and create thin juice.<ref name="Koyikkal2013" /> | |||

| ===Diffusion=== | |||

| * Evaporation, the thin juice is concentrated by evaporation to make a "thick juice", roughly 60% sucrose by weight. | |||

| After reception at the processing plant the beet roots are washed, mechanically sliced into thin strips called '''''cossettes''''', and passed to a machine called a diffuser to extract their sugar content into a water solution. | |||

| * Crystallization, by boiling under reduced pressure the sugar liquor is turned into crystals and remaining liquor.<ref name="sugarnutritionresource/refining-cane" /> | |||

| * Centrifugation, in a centrifuge the white sugar crystals are separated from the remaining sugar liquor.<ref name="silverwedge" /> | |||

| * The remaining liquor is then boiled and centrifuged, producing a lower grade of crystallised sugar (which is redissolved to feed the white sugar pans) and molasses.<ref name="silverwedge" /> | |||

| * Further sugar can be recovered from the molasses by methods such as the Steffen Process. | |||

| == Ethanol and alcohol == | |||

| Diffusers are long (many metres) vessels in which the beet slices go in one direction while hot water goes in the opposite direction. The movement may either be by a rotating screw or the whole unit rotates and the water and cossettes move through internal chambers. There are three common designs of diffuser, the horizontal rotating 'RT' (from "''Raffinière ]oise''", the manufacturer), inclined screw 'DDS' (''Det Danske Sukkerfabrik'')), or vertical screw "Tower". A less common design uses a moving belt of cossettes and water is pumped onto the top of the belt and pours through. In all cases the flow rates of cossettes and water are in the ratio one to two. Typically cossettes take about 90 minutes to pass through the diffuser, the water only 45 minutes. These are all ] methods that extract more sugar from the cossettes using less water than if they merely sat in a hot water tank. The liquid exiting the diffuser is called '''''raw juice'''''. The colour of raw juice varies from black to a dark red depending on the amount of oxidation which is itself dependent on diffuser design. | |||

| === From molasses === | |||

| The used cossettes, or '''''pulp''''', exits the diffuser at about 95% moisture but low sucrose content. Using ]es, the wet pulp is then pressed down to 75% moisture. This recovers additional sucrose in the liquid pressed out of the pulp, and reduces the energy needed to dry the pulp. The pressed pulp is dried and sold as animal feed, while the liquid pressed out of the pulp is combined with the raw juice or more often introduced into the diffuser at the appropriate point in the countercurrent process. | |||

| ]'', a sugar-beet-based alcohol from Czechia]] | |||

| There are two obvious methods to produce alcohol (]) from sugar beet. The first method produces alcohol as a byproduct of manufacturing sugar. It is about fermenting the sugar beet molasses that are left after (the second) centrifugation.<ref name="Levi1870" /> This strongly resembles the manufacture of ] from sugar cane molasses. In a number of countries, notably the ] and ], this analogy led to making a rum-like ] called '']''.<ref name="Czechs" /> On the ], a similar drink is made under the brand name ''Kobba Libre''. | |||

| === From sugar beet === | |||

| During diffusion there is a degree of breakdown of the sucrose into invert sugars and these can undergo further breakdown into acids. These breakdown products are not only losses of sucrose but also have knock-on effects reducing the final output of processed sugar from the factory. To limit (thermophilic) bacterial action the feed water may be dosed with ] and control of the feed water ] is also practised. There have been attempts at operating diffusion under alkaline conditions but the process has proven problematic - the improved sucrose extraction in the diffuser offset by processing problems in the next stages. | |||

| The second method to produce alcohol from sugar beet is to ferment the sugar beet themselves. I.e. without attempting to produce sugar. The idea to distill sugar from the beet came up soon after the first beet sugar factory was established.<ref name="Levi1870" /> Between 1852 and 1854 Champonnois devised a good system to distill alcohol from sugar beet.<ref name="Aligny1869" /> Within a few years a large sugar distilling industry was created in France.<ref name="Levi1870" /> The current process to produce alcohol by fermenting and distilling sugar beet consists of these steps:<ref name="TereosDistill" /> | |||

| * Adding ] milk | |||

| === Carbonatation=== | |||

| * ] and ] | |||

| The raw juice contains many impurities that must be removed before crystallisation. This is accomplished via ]. First, the juice is mixed with hot ] (a suspension of calcium hydroxide in water). This treatment ] a number of impurities, including ] ]s such as ], ], ] and ], which precipitate as their calcium salts and large organic molecules such as ]s, ]s and ]s, which aggregate in the presence of multivalent ]s. In addition, the alkaline conditions convert the simple sugars, ] and ], along with the amino acid ], to chemically stable ]s. Left untreated, these sugars and amines would eventually frustrate crystallization of the sucrose. | |||

| * ] in fermentation vats | |||

| * ] | |||

| * Dehydration, this results in Bioethanol | |||

| * ] | |||

| * Refining, the result is a highly pure alcohol | |||

| Large sugar beet distilleries remain limited to Europe. In 2023 ] had 8 beet sugar distilleries, located in France, Czechia and Romania.<ref name="Tereos8" /> | |||

| Next, ] is bubbled through the alkaline sugar solution, precipitating the lime as ] (]). The chalk particles entrap some impurities and ] others. A recycling process builds up the size of chalk particles and a natural ] occurs where the heavy particles settle out in tanks (clarifiers). A final addition of more carbon dioxide precipitates more calcium from solution; this is filtered off, leaving a cleaner golden light brown sugar solution called '''''thin juice'''''. | |||

| In many European countries rectified spirit from sugar beet is used to make ], e.g. ], ] etc.. | |||

| Before entering the next stage the thin juice may receive ] to modify the pH and sulphitation with a ]-based compound to reduce colour formation due to decomposition of monosaccharides under heat. | |||

| == |

== Other uses == | ||

| {{More citations needed section|date=February 2012}} | |||

| The thin juice, is concentrated via ] to make a '''''thick juice''''', roughly 60% sucrose by weight and similar in appearance to pancake syrup. Thick juice can be stored in tanks for later processing reducing load on the crystallization plant. | |||

| === |

=== Sugary syrup === | ||

| ] | |||

| The thick Juice is fed to the crystallisers, recycled sugar is dissolved into it and the resulting syrup is called "mother liquor". This is concentrated further by boiling under vacuum in large vessels and seeded with fine sugar crystals. These crystals grow, as sugar from the mother liquor forms around them. The resulting sugar crystal and syrup mix is called a ''massecuite'' (from ] "cooked mass"). The massecuite is passed to a ] where the liquid is removed from the sugar crystals. Remaining syrup is rinsed off with water and the crystals dried in a granulator using warm air. The remaining syrup is fed to another crystalliser from which a second batch of sugar is produced. This sugar ("raw") is of lower quality with a lot of colour and impurities and is the main source of the sugar that is re-dissolved into the mother liquor. The syrup from the raw is also sent to a crystalliser. From this a very low quality sugar crystal is produced (known in some systems as "AP sugar") that is also redissolved. The syrup separated is ]; still containing sugar but with too much impurity to be economically processed further. | |||

| An unrefined sugary syrup can be produced directly from sugar beet. This thick, dark syrup is produced by cooking shredded sugar beet for several hours, then pressing the resulting mash and concentrating the juice produced until it has a consistency similar to that of ]. No other ingredients are used. | |||

| In Germany, particularly the ] area, and in the Netherlands, this sugar beet syrup (called ''Zuckerrüben-Sirup'' or ''Zapp'' in German, or ''Suikerstroop'' in Dutch) is used as a spread for sandwiches, as well as for sweetening sauces, cakes and desserts. Dutch people generally top their ]s with stroop. | |||

| There are variations on the above system, with different recycling and crystallisation paths. | |||

| Suikerstroop made according to the Dutch tradition is a ] under EU and UK law.<ref>{{cite web|url=https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32018R0048|access-date=16 October 2021|title=Commission Implementing Regulation (EU) 2018/48 of 11 January 2018 entering a name in the register of traditional specialities guaranteed }}</ref> Commercially, if the syrup has a ] above 30, the product has to be ] and converted to a high-fructose syrup, much like ], or isoglucose syrup in the EU. | |||

| == Other uses== | |||

| ===Sugar beet syrup === | |||

| An unrefined sugary syrup can be produced directly from sugar beet. This thick, dark syrup is produced by cooking shredded sugar beet for several hours, then pressing the resulting sugar beet mash and concentrating the juice produced until it has the consistency similar to that of ]. No other ingredients are used. In ], particularly the ] area, this sugar beet syrup is used as a spread for sandwiches, as well as for sweetening sauces, cakes and desserts. | |||

| === Uridine === | |||

| Commercially, if the syrup has a Dextrose Equivalency above 30 DE, the product has to be ] and converted to a high fructose syrup, much like ], or iso-glucose syrup in the EU. | |||

| ] can be isolated from sugar beet. | |||

| === |

=== Alternative fuel === | ||

| ] and ] plan to use agricultural surpluses of sugar beet to produce ] in ] in the United Kingdom. | |||

| ] can be isolated from the by-products of sugar beet processing. Production is chiefly by ] separation using techinques such as the "moving bed". | |||

| The feedstock-to-yield ratio for sugarbeet is 56:9. Therefore, it takes 6.22 kg of sugar beet to produce 1 kg of ethanol (approximately 1.27 L at room temperature). In 2006 it was found that producing ethanol from sugar beet or cane became profitable when market prices for ethanol were close to $4 per gallon.<ref name="Gustafson" /> According to Atlantic Biomass president Robert Kozak, a study at University of Maryland Eastern Shore indicates sugar beets appear capable of producing 860 to 900 gallons (3,256 to 3,407 liters) of ethanol per acre.<ref name="WWWCP" /> | |||

| ===Uridine=== | |||

| ] can be isolated from sugar beet. Uridine in combination with ]s has been shown to alleviate ].. | |||

| === |

=== Cattle feed === | ||

| In New Zealand, sugar beet is widely grown and harvested as feed for dairy cattle. It is regarded as superior to ], because it has a lower water content (resulting in better storage properties). Both the beet bulb and the leaves (with 25% protein) are fed to cattle. Although long considered toxic to cattle, harvested beet bulbs can be fed to cattle if they are appropriately transitioned to their new diet. Dairy cattle in New Zealand can thrive on just pasture and beets, without ] or other supplementary feed. The crop is also now grown in some parts of Australia as cattle feed.<ref name="Wonder" /><ref name="RuralNews" /> | |||

| There are plans by ] and ] to use agricultural surpluses of sugar beet to produce ] in ] in the ]. | |||

| == |

=== Monosodium glutamate === | ||

| Molasses can serve to produce ] (MSG). | |||

| ] | |||

| == Agriculture == | |||

| Although beets have been grown as vegetables and for fodder since antiquity (a large root vegetable appearing in 4000-year old Egyptian temple artwork may be a beet), their use as a sugar crop is relatively recent. As early as ], the ] botanist ] extracted a sweet syrup from beetroot, but the practice did not become common. The ] chemist ] used alcohol to extract sugar from beets (and carrots) in ], but his methods did not lend themselves to economical industrial-scale production. His former pupil and successor ] began selectively breeding sugar beet from the ''White Silesian'' fodder beet in ]. By the beginning of the 19th century, his beet was approximately 5–6% sucrose by weight, compared to around 20% in modern varieties. Under the patronage of ], he opened the world's first beet sugar ] in ], at ] in ]. | |||

| ] | |||

| Sugar beets are an important part of a ] cycle. | |||

| The development of the European beet sugar industry was encouraged by the ]. In ] the British began a ] of France, preventing the import of ] from the ], in ], Frenchman ] came up with a sugar extraction process suitable for industrial application, and in ], ] instituted a retaliatory ]. By the end of the wars, over 300 beet sugar mills operated in France and central Europe. The first U.S. beet sugar mill opened in ]. | |||

| Sugar beet plants are susceptible to '']'' ("root madness"), which turns the bulbous tap root into many small roots, making the crop economically unprocessable. Strict controls are enforced in European countries to prevent the spread, but it is already present in some areas. It is also susceptible to both the ], which causes crinkling and stunting of the leaves and ]. | |||

| == Agriculture == | |||

| Sugar beet is an important part of a ]. | |||

| Continual research looks for varieties with resistance, as well as increased sugar yield. Sugar beet breeding research in the United States is most prominently conducted at various ] Agricultural Research Stations, including one in ], headed by Linda Hanson and Leonard Panella; one in ], headed by John Wieland; and one at ] in ], headed by Rachel Naegele. | |||

| Other economically important members of the ] |

Other economically important members of the subfamily ]: | ||

| *] | * ] | ||

| *] | * ] | ||

| *] or |

* '']'' or fodder beet | ||

| ===Genetic modification=== | |||

| ==See also== | |||

| {{Main|Genetically modified sugar beet}} | |||

| *] | |||

| In the United States, genetically modified sugar beets, engineered for resistance to ], a ] marketed as Roundup, were developed by ] as a ]. In 2005, the US Department of Agriculture-Animal and Plant Health Inspection Service (]-]) deregulated glyphosate-resistant sugar beets after it conducted an environmental assessment and determined glyphosate-resistant sugar beets were highly unlikely to become a plant pest.<ref name="Roundup Ready Sugarbeets"/><ref name=APHIS-history/> Sugar from glyphosate-resistant sugar beets has been approved for human and animal consumption in multiple countries, but commercial production of biotech beets has been approved only in the United States and Canada. Studies have concluded the sugar from glyphosate-resistant sugar beets has the same nutritional value as sugar from conventional sugar beets.<ref name=AppealDecision2011 /> After deregulation in 2005, glyphosate-resistant sugar beets were extensively adopted in the United States. About 95% of sugar beet acres in the US were planted with glyphosate-resistant seed in 2011.<ref name=James2011/> | |||

| Weeds may be chemically controlled using ] without harming the crop. After planting sugar beet seed, weeds emerge in fields and growers apply glyphosate to control them. Glyphosate is commonly used in field crops because it controls a broad spectrum of weed species<ref name=michsug/> and has a low ].<ref name=usda3/> A study from the UK<ref name=nih/> suggests yields of genetically modified beet were greater than conventional, while another from the North Dakota State University extension service found lower yields.<ref name=nlpw/> The introduction of glyphosate-resistant sugar beets may contribute to the growing number of glyphosate-resistant weeds, so Monsanto has developed a program to encourage growers to use different herbicide modes of action to control their weeds.<ref name="New Releases"/> | |||

| ==External links== | |||

| * | |||

| * | |||

| * | |||

| * | |||

| * | |||

| In 2008, the ], the ], the Organic Seed Alliance and High Mowing Seeds filed a lawsuit against USDA-APHIS regarding their decision to deregulate glyphosate-resistant sugar beets in 2005. The organizations expressed concerns regarding glyphosate-resistant sugar beets' ability to potentially ] with conventional sugar beets.<ref name="Roundup Ready Sugar Beet Case: Timeline"/> U.S. District Judge ], ], revoked the deregulation of glyphosate-resistant sugar beets and declared it unlawful for growers to plant glyphosate-resistant sugar beets in the spring of 2011.<ref name="Roundup Ready Sugar Beet Case: Timeline"/><ref name=usda5/> Believing a sugar shortage would occur USDA-APHIS developed three options in the environmental assessment to address the concerns of environmentalists.<ref name="USDA Prepares Draft Environmental Assessment on Regulatory Options for Roundup Ready Sugar Beets"/> In 2011, a federal appeals court for the Northern district of California in San Francisco overturned the ruling.<ref name=AppealDecision2011/> In July 2012, after completing an environmental impact assessment and a plant pest risk assessment the USDA deregulated Monsanto's Roundup Ready sugar beets.<ref name=usda6/> | |||

| ] | |||

| ] | |||

| ] | |||

| {{anchor|Genome|Genetics|Packaging of genome into chromosomes}} | |||

| {{Link FA|nl}} | |||

| == Genome and genetics == | |||

| ] | |||

| The sugar beet genome shares a triplication event somewhere super-Caryophyllales and at or sub-]s. It has been sequenced and two reference genome sequences have already been generated.<ref name="Dohm-et-al-2013" /> The genome size of the sugar beet is approximately 731 (714–758)<ref name="Dohm-et-al-2013" /> Megabases, and sugar beet DNA is packaged in 18 metacentric chromosomes (2n=2x=18).<ref name="Paesold" /> All sugar beet centromeres are made up of a single ] family<ref name="Zakrzewski" /> and centromere-specific ]s.<ref name="Weber2013" /> More than 60% of sugar beet's DNA is repetitive, mostly distributed in a dispersed way along the chromosomes.<ref name="Weber2010" /><ref name="Wollrab" /><ref name="Heitkam" /><ref name="Schwichtenberg" /> | |||

| ] | |||

| ] | |||

| Crop wild beet populations (''B. vulgaris'' ssp. ''maritima'') have been sequenced as well, allowing for identification of the resistance gene ''Rz2'' in the wild progenitor.<ref name="Capistrano-Gossmann" /> ''Rz2'' confers resistance to rhizomania, commonly known as the sugar beet root madness disease. | |||

| ] | |||

| ] | |||

| ==Breeding== | |||

| ] | |||

| Sugar beets have been bred for increased sugar content, from 8% to 18% in the 200 years {{as of|2013|alt=up to 2013}}, resistance to ] and ] diseases, increased taproot size, ]y, and less ]. Breeding has been eased by discovery of a ] line – this has especially been useful in yield breeding.<ref name="Dohm-et-al-2013" /> | |||

| ] | |||

| ] | |||

| ==References== | |||

| ] | |||

| {{Reflist|33em|refs= | |||

| ] | |||

| ] | |||

| <ref name="springer">{{cite book|title=Beta Maritima: The Origin of Beets|year=2012|publisher=Springer|isbn=978-1-4614-0841-3|quote=The volume will be completely devoted to the sea beet, that is, the ancestor of all the cultivated beets. The wild plant, growing mainly on the shore of the Mediterranean Sea, remains very important as source of useful traits for beet breeding.|url=https://www.springer.com/life+sciences/plant+sciences/book/978-1-4614-0841-3}}</ref> | |||

| ] | |||

| ] | |||

| <ref name="usda">{{cite web|title=Sugar:World Markets and Trade|publisher=United States Department of Agriculture: FAS Information|year=2011|url=http://www.fas.usda.gov/htp/sugar/2011/SugarMay2011.pdf}}</ref> | |||

| ] | |||

| <ref name="usda2">{{cite web|url=http://www.nass.usda.gov/QuickStats/index2.jsp |archive-url=https://web.archive.org/web/20061003083617/http://www.nass.usda.gov/QuickStats/index2.jsp |url-status=dead |archive-date=3 October 2006 |title=NASS – Statistics by Subject – Crops & Plants – Field Crops – Sugarbeets |publisher=United States Department of Agriculture |date= 2 October 2006 }}<!-- Java content not archived --></ref> | |||

| <ref name="usda4">{{cite web|url=https://www.usda.gov/sites/default/files/documents/coexistence-sugar-beets-factsheet.pdf |archive-url=https://web.archive.org/web/20240212163801/https://www.usda.gov/sites/default/files/documents/coexistence-sugar-beets-factsheet.pdf |url-status=dead |archive-date=12 February 2024 |title=USDA Coexistence Fact Sheets Sugar Beets |publisher=United States Department of Agriculture |date= 2 February 2015 }}<!-- Java content not archived --></ref> | |||

| <ref name="agrisugar1">{{cite web|title=Agribusiness Handbook: Sugar beet white sugar|publisher=Food and Agriculture Organization, United Nations|year=2009|url=http://www.eastagri.org/publications/pub_docs/4_Sugar_web.pdf|access-date=2012-02-06|archive-date=2015-09-05|archive-url=https://web.archive.org/web/20150905234431/http://www.eastagri.org/publications/pub_docs/4_Sugar_web.pdf|url-status=dead}}</ref> | |||

| <ref name="respons">{{cite web|title=Agribusiness Handbooks, vol. 4: Sugar Beets / White Sugar|year=1999|url=http://www.responsibleagroinvestment.org/rai/sites/responsibleagroinvestment.org/files/FAO_Agbiz%20handbook_White%20Sugar_0.pdf |archive-url=https://web.archive.org/web/20141006232501/http://www.responsibleagroinvestment.org/sites/responsibleagroinvestment.org/files/FAO_Agbiz%20handbook_White%20Sugar_0.pdf |archive-date=6 October 2014}}</ref> | |||

| <ref name="worldcat">{{cite book|title=Histoire Centennale du Sucre de Betterave|author=Jules Hélot|publisher=Fortier et Marotte|year=1912|oclc=11941819}}</ref> | |||

| <ref name="margg">{{cite book |chapter-url=https://books.google.com/books?id=lJQDAAAAMAAJ&pg=PA79 |chapter=Experiences chimiques faites dans le dessein de tirer un veritable sucre de diverses plantes, qui croissent dans nos contrées (Chemical experiments made with the intention of extracting real sugar from diverse plants that grow in our lands) |title=Histoire de l'académie royale des sciences et belles-lettres de Berlin |year= 1749 |publisher=Marggraf (1747) |pages=79–90 }}</ref> | |||

| <ref name="gr1">{{cite book|title=Something about sugar: its history, growth, manufacture and distribution|author=George Rolph|year=1873|url=https://archive.org/details/somethingaboutsu00rolprich|publisher=San Francisco, J. J. Newbegin}}</ref> | |||

| <ref name="voices">{{cite web |url=http://voices.yahoo.com/de-icing-highways-roads-using-sugar-beet-juice-5234321.html |title=De-icing Highways and Roads Using Sugar Beet Juice |publisher=] |access-date=2 November 2012 |archive-date=10 February 2013 |archive-url=https://archive.today/20130210092741/http://voices.yahoo.com/de-icing-highways-roads-using-sugar-beet-juice-5234321.html |url-status=dead }}<!-- No archive --></ref> | |||

| <ref name="fao">{{cite web|url=https://www.fao.org/faostat/en/#data/QCL |title=Crops and livestock products |publisher=Food and Agriculture Organization}}</ref> | |||

| <!-- <ref name="fao2">{{cite web|title=FAOSTAT: Production, Crops, Sugar beet, 2010 data |publisher=Food and Agriculture Organization |year=2011 |url=http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567#ancor |url-status=dead |archive-url=https://web.archive.org/web/20130114151638/http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567 |archive-date=14 January 2013 }}</ref> --> | |||

| <ref name="sasta">{{cite journal|title=THE EFFECTIVE COMMUNICATION OF AGRICULTURAL R&D OUTPUT IN THE UK BEET SUGAR INDUSTRY|author=Limb Re|journal=Proc South African Sugar Technology Association|year=2008|volume=81|pages=107–115|url=http://www.sasta.co.za/wp-content/uploads/Proceedings/2000s/2008_%20Limb_the%20effective%20communication%20.pdf|access-date=2012-02-07|archive-date=2013-02-06|archive-url=https://web.archive.org/web/20130206081803/http://www.sasta.co.za/wp-content/uploads/Proceedings/2000s/2008_%20Limb_the%20effective%20communication%20.pdf|url-status=dead}}</ref> | |||

| <ref name="farmg">{{cite web|title=Attention to detail critical in meeting beet yield targets|publisher=Farmers Guardian|date=June 2010|url=http://www.farmersguardian.com/home/arable/arable-features/attention-to-detail-essential-in-meeting-beet-yield-targets/32671.article}}</ref> | |||

| <ref name="Roundup Ready Sugarbeets">{{cite web|last=Monsanto|title=Roundup Ready Sugarbeets|url=http://www.monsanto.com/products/Pages/roundup-ready-sugarbeets.aspx}}</ref> | |||

| <ref name="APHIS-history">{{cite web|url=http://www.aphis.usda.gov/biotechnology/sugarbeet_case.shtml |archive-url=https://web.archive.org/web/20101017000748/http://www.aphis.usda.gov/biotechnology/sugarbeet_case.shtml |url-status=dead |archive-date=17 October 2010 |title=Roundup Ready® Sugar Beet Case – Timeline |publisher=APHIS |date= 7 September 2010 }}</ref> | |||

| <ref name="James2011">{{cite web|url=http://www.isaaa.org/resources/publications/briefs/43/executivesummary/default.asp |title=Brief 43-2011. Executive Summary: Global Status of Commercialized Biotech/GM Crops: 2011 |publisher=ISAAA |archive-url=https://web.archive.org/web/20120210025832/http://www.isaaa.org/resources/publications/briefs/43/executivesummary/default.asp |archive-date=10 February 2012 |url-status=dead }}</ref> | |||

| <ref name="michsug">{{cite web|last=Michigan Sugar Company|title=2010 Growers' Guide for Producing Quality Sugarbeets|url=http://www.michigansugar.com/agriculture/guide.php|access-date=2011-04-05|archive-date=2013-08-09|archive-url=https://web.archive.org/web/20130809170900/http://michigansugar.com/agriculture/guide.php|url-status=dead}}</ref> | |||

| <ref name="MMPND">{{cite web|url=http://www.plantnames.unimelb.edu.au/Sorting/Beta.html |title=Sorting Beta names |url-status=live |archive-url=https://web.archive.org/web/20130504173112/http://www.plantnames.unimelb.edu.au/Sorting/Beta.html |website=Multilingual Multiscript Plant Name Database |date=4 May 2013 |archive-date=4 May 2013 }}</ref> | |||

| <ref name="usda3">{{cite web |url=http://naldc.nal.usda.gov/download/17918/PDF |author1=Stephen O Duke |author2=Stephen B Powles |name-list-style=amp |title=Glyphosate: a once-in-a-century herbicide: Mini-review |publisher=Pest Management Science Pest Manag Sci 64:319–325 |date=2008 |access-date=2012-11-02 |archive-date=2019-07-02 |archive-url=https://web.archive.org/web/20190702211642/https://naldc.nal.usda.gov/download/17918/PDF |url-status=dead }}</ref> | |||

| <ref name="nih">{{cite journal|pmc=1634958 |author=May, MJ|title= Management of genetically modified herbicide-tolerant sugar beet for spring and autumn environmental benefit|volume=27 |issue=1559 |date=2005 |pages= 111–119|display-authors=etal |pmid=15695200 |doi=10.1098/rspb.2004.2948 |journal=Proc Biol Sci}}</ref> | |||

| <ref name="nlpw">{{cite web|url=http://www.nlpwessex.org/docs/fwsugarbeettext.htm |author=Mike Abrams |title=Roundup Ready Crops Prove to be a Hit in the USA |publisher=Farmers Weekly |date=6 February 2009 |archive-url =https://web.archive.org/web/20111124093827/http://www.nlpwessex.org/docs/fwsugarbeettext.htm|archive-date =24 November 2011|url-status=dead}}</ref> | |||

| <ref name="New Releases">{{cite web|url=http://monsanto.mediaroom.com/index.php?s=27632&item=77230 |archive-url=https://web.archive.org/web/20120622014411/http://monsanto.mediaroom.com/index.php?s=27632&item=77230 |url-status=dead |archive-date=22 June 2012 |title=Press Release: Monsanto Outlines New Weed Management Platform Under the Roundup Ready PLUS™ Brand|publisher=monsanto |date=19 October 2010 }}</ref> | |||

| <ref name="Roundup Ready Sugar Beet Case: Timeline">{{cite web|last=USDA-APHIS |title=Roundup Ready Sugar Beet Case: Timeline|url=http://www.aphis.usda.gov/biotechnology/sugarbeet_case.shtml|archive-date=1 July 2013|archive-url=https://web.archive.org/web/20130701195326/http://www.aphis.usda.gov/biotechnology/sugarbeet_case.shtml|date=4 February 2011}}</ref> | |||

| <ref name="usda5">{{cite web|last=USDA-APHIS|title=Environmental Compliance|url=http://www.aphis.usda.gov/regulations/compliance/environmental_quality_1502.shtml|date=29 January 2009|url-status=dead|archive-url=https://web.archive.org/web/20141006081332/http://www.aphis.usda.gov/regulations/compliance/environmental_quality_1502.shtml|archive-date=6 October 2014}}</ref> | |||

| <ref name="USDA Prepares Draft Environmental Assessment on Regulatory Options for Roundup Ready Sugar Beets">{{cite web|last=USDA-APHIS|title=USDA Prepares Draft Environmental Assessment on Regulatory Options for Roundup Ready Sugar Beets|url=http://www.aphis.usda.gov/newsroom/content/2010/11/enviro_sugar_beets.shtml|url-status=dead|archive-url=https://web.archive.org/web/20101106001117/http://www.aphis.usda.gov/newsroom/content/2010/11/enviro_sugar_beets.shtml|archive-date=6 November 2010}}</ref> | |||

| <ref name="AppealDecision2011">{{cite web|url=http://articles.law360.s3.amazonaws.com/0228000/228390/monsanto.pdf |archive-url=https://web.archive.org/web/20131016004552/http://articles.law360.s3.amazonaws.com/0228000/228390/monsanto.pdf |url-status=dead |archive-date=16 October 2013 |title=United States Court of Appeals for the Ninth Circuit. No. 10-17719, D.C. No. 3:10-cv-04038-JSW |date=25 February 2011 |access-date=28 August 2012 }}</ref> | |||

| <ref name="usda6">{{cite web|url=http://www.aphis.usda.gov/biotechnology/sugarbeet.shtml |archive-url=https://web.archive.org/web/20101013130952/http://www.aphis.usda.gov/biotechnology/sugarbeet.shtml |url-status=dead |archive-date=13 October 2010 |title=Roundup Ready® Sugar Beet News |publisher=USDA Animal and Plant Health Inspection Service |date=7 August 2012 |access-date=28 July 2012 }}</ref> | |||

| <ref name="Montana1970">{{cite web|url=https://scholarworks.montana.edu/xmlui/bitstream/handle/1/4350/31762100108123.pdf?sequence=1 |title=An economic study of the beet sugar industry in Montana |publisher=Montana State University |date=1 March 1969 |access-date=20 January 2023 }}</ref> | |||

| <ref name="WWWCP">{{cite web|url=https://wwwcp.umes.edu/pr/sugar-beets-a-reliable-source-of-biofuel/ |title=Sugar beets ~ a reliable source of biofuel? |publisher=University of Maryland |date=21 October 2016 |access-date=5 August 2024 }}</ref> | |||

| <ref name="Gustafson">{{Cite web|author= Cole Gustafson |year= 2010 |title=Economics of Sugar Beet and Cane Biofuel — Energy|url=https://www.ag.ndsu.edu/energy/biofuels/energy-briefs/economics-of-sugar-beet-and-cane-biofuel|access-date=2023-02-08|website=North Dakota State University}}</ref> | |||

| <ref name="Langer" >{{cite book |author1=Hill, G. |author2=Langer, R. H. M. |author-link=George Hill (agronomist) |author-link2=Reinhart Langer |title=Agricultural plants |publisher=Cambridge University Press |location=Cambridge, UK |year=1991 |pages= |isbn=978-0-521-40563-8 }}</ref> | |||

| <ref name="ucdsugar"> {{webarchive|url=https://web.archive.org/web/20090120002450/https://sugarbeet.ucdavis.edu/sbchap.html |date=20 January 2009 }} from a ] website</ref> | |||

| <ref name="Mansfeld">{{Cite book|author1=Hanelt, Peter |author2=Büttner, R. |author3=Mansfeld, Rudolf |author4=Kilian, Ruth | title=Mansfeld's Encyclopedia of Agricultural and Horticultural Crops| publisher=Springer| year=2001| isbn=978-3-540-41017-1| pages=235–241}}</ref> | |||

| <ref name="Dohm-et-al-2013">{{cite journal | last1=Dohm | first1=Juliane C. | last2=Minoche | first2=André E. | last3=Holtgräwe | first3=Daniela | last4=Capella-Gutiérrez | first4=Salvador | last5=Zakrzewski | first5=Falk | last6=Tafer | first6=Hakim | last7=Rupp | first7=Oliver | last8=Sörensen | first8=Thomas Rosleff | last9=Stracke | first9=Ralf | last10=Reinhardt | first10=Richard | last11=Goesmann | first11=Alexander | last12=Kraft | first12=Thomas | last13=Schulz | first13=Britta | last14=Stadler | first14=Peter F. | last15=Schmidt | first15=Thomas | last16=Gabaldón | first16=Toni | last17=Lehrach | first17=Hans | last18=Weisshaar | first18=Bernd | last19=Himmelbauer | first19=Heinz | title=The genome of the recently domesticated crop plant sugar beet (''Beta vulgaris'') | journal=] | publisher=] | volume=505 | issue=7484 | date=18 December 2013 | issn=0028-0836 | doi=10.1038/nature12817 | pages=546–549 | language=En | display-authors=3 | pmid=24352233 | doi-access=free | bibcode=2014Natur.505..546D| hdl=10230/22493 | hdl-access=free }}</ref> | |||

| <ref name="Paesold">{{Cite journal|last1=Paesold|first1=Susanne|last2=Borchardt|first2=Dietrich|last3=Schmidt|first3=Thomas|last4=Dechyeva|first4=Daryna|date=7 September 2012|title=A sugar beet (Beta vulgarisL.) reference FISH karyotype for chromosome and chromosome-arm identification, integration of genetic linkage groups and analysis of major repeat family distribution|journal=The Plant Journal|language=en|volume=72|issue=4|pages=600–611|doi=10.1111/j.1365-313x.2012.05102.x|pmid=22775355|issn=0960-7412|doi-access=free}}</ref> | |||

| <ref name="Zakrzewski">{{Citation|last1=Zakrzewski|first1=Falk|title=A Molecular Cytogenetic Analysis of the Structure, Evolution, and Epigenetic Modifications of Major DNA Sequences in Centromeres of Beta Species|date=2013|work=Plant Centromere Biology|pages=39–55|publisher=John Wiley & Sons, Ltd|language=en|doi=10.1002/9781118525715.ch4|isbn=9781118525715|last2=Weber|first2=Beatrice|last3=Schmidt|first3=Thomas}}</ref> | |||

| <ref name="Weber2013">{{Cite journal|last1=Weber|first1=Beatrice|last2=Heitkam|first2=Tony|last3=Holtgräwe|first3=Daniela|last4=Weisshaar|first4=Bernd|last5=Minoche|first5=André E.|last6=Dohm|first6=Juliane C.|last7=Himmelbauer|first7=Heinz|last8=Schmidt|first8=Thomas|display-authors=3|date=1 March 2013|title=Highly diverse chromoviruses of Beta vulgaris are classified by chromodomains and chromosomal integration|journal=Mobile DNA|volume=4|issue=1|pages=8|doi=10.1186/1759-8753-4-8|issn=1759-8753|pmc=3605345|pmid=23448600 |doi-access=free }}</ref> | |||

| <ref name="Weber2010">{{Cite journal|last1=Weber|first1=Beatrice|last2=Wenke|first2=Torsten|last3=Frömmel|first3=Ulrike|last4=Schmidt|first4=Thomas|last5=Heitkam|first5=Tony|display-authors=3|date=1 February 2010|title=The Ty1-copia families SALIRE and Cotzilla populating the Beta vulgaris genome show remarkable differences in abundance, chromosomal distribution, and age|journal=Chromosome Research|language=en|volume=18|issue=2|pages=247–263|doi=10.1007/s10577-009-9104-4|pmid=20039119|s2cid=24883110|issn=1573-6849}}</ref> | |||

| <ref name="Wollrab">{{Cite journal|last1=Wollrab|first1=Cora|last2=Heitkam|first2=Tony|last3=Holtgräwe|first3=Daniela|last4=Weisshaar|first4=Bernd|last5=Minoche|first5=André E.|last6=Dohm|first6=Juliane C.|last7=Himmelbauer|first7=Heinz|last8=Schmidt|first8=Thomas|display-authors=3|date=2012|title=Evolutionary reshuffling in the Errantivirus lineage Elbe within the Beta vulgaris genome|journal=The Plant Journal|language=en|volume=72|issue=4|pages=636–651|doi=10.1111/j.1365-313X.2012.05107.x|pmid=22804913|issn=1365-313X|doi-access=free|hdl=11858/00-001M-0000-000E-F0B9-B|hdl-access=free}}</ref> | |||

| <ref name="Heitkam">{{Cite journal|last1=Heitkam|first1=Tony|last2=Schmidt|first2=Thomas|date=2009|title=BNR – a LINE family from Beta vulgaris– contains a RRM domain in open reading frame 1 and defines a L1 sub-clade present in diverse plant genomes|journal=The Plant Journal|language=en|volume=59|issue=6|pages=872–882|doi=10.1111/j.1365-313X.2009.03923.x|pmid=19473321|issn=1365-313X|doi-access=free}}</ref> | |||

| <ref name="Schwichtenberg">{{Cite journal|last1=Schwichtenberg|first1=Katrin|last2=Wenke|first2=Torsten|last3=Zakrzewski|first3=Falk|last4=Seibt|first4=Kathrin M.|last5=Minoche|first5=André|last6=Dohm|first6=Juliane C.|last7=Weisshaar|first7=Bernd|last8=Himmelbauer|first8=Heinz|last9=Schmidt|first9=Thomas|display-authors=3|date=2016|title=Diversification, evolution and methylation of short interspersed nuclear element families in sugar beet and related Amaranthaceae species|journal=The Plant Journal|language=en|volume=85|issue=2|pages=229–244|doi=10.1111/tpj.13103|pmid=26676716|issn=1365-313X|doi-access=free}}</ref> | |||

| <ref name="Capistrano-Gossmann">{{Cite journal|last1=Capistrano-Gossmann|first1=Gina G.|last2=Ries|first2=D.|last3=Holtgräwe|first3=D.|last4=Minoche|first4=A.|last5=Kraft|first5=T.|last6=Frerichmann|first6=S.L.M.|last7=Rosleff Soerensen|first7=T.|last8=Dohm|first8=J. C.|last9=González|first9=I.|display-authors=3|date=6 June 2017|title=Crop wild relative populations of Beta vulgaris allow direct mapping of agronomically important genes |journal=Nature Communications|language=En|volume=8|pages=15708|doi=10.1038/ncomms15708 |pmc=5467160|pmid=28585529|bibcode=2017NatCo...815708C}}</ref> | |||

| <ref name="Wonder">{{Cite web|date=24 June 2014|title=Grower lauds sugar beet 'wonder fuel'|url=https://www.stuff.co.nz/business/farming/cropping/10191791/Grower-lauds-sugar-beet-wonder-fuel|access-date=25 September 2021|website=Stuff|language=en}}</ref> | |||

| <ref name="RuralNews">{{Cite web|last=Group|first=Rural News|title=Fodder, sugar beets dream feed if grown right|url=https://ruralnewsgroup.co.nz/dairy-news/dairy-farm-health/fodder-sugar-beets-dream-feed-if-grown-right|access-date=25 September 2021|website=ruralnewsgroup.co.nz|language=en-gb}}</ref> | |||

| <ref name="Doering">{{cite book |last=Doering |first=Emil |title=Die Zuckerrübe und ihr Anbau |year=1896 |publisher=Eduard Trewent, Breslau |url=https://books.google.com/books?id=O2AmAQAAMAAJ }}</ref> | |||

| <ref name="Birnbaum">{{cite book |last=Birnbaum |first=Eduard |title=Der Zuckerrübenbau: kurzgefasste Anleitung zum Anbau der Zuckerrübe für den praktischen Landwirth |year=1887 |publisher=W.G. Korn, Breslau |url=https://books.google.com/books?id=2ljZAAAAMAAJ }}</ref> | |||

| <ref name="Louisiana">{{cite news |newspaper=The Louisiana Planter and Sugar Manufacturer |title=Supplement to the Chronicle of the Beet Sugar Industry |location=New Orleans |date=November 18, 1897 |volume=XIX |number=20 |page=312 |url=https://books.google.com/books?id=ACw_AQAAMAAJ }}</ref> | |||

| <ref name="histoire">{{Cite web|title=L'histoire du sucre | Klorane Botanical Foundation|url=https://www.kloranebotanical.foundation/la-botanique/dossiers/plantes-alimentaires/lhistoire-du-sucre|access-date=2023-02-08|website=www.kloranebotanical.foundation|language=fr}}</ref> | |||

| <ref name="Koyikkal2013">{{Cite book|url=https://books.google.com/books?id=t08wJ9MRSXwC&q=Carbonatation+is+a+procedure+which+removes+impurities+from+raw+sugar+beet+juice+before+it+undergoes+crystallization&pg=PA53|title=Chemical Process Technology and Simulation|last=Koyikkal|first=Srikumar|date=8 April 2013|publisher=PHI Learning Pvt. Ltd.|isbn=9788120347090 }}</ref> | |||

| <ref name="sugarnutritionresource/refining-cane">{{cite web |last1=Dowse |first1=Peter |title=Refining sugar cane |url=https://www.sugarnutritionresource.org/news-articles/refining-sugar-cane |website=sugarnutritionresource.org |date=31 August 2021 |access-date=3 January 2023 |language=en-gb}}</ref> | |||

| <ref name="silverwedge">{{Cite web |title=Silver Wedge: The Sugar Beet Industry in Fort Collins |author=Eric Twitty |work=SWCA Environmental Consultants |date=August 2003 |access-date=9 August 2020 |url= https://www.fcgov.com/parkplanning/files/silver-wedge_the-sugar-beet-industry-in-fort-collins_a-historical-context.pdf}}</ref> | |||

| <ref name="Aligny1869">{{cite book |last=d'Aligny |first=Henry Ferdinand Quarré |year=1869 |title=The Manufacture of Beet Sugar and Alcohol, and the Cultivation of Sugar-beet |publisher=Government printing office, Washington |url=https://books.google.com/books?id=G55AAAAAYAAJ |pages=40–59 }}</ref> | |||

| <ref name="Levi1870">{{cite book |last=Levi |first=Nathaniel |year=1870 |title=The Sugar Beet: Its Adaptability for Cultivation in the Colony |publisher=George Robertson, Melbourne |url=https://books.google.com/books?id=aiVYAAAAcAAJ |pages=18 }}</ref> | |||

| <ref name="Czechs">{{cite web|url=http://www.tresbohemes.com/2017/02/czechs-and-their-billion-dollar-beets/|title=Czechs and Their Billion Dollar Beets |publisher=Tres Bohemes |access-date=2023-03-17 |date=2017-02-09}}</ref> | |||

| <ref name="Tereos8">{{Cite web|title=Raw Material, Sugar Beet|url=https://tereos.com/en/activities-and-products/raw-materials/sugar-beets/ |access-date=19 March 2023|website=Tereos}}</ref> | |||

| <ref name="TereosDistill">{{Cite web|title=Alcohol and ethanol |url=https://tereos.com/en/activities-and-products/product-lines/alcohol-ethanol/ |access-date=19 March 2023|website=Tereos}}</ref> | |||

| }} | |||

| ==External links== | |||

| {{Commons category|Sugar beets}} | |||

| {{Wiktionary}} | |||

| * | |||

| * | |||

| * hosted by the | |||

| * {{Webarchive|url=https://web.archive.org/web/20101213065400/http://www.gmo-safety.eu/news/1221.court-bans-sugar-beet-cultivation-under-controlled-conditions.html |date=13 December 2010 }} | |||

| * ''Popular Science Monthly'', March 1935 | |||

| *{{cite web|title=Beet Sugar|url=https://www.jstor.org/action/doBasicSearch?Query=ti%3A%22beet+sugar%22+&acc=off&wc=on&fc=off&group=none|publisher=]}} | |||

| {{Sugar}} | |||

| {{Bioenergy}} | |||

| {{Authority control}} | |||

| {{Taxonbar|from=Q151964}} | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 06:17, 23 December 2024

Plant grown commercially for sugar production| This article needs additional citations for verification. Please help improve this article by adding citations to reliable sources. Unsourced material may be challenged and removed. Find sources: "Sugar beet" – news · newspapers · books · scholar · JSTOR (February 2021) (Learn how and when to remove this message) |

| Sugar beet | |

|---|---|

Sugar beet, illustration of root, leaf, and flowering patterns Sugar beet, illustration of root, leaf, and flowering patterns | |

| Species | Beta vulgaris |

| Subspecies | Beta vulgaris subsp. vulgaris (var. saccharifera) |

| Cultivar group | Altissima Group |

| Origin | Silesia, mid-18th century |

A sugar beet is a plant whose root contains a high concentration of sucrose and that is grown commercially for sugar production. In plant breeding, it is known as the Altissima cultivar group of the common beet (Beta vulgaris). Together with other beet cultivars, such as beetroot and chard, it belongs to the subspecies Beta vulgaris subsp. vulgaris but classified as var. saccharifera. Its closest wild relative is the sea beet (Beta vulgaris subsp. maritima).

Sugar beets are grown in climates that are too cold for sugarcane. In 2020, Russia, the United States, Germany, France and Turkey were the world's five largest sugar beet producers. In 2010–2011, Europe, and North America except Arctic territories failed to supply the overall domestic demand for sugar and were all net importers of sugar. The US harvested 1,004,600 acres (406,547 ha) of sugar beets in 2008. In 2009, sugar beets accounted for 20% of the world's sugar production and nearly 30% by 2013. Sugarcane accounts for most of the rest of sugar produced globally. In February 2015, a USDA factsheet reported that sugar beets generally account for about 55 percent of domestically produced sugar, and sugar cane for about 45 percent.

Description

The sugar beet has a conical, white, fleshy root (a taproot) with a flat crown. The plant consists of the root and a rosette of leaves. Sugar is formed by photosynthesis in the leaves and is then stored in the root.

The root of the beet contains 75% water, about 20% sugar, and 5% pulp. The exact sugar content can vary between 12% and 21%, depending on the cultivar and growing conditions. Sugar is the primary value of sugar beet as a cash crop. The pulp, insoluble in water and mainly composed of cellulose, hemicellulose, lignin, and pectin, is used in animal feed. The byproducts of the sugar beet crop, such as pulp and molasses, add another 10% to the value of the harvest.

Sugar beets grow exclusively in the temperate zone, in contrast to sugarcane, which grows exclusively in the tropical and subtropical zones. The average weight of a sugar beet ranges between 0.5 and 1 kg (1.1 and 2.2 lb). Sugar beet foliage has a rich, brilliant green color and grows to a height of about 35 cm (14 in). The leaves are numerous and broad and grow in a tuft from the crown of the beet, which is usually level with or just above the ground surface.

History of the sugar beet

Discovery of beet sugar

Main article: Beta vulgaris

The species beet consists of several cultivar groups. The 16th-century French scientist Olivier de Serres discovered a process for preparing sugar syrup from (red) beetroot. He wrote: "The beet-root, when being boiled, yields a juice similar to syrup of sugar, which is beautiful to look at on account of its vermilion colour" (1575). Because crystallized cane sugar was already available and had a better taste, this process did not become popular.

Modern sugar beets date to the mid-18th century Silesia where Frederick the Great, king of Prussia, subsidized experiments to develop processes for sugar extraction. In 1747, Andreas Sigismund Marggraf, professor of physics in the Academy of Science of Berlin, isolated sugar from beetroots and found them at concentrations of 1.3–1.6%. He also demonstrated that the sugar that could be extracted from beets was identical to that produced from cane. He found the best of these vegetable sources for sugar was the white beet. Despite Marggraf's success in isolating sugar from beets, it did not lead to commercial sugar production.

Development of the sugar beet

Marggraf's student and successor Franz Karl Achard began plant breeding sugar beet in Kaulsdorf near Berlin in 1786. Achard started his plant breeding by evaluating 23 varieties of beet for sugar content. In the end he selected a local strain from Halberstadt in modern-day Saxony-Anhalt, Germany. Moritz Baron von Koppy and his son further selected white, conical tubers from this strain. The selection was named weiße schlesische Zuckerrübe, meaning white Silesian sugar beet. In about 1800, this cultivar boasted about 5–6% sucrose by (dry) weight. It would go on to be the progenitor of all modern sugar beets. The plant breeding process has continued since then, leading to a sucrose content of around 18% in modern varieties.

History of the beet sugar industry

Main article: Beet sugar factoryFranz Karl Achard opened the world's first beet sugar factory in 1801, at Kunern, Silesia (now Konary, Poland). The idea to produce sugar from beet was soon introduced to France, whence the European sugar beet industry rapidly expanded. By 1840, about 5% of the world's sugar was derived from sugar beets, and by 1880, this number had risen more than tenfold to over 50%. In North America, the first commercial production started in 1879 at a farm in Alvarado, California. The sugar beet was introduced to Chile by German settlers around 1850.

Culture

The sugar beet, like sugarcane, needs a particular soil and a proper climate for its successful cultivation. The most important requirements are that the soil must contain a large supply of nutrients, be rich in humus, and be able to contain a great deal of moisture. A certain amount of alkali is not necessarily detrimental, as sugar beets are not especially susceptible to injury by some alkali. The ground should be fairly level and well-drained, especially where irrigation is practiced.

Generous crops can be grown in both sandy soil and heavy loams, but the ideal soil is a sandy loam, i.e., a mixture of organic matter, clay and sand. A subsoil of gravel, or the presence of hardpan, is not desirable, as cultivation to a depth of from 12 to 15 inches (30 to 38 cm) is necessary to produce the best results.

Climatic conditions, temperature, sunshine, rainfall and winds have an important bearing upon the success of sugar beet agriculture. A temperature ranging from 15 to 21 °C (59 to 70 °F) during the growing months is most favorable. In the absence of adequate irrigation, 460 mm (18 inches) of rainfall are necessary to raise an average crop. High winds are harmful, as they generally crust the land and prevent the young beets from coming through the ground. The best results are obtained along the coast of southern California, where warm, sunny days succeeded by cool, foggy nights seem to meet sugar beet's favored growth conditions. Sunshine of long duration but not of great intensity is the most important factor in the successful cultivation of sugar beets. Near the equator, the shorter days and the greater heat of the sun sharply reduce the sugar content in the beet.

In high elevation regions such as those of Idaho, Colorado and Utah, where the temperature is high during the daytime, but where the nights are cool, the quality of the sugar beet is excellent. In Michigan, the long summer days from the relatively high latitude (the Lower Peninsula, where production is concentrated, lies between the 41st and 46th parallels North) and the influence of the Great Lakes result in satisfactory climatic conditions for sugar beet culture. Sebewaing, Michigan, lies in the Thumb region of Michigan; both the region and state are major sugar beet producers. Sebewaing is home to one of four Michigan Sugar Company factories. The town sponsors an annual Michigan Sugar Festival.

To cultivate beets successfully, the land must be properly prepared. Deep ploughing is the first principle of beet culture. It allows the roots to penetrate the subsoil without much obstruction, thereby preventing the beet from growing out of the ground, besides enabling it to extract considerable nourishment and moisture from the lower soil. If the latter is too hard, the roots will not penetrate it readily and, as a result, the plant will be pushed up and out of the earth during the process of growth. A hard subsoil is impervious to water and prevents proper drainage. It should not be too loose, however, as this allows the water to pass through more freely than is desirable. Ideally, the soil should be deep, fairly fine and easily penetrable by the roots. It should also be capable of retaining moisture and at the same time admit of a free circulation of air and good drainage. Sugar beet crops exhaust the soil rapidly. Crop rotation is recommended and necessary. Normally, beets are grown in the same ground every third year, peas, beans or grain being raised the other two years.

In most temperate climates, beets are planted in the spring and harvested in the autumn. At the northern end of its range, growing seasons as short as 100 days can produce commercially viable sugar beet crops. In warmer climates, such as in California's Imperial Valley, sugar beets are a winter crop, planted in the autumn and harvested in the spring. In recent years, Syngenta has developed the so-called tropical sugar beet. It allows the plant to grow in tropical and subtropical regions. Beets are planted from a small seed; 1 kg (2.2 lb) of beet seed comprises 100,000 seeds and will plant over one hectare (2.5 acres) of ground (one pound or 0.45 kilograms will plant about one acre or 0.40 hectares.

Until the latter half of the 20th century, sugar beet production was highly labor-intensive, as weed control was managed by densely planting the crop, which then had to be manually thinned two or three times with a hoe during the growing season. Harvesting also required many workers. Although the roots could be lifted by a plough-like device that could be pulled by a horse team, the rest of the preparation was by hand. One laborer grabbed the beets by their leaves, knocked them together to shake free loose soil, and then laid them in a row, root to one side, greens to the other. A second worker equipped with a beet hook (a short-handled tool between a billhook and a sickle) followed behind, and would lift the beet and swiftly chop the crown and leaves from the root with a single action. Working this way, he would leave a row of beets that could be forked into the back of a cart.

Today, mechanical sowing, herbicide application for weed control, and mechanical harvesting have displaced this reliance on manual farm work. A root beater uses a series of blades to chop the leaf and crown (which is high in nonsugar impurities) from the root. The beet harvester lifts the root, and removes excess soil from the root in a single pass over the field. A modern harvester is typically able to cover six rows at the same time. The beets are dumped into trucks as the harvester rolls down the field, and then delivered to the factory. The conveyor then removes more soil.

If the beets are to be left for later delivery, they are formed into clamps. Straw bales are used to shield the beets from the weather. Provided the clamp is well built with the right amount of ventilation, the beets do not significantly deteriorate. Beets that freeze and then defrost, produce complex carbohydrates that cause severe production problems in the factory. In the UK, loads may be hand examined at the factory gate before being accepted.

In the US, the fall harvest begins with the first hard frost, which arrests photosynthesis and the further growth of the root. Depending on the local climate, it may be carried out over the course of a few weeks or be prolonged throughout the winter months. The harvest and processing of the beet is referred to as "the campaign", reflecting the organization required to deliver the crop at a steady rate to processing factories that run 24 hours a day for the duration of the harvest and processing (for the UK, the campaign lasts about five months). In the Netherlands, this period is known as de bietencampagne, a time to be careful when driving on local roads in the area while the beets are being grown, because the naturally high clay content of the soil tends to cause slippery roads when soil falls from the trailers during transport.

Production statistics

| Rank | Country | Production (million tonnes) |

|---|---|---|

| 1 | 48.9 | |

| 2 | 31.5 | |

| 3 | 29.6 | |

| 4 | 28.2 | |

| 5 | 19.0 | |

| 6 | 14.2 | |

| 7 | 13.6 | |

| 9 | 9.9 | |

| 8 | 8.9 | |

| 10 | 7.3 | |

| Total | World | 261.0 |

The world harvested 260,998,614 metric tons (256,900,000 long tons; 287,700,000 short tons) of sugar beets in 2022. The world's largest producer was Russia, with a 48,907,753 metric tons (48,100,000 long tons; 53,900,000 short tons) harvest. The average yield of sugar beet crops worldwide was 60.8 tonnes per hectare.

The most productive sugar beet farms in the world, in 2022, were in Chile, with a nationwide average yield of 106.2 tonnes per hectare.

Imperial Valley (California) farmers have achieved yields of about 160 tonnes per hectare and over 26 tonnes sugar per hectare. Imperial Valley farms benefit from high intensities of incident sunlight and intensive use of irrigation and fertilizers.

From sugar beet to white sugar