| Revision as of 03:11, 19 July 2008 editInternetHero (talk | contribs)2,457 editsm Undid revision 226539006 by Wolfkeeper (talk)← Previous edit | Revision as of 17:35, 19 July 2008 edit undoWolfkeeper (talk | contribs)31,832 edits Revert to revision 226539006 dated 2008-07-18 23:20:20 by Wolfkeeper using popupsNext edit → | ||

| Line 1: | Line 1: | ||

| ] engine]] | ] engine]] | ||

| The '''internal combustion engine''' is an engine in which the ] of ] and an ] (typically air) occurs in a confined space called a ] (or "cylinder"). This ] creates gases at high ] and ], which are permitted to expand. |

The '''internal combustion engine''' is an engine in which the ] of ] and an ] (typically air) occurs in a confined space called a ] (or "cylinder"). This ] creates gases at high ] and ], which are permitted to expand. The defining feature of an internal combustion engine is that useful work is performed by the expanding hot gases acting directly to cause the movement of solid parts of the engine: by acting on pistons, rotors, or even by pressing on and moving the entire engine itself.<ref name=r1></ref><ref name=r2></ref><ref name=r3></ref><ref name=r4></ref> | ||

| The term ''Internal Combustion Engine'' (ICE) is almost always used to refer specifically to reciprocating piston engines, ]s, and similar designs in which combustion is intermittent. However, continuous combustion engines such as jet engines, most rockets, and many gas turbines are also classified as types of internal combustion engines.<ref name=r1/><ref name=r2/><ref name=r3/><ref name=r4/> |

The term ''Internal Combustion Engine'' (ICE) is almost always used to refer specifically to reciprocating piston engines, ]s, and similar designs in which combustion is intermittent. However, continuous combustion engines such as jet engines, most rockets, and many gas turbines are also classified as types of internal combustion engines.<ref name=r1/><ref name=r2/><ref name=r3/><ref name=r4/> | ||

| Internal combustion engines contrast with ]s such as ] and ] that use a separate combustion chamber to heat a separate working fluid—which then in turn does work. For example, by moving a piston or a turbine. | |||

| == History == | == History == | ||

Revision as of 17:35, 19 July 2008

The internal combustion engine is an engine in which the combustion of fuel and an oxidizer (typically air) occurs in a confined space called a combustion chamber (or "cylinder"). This exothermic reaction creates gases at high temperature and pressure, which are permitted to expand. The defining feature of an internal combustion engine is that useful work is performed by the expanding hot gases acting directly to cause the movement of solid parts of the engine: by acting on pistons, rotors, or even by pressing on and moving the entire engine itself.

The term Internal Combustion Engine (ICE) is almost always used to refer specifically to reciprocating piston engines, Wankel engines, and similar designs in which combustion is intermittent. However, continuous combustion engines such as jet engines, most rockets, and many gas turbines are also classified as types of internal combustion engines.

Internal combustion engines contrast with external combustion engines such as steam engines and Stirling engines that use a separate combustion chamber to heat a separate working fluid—which then in turn does work. For example, by moving a piston or a turbine.

History

The first piston engines did not have compression, but ran on an air-fuel mixture sucked or blown in during the first part of the intake stroke. The most significant distinction between modern internal combustion engines and the early designs is the use of compression and, in particular, in-cylinder compression.

- 1206: Al-Jazari described a double-acting reciprocating piston pump with a crankshaft-connecting rod mechanism.

- 1232c: Rocket, China - first internal combustion engine, very short duration and very inefficient

- 1509: Leonardo da Vinci described a compressionless engine.

- 1673: Christiaan Huygens described a compressionless engine.

- 17th century: English inventor Sir Samuel Morland used gunpowder to drive water pumps, essentially creating the first rudimentary internal combustion engine.

- 1780's: Alessandro Volta built a toy electric pistol in which an electric spark exploded a mixture of air and hydrogen, firing a cork from the end of the gun.

- 1791: John Barber receives British patent #1833 for A Method for Rising Inflammable Air for the Purposes of Producing Motion and Facilitating Metallurgical Operations. In it he describes a turbine.

- 1794: Robert Street built a compressionless engine whose principle of operation would dominate for nearly a century.

- 1798 - Tipu Sultan, the of the city-state of Mysore in India, uses the first iron rockets against the British Army and wins the first war.

- 1806: Swiss engineer François Isaac de Rivaz built an internal combustion engine powered by a hydrogen and oxygen mixture.

- 1823: Samuel Brown patented the first internal combustion engine to be applied industrially. It was compressionless and based on what Hardenberg calls the "Leonardo cycle," which, as the name implies, was already out of date at that time.

- 1824: French physicist Sadi Carnot established the thermodynamic theory of idealized heat engines. This scientifically established the need for compression to increase the difference between the upper and lower working temperatures.

- 1826 April 1: American Samuel Morey received a patent for a compressionless "Gas or Vapor Engine."

- 1838: a patent was granted to William Barnet (English). This was the first recorded suggestion of in-cylinder compression.

- 1854: The Italians Eugenio Barsanti and Felice Matteucci patented the first working efficient internal combustion engine in London (pt. Num. 1072) but did not go into production with it. It was similar in concept to the successful Otto Langen indirect engine, but wasn't so well worked out in detail.

- 1856: in Florence at Fonderia del Pignone (now Nuovo Pignone, a subsidiary of General Electric), Pietro Benini realized a working prototype of the Barsanti-Matteucci engine, supplying 5 HP. In subsequent years he developed more powerful engines—with one or two pistons—which served as steady power sources, replacing steam engines.

- 1860: Belgian Jean Joseph Etienne Lenoir (1822–1900) produced a gas-fired internal combustion engine similar in appearance to a horizontal double-acting steam beam engine, with cylinders, pistons, connecting rods, and flywheel in which the gas essentially took the place of the steam. This was the first internal combustion engine to be produced in numbers.

- 1862: German inventor Nikolaus Otto designed an indirect-acting free-piston compressionless engine whose greater efficiency won the support of Langen and then most of the market, which at that time was mostly for small stationary engines fueled by lighting gas.

- 1870: In Vienna, Siegfried Marcus put the first mobile gasoline engine on a handcart.

- 1876: Nikolaus Otto, working with Gottlieb Daimler and Wilhelm Maybach, developed a practical four-stroke cycle (Otto cycle) engine. The German courts, however, did not hold his patent to cover all in-cylinder compression engines or even the four-stroke cycle, and after this decision, in-cylinder compression became universal.

- 1879: Karl Benz, working independently, was granted a patent for his internal combustion engine, a reliable two-stroke gas engine, based on Nikolaus Otto's design of the four-stroke engine. Later, Benz designed and built his own four-stroke engine that was used in his automobiles, which became the first automobiles in production.

- 1882: James Atkinson invented the Atkinson cycle engine. Atkinson’s engine had one power phase per revolution together with different intake and expansion volumes, making it more efficient than the Otto cycle.

- 1885: German engineer Gottlieb Daimler received a German patent for a supercharger

- 1891: Herbert Akroyd Stuart built his oil engine, leasing rights to Hornsby of England to build them. They built the first cold-start compression-ignition engines. In 1892, they installed the first ones in a water pumping station. In the same year, an experimental higher-pressure version produced self-sustaining ignition through compression alone.

- 1892: Rudolf Diesel developed his Carnot heat engine type motor burning powdered coal dust.

- 1887: Gustaf de Laval introduces the de Laval Nozzle

- 1893 February 23: Rudolf Diesel received a patent for the diesel engine.

- 1896: Karl Benz invented the boxer engine, also known as the horizontally opposed engine, in which the corresponding pistons reach top dead center at the same time, thus balancing each other in momentum.

- 1900: Rudolf Diesel demonstrated the diesel engine in the 1900 Exposition Universelle (World's Fair) using peanut oil (see biodiesel).

- 1900: Wilhelm Maybach designed an engine built at Daimler Motoren Gesellschaft—following the specifications of Emil Jellinek—who required the engine to be named Daimler-Mercedes after his daughter. In 1902 automobiles with that engine were put into production by DMG.

- 1903 - Konstantin Tsiolkovsky begins a series of theoretical papers discussing the use of rocketry to reach outer space. A major point in his work is liquid fueled rockets.

- 1903: Ægidius Elling builds a gas turbine using a centrifugal compressor which runs under its own power. By most definitions, this is the first working gas turbine.

- 1903-1906: The team of Armengaud and Lemale in France build a complete gas turbine engine. It uses three separate compressors driven by a single turbine. Limits on the turbine temperatures allow for only a 3:1 compression ratio, and the turbine is not based on a Parsons-like "fan", but a Pelton wheel-like arrangement. The engine is so inefficient, at about 3% thermal efficiency, that the work is abandoned.

- 1908: New Zealand inventor Ernest Godward started a motorcycle business in Invercargill and fitted the imported bikes with his own invention – a petrol economiser. His economisers worked as well in cars as they did in motorcycles.

- 1908: Holzwarth starts work on extensive research on an "explosive cycle" gas turbine, based on the Otto cycle. This design burns fuel at a constant volume and is somewhat more efficient. By 1927, when the work ended, he has reached about 13% thermal efficiency.

- 1908: René Lorin patents a design for the ramjet engine.

- 1910: Henri Coandă builds and flies the world's first jet powered aircraft, the Coanda-1910. It uses an engine-powered compressor mounted in a short duct. Efficiency is low and he abandons the concept, although his studies of burning resulted in the discovery of the Coanda effect. Although this is the first design to be powered by a jet of air, it does not get its power from a gas turbine and is thus not a "jet engine" in the current meaning of the term.

- 1916: Auguste Rateau suggests using exhaust-powered compressors to improve high-altitude performance, the first example of the turbocharger.

- 1926 - Robert Goddard builds and launches the first liquid fuel rocket.

- 1920: W.J. Stern reports to the Royal Air Force that there is no future for the turbine engine in aircraft. He bases his argument on the extremely low efficiency of existing compressor designs. Stern's paper is so convincing there is little official interest in gas turbine engines anywhere, although this does not last long.

- 1921: Maxime Guillaume patents the axial-flow gas turbine engine. It uses multiple stages in both the compressor and turbine, combined with a single very large combustion chamber.

- 1923: Edgar Buckingham at the United States National Bureau of Standards publishes a report on jets, coming to the same conclusion as W.J. Stern, that the turbine engine is not efficient enough. In particular he notes that a jet would use five times as much fuel as a piston engine.

- 1925: Wilhelm Pape patents a constant-volume engine design.

- 1926: Alan Arnold Griffith publishes his groundbreaking paper Aerodynamic Theory of Turbine Design, changing the low confidence in jet engines. In it he demonstrates that existing compressors are "flying stalled", and that major improvements can be made by redesigning the blades from a flat profile into an airfoil, going on to mathematically demonstrate that a practical engine is definitely possible and showing how to build a turboprop.

- 1926 - Robert Goddard launches the first liquid fuelled rocket

- 1927: Aurel Stodola publishes his "Steam and Gas Turbines" - basic reference for jet propulsion enginers in the USA.

- 1927: A testbed single-shaft turbocompressor based on Griffith's blade design is tested at the Royal Aircraft Establishment.

- 1929: Frank Whittle's thesis on jet engines is published

- 1930: Schmidt patents a pulsejet engine in Germany.

- 1936: French engineer René Leduc, having independently re-discovered René Lorin's design, successfully demonstrates the world's first operating ramjet.

- March, 1937: The Heinkel HeS 1 experimental hydrogen fueled centrifugal jet engine is tested at Hirth.

- July 18, 1942: The Messerschmitt Me 262 first jet engine flight

- 2004 Hyper-X first scramjet to maintain altitude

Applications

Internal combustion engines are most commonly used for mobile propulsion in automobiles, equipment, and other portable machinery. In mobile equipment, internal combustion is advantageous since it can provide high power-to-weight ratios together with excellent fuel energy-density. Generally using a petroleum called All-Petroleum Internal Combustion Engine Vehicles or APICEVs, these engines have appeared in transport in almost all automobiles, trucks, motorcycles, boats, and in a wide variety of aircraft and locomotives. They appear mostly in the form of turbines where a very high power is required, such as in jet aircraft, helicopters, and large ships.

They are also used for electric generators (i.e., 12V generators) and by industry.

Operation

1. Intake

2. compression

3. power

4. exhaust

All internal combustion engines depend on the exothermic chemical process of combustion: the reaction of a fuel, typically with the oxygen from the air—although other oxidizers such as nitrous oxide may be employed. Also see stoichiometry.

The most common modern fuels are made up of hydrocarbons and are derived mostly from petroleum. These include the fuels known as dieselfuel, gasoline and petroleum gas, and the rarer use of propane. Except for the fuel delivery components, most internal combustion engines that are designed for gasoline use can run on natural gas or liquefied petroleum gases without major modifications. Liquid and gaseous biofuels, such as ethanol and biodiesel (a form of diesel fuel that is produced from crops that yield triglycerides such as soybean oil), can also be used. Some others can also run on hydrogen gas.

All internal combustion engines must achieve ignition in their cylinders to create combustion. Typically engines use either a spark ignition (SI) method or a compression ignition (CI) system. In the past, other methods using hot tubes or flames have been used.

- Gasoline Ignition Process

Electrical or gasoline ignition systems—that can also run on other fuels—generally rely on a combination of a lead-acid battery and an induction coil to provide a high-voltage electrical spark to ignite the air-fuel mix in the engine's cylinders. This battery can be recharged during operation using an electricity-generating device such as an alternator or generator driven by the engine. Gasoline engines take in a mixture of air and gasoline and compress to less than 185 psi, then use a spark plug to ignite the mixture when it is compressed by the piston head in each cylinder.

- Diesel Ignition Process

Diesel Engine ignition systems, such as the diesel engine and HCCI engines, rely solely on heat and pressure created by the engine in its compression process for ignition. The compression that occurs is usually twice or more higher than a gasoline engine. Diesel engines will take in air only, and shortly before peak compression, a small quantity of diesel fuel is sprayed into the cylinder via a fuel injector that allows the fuel to instantly ignite. HCCI type engines will take in both air and fuel but continue to rely on an unaided auto-combustion process, due to higher pressures and heat. This is also why diesel and HCCI engines are also more susceptible to cold-starting issues, although they will run just as well in cold weather once started. Most diesels also have a battery and charging system; nevertheless, this system is secondary and is added by manufacturers as a luxury for the ease of starting, turning fuel on and off (which can also be done via a switch or mechanical apparatus), and for running auxiliary electrical components and accessories. Most new engines rely on electrical systems that also control the combustion process to increase efficiency and reduce emissions.

Measures of engine performance

Engine types vary greatly in a number of different ways:

- energy efficiency

- fuel/propellant consumption (brake specific fuel consumption for shaft engines, thrust specific fuel consumption for jet engines)

- power to weight ratio

- thrust to weight ratio

Energy Efficiency

Once ignited and burnt, the combustion products—hot gases—have more available thermal energy than the original compressed fuel-air mixture (which had higher chemical energy). The available energy is manifested as high temperature and pressure that can be translated into work by the engine. In a reciprocating engine, the high-pressure gases inside the cylinders drive the engine's pistons.

Once the available energy has been removed, the remaining hot gases are vented (often by opening a valve or exposing the exhaust outlet) and this allows the piston to return to its previous position (top dead center, or TDC). The piston can then proceed to the next phase of its cycle, which varies between engines. Any heat that isn't translated into work is normally considered a waste product and is removed from the engine either by an air or liquid cooling system.

Engine efficiency can be discussed in a number of ways but it usually involves a comparison of the total chemical energy in the fuels, and the useful energy abstracted from the fuels in the form of kinetic energy. The most fundamental and abstract discussion of engine efficiency is the thermodynamic limit for abstracting energy from the fuel defined by a thermodynamic cycle. The most comprehensive is the empirical fuel economy of the total engine system for accomplishing a desired task; for example, the miles per gallon accumulated.

Internal combustion engines are primarily heat engines and as such the phenomenon that limits their efficiency is described by thermodynamic cycles. None of these cycles exceed the limit defined by the Carnot cycle which states that the overall efficiency is dictated by the difference between the lower and upper operating temperatures of the engine. A terrestrial engine is usually and fundamentally limited by the upper thermal stability derived from the material used to make up the engine. All metals and alloys eventually melt or decompose and there is significant researching into ceramic materials that can be made with higher thermal stabilities and desirable structural properties. Higher thermal stability allows for greater temperature difference between the lower and upper operating temperatures—thus greater thermodynamic efficiency.

The thermodynamic limits assume that the engine is operating in ideal conditions. A frictionless world, ideal gases, perfect insulators, and operation at infinite time. The real world is substantially more complex and all the complexities reduce the efficiency. In addition, real engines run best at specific loads and rates as described by their power curve. For example, a car cruising on a highway is usually operating significantly below its ideal load, because the engine is designed for the higher loads desired for rapid acceleration. The applications of engines are used as contributed drag on the total system reducing overall efficiency, such as wind resistance designs for vehicles. These and many other losses result in an engines' real-world fuel economy that is usually measured in the units of miles per gallon (or kilometers per liter) for automobiles. The miles in, "MPG" represents a meaningful amount of work and the volume of hydrocarbon implies a standard energy content.

Most steel engines have a thermodynamic limit of 37%. Even when aided with turbochargers and stock efficiency aids, most engines retain an average efficiency of about 20%.

There are many inventions concerned with increasing the efficiency of IC-Engines. In general, practical engines are always compromised by trade-offs between different properties such as efficiency, weight, power, response, exhaust emissions, or noise. Sometimes economy also plays a role in not only in the cost of manufacturing the engine itself, but also manufacturing and distributing the fuel. Increasing the engines' efficiency brings better fuel economy but only if the fuel cost per energy content is the same.

Measures of fuel/propellant efficiency

For stationary and shaft engines including propeller engines, fuel consumption is measured by calculating the brake specific fuel consumption which measures the number of pounds of fuel that is needed to generate an hours' worth of horsepower-energy. In metric units, the number of grams of fuel needed to generate a kWh of energy is calculated.

For internal combustion engines in the form of jet engines, the power output varies drastically with airspeed and a less variable measure is used: thrust specific fuel consumption (TSFC), which is the number of pounds of propellant that is needed to generate impulses that measure a pound an hour. In metric units, the number of grams of propellant needed to generate an impulse that measures one kilonewton per second.

For rockets— TSFC can be used, but typically other measures are traditionally used, such as specific impulse and effective exhaust velocity.

Air and noise pollution

Internal combustion engines such as reciprocating internal combustion engines produce air pollution emissions, due to incomplete combustion of carbonaceous fuel. The main derivatives of the process are carbon dioxide CO

2, water and some soot—also called particulate matter (PM). The effects of inhaling particulate matter have been widely studied in humans and animals which include asthma, lung cancer, cardiovascular issues, and premature death. There are however some additional products of the combustion process that include nitrogen oxides and sulfur and some uncombusted hydrocarbons, depending on the operating conditions and the fuel-air ratio.

The fuel does not get completely burned in the engine and passes through the exhaust unchanged. The primary causes of this is the need to operate near the stoichiometric ratio for gasoline engines in order to achieve combustion and the resulting "quench" of the flame by the relatively cool cylinder walls, otherwise the fuel would burn more completely in excess air. When running at lower speeds, quenching is commonly observed in diesel (compression ignition) engines that run on natural gas. It reduces the efficiency and increases knocking, sometimes causing the engine to stall. Increasing the amount of air in the engine reduces the amount of the first two pollutants, but tends to encourage the oxygen and nitrogen in the air to combine to produce Nitrogen Oxides (NOx) that has been demonstrated to be hazardous to both plant and animal health. Further chemicals released are Benzene and 1,3-Butadiene that are also particularly harmful; and not all of the fuel burns up completely, so Carbon Monoxide (CO) is also produced.

Carbon fuels contain sulfur and impurities that eventually lead to producing sulfur oxides (SO) and Sulphur Dioxide (SO2) in the exhaust which promotes acid rain. One final element in exhaust pollution is Ozone (O3). This is not emitted directly but made in the air by the action of sunlight on other pollutants to form "ground level Ozone", which, unlike the "Ozone Layer" in the high atmosphere, is regarded as a bad thing if the levels are too high. Ozone is actually broken down by Nitrogen Oxides, so one tends to be lower where the other is higher.

For the pollutants described above (Nitrogen Oxides, Carbon Monoxide, Sulphur Dioxide, and Ozone) there are accepted levels that are set by legislation to which no harmful effects are observed—even in sensitive population groups. For the other three: Benzene: 1:3 butadiene: particulates, there is no way of proving they are safe at any level so the experts set standards where the risk to health is, "exceedingly small".

Finally, significant contributions to noise pollution are made by internal combustion engines. Most of this noise produced is due to automobile and truck traffic operating on highways and street systems.

Parts

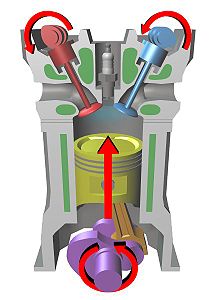

For a four-stroke engine, key parts of the engine include the crankshaft (purple), connecting rod (orange), one or more camshafts (red and blue), and valves. For a two-stroke engine, there may simply be an exhaust outlet and fuel inlet instead of a valve system. In both types of engines there are one or more cylinders (grey and green), and for each cylinder there is a spark plug (darker-grey), a piston (yellow), and a crank (purple). A single sweep of the cylinder by the piston in an upward or downward motion is known as a stroke. The downward stroke that occurs directly after the air-fuel mix passes from the carburetor or fuel injector to the cylinder, where it is ignited. This is also known as a power stroke.

A Wankel engine has a triangular rotor that orbits in an epitrochoidal (figure 8 shape) chamber around an eccentric shaft. The four phases of operation (intake, compression, power, and exhaust) take place in what is effectively a moving, variable-volume chamber.

A Bourke Engine uses a pair of pistons integrated to a Scotch Yoke that transmits reciprocating force through a specially designed bearing assembly to turn a crank mechanism. The intake, compression, power, and exhaust occur in each stroke.

Classification

At one time the word, "engine" (from Latin, via Old French, ingenium, "ability") meant any piece of machinery—a sense that persists in expressions such as siege engine. A "motor" (from Latin motor, "mover") is any machine that produces mechanical power. Traditionally, electric motors are not referred to as, "engines"; however, combustion engines are often referred to as, "motors." (An electric engine refers to a locomotive operated by electricity).

However, many people consider engines as things which generate their power from within, and motors as requiring an outside source of energy to perform work.

Engines can be classified in many different ways: by the principles of operation: by the source of energy: by the use of the engine, or by the cooling system employed.

Principles of operation

- Crude oil engine

- Two-stroke cycle

- Four-stroke cycle

- Six-stroke engine

- Hot bulb engine

- Diesel engine

- Poppet valves

- Sleeve valve

- Atkinson cycle

- Free-piston engine

- Proposed

- Improvements

- Controlled Combustion Engine

- Demonstrated:

- Proposed:

- Differential-Stroke Cycle (D-Cycle) Engine

- Orbital engine

- Quasiturbine

- Rotary Atkinson cycle engine

- Toroidal engine

- Trochilic engine

Continuous combustion:

- Gas turbine

- Jet engine (including turbojet, turbofan, ramjet, Rocket etc.)

Engine cycle

Two-stroke

Main article: Two-stroke cycleEngines based on the two-stroke cycle use two strokes (one up, one down) for every power stroke. Since there are no dedicated intake or exhaust strokes, alternative methods must be used to scavenge the cylinders. The most common method in spark-ignition two-strokes is to use the downward motion of the piston to pressurize fresh charge in the crankcase, which is then blown through the cylinder through ports in the cylinder walls.

Spark-ignition two-strokes are small and light for their power output and mechanically very simple; however, they are also generally less efficient and more polluting than their four-stroke counterparts. In terms of cubic centimeter for cubic centermeter, a single-cylinder small motor application like a two-stroke engine produces much more power than an equivalent four-strokes due to the enormous advantage of having one power stroke for every 360 degrees of crankshaft rotation (compared to 720 degrees in a 4 stroke motor).

Small displacement, crankcase-scavenged two-stroke engines have been less fuel-efficient than other types of engines when the fuel is mixed with the air prior to scavenging allowing some of it to escape out of the exhaust port. Modern designs (Sarich and Paggio) use air-assisted fuel injection which avoids this loss, and are more efficient than comparably sized four-stroke engines. Fuel injection is essential for a modern two-stroke engine in order to meet ever more stringent emission standards.

Research continues into improving many aspects of two-stroke motors including direct fuel injection, amongst other things. The initial results have produced motors that are much cleaner burning than their traditional counterparts. Two-stroke engines are widely used in snowmobiles, lawnmowers, weed-whackers, chain saws, jet skis, mopeds, outboard motors, and many motorcycles.

The largest compression-ignition engines are two-strokes and are used in some locomotives and large ships. These particular engines use forced induction to scavenge the cylinders; an example of this type of motor is the Wartsila-Sulzer turbocharged two-stroke diesel as used in large container ships. It is the most efficient and powerful engine in the world with over 50% thermal efficiency. For comparison, the most efficient small four-stroke motors are around 43% thermal efficiency (SAE 900648); size is an advantage for efficiency due to the increase in the ratio of volume to area.

Four-stroke

Main article: Four-stroke cycleEngines based on the four-stroke or Otto cycle have one power stroke for every four strokes (up-down-up-down) and are used in cars, larger boats, some motorcycles, and many light aircraft. They are generally quieter, more efficient, and larger than their two-stroke counterparts. There are a number of variations of these cycles, most notably the Atkinson and Miller cycles. Most truck and automotive diesel engines use a four-stroke cycle, but with a compression heating ignition system. This variation is called the diesel cycle. The steps involved here are:

- Intake stroke: Air and vaporized fuel are drawn in.

- Compression stroke: Fuel vapor and air are compressed and ignited.

- Combustion stroke: Fuel combusts and piston is pushed downwards.

- Exhaust stroke: Exhaust is driven out. During the 1st, 2nd, and 4th stroke the piston is relying on power and the momentum generated by the other pistons. In that case, a four cylinder engine would be less powerful than a six or eight cylinder engine.

Five-stroke

Engines based on the five-stroke cycle are a variant of the four-stroke cycle. Normally, the four cycles are intake, compression, combustion, and exhaust. The fifth cycle is added by Delautour is refrigeration. Engines running on a five-stroke cycle are claimed to be up to 30% more efficient than equivalent four-stroke engines.

Six-stroke

The six stroke engine captures the wasted heat from the four-stroke Otto cycle and creates steam, which simultaneously cools the engine while providing a free power stroke. This removes the need for a cooling system making the engine lighter while giving 40% increased efficiency over the Otto Cycle.

Beare Head Technology combines a four-stroke engine bottom end with a ported cylinder which closely resembles that of a two-stroke: thus, 4+2 equals a six-stroke. It has an opposing piston that acts in unison with auxiliary low pressure reed and rotary valves, which allows variable compression and a range of tuning options.

IRIS Engine

Main article: IRIS engineThe IRIS design replaces the piston and cylinder architecture of conventional engines with a mechanism called the Internally Radiating Impulse Structure or, "IRIS". In an IRIS combustion chamber, a number of inverted segments of a circle or, "chordons", interact to create a continuously sealed chamber of variable volume. Instead of elongating during combustion—as a traditional engine does—the IRIS engines' chamber expands in diameter. This innovation may significantly enhance fuel efficiency by reducing waste heat and increasing the amount of surface area the engine has available to produce torque.

Bourke engine

Main article: Bourke engineIn this engine, two opposed cylinders are linked to the crank by a Scotch yoke. The Scotch yoke mechanism prevents side thrust which in turn prevents any piston slap allowing the operation as a detonation or "explosion" engine. This also greatly reduces friction between pistons and cylinder walls. The Bourke engine uses fewer moving parts and has to overcome less friction than conventional crank and slider engines with poppet valves, however no independent testing of this engine has ever expanded any of these claims.

Controlled Combustion Engine

Main article: Controlled Combustion EngineThese are also cylinder-based engines, which may be one or two-stroke but instead of a crankshaft and piston rods, use two gear-connected, counterrotating concentric cams to convert reciprocating motion into rotary movement. These cams practically cancel out sideward forces that would otherwise be exerted on the cylinders by the pistons greatly improving mechanical efficiency. The number of lobes of the cams (always an odd number not less than 3) determines the piston travel versus the torque delivered. In this engine, there are two cylinders that are 180 degrees apart for each pair of counterrotating cams. For single-stroke versions, there are as many cycles per cylinder pair as there are lobes on each cam and twice as many for two-stroke engines.

Wankel

Main article: Wankel engineThe Wankel engine (rotary engine) does not have piston strokes so it is more properly called a, "four-phase"—rather than a four-stroke engine. It operates with the same separation of phases as the four-stroke engine with the phases taking place in separate locations in the engine. While it is true that three power strokes typically occur per rotor revolution due to the 3/1 revolution ratio of the rotor to the eccentric shaft, only one power stroke per shaft revolution actually occurs; this engine provides three power 'strokes' per revolution per rotor giving it a greater power-to-weight ratio than piston engines. This type of engine is most notably used in the current Mazda RX-8, the earlier RX-7, and other models.

Gas turbine

Main article: Gas turbineGas turbine cycle engines employ a continuous combustion system where compression, combustion, and expansion occur simultaneously at different places in the engine—giving continuous power.

A gas turbine is a rotary machine similar in principle to a steam turbine and it consists of three main components: a compressor, a combustion chamber, and a turbine. The air after being compressed in the compressor is heated by burning fuel in it. About two-thirds of the heated air combined with the products of combustion is expanded in a turbine resulting in work output which is used to drive the compressor. The rest (about one-third) is available as useful work output.

Jet engine

Main article: Jet engineJet engines take a large volume of hot gas from a combustion process (typically a gas turbine, but rocket forms of jet propulsion often use solid or liquid propellants) and feed it through a nozzle which accelerates the jet to high speed. As the jet accelerates through the nozzle, this creates thrust and in turn does useful work.

Disused methods

In some old noncompressing internal combustion engines: in the first part of the piston downstroke, a fuel-air mixture was sucked or blown in, and in the rest of the piston downstroke, the inlet valve closed and the fuel-air mixture fired. In the piston upstroke, the exhaust valve was open. This was an attempt at imitating the way a piston steam engine works, and since the explosive mixture was not compressed, the heat and pressure generated by combustion was much less causing lower overall efficiency.

Fuels and oxidizers

Fuels

Nowadays, fuels used include:

- Petroleum:

- Petroleum spirit (North American term: gasoline, British term: petrol)

- Petroleum diesel.

- Autogas (liquified petroleum gas).

- Compressed natural gas.

- Jet fuel (aviation fuel)

- Coal:

- Most methanol is made from coal.

- Gasoline-like fuels can be made from coal.

- Biofuels and vegoils:

- Peanut oil and other vegoils.

- Biofuels:

- Biobutanol (replaces gasoline).

- Biodiesel (replaces petrodiesel).

- Bioethanol and Biomethanol (wood alcohol) and other biofuels (see Flexible-fuel vehicle).

- Biogas

- Hydrogen (mainly spacecraft rocket engines)

Even fluidized metal powders and explosives have seen some use. Engines that use gases for fuel are called gas engines and those that use liquid hydrocarbons are called oil engines, however gasoline engines are also often colloquially referred to as, "gas engines".

The main limitations on fuels are that it must be easily transportable through the fuel system to the combustion chamber, and that the fuel releases sufficient energy in the form of heat upon combustion to make practical use of the engine.

Diesel engines are generally heavier, noisier, and more powerful at lower speeds than gasoline engines. They are also more fuel-efficient in most circumstances and are used in heavy road vehicles, some automobiles (increasingly so for their increased fuel efficiency over gasoline engines), ships, railway locomotives, and light aircraft. Gasoline engines are used in most other road vehicles including most cars, motorcycles, and mopeds. Note that in Europe, sophisticated diesel-engined cars have taken over about 40% of the market since the 1990s. There are also engines that run on hydrogen, methanol, ethanol, liquefied petroleum gas (LPG), and biodiesel. Paraffin and tractor vaporizing oil (TVO) engines are no longer seen.

Hydrogen

At present, hydrogen is mostly used as fuel for rocket engines. In the future, hydrogen might replace more conventional fuels in traditional internal combustion engines. If hydrogen fuel cell technology becomes widespread, then the use of internal combustion engines may be phased out.

Although there are multiple ways of producing free hydrogen, those methods require converting combustible molecules into hydrogen or consuming electric energy. Unless that electricity is produced from a renewable source—and is not required for other purposes—it seems hydrogen does not solve any energy crisis. The disadvantage of hydrogen in many situations is its storage. Liquid hydrogen has extremely low density (14 times lower than water) and requires extensive insulation—whilst gaseous hydrogen requires heavy tankage. Even when liquefied, hydrogen has a higher specific energy but the volumetric energetic storage is still roughly five times lower than petrol. The 'Hydrogen on Demand' process (see direct borohydride fuel cell) creates hydrogen as it is needed, but has other issues such as the high price of the sodium borohydride which is the raw material.

Oxidizers

Since air is plentiful at the surface of the earth, the oxidizer is typically atmospheric oxygen which has the advantage of not being stored within the vehicle, increasing the power-to-weight and power to volume ratios. There are other materials that are used for special purposes, often to increase power output or to allow operation under water or in space.

- Compressed air has been commonly used in torpedoes.

- Compressed oxygen, as well as some compressed air, was used in the Japanese Type 93 torpedo. Some submarines are designed to carry pure oxygen. Rockets very often use liquid oxygen.

- Nitromethane is added to some racing and model fuels to increase power and control combustion.

- Nitrous oxide has been used—with extra gasoline—in tactical aircraft and in specially equipped cars to allow short bursts of added power from engines that otherwise run on gasoline and air. It is also used in the Burt Rutan rocket spacecraft.

- Hydrogen peroxide power was under development for German World War II submarines and may have been used in some non-nuclear submarines.

- Black or smokeless gunpowder has been used in diesel engine starters to deploy or jettison equipment remotely, and by Alphonse Pénaud in pioneering model aircraft.

- Other chemicals such as chlorine or fluorine have been used experimentally, but have not been found to be practical.

Engine configuration

Internal combustion engines can be classified by their configuration which affects their physical size and smoothness, with smoother engines producing less vibration. Common configurations include the straight or inline configuration, the more compact V configuration, and the wider but smoother flat or boxer configuration. Aircraft engines can also adopt a radial configuration which allows more effective cooling. More unusual configurations such as the H, U, X, and W have also been used.

Multiple crankshaft configurations do not necessarily need a cylinder head at all because it can instead have a piston at each end of the cylinder called an opposed piston design. This design was used in the Junkers Jumo 205 diesel aircraft engine, using at either end of a single bank of cylinders with two crankshafts, and most remarkably in the Napier Deltic diesel engines. These used three crankshafts to serve three banks of double-ended cylinders arranged in an equilateral triangle with the crankshafts at the corners. It was also used in single-bank locomotive engines, and continues to be used for marine engines, both for propulsion and for auxiliary generators. The Gnome Rotary engine, used in several early aircraft, had a stationary crankshaft and a bank of radially arranged cylinders rotating around it.

Engine capacity

An engines' capacity is the displacement or swept volume by the pistons of the engine. It is generally measured in liters (L) or cubic inches (c.i.d. or cu in or in³) for larger engines, and cubic centimeters (abbreviated cc) for smaller engines. Engines with greater capacities are usually more powerful and provide greater torque at lower rpm, but also consume more fuel. Apart from designing an engine with more cylinders, there are two ways to increase an engines' capacity. The first is to lengthen the stroke: the second is to increase the pistons' diameter (See also: Stroke ratio). In either case, it may be necessary to make further adjustments to the fuel intake of the engine to ensure optimal performance.

Common components

Combustion chambers

Internal combustion engines can contain any number of combustion chambers (cylinders), with numbers between one and twelve being common, though as many as 36 (Lycoming R-7755) have been used. Having more cylinders in an engine yields two potential benefits: first, the engine can have a larger displacement with smaller individual reciprocating masses, that is, the mass of each piston can be less thus making a smoother-running engine since the engine tends to vibrate as a result of the pistons moving up and down: secondly, with a greater displacement and more pistons, more fuel can be combusted and there can be more combustion events (more power strokes) in a given period of time. This means that such an engine can generate more torque than a similar engine with fewer cylinders.

The downside to having more pistons is that the engine will tend to weigh more and generate more internal friction as the greater number of pistons rub against the inside of their cylinders. This tends to decrease fuel efficiency and robs the engine of some of its power. For high-performance gasoline engines using current materials and technology—such as the engines found in modern automobiles, there seems to be a break-point around 10 or 12 cylinders after which the addition of cylinders becomes an overall detriment to performance and efficiency. Although, exceptions such as the W16 engine from Volkswagen exist.

- Most car engines have four to eight cylinders with some high performance cars having ten, twelve—or even sixteen, and some very small cars and trucks having two or three. In previous years, some quite large cars such as the DKW and Saab 92, had two-cylinder or two-stroke engines.

- Radial aircraft engines (now obsolete) had from three to 28 cylinders; an example is the Pratt & Whitney R-4360. A row contains an odd number of cylinders so an even number indicates a two- or four-row engine. The largest of these was the Lycoming R-7755 with 36 cylinders (four rows of nine cylinders), but it did not enter production.

- Motorcycles commonly have from one to four cylinders, with a few high performance models having six; although, some 'novelties' exist with 8, 10, or 12.

- Snowmobiles usually have two cylinders. Some larger but not necessarily high-performance touring machines, have four.

- Small portable appliances such as chainsaws, generators, and domestic lawn mowers most commonly have one cylinder, but two-cylinder chainsaws exist.

Ignition system

An internal combustion engine can be classified by its ignition system. Today most engines use an electrical or compression heating system for ignition. However, outside flame and hot-tube systems have been used historically. Nikola Tesla gained one of the first patents on the mechanical ignition system with U.S. patent 609,250, "Electrical Igniter for Gas Engines", on 16 August, 1898.

Spark

Main article: ignition systemThe mixture is ignited by an electrical spark from a spark plug—the timing of which is very precisely controlled. Almost all gasoline engines are of this type, but not diesel engines.

Compression

Ignition comes from the heat derived from oxidation and the mechanical compression of the air or mixture. The vast majority of compression ignition engines are diesels in which the fuel is mixed with the air after the air has reached ignition temperature. In this case, the timing comes from the fuel injection system. Very small model engines for which simplicity is more important than fuel costs, use special fuels to control ignition timing.

Timing

The point in the cycle at which the fuel-oxidizer mixture is ignited has a direct effect on the efficiency and output of the ICE. The thermodynamics of the idealized Carnot heat engine tells us that an ICE is most efficient if most of the burning takes place at a high temperature, resulting from compression—near top dead center. The speed of the flame front is directly affected by the compression ratio, fuel mixture temperature, and octane or cetane rating of the fuel. Leaner mixtures and lower mixture pressures burn more slowly requiring more advanced ignition timing. It is important to have combustion spread by a thermal flame front (deflagration), not by a shock wave. Combustion propagation by a shock wave is called detonation and, in engines, is also known as pinging or knocking.

So at least in gasoline-burning engines, ignition timing is largely a compromise between an earlier "advanced" spark—which gives greater efficiency with high octane fuel—and a later "retarded" spark that avoids detonation with the fuel used. For this reason, high-performance diesel automobile proponents such as, Gale Banks, believe that

- There’s only so far you can go with an air-throttled engine on 91-octane gasoline. In other words, it is the fuel, gasoline, that has become the limiting factor. ... While turbocharging has been applied to both gasoline and diesel engines, only limited boost can be added to a gasoline engine before the fuel octane level again becomes a problem. With a diesel, boost pressure is essentially unlimited. It is literally possible to run as much boost as the engine will physically stand before breaking apart. Consequently, engine designers have come to realize that diesels are capable of substantially more power and torque than any comparably sized gasoline engine.

Fuel systems

Main article: Fuel injection

Fuels burn faster and more completely when they have lots of surface area in contact with oxygen. In order for an engine to work efficiently the fuel must be vaporized into the incoming air in what is commonly referred to as a fuel-air mixture. There are two commonly used methods of vaporizing fuel into the air: one is the carburetor: the other is fuel injection.

Often for simpler reciprocating engines, a carburetor is used to supply fuel into the cylinder. However, exact control of the correct amount of fuel supplied to the engine is impossible. Carburetors are the current most widespread fuel mixing device used in lawn mowers and other small engine applications. Prior to the mid-1980s, carburetors were also common in automobiles.

Larger gasoline engines used in automobiles have mostly moved to fuel injection systems (see Gasoline Direct Injection). Diesel engines always use fuel injection because it is the fuel system that controls the ignition timing.

Autogas (LPG) engines use either fuel injection systems or open- or closed-loop carburetors.

Other internal combustion engines like jet engines use burners and rocket engines use various different ideas including impinging jets, gas/liquid shear, preburners, and many other ideas.

Oxidiser-Air inlet system

Some engines such as solid rockets have oxidisers already within the combustion chamber but in most cases for combustion to occur, a continuous supply of oxidiser must be supplied to the combustion chamber.

Oxidisers can be liquid or gas and are either sucked in by a piston increasing the volume of the chamber ("Naturally aspirated"), or pumped in by a centrifugal or axial compressor; for example, by a forced induction system. Forced induction systems are particularly important at high altitude such as with aeronautic engines, but at lower altitudes they are often used to increase the airflow through the engine at high engine speeds thus permitting improved power outputs.

Valves

Main article: valveWith a few exceptions, all internal combustion engines employ valves to control the admittance of fuel and air into the combustion chamber.

Piston engine valves

Main article: Piston engine valveIn piston engines, the valves are grouped into 'inlet valves' which admit the entrance of fuel and air and 'outlet valves' which allow the exhaust gases to escape. Each valve opens once per cycle and the ones that are subject to extreme accelerations are held closed by springs that are typically opened by rods running on a camshaft rotating with the engines' crankshaft.

Control valves

Continuous combustion engines—as well as piston engines—usually have valves that open and close to admit the fuel and/or air at the startup and shutdown. Some valves feather to adjust the flow to control power or engine speed as well.

Cooling systems

Combustion generates a great deal of heat, and some of this transfers to the walls of the engine. Material failure will also occur if the body of the engine is allowed to reach a high temperature.

Cooling systems usually employ air or liquid cooling while some very hot engines using radiative cooling (especially some Rocket engines). Some high altitude rocket engines use ablative cooling where the walls gradually erode in a controlled fashion.

Lubrication Systems

Internal combustions engines require lubrication in operation to allow moving parts to slide smoothly over each other. Insufficient lubrication will subject the engine to rapid wear and ultimately, it may even seize up entirely.

Several different types of lubrication systems are used. Simple two-stroke engines are lubricated by oil mixed into the fuel or injected into the induction stream as a spray. Early slow-speed stationary and marine engines were lubricated by gravity from small chambers similar to those used on steam engines at the time—with an engine tender refilling these as needed. As engines were adapted for automotive and aircraft use, the need for a high power-to-weight ratio led to increased speeds, higher temperatures, and greater pressure on bearings which in turn required pressure-lubrication for crank bearings and connecting-rod journals. This was provided either by a direct lubrication from a pump, or indirectly by a jet of oil directed at pickup cups on the connecting rod ends which had the advantage of providing higher pressures as the engine speed increased.

Diagnosis systems

Main article: On Board DiagnosticsEngine On Board Diagnostics (also known as OBD) is a computerized system that allows for electronic diagnosis of a vehicles' powerplant. The first generation, known as OBD1, was introduced 10 years after the U.S. Congress passed the Clean Air Act in 1970 as a way to monitor a vehicles' fuel injection system. OBD2, the second generation of computerized on-board diagnostics, was codified and recommended by the California Air Resource Board in 1994 and became mandatory equipment aboard all vehicles sold in the United States as of 1996.

References

- ^ Encyclopedia Britannica: Internal Combustion engines

- ^ Answers.com Internal combustion engine

- ^ Columbia encyclopedia: Internal combustion engine

- ^

- Donald Routledge Hill (1998). Studies in Medieval Islamic Technology II, p. 231-232.

- Physics In an Automotive Engine

- Improving IC Engine Efficiency

- Williams, Tony (2006). 101 Ingenious Kiwis. Reed Publishing (NZ) Ltd. pp. pp.83.

{{cite book}}:|pages=has extra text (help); Cite has empty unknown parameter:|coauthors=(help) - Diesel — The Performance Choice, Banks Talks Tech, 11.19.04

Bibliography

- Singer, Charles Joseph; Raper, Richard, A History of Technology : The Internal Combustion Engine, edited by Charles Singer ... , Clarendon Press, 1954-1978. pp.157-176

- Hardenberg, Horst O., The Middle Ages of the Internal combustion Engine, Society of Automotive Engineers (SAE), 1999

See also

- Cox Models for simple and inexpensive working engines, suitable for demonstrations

- Dynamometer

- Electric vehicle

- Engine test stand — information about how to check an internal combustion engine

- External Combustion Engine

- Heat pump

- Hybrid vehicle

- Petrofuel

- William Barnett — an early patentee (1838)

External links

- Animated Engines - explains a variety of types

- Intro to Car Engines - Cut-away images and a good overview of the internal combustion engine

- The Fuel and Engine Bible - A good resource for different engine types and fuels

- Self Improvement Wednesday - ABC 702 Drive audio

- The role of spray technology and combustion engines

- Walter E. Lay Auto Lab - Research at The University of Michigan

- youtube - Animation of the components and built-up of a 4-cylinder engine

- youtube - Animation of the internal moving parts of a 4-cylinder engine

- Small engine repair Carburetor Adjustments

- A site dedicated to Barsanti & Matteucci engine

- Hypervideo showing construction and operation of a four cylinder internal combustion engine courtesy of Ford Motor Company

- Next generation engine technologies retrieved May 9, 2009

| Thermodynamic cycles | |||||

|---|---|---|---|---|---|

| External combustion / thermal |

| ||||

| Internal combustion / thermal | |||||

| Mixed | |||||

| Refrigeration | |||||

| Internal combustion engine | |

|---|---|

| Part of the Automobile series | |

| Engine block and rotating assembly | |

| Valvetrain and Cylinder head | |

| Forced induction | |

| Fuel system | |

| Ignition | |

| Engine management | |

| Electrical system | |

| Intake system | |

| Exhaust system | |

| Cooling system | |

| Lubrication | |

| Other | |