| Revision as of 14:24, 29 June 2009 editBarnstarbob (talk | contribs)23,416 editsNo edit summary← Previous edit | Revision as of 23:10, 29 June 2009 edit undoScheinwerfermann (talk | contribs)Extended confirmed users, Pending changes reviewers, Rollbackers10,205 edits →Early 140 CID engine: Cleanup, rm/rw POV and essay, spelling grammar, tense.Next edit → | ||

| Line 254: | Line 254: | ||

| ===Early 140 CID engine=== | ===Early 140 CID engine=== | ||

| ] | ] | ||

| Jacobson confirmed a problem involving the early two-barrel Rochester carburetor. The Vega engine sometimes shook so violently that it would loosen the screws holding the top cover to the carburetor body. The top cover would then jump up and down, which activated the accelerator pump, which shot raw ] through the cylinders and into the exhaust system. Fuel would puddle inside the ] and eventually explode. The early mufflers would blow out towards the fuel tank, so later ones were engineered so they'd blow away from the tank. ] was also applied to the carburetor bolts in production.<ref name="ReferenceA"/> For 1973, the Rochester carb was replaced with a Holly-Weber design.<ref>1973 Motor Trend 1973 Yearbook</ref> | |||

| According to Jacobson |

According to Jacobson, customers began complaining to dealers of excessive ] consumption. When the customer came in and complained that his car was getting {{convert|200|mi}} per quart (0.9 L) of oil, the mechanic would peer down the bore scope and see a little scuffing. Chevrolet engineers eventually found out that the problem had never been the scuffing of the (cylinder) bore. "The real problem was the valve stem seals. They'd harden, split, fall off, and oil would leak down past the valves and into the ]. So we did some experiments. When we got an oil burner, we simply replaced the valve-stem seals, and that cured it."<!-- where is the start of quote --><ref name="ReferenceA"/> 1976-77 Dura-built engines had redesigned seals that reduced oil consumption by fifty percent.<ref name="chevrolet1976">1976 Chevrolet brochure-Vega Dura-built engine-built to take it</ref> | ||

| The Vega's cooling system came in for criticism |

The Vega's cooling system also came in for criticism; it held only {{convert|6|usqt|l|1|abbr=off}} and had a tiny two-tube, {{convert|1|sqft|m2|1|abbr=on}} ]. Because of the leaking valve stem seals, the engine would often be low on oil and coolant simultaneously. This caused overheating, which distorted the open-deck block, allowing antifreeze to seep past the head gasket and causing piston scuffing inside the cylinders. | ||

| Fred Kneisler from GM Engineering maintained that too much emphasis has been put on overheating problems versus the real culprits: brittle valve stem seals and too-thin piston plating. Vega owners and many mechanics believed, though, that overheating was the big problem. In response, Chevrolet added a coolant overflow bottle and an electronic low-coolant indicator for 1974 that could be retrofitted to earlier models at no cost.<ref>1974 Chevrolet brochure-Vega</ref> | Fred Kneisler from GM Engineering maintained that too much emphasis has been put on overheating problems versus the real culprits:{{Fact|Date=June 2009}} brittle valve stem seals and too-thin piston plating. Vega owners and many mechanics believed, though, that overheating was the big problem. In response, Chevrolet added a coolant overflow bottle and an electronic low-coolant indicator for 1974 that could be retrofitted to earlier models at no cost.<ref>1974 Chevrolet brochure-Vega</ref> | ||

| Regardless of the cause, damaged cylinder walls were common - a problem that presented the Vega owner with three choices: | Regardless of the cause, damaged cylinder walls were common - a problem that presented the Vega owner with three choices: | ||

| *Have the block overbored and re-etched, and have new pistons installed. | *Have the block overbored and re-etched, and have new pistons installed. | ||

| Line 266: | Line 266: | ||

| *Replace the short block with a brand new unit. | *Replace the short block with a brand new unit. | ||

| Most owners |

Most owners opted to have the revised {{convert|50000|mi|km|0|abbr=on}} engine warranty cover the installation of a new short block.{{Fact|Date=June 2009}} This proved costly for Chevrolet. The 1976-77 Dura-Built 140 engine had improved engine block coolant pathways, a redesigned head gasket, water pump, and thermostat, and had a 5-year/{{convert|60000|mi|km|0|abbr=on}} warranty.<ref name="chevrolet1976"/> | ||

| Despite its |

Despite its problematic application in the Vega, the linerless aluminum/silicon engine block concept that GM and Reynolds developed turned out to be sound. ] and ] both use sleeveless aluminum engines today, the basic principles of which were developed for the Vega engine.<ref name="Collectable Automobile-April 2000"/> | ||

| {{clear}} | {{clear}} | ||

Revision as of 23:10, 29 June 2009

Motor vehicle| Chevrolet Vega | |

|---|---|

| File:1972 Chevy Vega GT.jpg 1972 Chevrolet Vega GT Hatchback | |

| Overview | |

| Manufacturer | General Motors Corporation Chevrolet Division |

| Also called | Vega 2300 |

| Production | 1970–1977 |

| Model years | 1971–1977 |

| Assembly | Lordstown Assembly-, Lordstown, Ohio, United States Sainte-Therese Assembly- Quebec, Canada |

| Designer | GM design staff Ed Cole-chief engineer Bill Mitchell-chief stylist |

| Body and chassis | |

| Class | Subcompact |

| Body style | 2-door sedan 2-door hatchback 2- door wagon 2- door panel delivery |

| Layout | FR layout |

| Platform | GM H platform (RWD) |

| Related | Pontiac Astre, Chevrolet Monza, Pontiac Sunbird, Buick Skyhawk, Oldsmobile Starfire |

| Powertrain | |

| Engine | 140 CID 2.3 Liter OHC 1bbl I4 140 CID 2.3 Liter OHC 2bbl I4 122 CID 2.0 Liter DOHC EFI I4 |

| Transmission | 3-speed manual 4-speed manual 5-speed manual w/overdrive Torque-Drive clutchless manual Powerglide 2 spd. automatic Turbo-Hydramatic 3 spd.automatic |

| Dimensions | |

| Wheelbase | 97.0 in (2,464 mm) |

| Length | 169.7 in (4,310 mm) |

| Width | 65.4 in (1,661 mm) |

| Height | 51 in (1,295 mm) |

| Curb weight | 2,181–2,270 lb (989–1,030 kg) (1971) |

| Chronology | |

| Successor | Chevrolet Monza |

The Chevrolet Vega is a subcompact, four passenger automobile produced by the Chevrolet division of General Motors for the 1971–1977 model years. Designed from scratch by a corporate design team headed by GM President Ed Cole, the Vega was brought to production by Chevrolet in only two years. Vega was available in two-door body-styles: Notchback sedan, Hatchback coupe, Kammback wagon, and Panel Express delivery truck. Vega's engine is an aluminum-block 140 cu in (2,300 cc) inline-4. By 1974, Vega was among the top 10 best selling American cars. Its H-body platform expanded, starting in 1975, with the Vega-based Monza and variants for three other GM divisions which offered new body-styles that cut into Vega's sales. The buying public's poor perception of the Vega, which had developed mainly due to early model engine troubles, also contributed to its reduced sales. The 1975 Chevette introduction sealed Vega's fate as the smaller, lower priced Chevette's sales matched Vega in 1976 and outsold Vega two to one in 1977 Without emotion, Chevrolet trimmed the Vega from its lineup after the 1977 model run. The Vega-based Monza and variants continued through 1980. Today, the Vega has become a symbol for the problems Detroit automakers faced in the seventies.

Subcompact

In the fall of 1959 Detroit automakers attempted to confront entry-level imports and domestic small cars such as the Studebaker Lark and Rambler American and in doing so created the compact class of cars, including the Chevrolet Corvair, Ford Falcon and Plymouth Valiant, each introduced as 1960 models. By the 1970s, while cars like the Chevrolet Nova, Ford Maverick, and AMC Hornet had evolved into the smallest versions of the traditional six passenger American family cars, they were larger than subcompacts, and many were delivered with optional V8 engines.

The Chevrolet Vega was introduced September 10, 1970 as part of GM, Ford and AMC automakers entering a new subcompact car class. The AMC Gremlin was introduced six months prior and the Ford Pinto one day after Vega's introduction They competed directly with the successful, but aging Volkswagen Beetle, as well as Japanese imports from Toyota, Datsun and Honda. Although Vega's conventional rear wheel drive layout and unibody was similar to the Japanese subcompacts, its 97.0-inch (2,460 mm) wheelbase and 169.7-inch (4,310 mm) overall length were longer than the Toyota's Corolla's 91.9-inch (2,330 mm) wheelbase and 161.4-inch (4,100 mm) length.

History

Design and engineering

Vega's chief engineer Ed Cole wanted a world-beater, and he wanted it in showrooms in 24 months. This was a brutally short time to design and engineer a new car, especially one that borrowed almost nothing from any other. The Vega, like the Corvair, has long been referred to as Ed Cole's baby. It was as GM president that Cole oversaw the genesis of the Chevrolet Vega. Code-named XP-887, Chevrolet "teaser" ads began in May 1970, not announcing its name at first, stating-"you'll see."

Vega's aluminum block inline-4 engine was a joint effort from General Motors, Reynolds Metal Corp. and Sealed Power Corp. GM purpose-built an advanced $75 million plant, Lordstown Assembly in Lordstown, Ohio to produce the Vega where 90 percent of the necessary welding was performed by high-tech unimate robots. Due to its "Modular Construction Design", a Vega sedan with 578 body parts had 418 fewer parts than its full-size Chevrolet counterpart. Modular Construction Design reduced the number of joints and sealing operations resulting in stronger, tighter bodies, effectively contributed to vehicle quality and made possible a very high rate of production.

Vega's body surface was the first accomplished completely through use of computers. Body surface information recorded on tape derived from the clay styling model, allowed computers to improve the body surface mathematically. Tapes developed through the computer were also used to control drafting machines in producing master surface plates which were extremely accurate. The computer was also utilized in making the hundreds of necessary engineering calculations including vision angle, field of view, rear compartment lid and door counterbalance geometries, structural stresses, deflection calculations and tolerence studies.. All Vega models share the same hood, fenders, floor pan, door lower panels, rocker panel, engine compartment, and front end. In a size comparison with a 1970 Nova, Vega has 20 inches (510 mm) less overall length, 14 inches (360 mm) less wheelbase, 7 inches (180 mm) narrower width and 2 inches (51 mm) lower height.

Introduced as Vega 2300, it was one of the first Chevrolet vehicles to have as standard equipment- front disc brakes, an electric fuel pump, side guard door beams, a double paneled roof, and foam-filled, hi-back bucket seats with floor mounted controls. Its suspension and live rear axle design, near ideal weight distribution, low center of gravity and neutral steering give the Vega handling characteristics that were praised by the automotive press. The overall chassis suspension was to be tuned to a new A78 x 13 tire that was being developed concurrently with the vehicle. The front suspension is classic General Motors short-and long-arm. The lower control arm bushings were actually larger than those of the Camaro. The four-link rear suspension copied that of the Chevelle, and coil springs are used throughout. This was a significant departure from the leaf spring suspension used in the Camaro and Nova. The Vega's brake system copied an Opel design including solid rotors and a lack of a proportioning valve. Vega's styling was judged conservative, clean-lined and timeless. GM styling studio's main influence was the 1967-1969 Fiat 124 Sport Coupe AC, and the Chevrolet Camaro/Corvette studio grafted a 1970 Camaro-like egg-crate grille and Chevy-style dual tailights. Many service operations were intentionally designed so that they were able to be performed by Vega owners. To further that end, the "Do-It-Yourself" service manual was made available with each new Vega.

1971–1977

Vega Hatchback was the most popular Vega model with its lower roofline and useful hatchback with fold-down rear seat, and accounted for nearly half of Vega's total production. Vega Sedan, re-named Notchback in 1973, had the lowest price at $2090 and features an enclosed trunk and more rear seat head room than the Hatchback.

Vega Kammback Wagon offered more cargo capacity, fold-down rear seat and a swing-up liftgate. Vega Panel Express, a one passenger panel delivery based on the wagon, has steel panels in place of the rear side glass, and an additional enclosed storage area.

In mid-1971 a GT version for Hatchback and Kammback models was introduced. The GT package includes the L11 2 barrel carburetor engine, F41 Handling suspension, 6 inch GT wheels with trim rings, center caps and A70-13 raised white-letter tires, black-finished grill and lower body sills, full instrumentation, and a hood/deck sport stripe option.Yenko Chevrolet sold a specially modified Vega called the Yenko Stinger II through 1973. Based on the GT, its 140 CID L11 engine features a turbocharger, high compression pistons and was rated 155 hp (116 kW). Included were front and rear spoilers and side striping with "Yenko Stinger II" identification.

1972 models were essentially carried over from 1971 with a few refinements including revised rear shocks and exhaust. A glove box was added and replaced dash storage bin.

The 1973 Vega had over 300 changes including new colors and new standard interior trim. Vega's front bumper was extended three inches (76 mm) on stronger brackets with a steel color keyed filler panel to meet the 1973 5-mph front bumper standards. Two new models were introduced- LX Notchback included a vinyl roof and Estate (Woody) Kammback featured vinyl wood side trim. Both models include the custom exterior and interior options. New Saginaw manual transmissions replaced the Opel designed units and Turbo-hydramatic transmission replaced Powerglide.

Sub-zero degree temperature durability testing of GM's Wankel rotary engine installed in 1973 Vegas began in Canada. Initially planned as a 1974 Vega option, the engine was first delayed, then planned for the proposed Vega-based Monza 2+2. The 1975 Monza's high floor tunnel was designed to accept the Wankel, but GM cancelled the engine due to emissions and fuel economy considerations.

Millionth Vega special limited edition

On May 17, 1973 the Millionth Vega was produced at the Lordstown, Ohio assembly plant - a bright orange GT Hatchback with white sport stripes and "Millionth Vega" door handle accents. It featured a neutral custom vinyl interior with orange accent color carpeting. A special edition of the milestone car was produced, limited to one per dealer.

1974 model year brought the only major exterior design changes, due to the revised, Federal front and rear 5 mph (8.0 km/h) bumper standards-A slanted header panel with a steel louvered grill (replacing the plastic egg-crate grill) and recessed headlamp bezels complement the larger, front 5 mph (8.0 km/h) aluminum bumper. Front and rear license plate brackets were relocated and a larger rear 5 mph (8.0 km/h) aluminum bumper is used. A revised rear panel on Notchback and Hatchback had larger single unit tailights and ventilation extractor grills were eliminated on trunk and hatch lids. Overall length was increased six inches (152 mm) compared to the 1971-1972 models. Vega's sales peaked for 1974 with 460,374 produced.

The 1974 Vega Spirit of America Hatchback limited edition features a white exterior, white vinyl roof, blue and red striping on body-sides, hood and rear-end panel, Spirit of America I.D. on front fenders and rear panel, white "GT" wheels, trim rings and Chevy center caps with A70-13 raised white-letter tires, and a white custom vinyl interior with red accent color carpeting.

The 1975 Vega had 264 changes including High-energy Electronic ignition and Catalytic converter. Power brakes and Tilt steering wheel were new options. A new special custom cloth interior option was offered with interior trim and carpeting upgrades similar to the Monza 2+2. The Pontiac Astre was introduced. Pontiac's version of Vega was offered as Notchback, Hatchback and Safari Wagon models. Astre Panel Delivery was also offered, only in 1975. SJ models (hatchback and wagon) are luxuriously appointed. GT models (hatchback and wagon) and 'Lil Wide Track' and Formula (hatchbacks) offered a choice of sporty models.

In March, 1975 the Cosworth Vega was introduced after a year and a half delay. Chevrolet's single color ad stated, "Cosworth Twin Cam-one Vega for the price of two." It features an all-aluminum 122 cu in (2,000 cc) DOHC 16 valve inline 4 with stainless steel headers and Bendix Electronic fuel injection. All 1975 Cosworth Vegas are black w/gold accent stripping, gold-colored aluminum wheels and a black custom vinyl, black custom cloth, or white custom vinyl interior with a gold "engine turned" dash bezel and gold plated plaque with Cosworth ID and build number. In 1976, eight additional exterior, and two additional interior colors were offered. Only 3,508 were built through 1976. The Vega Panel Express was discontinued at the end of the 1975 model year. Never a big seller, Panel sales peaked Vega's first year, in 1971 at 7,800 units. After leveling off to an average of 4,000 units per year, only 1,525 1975 Panels were sold.

1976 Vegas were refined with extensive engine, chassis, and body integrity improvements. Chevrolet advertised the 1976 Vega as "Built to take it." Vega received a facelift including, a revised header panel, wider grill, revised headlamp bezels-all made of corrosion resistant material, and tri-color tailights for Notchback and Hatchback. Vega's 2.3L engine, named Dura-built 140, received improved cooling and durability refinements. The chassis was now the same as Monza's including a box section front crossmember, larger rear brakes and torque-arm rear suspension, replacing the four-link design, and effectively eliminating wheel-hop on rough roads. Vega's body received extensive anti-rust improvements. New models introduced were GT Estate wagon and Cabriolet package for Notchback, replacing the LX. It features a half vinyl roof and opera windows similar to Monza Towne Coupe. The Cosworth Vega was quietly discontinued.

Spirit of America special limited edition

1977 was the final year for Vega, carried over from 1976 with a few revisions and additions. The Notchback was re-named Coupe. Vega's Dura-built 140 engine received a version of the Cosworth engine's pulse-air system to meet the more strict 1977 Federal emission standards. A full console was a new option, and the GT received blacked-out trim and a revised side stripping option.

Vega production totaled over 1.9 million vehicles in seven model years. Ed Cole retired from General Motors in 1974, and was tragically killed in an airplane crash in 1977. The Chevrolet Vega was discontinued at the end of the 1977 model year.

Vega's design expanded with four additional car lines in four GM divisions - Chevrolet Monza, Pontiac Sunbird, Buick Skyhawk, and Oldsmobile Starfire. These new models introduced in September 1974, (Sunbird in 1975) as 1975 and 1976 models respectively, are derived from the Vega and share its wheelbase and width. Vega's 140 CID inline 4 engine was standard equipment on 1975–1977 Monza, 1976 Sunbird and 1977 Starfire. The four Vega-based models continued through 1980.

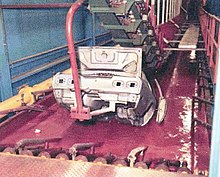

Vert-a-pac

Vega was designed to be shipped vertically, nose down. Special rail cars known as Vert-A-Pac cars held 30 Vegas versus 18 in normal tri-level box cars. Each Vega was fitted with four removable, cast-steel sockets inserted into the undercarriage.

Chevrolet conducted vibration and low-speed crash tests to make sure nose-down Vegas wouldn't shift or be damaged in railcar collisions. Chevrolet's goal was to deliver Vegas topped with fluids and ready to drive to the dealership. To do this Vega engineers had to design a special engine oil baffle to prevent oil from entering the No. 1 cylinder, batteries had filler caps located high up on the rear edge of the case to prevent acid spilling, the carburetor float bowl had a special tube that drained gasoline into the vapor canister during shipment, and the windshield washer bottle stood at a 45 degree angle. Plastic spacers were wedged in beside the powertrain to prevent damage to engine and transmission mounts. The wedges were removed when cars were unloaded.

Engine

140 CID OHC

The Vega engine is, without a doubt, the most extraordinary part of the car, according to Collectable Automobile magazine. It is a 140 cubic inch (2.3 liter) inline-4 featuring a die-cast aluminum cylinder and case assembly and a cast-iron cylinder head with a single overhead camshaft (SOHC). The cylinder block is an open deck design with siamesed free-standing cylinder bores. Outer case walls form the water jacket and are sealed off by the head and the head gasket. The block has cast iron main caps and a cast iron crankshaft. The cast iron cylinder head was chosen for low cost and structural integrity. The overhead valvetrain is a direct acting design of extreme simplicity. Only three components activate the valve rather than the usual seven of a typical push rod system. The camshaft is supported by five conventional pressed-in bearings. The camshaft is driven from the crankshaft by an externally mounted continuous cogged belt and sprocket system. Six v-grooves on the outside of the belt drive the water pump and fan. The large bore and long stroke design provide good torque and lower rpm operation for reduced wear. Compression ratio for the standard and optional engine is 8.5:1 as engine was designed to operate on low-lead and no-lead fuels. A single-barrel carburetor version produces 90 gross hp. The two-barrel version (RPO L11) 110 gross hp. From 1972 on, rating was listed as net hp. The one-barrel engine produceds 80 hp (60 kW). The two-barrel option boosted output to 90 hp (67 kW). The 1972 Rochester 2bbl carb required an air pump for emission certification and was replaced in 1973 with a Holley-built 5210C staged 2bbl. carburetor. Vega engines have a small 12-inch (300 mm) by 12-inch (300 mm) radiator core. The reason for the relatively small radiator was the aluminum engine block and its superior heat conductivity as compared to iron.

Sports Car Graphic magazine said in 1970, "The new die cast aluminum Vega 2300 (engine) is a masterpiece of simplicity. There are many innovations made to reduce the number of pieces and improve repairabilaty. One belt drives cam and water pump. The movable water pump is also the belt tensioner. The oil pump is on the crankshaft and is also the front engine cover."

The relatively large (for an inline-4) engine is naturally prone to vibration and is subdued by large rubber engine mounts. Vibration and noise levels were reduced in the 1972 models with a redesigned exhaust and better driveline damping. Emission control revisions made in 1973 reduced power output by 3 bhp, although engine's cruising noise levels were reduced. High energy electronic ignition and catalytic converter were additions for 1975.

Dura-built 140

The 1976 2.3 engine, named "Dura-built 140", features improved coolant pathways for the aluminum-block, a redesigned cylinder head incorporating quieter hydraulic valve lifters to replace the Vauxhall-designed taper-screw valve adjusters, longer life valve stem seals, which reduce oil consumption by 50%, a redesigned water pump, head gasket, and thermostat. Warranty on the engine was 5 years/60,000-mile (97,000 km).

"August 1, 1975. 8 a.m. Outside the southern edge of Las Vegas. Three medium orange Vegas start their engines. They won't be turning them off much during the next 58 days except for rest and food stops, refueling and maintenance. They have a job to do." Chevrolet conducted an advertised 60,000 miles in 60 days Durability Run of the 1976 Vega and its Dura-built 140 engine. Three new Vega hatchback coupes equipped with manual transmissions and air conditioning were driven non-stop for 60,000 miles (97,000 km) in 60 days through a Nevada desert, Death Valley test loop with air temperatures seldom under 100 °F (38 °C) degrees. Fuel stops and oil changes were supervised by the US Auto Club. All three 1976 Vegas completed a total of 180,000 miles (290,000 km) with no failures. (One car needed a timing belt replacement and twenty four ounces of coolant) The 1976 Vega was proven a durable and reliable car, but the new for 1976 Chevy Chevette and the Vega-based Monza introduced a year earlier, were new alternatives to the Vega, its reputation tarnished from early model engine and rust problems. The 1977 Dura-built 140 engine, painted blue its final year, added a pulse-air emission control system adopted from the Cosworth engine, needed to meet the more strict for 1977, United States Environmental Protection Agency (EPA) emission standards.

Chevy Monza continued with the Vega Dura-Built Template:Auto CID straight-4 as its standard engine in the 1976 and 1977 model years. Pontiac continued with the Vega Dura-Built 140 engine in 1976 only, in both Astre and Sunbird, then chose its own, new 151 cu in (2,470 cc) overhead valve straight-4 Iron Duke engine for Astre in 1977, its final year, and Sunbird from 1977 on. Oldsmobile chose to offer a four cylinder engine, for the first time, in 1977. Olds Starfire featured Vega's Dura-Built 140 as standard that year. Pontiac's Iron-Duke Template:Auto CID replaced the Vega engine as Starfire's standard engine from 1978 on.

Aluminum engine block

GM Research Labs had been working on a sleeveless aluminum block since the late 50's. The incentive was cost. Getting rid of those liners on a four-cylinder block would save $8, which was a substantial amount of money back then. Reynolds Metal Corp. came up with an alloy called A-390, composed of 77 percent aluminum, 17 percent silicon, 4 percent copper, 1 percent iron, and traces of phosphorus, zinc, manganese, and titanium. The A-390 alloy was suitable for faster production diecasting which made the Vega block less expensive to manufacture than other aluminum engines. Sealed Power Corp. developed special chrome-plated piston rings for the engine that were blunted to prevent scuffing. Basic work had been done under Eudell Jackobson of GM engineering, not at Chevrolet. But then, suddenly, Chevrolet got handed the job of putting this ohc sleeveless, aluminum block into production-a feat never before attempted. According to Jackobson, "The aluminum blocks were inpregnated with sodium silicate before shipping to Tonawanda (engine plant). Machining through the outer skin exposed areas that had not previously leaked, so various leak tests were required as the block progressed through the machining line. As I recall, if a part still leaked after three tries, it was scrapped."

The Vega engine block was cast in Massena, New York, at the same factory that produced the Corvair engine. Molten aluminum was transported from Reynolds and Alcoa smelting plants to the foundry, inside thermos tank trucks. The block was cast using the Accurad process. The casting process provided a uniform distribution of fine primary silicon particles approximately 0.001 inches (0.025 mm) in size. Pure silicon provides a hard scuff and wear resistant surface, having a rating of 7 on the mohs scale of hardness as compared to diamond which is 10. The blocks were aged 8 hours at 450 °F (232 °C) to achieve dimensional stability. The technical breakthroughs of the block lied in the precision die-casting method used to produce it, and in the silicon alloying which provide a compatible bore surface without liners.

From Massena, the cast engine blocks were shipped as raw castings to Chevy's engine plant in Tonawanda, New York. Here they underwent the messy etch and machining operations. The cylinder bores were rough and finished honed conventionally to a 7 micro-inch finish then etched by a new (then) electro-chemical process. The etching removed approximately 0.00015-inch (0.0038 mm) of aluminum leaving the pure silicon particles prominent to form the bore surface. (left image) At a machined weight of 36 pounds (16 kg), this block is 51 pounds (23 kg) less than the cast-iron block in the Chevy II 153 cu in (2,510 cc) straight-4. Plating the piston skirts was necessary to put a hard iron skirt surface opposite the silicon of the block to prevent scuffing. The plating was a four layer electo-plating process. (right image) The first plate was a flash of zinc followed by a very thin flash of copper. The third and primary coating was hard iron, 0.0007 in (0.018 mm) thick. The final layer was a flash of tin. The zinc and copper were necessary to adhere the iron while the tin prevented corrosion before assembly of the piston into the engine. Piston plating was done on a 46 operation automatic line. From Tonawanda, the engines went to the Chevrolet assembly plant in Lordstown, Ohio.

Cosworth Twin-Cam

Motor vehicle| Chevrolet Cosworth Vega | |

|---|---|

1975 Chevrolet Cosworth Vega 1975 Chevrolet Cosworth Vega | |

| Overview | |

| Manufacturer | General Motors Corporation Chevrolet Division |

| Also called | Cosworth Twin-Cam |

| Production | 1975–1976 |

| Model years | 1975–1976 |

| Assembly | Lordstown Assembly- Lordstown, Ohio, United States |

| Body and chassis | |

| Class | Subcompact |

| Body style | 2-door hatchback |

| Layout | FR layout |

| Platform | GM H platform (RWD) |

| Powertrain | |

| Engine | 122 CID 2.0 L DOHC EFI I4 |

| Transmission | 4-speed manual 5-speed manual w/overdrive (1976) |

| Dimensions | |

| Wheelbase | 97.0 in (2,464 mm) |

| Length | 176.4 in (4,481 mm) |

| Width | 65.4 in (1,661 mm) |

| Height | 50.0 in (1,270 mm) |

| Curb weight | 2,760 lb (1,250 kg) |

The 1975-76 Cosworth Twin-Cam is a limited production, performance version of Vega. Its purpose was to "create excitement" for the entire Vega line. Only 3,508 were built from March 1975 through 1976.

Development

The racing version was known internally at Cosworth as Project EA. It was not a successful racing engine due to Vega block structural failures. Chevrolet later offered a special heavy-duty block with thicker case walls for racing applications, but by that time Cosworth had moved on. The Vega production version was developed and built by Chevrolet at its Tonawanda engine plant. The first 1971 development engines delivered an impressive 180 bhp (130 kW). Chevrolet had originally planned to introduce the car for the 1974 model year, but a burnt exhaust valve in a test engine caused the engine to fail the U.S. Environmental Protection Agency's 50,000-mile (80,000 km) emission control system durability test. This delayed the car's introduction a year and a half while Chevrolet revised the Cosworth engine's emission control system, adding the pulse-air tubes, and revised its Bendix Electronic fuel injection and timing specs. It passed the EPA test the second time, and the Cosworth Vega was introduced in March, 1975. Final rating is 110 bhp (82 kW)

122 CID DOHC-16 valves

The Cosworth Vega engine is a 122 cubic inch (2.0 liter) inline-4 and features a die cast aluminum cylinder and case assembly and an aluminum, 16 valve cylinder head with double overhead camshafts(DOHC). The head design was assisted by Cosworth Engineering in England. The camshafts are held in a removable cam-carrier which also serves as a guide for the valve lifters. Each camshaft is supported by five bearings and is turned by individual cam gears on the front end. The two overhead camshafts are driven, along with the water pump and fan, by a fiberglass cord reinforced neoprene rubber belt, much like the Vega 140 (2.3 liter) L-4 engine. Below the cam carrier is a 16 valve cylinder head constructed of an aluminum alloy and using sintered iron valve seats and iron cast valve guides for added durability. Forged aluminum pistons are used because of their added strength, and results in improved durability under severe operating conditions. The engine features an electronic fuel injection system, and a stainless steel exhaust header. Each engine was hand built and includes a cam cover sticker with the engine builder's signature. The engine develops its maximum power at 5600 rpm and is redlined at 6500, where the SOHC Vega engine peakes at 4400, and all is done at 5000. Car and Driver reported, "The 3.11 First gear matched to a 3.73 Axle ratio makes the Cosworth Vega tough to launch from a stop." They measured 0-60 mph (97 km/h) times of 8.7 seconds.

Features

Chevrolet general manager, John DeLorean chose black over Cosworth silver, the original choice, as the car's exclusive color. 1974 pre-production cars released to the press, and all 2,062 1975 Cosworth Vegas were indeed, black with gold "Cosworth Twin Cam" lettering on the front fenders and rear cove panel and gold pinstripping on hood buldge, body sides, wheel openings, and rear cove. Black exterior color wasn't available on lesser Vegas until the following year. The black or white custom vinyl, or black custom cloth interior, includes a gold engine-turned dash bezel and gold-plated dash plaque with build sequence number, a specific 8000 RPM tachometer and Cosworth Twin-Cam Vega steering wheel emblem. At $5,916, it cost double a normal hatchback, and only $900 less than a Corvette. The Cosworth package includes a 'torque arm' rear suspension which provides optimum rear axle power control. This unit compares to the assembly used on the Monza 2+2. The Monza 2+2 axle is also used and provides a 3.73:1 gear ratio from a 7-1/2" ring gear. No other gear ratios were available, but a limited slip differential was optional. GT special springs, shocks, and stabilizer bars are included as are exclusive BR70-13 BSW radial tires on British-made 6 inch, gold-painted cast aluminum wheels with Chevy center caps. The Vega engine overheat protection system is used on the Cosworth package. This adds add coolant and temp/press warning lights to the instrument cluster. If the radiator coolant level becomes one quart or more low, a sensor, located in the radiator, activates the add coolant light. If the coolant temperature reaches 260 °F (127 °C). or greater or if the engine oil pressure drops below 6 psi (0.41 bar), then the temp/press light is activated. Air conditioning was not offered on the Cosworth Vega, due to interference between the induction system, specifically the air cleaner and the air conditioner's evaporator case. Power steering and power brakes were also not offered.

1976 Changes

For 1976, the Cosworth, like all Vegas, received a facelift including a wider grill and tri-color tailamps and the extensive body anti-rust improvements. A new Borg-Warner 5-speed manual overdrive transmission with 4.10 axle was optional in addition to the std. Saginaw 4-speed manual. The exhaust system featured a single outlet tailpipe as opposed to the dual outlet pipe on the '75. Eight additional exterior colors were offered in addition to black and two additional interior colors were offered. Still, only 1,446 were built for 1976. The Cosworth Vega, although meeting the more strict 1977 emission standards in advance, would not be offered in the Vega's final year. Production fell well short of projected sales of 5,000 per year, which was figured before the Vega's early model troubles became well known. Introduced a year earlier in 1974, as planned, the car might have met its sales goal. As it stood though, 1,500 unused Cosworth engines were simply scrapped for lack of demand.

Reviews

The Chevrolet Vega was initially popular with the automotive press, winning awards and praise for its innovative engineering, timeless styling, and sports car-like handling. Chevrolet advertising for the Vega included ads promoting Vega's award winning status.

Car and Driver magazine in 1971, awarded top pick to the Vega above five other cars including the Ford Pinto, AMC Gremlin, VW Beetle, Toyota Corolla and Chrysler Simca "because of its particular suitability to American driving conditions." It was the only car besides the shortened compact Gremlin that could cruise at 70 miles per hour or above. Its long 2.53:1 axle ratio allowed a low 3,000 rpm at 80 mph (130 km/h). The Vega's ride and handling were highly rated. It was the quickest of the cars tested, taking 12.2 seconds to reach 60 mph (97 km/h). C&D stated, "It provides an excellent combination of performance and economy." "It's a car for all occasions."

Car and Driver in a 1972 Super Coupes test including Vega GT, Pinto Runabout, Opel 1900 Rallye, Mazda RX-2, Capri 2000 and Toyota Celica said, "..If looks alone determined the best Super coupe, the Vega GT would win hands down without ever turning a wheel."

Car and Driver readers voted Vega "Best Economy Sedan" three years in a row (1971-1973) in its Annual Reader's Choice Poll. In 1971, Vega's first year on the market, it managed to unseat the incumbent import, breaking its eight year winning streak.

Motor Trend magazine in its August 1970 issue said, "In summary, the Vega GT comes close to what a racing GT car should be, in handling, performance and comfort. Because it's basically a low-priced compact, the results are all the more surprising and rewarding."

Motor Trend selected Vega one of the "Ten Best Cars of 1971" and "Motor Trend Car of the Year" for 1971. "The base Vega is a magnificent automobile without any options at all." "We choose the Vega as the Car of the Year because of Vega's engineering excellence, timeliness, styling, and overall value...for the money, no other American car can deliver more."

Motor Trend selected Vega GT "1973 Car of the Year in the economy class" stating, "The Vega was judged solid, warm and comfortable, with a good finish."

Vega Wagon's 27.083 mpg‑US (8.685 L/100 km; 32.525 mpg‑imp) fuel economy was rated number ten in Motor Trend's mid-summer cruise of "15 Cars To Own in a Gas Crisis" in 1973. Vega LX Notchback's 30.0 mpg‑US (7.8 L/100 km; 36.0 mpg‑imp) was rated number nine in Motor Trend's "50 Cars Worth Their Weight In Gold" in 1974. Vega was in Motor Trend's "10 Best Selling (American Made) Cars" test in 1975. "The Vega has been vacillating on the sales charts from just out of the top 10 to just into the top 10. We have to conclude that Monza sales have hurt the Vega and will continue to do so."

Road & Track magazine stated in September 1970, "Vega is the best handling car ever sold in America."

Road & Track in their 1970 road test of "Vegas Plain and Fancy" said, "..with the Vega, they've turned out one of the finest-looking compact sedans in the world." "The engine proved a let down. It's extremely rough and noisy..on the positive side, freeway cruising is relaxed and quiet, the slow-running engine's noise covered by wind and road noise, and it was economical not withstanding our overall mileage figures which include some very hard driving." "Ride and handling were departments in which we also expected good things and here we weren't disappointed. The Vega in standard form rides and handles very well indeed."

Road & Track in their Vega owner survey from 1973, stated, "The level of assembly doesn't match the virtues of the design."

Road & Track in a Vega GT road test, began, "The 1973 Vega is still the stylish, somewhat sporting economy car it was when new, but improved. The Vega's engine is much improved, with cruising speed noise levels lower than most economy cars." Closing the test article, R&T stated, "After what we've said about earlier Vegas, it's a pleasure to report the current Vega is attractive, respectably quick, and frugal-and it's the best highway car in class. Well done Chevrolet."

Road Test magazine in September 1970, "Chevy pulled out the stops on this one-aluminum ohc engines, four body styles, high style options put it in a class by itself." "It's innovative without being complex."

In a July 1974 Test report on a Vega LX Notchback, Road Test said, "Vega engineers have tamed the low-speed characteristics of the engine. It's wonderfully torquey and flexible at drive-away speeds, and you can shift early into fourth and chug around town all day if you like...in normal driving low and mid-range torque is what counts and this engine has plenty of it." "The Vega ride is not like that of a Caprice, but neither is it a choppy "little-car" ride thanks to the big car rear suspension (coil springs and control arms), ample suspension travel and reasonably good damping..." "The standard manual steering is on the heavy side and is too slow to permit fancy maneuvering..." "Braking performance is right in there too, which is credited to the brakes themselves and the big (radial) tires." "In summary, the 1974 Vega is a vastly improved car over the original and even over last year's model. All of the important gripes have been taken care of and it can now face up to its competition, domestic and imported, on a feature for feature basis.

Hot Rod magazine in 1972, road tested a Vega GT Kammback, and said, "The car never looks like something you had to buy..It's the kind of car we'd buy to look good in, work on, add to, and wash once a week." Hot Rod in a 1972 models introduction issue, voted Vega GT "Best Buy" of the entire 1972 Chevrolet line. Hot Rod on the Millionth Vega-"Chevrolet was so smitten with the car, they've built 6143 Millionth Vegas. The series is basically a styled-up Vega GT with some nice interior touches..They'll probably sell a million of 'em."

Small cars magazine, said in 1972, "Z/29 Vega GT: It's either the sportiest economy car in the world or the most economical sports car in the world."

Road & Track, in its 1976 Cosworth Vega road test noted, "The reduction in displacement adds an important degree of smoothness..." a result of the shorter stroke. "We can't resist saying that with the Cosworth Vega engine, the Vega now runs the way it should have run all the time-easy, smooth, good response, good handling: a nice balance between performance and economy." "For all its exotic features, however, the Cosworth Vega engine is not a high performance unit with a specfic output of only 55 bhp (41 kW; 56 PS) per liter, modest indeed when compared to engines of equal sophistication." "The Cosworth Vega's handling is very good..." "All our drivers agreed that it is a far better handling car than those Vega derivatives that have been fitted out with V6 or V8 engines."

Car and Driver stated in 1977, "John R. Bond, the recently retired editor of Road & Track, once caused himself and GM a peck of trouble with the Federal Trade Commission by calling the Vega the best handling sedan from Detroit in the pages of his magazine, and though he may have been stretching the point a bit, the Vega/Astre does handle awfully well, provided there are no bumps in the road. The suspension is well tuned and the car stays flat and goes where its pointed."

The 1974 Pre-production Cosworth Vega made Car and Driver's Top 25 Acceleration Champs. "Each year one car emerges as the winner." The Cosworth Vega was the quickest 0-60 mph car of 1974.

Car and Driver chose the Cosworth Vega as one of the "10 Best Collectable Cars" in its fourth annual Ten Best issue stating, "We're talking about historical significance here."

Car and Driver', in its 35th anniversary issue in 1990, looked back, and Vega was mentioned three times. Detroit Fights Back - Ford Pinto and Vega 2300: "...they are the best, most import-beating subcompacts that American Technology knows how to build. If VW and the other small intruders survive this attack, they'll be assumed invincible." Cosworth Vega Preview - "A sixteen-valve head on a Vega aluminum block seems like a neat idea to us, so we rev up our prose. The car when it finally arrives, cannot keep up with our feverish preview." Showroom-Stock Challenge III - "We win again, this time in a-Vega GT, proof that truth is stranger than fiction." Detroit Fights Back - "The Pontiac Astre is introduced. It's a Vega with better decals."

Car and Driver.com recently included the 1971 Chevrolet Vega on its "10 most Embarrassing Award Winners in Automotive History" list, criticizing Motor Trend, 38 years after the fact, for selecting the 1971 Vega "Car of the Year."

Poular Mechanics.com in November 2008, listed the 1971–1977 Chevrolet Vega as one of 10 cars that damaged GM's reputation.

The DeLorean factor

John Z. DeLorean, General Motors vice president and Pontiac general manager was "promoted" to Chevrolet general manager in 1969, a year before the Vega introduction. In 1974, a year after his resignation, he stated, "The Vega program produced a hostile relationship between the corporate staffs, which essentially designed and engineered the car, and the Chevrolet Division which was to sell it."

Chevrolet and Pontiac Divisions were working separately on small cars in the early and mid 60's. Ed Cole, who was executive vice-president of Operating Staffs, was working on his own small-car project using the corporate engineering and design staffs. He presented the program to GM's president in 1967. When the corporation started seriously talking about a mini-car, Cole's version was chosen with the proposals from Chevy and Pontiac rejected, and Cole's new mini-car given to Chevrolet to sell. Not only did corporate management make the decision to enter the mini-car market, it also decided to develop the car itself. It was a corporate car, not a divisional one. Cole was the chief engineer and Bill Mitchell, the vice-president of the Design Staff, was the chief stylist.

"From the first day I stepped into Chevrolet, the Vega was in trouble. General Motors was basing its image and reputation on the car, and there was practically no interest in it in the division. We were to start building the car in about a year, and nobody wanted anything to do with it. Chevy's engineering staff was only going through the motions of preparing the car for production, but nothing more. Engineers are a very proud group. They take interest and pride in their designs, but this was not their car and they did not want to work on it." The biggest objection from the Chevrolet engineering staff, was reserved for the Vega engine. GM Engineering policy group chose the engine pushed by Cole and the corporate staff which used an aluminum cylinder block, a cast iron head and a longer stroke design which was traditionally less polluting. DeLorean's conclusion was they were using an innovative production process using aluminum while they were relying on an old basic design for the engine, and Chevrolet engineers were ashamed of the engine.

DeLorean's most important problem was to motivate the division to get the car into as good shape as they could before introduction. As the Lordstown, Ohio assembly plant was converted to Vega production, he introduced an intense program for quality control with the target of making the first cars off the assembly line the best quality cars, from a manufacturing standpoint, ever built. As the starting date approached, he put tens of additional inspectors and workers on the line and introduced a computerized quality control program in which each car was inspected as it came off the line and, if necessary, repaired. The first 2,000 Vegas built were test driven and a sizable proportion of the others thereafter. He was able when the car was introduced to brag that it was the best quality car they had ever introduced, however he did not think it was the best designed vehicle they had introduced. Work that had proceeded on the car revealed that the central staff had completely misgauged the weight and cost of the car they designed. As general manager of Chevy, he was called upon to explain why the car differed from GM chairman James Roche's announcement description given two years earlier. How could DeLorean call his car "competitive" when it weighed almost 400 pounds more, and was priced more than $300 above the intended foreign competitor. While he was convinced that Chevy was doing their best with the car that was given to them, he was called upon by the corporation to tout the car far beyond his personal convictions about it. This conflict never did resolve itself fully in his mind and was one of the many factors that precipitated his departure from the company. "I said with a clear conscience that it was a quality car, and I believed it was because the first 2,000 cars were road tested off the assembly line and millions of dollars was spent to reinspect and repair each vehicle." In naming the car, DeLorean pointed out that studies were conducted showing that one name stood above every other - Gemini. When pronounced it almost said "G-M-ini". But modern, scientific, marketing tests not withstanding, Ed Cole liked the name Vega and so did top corporate management, who disregarded Chevrolet's test results and named the mini-car the Vega.

Problems

Pre-production

Jerry L Brockstein, assistant to Henry Haga, head of the Camaro/Corvette studio where the Vega prototype was restyled, recalls finalizing the Vega bodies. "Chevrolet was trying to build this car as cheaply as possible and wanted us to take a lot of money out of it. At first the metal was so thin on the Kammback wagon that in the test facilty it kept buckling under its own weight. Fisher Body had to come back and put stiffing ribs in the roof." John DeLorean recalls in 1974, "The first prototype was sent to the GM proving grounds for durability testing. After only eight miles on the Belgian blocks, it broke in two." Note, though, that Fisher often under-engineered prototype bodies because it was easier and more economical to reinforce a weak body than to shave one that had more strength than needed. Chevrolet, in a January 1971 Vega engineering report stated early difficulties were experienced at the front and rear suspension attaching points. Using scaled suspension members to impose static loads, stress evaluations were conducted. It was determined that addition of reinforcements, metal gauge increases, and some redesign of the pieces would give desired structure.

Eudell G. "Jake" Jacobsen, a GM engineer, pointed out just one of the early problems. They had a catastrophe when they first started trying to finish the aluminum engine-block castings at Tonowanda (Vega engine plant) They found scuffing in the cylinders and couldn't figure out why... they finally figured out that they were putting too much pressure on the bore hones and cracking the silicon. "We were trying to put a product into production and learning the technology simultaneously. And the pressure becomes very, very great when that happens. The hone-pressure problem was solved before engines actually went out the door, affecting pre-production engines only."

Lordstown, Ohio assembly

When completed Lordstown was the world's most automated auto plant. It had 26 unimate industrial robots performing 520 welds on each Vega. Sub-assembly areas, conveyor belts and quality control were all computer directed. The result of this investment and the car's modular design, Vega production at Lordstown was projected at 100 cars an hour from the beginning; one vehicle every 36 seconds. This was nearly twice the normal volume and by far was the fastest rate in the world. Instead of the normal minute, the worker had 36 seconds to do his job. Even if the work was reduced the job was intolerable. With 25 percent more line workers than needed, the speed of assembly didn't bother most workers at first, and the Vegas that came off the line in those early months were well built. They still had mechanical flaws but issues such as fit-and-finish were not a problem. Then in October 1971, General Motors ordered Chevrolet and Fisher Body to turn over Lordstown to the General Motors Assembly Division (GMAD) One of its missions was to cut costs. Typical Lordstown employees (average age, 22) were products of the 60's. They'd grown up in an age of civil disobedience. GMAD ran a much tighter ship and discipline became more rigorous. The United Auto Workers (UAW) claimed that 800 workers were laid off at Lordstown within the first year of GMAD's arrival and the line speed didn't slow. Feelings got worse with management accusing workers of intentionally slowing the line and sabotaging cars by leaving parts off and doing shoddy work. Quality did suffer, and in March 1972, the plant's 7,700 workers called a wildcat strike that lasted a month and cost GM 150 million dollars. Although the Vega sold well from the beginning, the buying public soon started to question the car's quality. It had every right to. It came out prematurely and still had a lot of glitches.

Fisher Body was very proud of its Elpo primering process, which should have prevented rust, but didn't. The Elpo process involved submerging the assembled Vega body in a huge vat. The Elpo vats at Lordstown each contained reddish-brown paint-primer particles in 65,000 US gallons (246,052 L; 54,124 imp gal) of water. In the Elpo dip, the metal body received a positive electrical charge, the primer particles carried a negative charge, and by leaving the body in the vat for two minutes even the most remote recesses get coated-theoretically. The body was then dried, sprayed with acrylic lacquer and baked in a 300 °F (149 °C) degree oven. The Elpo dip, however, did not flow to every surface. According to Vega expert, Gary Derian, the design of the front end caused air to be trapped at the tops of the fenders, so they never got coated. Early cars had no inner fenders or fender liners, so the tops of the front fenders got blasted by sand and salt thrown up by the tires, and they quickly rusted. Chevrolet installed plastic deflectors in late 1973, and full plastic inner fenders in 1974. Derion pointed out, too, that a rust-prone gap existed between the front fenders and the cowl vent. Moist debris and salt would pack into this area, and rust through the metal in a couple of years. Chevrolet did replace rusted-out fenders for many owners free of charge. But rust damage also affected the rocker panels, the door bottoms, the area beneath the windshield, and the primary body structure above the rockers. There were many Vegas on the road with sagging front frames, according to Darien. Starting in 1976, Chevrolet began spraying the inner doors with an aluminized wax, and making front fenders and rocker panels out of galvanized Zincrometal.

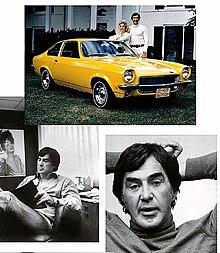

Early 140 CID engine

with 2bbl. Rochester carburetor

Jacobson confirmed a problem involving the early two-barrel Rochester carburetor. The Vega engine sometimes shook so violently that it would loosen the screws holding the top cover to the carburetor body. The top cover would then jump up and down, which activated the accelerator pump, which shot raw gasoline through the cylinders and into the exhaust system. Fuel would puddle inside the muffler and eventually explode. The early mufflers would blow out towards the fuel tank, so later ones were engineered so they'd blow away from the tank. Threadlocker was also applied to the carburetor bolts in production. For 1973, the Rochester carb was replaced with a Holly-Weber design.

According to Jacobson, customers began complaining to dealers of excessive oil consumption. When the customer came in and complained that his car was getting 200 miles (320 km) per quart (0.9 L) of oil, the mechanic would peer down the bore scope and see a little scuffing. Chevrolet engineers eventually found out that the problem had never been the scuffing of the (cylinder) bore. "The real problem was the valve stem seals. They'd harden, split, fall off, and oil would leak down past the valves and into the combustion chamber. So we did some experiments. When we got an oil burner, we simply replaced the valve-stem seals, and that cured it." 1976-77 Dura-built engines had redesigned seals that reduced oil consumption by fifty percent.

The Vega's cooling system also came in for criticism; it held only 6 US quarts (5.7 litres) and had a tiny two-tube, 1 sq ft (0.1 m) radiator. Because of the leaking valve stem seals, the engine would often be low on oil and coolant simultaneously. This caused overheating, which distorted the open-deck block, allowing antifreeze to seep past the head gasket and causing piston scuffing inside the cylinders.

Fred Kneisler from GM Engineering maintained that too much emphasis has been put on overheating problems versus the real culprits: brittle valve stem seals and too-thin piston plating. Vega owners and many mechanics believed, though, that overheating was the big problem. In response, Chevrolet added a coolant overflow bottle and an electronic low-coolant indicator for 1974 that could be retrofitted to earlier models at no cost. Regardless of the cause, damaged cylinder walls were common - a problem that presented the Vega owner with three choices:

- Have the block overbored and re-etched, and have new pistons installed.

- Overbore and have aftermarket cast-iron cylinder liners pressed in.

- Replace the short block with a brand new unit.

Most owners opted to have the revised 50,000 mi (80,467 km) engine warranty cover the installation of a new short block. This proved costly for Chevrolet. The 1976-77 Dura-Built 140 engine had improved engine block coolant pathways, a redesigned head gasket, water pump, and thermostat, and had a 5-year/60,000 mi (96,561 km) warranty.

Despite its problematic application in the Vega, the linerless aluminum/silicon engine block concept that GM and Reynolds developed turned out to be sound. Mercedes and Porsche both use sleeveless aluminum engines today, the basic principles of which were developed for the Vega engine.

Production

1,966,157 Chevrolet Vegas were produced from 1970 through 1977, including 3,507 Cosworth Vegas.

The majority were built in the United States at the GM Lordstown Assembly plant in Lordstown, Ohio. Starting In 1973 through 1974, Vegas were also built at the GM of Canada plant Saint Therese Assembly in Quebec.

| Year | Notchback | Hatchback | Kammback | Panel | Cosworth | Total | Notes |

|---|---|---|---|---|---|---|---|

| 1971 | 58,800 | 168,300 | 42,800 | 7,800 | - | 277,700 | GT Package introduced mid-year for Hatchback and Kammback (includes-L11 110 hp 2bbl engine, ride and handing suspension (includes-stabilizer bars front and rear, firmer springs and shocks, A70-13 raised white letter tires, 6" GT wheels w/trim rings and center caps), black grill with moldings, clear parking light lenses, GT emblems-front fenders, window reveal moldings and lower body chrome moldings w/black accents, black finish lower body sill, instrumentation package w/tach and clock, four spoke sport steering wheel w/GT emblem, passenger assist handle and two position driver's seatback) |

| 1972 | 55,800 | 262,700 | 72,000 | 4,114 | - | 394,592 | Carry over except - Revised exhaust system. Revised rear shock absorbers. Engine coolant recovery system added. Glove box replaces dash storage bin. Emission control air pump added for 2bbl engine, Horsepower ratings change from "gross" to "net" figures. |

| 1973 | - | - | - | - | - | 395,792 | Over 300 changes including revised Emission control system, Extended front bumper with heavier brackets, New "Vega by Chevrolet" nameplates- front and rear (changed from "Chevrolet Vega 2300"), New exterior & interior colors, New std. vinyl seat trim, Interior wood trim revision (GT/custom interior), LX option for Notchback (includes-vinyl roof, black grill with moldings, LX emblems-front fenders, wheel opening moldings, clear parking light lenses, custom interior and sport steering wheel) Estate option for Kammback Wagon (includes-woodgrain exterior side trim with surround moldings, Estate emblem-tailgate, custom interior and sport steering wheel), New body side molding w/ black rubber insert option, New sport stripes w/color-keyed side molding option for Hatchback, BR70-13 white stripe steel belted Radial tires option, Full wheel covers option. Holley carb replaces Rochester units on 2 bbl engines. American-built Saginaw three and four-speed Manual transmissions replace the German Opel-built units of '71-'72 models. 3-speed Turbo-Hydramatic transmission replaces 2-speed Powerglide. New shift linkage with revised selector console. Limited edition Vega GT-Millionth Vega-bright orange exterior with white sport stripes, neutral custom vinyl interior with orange accent color carpeting. |

| 1974 | 63,591 | 271,682 | 113,326 | 4,287 | - | 452,886 | New front end design to accept the (stricter for '74) federally required 5 mph (8.0 km/h) bumper standards, Aluminum bumpers front and rear with inner steel spring similar to the 1974 Camaro, Optional bumper rubber strips and guards (included with GT, LX, and Estate) Larger 16 gallon fuel tank, Full front fender inner liners, Larger outside mirror, Color keyed dual sport mirrors with driver's side remote feature (included with GT, LX and Estate), New Notchback/Hatchback rear panel with larger single unit taillights, Relocated license plate-front and rear, Fuel filler relocated to passenger side rear quarter panel (previously under a hinged rear licence plate), Ventilation extractor vents removed from trunk lid/hatch on coupes, Full wheel covers now included with LX/Estate options, New std. pattern cloth Seat trim, Revised gauge graphics. Limited edition Spirit of America Hatchback- white with red and blue stripping, white custom vinyl interior with red accent color carpeting. |

| 1975 | 35,133 | 112,912 | 56,133 | 1,525 | 2,061 | 206,239 | 264 changes including Electronic ignition, Catalytic converter, Larger lower Ball joints, BR78-13B GM-spec steel belted wsw Radial Tires option, New quiet sound group option, Power brakes and Tilt steering wheel options, New GT side stripes option-black or white (replaces hood/deck stripe option), Special luxury cloth interior option (similar to Monza), GT Estate introduced. Cosworth Vega introduced March '75. |

| 1976 | 27,619 | 77,409 | 46,114 | - | 1,446 | 160,523 | Panel Express discontinued. Revised and newly-named Dura-built 140 engine, Vega chassis/floor pan now shared with Monza (including Torque-arm rear suspension and larger rear brakes). New Delco Freedom maintenance-free battery, BR78-13B GM-spec steel belted radial tire option now available in bsw, wsw, and rwl. Extensive ant-rust improvements on Vega's body (including "four layer" fender protection with zinc coated and primed inner fenders and wheelwell protective mastic, galvanized steel rocker panels, zinc-rich pre-prime coating on inner doors, expandable sealer installed between rear quarter panel and wheel housing panel, and a corrosion resistant grill and headlamp housings). New tri-color taillights for coupes, New Borg Warner 5-speed transmission option with 4.11 final drive axle ratio, Cabriolet Coupe equipment option (Notchback w/half vinyl top and "opera windows", full wheel covers and wheel opening moldings). New Sky-Roof option with tinted reflectorized sliding glass. Cosworth Vega now available in eight additional exterior colors and two additional interior colors at mid-year. Limited edition Nomad Wagon (includes restyled rear side windows) |

| 1977 | 12,365 | 37,395 | 25,181 | - | - | 78,402 | Cosworth Vega discontinued. 1bbl version of 2.3 engine discontinued, 2.3 2bbl engine now std. 3-speed manual trans. discontinued, 4-speed manual now std. Notchback renamed Sport Coupe, New color keyed full console option, New GT blackout moldings, Revised GT side stripes option, Gold colored Aluminum Wheel option (leftover Cosworth stock). |

| Total | - | - | - | - | 3,508 | 1,966,157 | Model breakdown not available for 1973 model year. |

Vega variants

Pontiac Astre

The Pontiac Astre was introduced in the September, 1974 and was sold in the US for the 1975–1977 model years. Pontiac's version of Vega had been sold exclusively in Canada from 1973. Notchback, Hatchback, Safari Wagon, and Panel Delivery body styles were offered. Only 131 Astre Panels were sold, produced in the 1975 model year. Pontiac's trademark split grill, emblems, steering wheel, and Firebird styled tailights (notchback and hatchback) differentiate it from Vega. Astre's engine is Vega's Template:Auto CID inline-4 through 1976. Transmissions are the 3 and 4-speed manual, 5-speed manual with overdrive (for 1976–77) and the 3-speed automatic. SJ models, optional on hatchback and wagon, feature soft nylon upholstery, cut pile carpeting, padded and cloth covered door panels, and a fabric headliner, plus rally instruments, the two barrel engine, four-speed or automatic (over a 3-speed manual) gearbox and radial tires. A GT package was optional for the hatchback and wagon and Li'l Wide Track package for the hatchback. Li'l Wide Track, for $401.50, added a front air dam, rear spoiler, quarter window louvers, stripes on the hood, lower body, spoiler, door handles and wheel centers, chrome exhaust extension and cast aluminum wheels. The package was designed by BORT (British Overseas Racing Team) and produced by Motortown Corp. The package was installed at the Lordstown Assembly plant.

For its final year, the 1977 Astre featured Pontiac's own Template:Auto CID 'Iron-Duke' inline-4 and received a facelift with a new vertical design split grill, Aluminum wheels (13") was a new option. Astre Formula was introduced, which included the handling package, chrome valve cover, three-piece spoiler, Formula T/A steering wheel and special decals.

Car and Driver in a 1975 Astre road test, said, "For $180 over the price of a Vega, the Astre features upgraded interior trim-primarily the items for which Chevrolet charges $134 in their custom interior. You also have the opportunity to go one big step up in luxury if you choose the SJ line which is available in hatchback and wagon body styles."

Car and Driver in a 1977 Astre road test, said, "The Astre is the Vega-polished and refined and significantly improved, but still a Vega in perhaps its ultimate state of development..It remained for Pontiac to do what Chevrolet probably should have done in the first place: the substitution of the marvelous old Chevy II cast-iron four-cylinder econo-motor for the much-troubled aluminum-block Vega engine. Sliding in and starting the engine was a revelation because its so quiet and smooth compared to the Vega. Also the Astre's interior trim was judged more plush than Vega's."

Chevy Monza 'S' & Monza Wagon

The Vega Hatchback body style continued in 1978 as Monza 'S', marketed as the price leader for the Chevy Monza line. To differentiate the Monza 'S' from Vega, it featured Monza's new front end header panel and grill with Chevy bowtie emblem, steel front and rear bumpers (replacing Vega's aluminum bumpers), Monza front fender nameplates, and a two-spoke color keyed steering wheel with Monza emblem. White wall tires and full wheel covers were standard as were bumper rub strips. In addition, there was an expanded engine availability. Pontiac's Template:Auto CID OHV 'Iron-Duke' in-line 4 was standard. A choice of two V6 engines were available. Buick's Template:Auto CID 90 hp (67 kW) V6 and Template:Auto CID 105 hp (78 kW) V6. The 4-speed manual was standard with all engines. The 5-speed manual with overdrive and 3-speed automatic transmissions were optional.

The Vega Kammback wagon body style continued in 1978–1979 as Monza Wagon. It featured the new Monza front end and grill, front and rear steel bumpers with rub strips, Monza front fender namplates, standard white-wall tires, full wheel covers and steering wheel with Monza emblem. The Monza Estate was offered, and like the Vega Estate wagon it replaced, features wood grain sides and rear trim with outline moldings and the custom interior. Monza wagon models included, as standard, the 151 CID I-4. The Template:Auto CID and Template:Auto CID CID V6 engines were optional. The 4-speed manual was standard with all engines. The 5-speed manual with overdrive, and 3-speed automatic transmissions optional.

Pontiac Sunbird Safari Wagon

The Pontiac Sunbird Safari wagon replaced the discontinued Pontiac Astre Safari wagon which was essentially carried over with Sunbird badging. Sunbird Safari uses the Vega Kammback wagon body and was produced for the 1978–1979 model years. It retains Vega/Astre's aluminum bumpers, unlike the Monza wagon, which features a new front end and steel bumpers, but 1979 Sunbird wagons featured a revised horizontal styled grill. Standard powertrain was Pontiac's 151 CID I-4 with a 4-speed manual transmission. Previously unavailable for Astre were Sunbird's optional 196 CID and 231 CID V6 engines. 5-speed manual and 3-speed automatic were transmission options.

| Vega variant | Production |

|---|---|

| 1975–1977 Pontiac Astre | 147,773 |

| 1978 Chevrolet Monza 'S' Hatchback | 2,326 |

| 1978–1979 Chevrolet Monza Wagon | 41,023 |

| 1978–1979 Pontiac Sunbird Wagon | 11,336 |

| Total | 192,458 |

Hot Rodding & Racing

V8 Vegas

Because of the Vega's design, light weight and low cost, it is often modified. A small-block Chevy V8 engine fits in the engine compartment; and a big-block will fit with modifications.

Hot Rod magazine, in 1972, tested a Chevrolet prototype Vega featuring a 302 CID all-aluminum V8. The fitted engine was the last of several 283 CID V8's used in Chevrolet late 50's Corvette research and development, and bored out to 302 CID for the Vega application. Hot Rod's road test of the prototype with Turbo Hydramatic, Vega's stock differential, and street tires yielded quarter mile (~400 m) times under 14 seconds. In the end, Vega was not offered with a factory V8 option. The Vega-based Monza did instead, first in 1975 with a new Template:Auto CID 110 hp (82 kW) V8 then in 1977–79, with the Template:Auto CID 140 hp (100 kW) V8. (Template:Auto CID 125 hp (93 kW) V8 1975 Calif. only)

Green Valley, 1975

An engine swap is how Vega gets V8 power. Motion Performance of Baldwin NY and Scuncio Chevrolet sold new, converted V8 small and big block Vegas. Heavy duty engine mounts and front springs are fitted to support the increased engine weight, a larger radiator for the increased cooling demand and modified driveshaft are required. For engines over 300 hp (220 kW), or with a manual transmission, a narrowed 12-bolt differential replaces the stock Vega unit.

Drag racer Bill "Grumpy" Jenkins in the 1972 season, won six of eight National Pro-Stock division events with his '72 Vega Grumpy's Toy X small block. In its first entered event, the untested Vega ran low 9.6 second runs and won the 1972 Winternationals. Jenkins built and raced Pro-stock '74 Vega and '75 Monza drag cars. His Grumpy's Toy XI 1974 Vega (pictured) sold for $550,000 in 2007.

Car and Driver's Showroom Stock #0

Car and Driver magazine challenged its readers to a Sports Car Club of America (SCCA) sanctioned series of Showroom Stock races in the 70's at Lime Rock Park, Lime Rock Conn. Patrick Bedard, C&D Writer, was the driver of their '73 Vega GT Showroom Stock #0 in the Car and Driver Showroom Stock Challenge III in 1975, and had just edged out an Opel to win the event. Bedard said, "The lone Vega outran every single Opel, Colt, Pinto, Datsun, Toyota and Subaru on the starting grid. A 25 lap sprint into racing's hall of fame." Bedard drove the car to the impound area after the victory lap, a metallic bronze coupe with a big yellow zero on its battle scared door, water boiling out of the coolant tank, a moan broadcasting from the cam drive, its left front tire rough and worn. The tech inspectors checked under the hood looking for the secrets of its speed. It had done the job-this Vega GT faced off against 31 showroom stocks and it had finished first.

The year old Vega was bought in California for $1900. While there, Bedard talked to Doug Roe, an ex Chevrolet engineer with a reputation as a Vega specialist. He mentioned the Vega showroom stocker-Roe replied, "Better overfill it about a quart. When you run them over 5,000 rpm, all the oil stays up in the head and you'll wipe the bearings. And something has to be done with the crankcase vents. If you don't it'll pump all that oil into the intake." On its very first lap around Lime Rock the Vega blew its air cleaner full of oil. And it also ran 215 °F (102 °C) on the water temperature gauge. When he called Roe about the overheating, Roe said, "All Vegas run at 215 degrees on the water temp gauge. It would be ok to about 230 degrees. Then it would probably start to detonate." Bedard wasn't even convinced that it could finish. And he didn't even know all of its bad habits yet. Five laps from the end he discovered that once the tank drops below a quarter full, the fuel won't pick up in the right turns. Twice per lap the carburator would momentarily run dry. And if that wasn't bad enough, the temperature gauge read exactly 230 degrees and a white Opel was unshakably on his tail.

Bedard recalls, "It was clear that no matter how good a driver Don Knowles was and no matter how quick his Opel, he wasn't going to get by if the Vega simply stayed alive. Which it did. You have to admire a car like that. If it wins, it must be the best, never mind all of the horror stories you hear, some of them from me."

See also

1973 Chevrolet Vega GT-Millionth Vega

Photographed Long Island, New York, 2008

- GM H-platform

- GM 2300 engine

- Cosworth: Road Engine Division

- Economy car: 1970s–1990s

- Subcompact car

- Sedan: Two-door sedan

- Hatchback: Hatchbacks in North America

- Station wagon: Two-door wagons

- Sedan delivery: History 1970's

- Fastback:Hatchback and liftback cars

- Kammback: Mass-production cars

- Woodie (wagon): History

- Yenko Chevrolet

- Lordstown Assembly: production

- Grille:Material types

- Bumper:North America-USA-First standards

- Ed Cole

- John DeLorean:Career-Chevrolet

- Motor Trend Car of the Year

- Pontiac:History 1970-1982

- List of automobile sales by model: (C) Chevrolet Vega

- List of automobile sales by model: (P) Pontiac Astre

- List of best selling vehicle nameplates

References

- ^ Motor Trend-April 1975 "The 10 Best Selling (American Made) Cars in the Country."

- Motor Trend-April 1975

- h-body.org

- Collectable Automobile. April 2000

- Motor Trend: August 1959

- Motor Trend 1970 yearbook

- Collectable Automobile: April 2000

- ^ Engineering Concept, Design and Development of Chevrolet's new little car Vega 2300

- ^ Collectable Automobile-April 2000

- ^ Collectable Automobile-April 2000.

- 1970 Chevrolet Ad-Coming soon. The little car that does everthing well..You'll see.

- ^ Vega 2300 The story of the Engineering Concept, design and Development of Chevrolet's new little car-Chevrolet Engineering.

- 1971 Chevrolet Vega brochure-standard equipment

- Road & Track magazine-August 1970

- Chevrolet Vega cngineering report-1970

- ^ Motor Trend-August 1970.

- Collectible Automobile-April 2000

- Motor Trend February 1971- Vega 1971 Car of the year

- Road & Track August 1970-Vega 2300 by Chevrolet-technical Analysis & Driving impression

- Road and Track-September 1970.

- h-body.org

- 1973 Chevrolet Vega brochure

- 1971 Chevrolet Vega brochure

- 1972 Chevrolet Vega brochure.

- 1973 Chevrolet Vega brochure.

- Chevrolet press release-May 17, 1973.

- Hot Rod-December 1973

- 1974 Chevrolet Vega brochure.

- H-Body.org

- 1974 Chevrolet Folder-Spirit of America Vega

- 1975 Chevrolet Vega brochure.

- Chevrolet Ad-Cosworth Twin-Cam:One Vega for the price of two.

- 1975 Chevrolet Cosworth Twin-Cam folder-March 1975.

- H Body.org FAQ

- 1976 Chevrolet Vega ad-Chevy Vega-Built to take it.

- 1976 Chevrolet Vega brochure.

- Collectable Automobile. April 2000 p.37 "Riding the rails: Shipping Vegas by Vert-a-pac."

- quoted from: Collectable Automobile-April 2000

- 1971 Chevrolet Vega shop manual

- ^ Engineering Concept, Design and Development of Chevrolet's new liitle car Vega 2300

- Sports Car Graphic-September 1970.

- Road & Track-June 1973

- 1975 Chevrolet Vega brochure

- 1976 Chevrolet Vega brochure

- Chevrolet brochure-60,000 miles in less than 60 days in and around Death Valley. '76 Vega Dura-Built engine. Built to take it.

- 1976 Chevrolet Brochure-'76 Vega Dura-built engine. Built to take it.

- 1976 Pontiac brochure

- 1977 Oldsmobile Starfire brochure

- h-body.org

- Road & Track-March 1975. Chevrolet Cosworth Vega

- Chevrolet `1975 Cosworth Vega Service and Overhaul supplement-General information

- Cosworth Vega Owners Association-Cosworth Vega History

- 1975 Chevrolet Cosworth Vega Service and Overhaul Manual Supplement

- Collectable Automobile-April 2000. Chevrolet's Vega

- Motor Trend-Feb 1971

- Road & Track-August 1970, November 1970

- Car and Driver-May 1972

- Car and Driver-January 1971. Six-Car Comparison Test

- Car and Driver-December 1971. Super Coupe Comparison Test

- Car and Driver-May 1971, May-1972, May-1973. Car and Driver Reader's Choice Poll.

- Motor Trend-December 1970. 10 Best Cars of 1971

- Motor Trend-February 1971. 1971 Car of The Year: Chevrolet Vega 2300

- Motor Trend-February 1973. Monte Carlo: The Car of the Year.

- Motor Trend-August 1973. 15 Cars To Own in a Gas Crisis.

- Motor Trend-March 1974. 50 Cars Worth Their Weight in Gold.

- Road & Track September-1970. Technical Analysis & Driving Impression-Vega 2300 by Chevrolet

- Road and Track-November 1970. Vegas Plain and Fancy.

- Road & Track-June 1973. Road & Track Owner Survey-Chevrolet Vega

- Road & Track-June 1973. Road & Track road test:1973 Chevrolet Vega

- Road Test-November 1970. Vega 2300-Most innovative U.S. minicar

- Road Test-July 1974. Chevrolet's Energy Miser

- Hot Rod-March 1972. Don't Call it a Station Wagon-1972 Chevy Vega GT Kammback

- Hot Rod-December 1973. Rodden at Random

- Small Cars-1972.

- Road & Track-March 1976. Road & Track road test-Chevrolet Cosworth Vega