| Revision as of 14:39, 16 December 2013 edit109.84.2.117 (talk) Misplaced Pages poloicy is not to prefer a spelling - Undid unwarranted revision 581083446 by 75.102.131.3 (talk)← Previous edit | Revision as of 07:01, 28 December 2013 edit undoEspilceranul (talk | contribs)99 editsmNo edit summaryNext edit → | ||

| Line 1: | Line 1: | ||

| ] | ] | ||

| '''Baking powder''' is a dry chemical ], a mixture of a |

'''Baking powder''' is a dry chemical ], a mixture of a ] or bicarbonate and a weak ], and is used for increasing the volume and lightening the texture of baked goods. Baking powder works by releasing ] gas into a batter or dough through an acid-base reaction, causing bubbles in the wet mixture to expand and thus ] the mixture. It is used instead of ] for end-products where fermentation flavors would be undesirable<ref>{{cite book | last=Matz | first=Samuel A. | title=Bakery Technology and Engineering | edition=3 | year=1992 | page=54 | publisher=Springer | url=http://www.google.com/books?id=rU1wQotD3jIC&lpg=PP1&pg=PA54#v=onepage&q=&f=false | accessdate=2009-08-12}}</ref> or where the batter lacks the elastic structure to hold gas bubbles for more than a few minutes.<ref>{{cite book | last=McGee| first=Harold | title=On Food and Cooking | edition=revised | year=2004 | page=533 | publisher=Scribner-Simon & Schuster | url=http://www.google.com/books?id=iX05JaZXRz0C&lpg=PP1&pg=PA533#v=onepage&q=&f=false | accessdate=2009-08-12}}</ref> Because carbon dioxide is released at a faster rate through the acid-base reaction than through fermentation, breads made by chemical leavening are called ]s. | ||

| Most commercially available baking powders are made up of an alkaline component (typically ], also known as baking soda), one or more ]s (such as ]), and an inert starch (] in most cases, though ] may also be used). Baking soda is the source of the carbon dioxide,<ref>{{cite web|url=http://www.lallemand.com/BakerYeastNA/eng/PDFs/LBU%20PDF%20FILES/1_12CHEM.PDF|archiveurl=http://web.archive.org/web/20061014185015/http://www.lallemand.com/BakerYeastNA/eng/PDFs/LBU+PDF+FILES/1_12CHEM.PDF|archivedate=2006-10-14 |title=Chemical Leaveners, Lallemand Baking Update, Vol. 1 No. 12, 1996 |accessdate=2009-03-05 |publisher=Lallemand Inc. }}</ref> and the acid-base reaction can be generically represented as<ref>{{cite book | editor=A.J. Bent | title=The Technology of Cake Making | edition=6 | year=1997 | page=102 | publisher=Springer | url=http://www.google.com/books?id=OTy8aIWxHhQC&lpg=PP1&pg=PA102#v=onepage&q=&f=false | accessdate=2009-08-12}}</ref> | Most commercially available baking powders are made up of an alkaline component (typically ], also known as baking soda), one or more ]s (such as ]), and an inert starch (] in most cases, though ] may also be used). Baking soda is the source of the carbon dioxide,<ref>{{cite web|url=http://www.lallemand.com/BakerYeastNA/eng/PDFs/LBU%20PDF%20FILES/1_12CHEM.PDF|archiveurl=http://web.archive.org/web/20061014185015/http://www.lallemand.com/BakerYeastNA/eng/PDFs/LBU+PDF+FILES/1_12CHEM.PDF|archivedate=2006-10-14 |title=Chemical Leaveners, Lallemand Baking Update, Vol. 1 No. 12, 1996 |accessdate=2009-03-05 |publisher=Lallemand Inc. }}</ref> and the acid-base reaction can be generically represented as<ref>{{cite book | editor=A.J. Bent | title=The Technology of Cake Making | edition=6 | year=1997 | page=102 | publisher=Springer | url=http://www.google.com/books?id=OTy8aIWxHhQC&lpg=PP1&pg=PA102#v=onepage&q=&f=false | accessdate=2009-08-12}}</ref> | ||

Revision as of 07:01, 28 December 2013

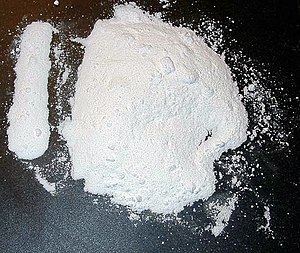

Baking powder is a dry chemical leavening agent, a mixture of a carbonate or bicarbonate and a weak acid, and is used for increasing the volume and lightening the texture of baked goods. Baking powder works by releasing carbon dioxide gas into a batter or dough through an acid-base reaction, causing bubbles in the wet mixture to expand and thus leavening the mixture. It is used instead of yeast for end-products where fermentation flavors would be undesirable or where the batter lacks the elastic structure to hold gas bubbles for more than a few minutes. Because carbon dioxide is released at a faster rate through the acid-base reaction than through fermentation, breads made by chemical leavening are called quick breads.

Most commercially available baking powders are made up of an alkaline component (typically sodium bicarbonate, also known as baking soda), one or more acid salts (such as cream of tartar), and an inert starch (cornstarch in most cases, though potato starch may also be used). Baking soda is the source of the carbon dioxide, and the acid-base reaction can be generically represented as

- NaHCO3 + H → Na + CO2 + H2O

The inert starch serves several functions in baking powder. Primarily it is used to absorb moisture, and thus prolong shelf life by keeping the powder's alkaline and acidic components dry so as not to react with each other prematurely. A dry powder also flows and mixes more easily. Finally, the added bulk allows for more accurate measurements.

The acid in a baking powder can be either fast-acting or slow-acting. A fast-acting acid reacts in a wet mixture with baking soda at room temperature, and a slow-acting acid will not react until heated in an oven. Baking powders that contain both fast- and slow-acting acids are double acting; those that contain only one acid are single acting. By providing a second rise in the oven, double-acting baking powders increase the reliability of baked goods by rendering the time elapsed between mixing and baking less critical, and this is the type most widely available to consumers today. Double-acting baking powders work in two phases; once when cold, and once when hot. Common low-temperature acid salts include cream of tartar and monocalcium phosphate (also called calcium acid phosphate). High-temperature acid salts include sodium aluminium sulfate, sodium aluminum phosphate and sodium acid pyrophosphate.

History

Early chemical leavening was accomplished by activating baking soda in the presence of liquid(s) and an acid such as sour milk, vinegar, lemon juice, or cream of tartar. These acidulants all react with baking soda quickly, meaning that retention of gas bubbles was dependent on batter viscosity and that it was critical for the batter to be baked before the gas escaped. The development of baking powder created a system where the gas-producing reactions could be delayed until needed.

While various baking powders were sold in the first half of the 19th century, our modern variants were discovered by Alfred Bird in 1843. August Oetker, a German pharmacist, made baking powder very popular when he began selling his mixture to housewives. The recipe he created in 1891 is still sold as Backin in Germany. Oetker started the mass production of baking powder in 1898 and patented his technique in 1903.

Following the American Civil War Joseph and Cornelius Hoagland developed a baking powder with the help of an employee, in Fort Wayne, Indiana, and their formula became known as Royal Baking Powder. The small company eventually moved to New York in the 1890s and became the largest manufacturer of baking powder.

Eben Norton Horsford, a student of Justus von Liebig, who began his studies on baking powder in 1856, eventually developed a variety he named in honor of Count Rumford. By the mid-1860s "Horsford's Yeast Powder" was on the market as an already-mixed leavening agent, distinct from separate packages of calcium acid phosphate and sodium bicarbonate. This was packaged in bottles, but Horsford was interested in using metal cans for packing; this meant the mixture had to be more moisture resistant. This was accomplished by the addition of corn starch, and in 1869 Rumford began the manufacture of what can truly be considered baking powder.

During World War II, Byron H. Smith, an inventor in Bangor, Maine, created a substitute product for American housewives, who were unable to obtain cream of tartar or baking powder due to war food shortages. Under the name "Bakewell", Smith marketed a mixture of sodium pyrophosphate mixed with corn starch to replace the acid cream of tartar component of baking powder. When mixed with baking soda, the product behaved like a single-acting baking powder, the only difference being that the acid is sodium pyrophosphate.

In 2006 the development of Rumford Baking Powder was designated a National Historic Chemical Landmark in recognition of its significance for making baking easier, quicker, and more reliable.

Use

Generally one teaspoon (5 ml) of baking powder is used to raise a mixture of one cup (200-250 ml) of flour, one cup of liquid, and one egg. However, if the mixture is acidic, baking powder's additional acids will remain unconsumed in the chemical reaction and often lend an unpleasant taste to food. High acidity can be caused by ingredients like buttermilk, lemon, yogurt, citrus or honey. When excessive acid is present, some of the baking powder should be replaced with baking soda. For example, one cup of flour, one egg, and one cup of buttermilk requires only ½ teaspoon of baking powder—the remaining leavening is caused by buttermilk acids reacting with ¼ teaspoon of baking soda.

On the other hand, if baking powders that contain sodium acid pyrophosphate, excess alkaline substances can sometimes deprotonate the acid in two steps instead of the one that normally occurs, resulting in an offensive bitter taste to baked goods. Calcium compounds and aluminium compounds do not have that problem though, since calcium compounds that deprotonate twice are insoluble and aluminium compounds do not deprotonate in that fashion.

Moisture and heat can cause baking powder to lose its effectiveness over time, and commercial varieties have a somewhat arbitrary expiration date printed on the container. Regardless of the expiration date, the effectiveness can be tested by placing a teaspoon of the powder into a small container of hot water. If it fizzes energetically, it is still active and usable.

Substituting in recipes

Baking powder is generally just baking soda mixed with an acid, and a number of kitchen acids may be mixed with baking soda to simulate commercial blends of baking powder. Vinegar (dilute acetic acid), especially white vinegar, is also a common acidifier in baking; for example, many heirloom chocolate cake recipes call for a tablespoon or two of vinegar. Where a recipe already uses buttermilk or yogurt, baking soda can be used without cream of tartar (or with less). Alternatively, lemon juice can be substituted for some of the liquid in the recipe, to provide the required acidity to activate the baking soda.

In times past, when chemically manufactured baking soda was not available, ash water was used instead, especially in confectionery. Wood ash is also weakly alkaline. To prepare ash water, one used a fistful of ash from the fireplace in a big pot of water. Ash from hardwoods, such as maple and ash trees, is preferred, whereas resinous woods, like pine, shouldn't be used unless completely burned. The ash water is given a boil, then left overnight to settle. The water is then filtered through a cloth and is ready to use. Many traditional recipes call for ash water instead of baking soda, because of some unique qualities: for example, ash water dripped on hot vegetable oils congeals into a gel-like mixture.

Usage of aluminium compounds

Baking powders are available both with and without aluminium compounds. Some people prefer not to use baking powder with aluminium because they believe it gives food a vaguely metallic taste and aluminium is not an essential mineral.

See also

References

- Matz, Samuel A. (1992). Bakery Technology and Engineering (3 ed.). Springer. p. 54. Retrieved 2009-08-12.

- McGee, Harold (2004). On Food and Cooking (revised ed.). Scribner-Simon & Schuster. p. 533. Retrieved 2009-08-12.

- "Chemical Leaveners, Lallemand Baking Update, Vol. 1 No. 12, 1996" (PDF). Lallemand Inc. Archived from the original (PDF) on 2006-10-14. Retrieved 2009-03-05.

- A.J. Bent, ed. (1997). The Technology of Cake Making (6 ed.). Springer. p. 102. Retrieved 2009-08-12.

- McGee, Harold (2004). On Food and Cooking (revised ed.). Scribner-Simon & Schuster. p. 534. Retrieved 2009-08-12.

- Lindsay, Robert C. (1996). Owen R. Fennema (ed.). Food Chemistry (3 ed.). CRC Press. p. 772. Retrieved 2009-08-12.

- http://books.google.com/books?id=b-iwjIb2RxwC&printsec=frontcover&dq=baking+science&hl=en&ei=gPOVTYfhFOzZiAKyjqGdCQ&sa=X&oi=book_result&ct=result&resnum=10&ved=0CF8Q6AEwCQ#v=onepage&q=sifting&f=false

- Matz, Samuel A. (1992). Bakery Technology and Engineering (3 ed.). Springer. pp. 71–72. Retrieved 2009-08-12.

- Stauffer, Clyde E. (1990). Functional Additives for Bakery Foods. Springer. p. 193. Retrieved 2009-08-12.

- Edwards, W.P. (2007). The Science of Bakery Products. Royal Society of Chemistry. p. 73. Retrieved 2009-08-12.

- ^ "Development of Baking Powder". American Chemical Society. Retrieved June 6, 2012.

- Tetrasodium pyrophosphate : Who, What, Where, When

- "Baking Powder". Fine Cooking. Archived from the original on 1 February 2009. Retrieved 2009-03-06.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - "Chocolate Cake with Vinegar - Antique Recipe Still Very Good". Cooks.com. Retrieved 2009-06-12.

{{cite news}}: Cite has empty unknown parameter:|coauthors=(help) - Template:Title=Wood Ash a Carcinegen? or dangerous to humans?

- "All About Baking Powder". What's Cooking America. Archived from the original on 14 September 2008. Retrieved 2008-09-28.

{{cite news}}: Cite has empty unknown parameter:|coauthors=(help); Unknown parameter|deadurl=ignored (|url-status=suggested) (help)

External links

- How Products Are Made: Baking Powder Background, history, and production

- Cook's Thesaurus: Leavens Descriptions of various chemical leavening agents and substitutions.

- Baking Powder Contains list of aluminum-free baking powders available in the US.

- Baking Powder Filling Machine

| Bread | ||

|---|---|---|

| Types |  | |

| Ingredients | ||

| Equipment | ||

| Processes and techniques | ||

| Uses | ||

| Other | ||

| List articles | ||