This is an old revision of this page, as edited by 129.247.247.238 (talk) at 16:00, 7 April 2006 (→Construction and operation). The present address (URL) is a permanent link to this revision, which may differ significantly from the current revision.

Revision as of 16:00, 7 April 2006 by 129.247.247.238 (talk) (→Construction and operation)(diff) ← Previous revision | Latest revision (diff) | Newer revision → (diff)A cavity magnetron is a high-powered vacuum tube that generates coherent microwaves. They are commonly found in the microwave oven, as well as various radar applications.

Construction and operation

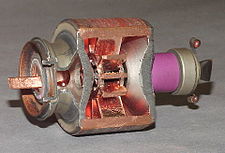

All cavity magnetrons consist of a hot filament (cathode) kept at or pulsed to a high negative potential by a high-voltage direct-current power supply. The cathode is built into the center of an evacuated, lobed, circular chamber. A perpendicular magnetic field is imposed by a permanent magnet. The magnetic field causes the electrons, attracted to the (relatively) positive outer part of the chamber, to spiral outward in a circular path rather than moving directly to this anode. Spaced about the rim of the chamber are cylindrical cavities. The cavities are open along their length and so connect the common cavity space. As electrons sweep past these openings they induce a resonant high frequency radio field in the cavity, which in turn causes the electrons to bunch into groups. A portion of this field is extracted with a short antenna that is connected to a waveguide (a metal tube usually of rectangular cross section). The waveguide directs the extracted RF energy to the load, which may be a cooking chamber in a microwave oven or a high gain antenna in the case of radar.

The size of the cavities determine the resonant frequency, and so the frequency of the emitted microwaves. However, the frequency is not precisely controllable; but this is not a problem in many applications such as heating or some forms of radar where the receiver can be synchronised with the nonprecision output. Where precise frequencies are required, other devices such as the klystron are used. The voltage applied and the characteristics of the cathode determine the power of the device.

The magnetron is a fairly efficient device. In a microwave oven, for instance, a 1100 watt input will generally create about 700 watts of microwave energy, an efficiency around 65%. This is far more efficient than the klystron, which typically operates around 30%. Modern solid state microwave sources typically operate around 25 to 30%, and are used primarily because they can generate a wide range of frequencies. Thus the magnetron remains in widespread use in roles where precise frequency control is not important.

Applications

Radar

- See also History of radar (Magnetron)

In radar devices the waveguide is connected to an antenna, which may be a slotted waveguide or a conical feedhorn pointing into a parabolic reflector. The magnetron is operated with very short high intensity pulses of applied voltage, resulting in a short pulse of microwave energy being emitted. A small portion of this energy is reflected back to the antenna and the waveguide where it is directed to a sensitive receiver. With further signal processing the signal is ultimately displayed as a radar map on a cathode ray tube (CRT) or a liquid crystal display.

Heating

In microwave ovens the waveguide leads to a radio frequency transparent port into the cooking chamber. It is important that there be food in the oven when it is operated so that these waves are absorbed, rather than reflecting back into the waveguide where the intensity of standing waves can cause arcing. The arcing, if allowed to occur for long periods, will destroy the magnetron. If a very small object is being microwaved, it is recommended to add a glass of water as an energy sink, although care must be taken not to "superheat" the water.

History

Simple two-pole magnetrons were developed in the 1920s by Albert Hull at General Electric, as an outgrowth of his work on the magnetic control of vacuum tubes in an attempt to work around the patents held by Lee DeForest on electrostatic control. The two-pole magnetron, also known as a split-anode magnetron, gave relatively low efficiencies. The cavity version (properly referred to as a resonant-cavity magnetron) proved to be far more useful.

There was an urgent need during radar development in World War II for a high-power microwave generator that worked in shorter wavelengths - around 10 cm rather than 150 cm - available from tube-based generators of the time. It was known that a multi-cavity resonant magnetron had been developed in 1935 by Hans Hollmann in Berlin. However the German military considered its frequency drift to be undesirable, and based their radar systems on the klystron instead. It was primarily for this reason that German night fighter radars were never a match for their British counterparts.

In 1940, at the University of Birmingham in the UK, John Randall and Dr. Harry Boot produced a working prototype similar to Hollman's cavity magnetron, but added liquid cooling and a stronger cavity. Randall and Boot soon managed to increase its power output 100-fold. Instead of giving up on the magnetron due to its frequency inaccuracy, they instead sampled the output signal and synced their receiver to whatever frequency was actually being generated.

An early 6kW version built by G.E.C. and given to the U.S. government in September 1940 was called "the most valuable cargo ever brought to our shores" (see Tizard Mission). At the time the most powerful equivalent microwave-producer available in the US (a klystron) had a power of only ten watts. The cavity magnetron was widely used during World War II in microwave radar equipment, and is often credited with giving Allied radar a considerable performance advantage over German and Japanese radars, thus directly influencing the outcome of the war.

Short wave centimetric radar, which was made possible by the cavity magnetron, allowed for the detection of much smaller objects and the use of much smaller antennas. The combination of the small sized cavity magnetron, small antennas and high resolution allowed small high quality radars to be installed in aircraft. They could be used by maritime patrol aircraft to detect objects as small as a submarine periscope, which allowed aircraft to attack and destroy submerged submarines which had previously been undetectable from the air. Centimetric contour mapping radars like H2S improved the accuracy of Allied bombers used in the strategic bombing campaign. Centimetric gun laying radars were likewise far more accurate than the older technology. They made the big gunned Allied battleships more deadly and along with the newly developed proximity fuze made anti-aircraft guns much more dangerous to attacking aircraft. The two coupled together and used by anti-aircraft batteries, placed along on the German V-1 flying bomb flight paths to London, are credited with destroying many of the flying bombs before they reached their target.

Since then, many millions of cavity magnetrons have been manufactured; some for radar, but the vast majority for another application far more domestic — the microwave oven. The use in radar itself has dwindled to some extent, as more accurate signals have generally been needed and developers have moved to klystron and travelling wave tube systems for these needs.

Health hazards

Among more speculative hazards, at least one in particular is well known and documented. As the lens of the eye has no cooling blood flow it is particularly prone to overheating when exposed to microwave radiation. This heating can in turn lead to a higher incidence of cataracts in later life. A microwave oven with a warped door or poor microwave sealing can be hazardous.

References

- T. J. Morgan - RADAR - The Mechanical Age Library - Mullen - circa 1952

- A. P. Rowe: One Story of Radar - Camb Univ Press - 1948

- Dudley Saward, Bernard Lovell: A Biography - Robert Hale - 1984

- Tuxedo Park, Jennet Conant. New York, Simon & Schuster, c2002. ISBN 0-684-87287-0

See also

- Cyclotron - An atomic accelerator that also directs particles in a spiral with a transverse magnetic field.

- Klystron - A device for amplifying or generating microwaves with greater precision and control than is available from the magnetron.

- Traveling wave tube - Another microwave amplifier device, capable of greater bandwidths than a klystron.

- Crossed-field amplifier - A device combining characteristics of magnetrons and TWTs, resulting in a high-power narrowband amplifier.

- Free electron laser - A device for amplifying or generating microwaves, infrared light, UV, and X-Rays.

- Maser - A device for generating microwaves that produces a very low noise and stable signal, a predecessor of the laser.

- Laser - A device for generating coherent light, an evolution of the maser

- Sputtering - An important industrial application of magnetrons

External links

- Information

- Patents

- U.S. patent 2,315,313 - Cavity resonator - H. Bushholz

- U.S. patent 2,357,313 - High frequency resonator and circuit therefor -- P. S. Carter

- U.S. patent 2,357,314 - Cavity resonator circuit - P. S. Carter

- U.S. patent 2,444,152 - Cavity resonator circuit - P. S. Carter

- U.S. patent 2,611,094 - Inductance-capacitance resonance circuit - H. B. Rex

- U.S. patent 2,408,236 - Magnetron casing - P. L. Spencer