This is an old revision of this page, as edited by TwoScars (talk | contribs) at 19:27, 1 July 2018 (→Beginning). The present address (URL) is a permanent link to this revision, which may differ significantly from the current revision.

Revision as of 19:27, 1 July 2018 by TwoScars (talk | contribs) (→Beginning)(diff) ← Previous revision | Latest revision (diff) | Newer revision → (diff)| Company type | Private company |

|---|---|

| Industry | Glassware |

| Founded | December 15, 1887 in Fostoria, Ohio (December 15, 1887 in Fostoria, Ohio) |

| Founder | Lucian B. Martin, William S. Brady |

| Defunct | 1986 |

| Headquarters | Moundsville, West Virginia, USA |

| Key people | Lucian B. Martin, William S. Brady, Charles Foster, William A. B. Dalzell |

| Products | decorated lamps, blown and pressed tableware, stemware, and novelties |

| Number of employees | 1000 (at peak) |

The Fostoria Glass Company manufactured pressed, blown and hand-molded glassware and tableware for almost 100 years. It began operations in Fostoria, Ohio, on December 15, 1887, on land donated by the townspeople. The new company was formed by men from West Virginia, who were experienced in the glassmaking business. They started their company in northwest Ohio to take advantage of newly discovered natural gas that was an ideal fuel for glassmaking. Numerous other businesses were started in the area, and the supply of natural gas began to diminish. Fuel shortages caused the company to move to Moundsville, West Virginia in 1891. To keep brand awareness and loyalty, the company kept the name "Fostoria".

After the move to Moundsville, the company achieved a national reputation. Fostoria was considered one of the top producers of elegant glass. The company had over 1,000 patterns, including one (American) that was produced for over 75 years. Eventually, Fostoria employed 1,000 people, and had sample rooms in New York, Chicago, Dallas, San Francisco, and other locations. The company advertised heavily, and one of its successes was sales through bridal registries. It also made products for several U.S. presidents.

During the 1970s, foreign competition and changing preferences made profitability difficult for the company. The plant was closed permanently on February 28, 1986. Several companies continued making products using the Fostoria patterns.

Background

See also: List of Glass Companies Led by Former Employees of Hobbs, Brockunier and Company See also: Petroleum industry in OhioIn the last half of the 19th century, labor was one of the two largest cost categories in the United States glass making industry. People with the knowledge necessary to make glass were difficult to find. Management at Wheeling's J. H. Hobbs, Brockunier and Company had a policy of using skilled glassworkers from Europe, who would train the local employees—resulting in a superior workforce. In the 1860s, Wheeling, West Virginia, became a "hub for chemical and technological improvements to the composition of glass and the development of furnaces, molds, and presses" for making glass. By the end of the 1870s, the Hobbs glass works became the largest glass maker in the United States. One of the earliest places where the Hobbs glass making talent spread to was Bellaire, Ohio, which is located in Belmont County across the river from Wheeling and Ohio County. Former employees of the Hobbs glass works became the talent that established many of the region's glass factories, and many became company presidents or plant managers.

Transportation resources were also important to the glass industry. Waterways provided an efficient and safe way to transport glass. As the railroad industry developed, it also became an important transportation resource. As of 1880, almost all of the nation's top ten glass producing counties were located on a waterway. Allegheny County, Pennsylvania, (Pittsburgh) was the nation's leading glass producer based on value of production. Ohio's Belmont County and West Virginia's Ohio County, separated by the Ohio River, ranked 6th and 7th.

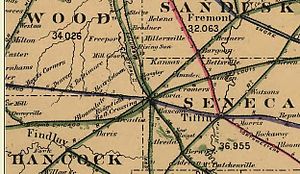

Fuel was the other large cost category for making glass in the United States. Furnaces needed to reach a temperature of more than 3,000 °F (1,650 °C) to melt the materials (known as the batch) together that make molten glass. Fuel is also needed for the gradual cooling (annealing) of hot glass in long ovens known as lehrs. Wood and coal had long been used as fuel for glassmaking. An alternative fuel, gas, became a desirable fuel for making glass glass because it is clean, gives a uniform heat, is easier to control, and melts the batch of ingredients faster. Gas furnaces for making glass were first used in Europe in 1861. In early 1886, a major discovery of natural gas occurred near the small village of Findlay, Ohio. Communities in northwestern Ohio began using low-cost natural gas along with free land and cash to entice glass companies to start operations in their town. Their efforts were successful, and at least 70 glass factories existed in northwest Ohio between 1886 and 1900.

Beginning

The Fostoria Glass Company was incorporated in West Virginia in July 1887. The founders of the Fostoria Glass Company were drawn to Fostoria, Ohio, to exploit the newly discovered natural gas. In addition to the natural gas, Fostoria was well served by railroads. The new firm also received incentives of $5,000 to $10,000 cash. ($10,000 in 1887 is equivalent to $339,111 in 2023.) The plant was located on Fostoria's South Vine Street. The factory’s furnace had a capacity of 12 pots, and originally employed 125 workers. Production began December 15, 1887, and products included tableware, bar goods, and lamps.

The glass men that formed the new company were from Wheeling or had worked there at one time. Lucian B. Martin was the new company's first president. Martin had been a sales executive for Wheeling's Hobbs, Brockunier and Company. William S. Brady was the new company's secretary. Brady had also worked at the Hobbs plant, and was a financial manager. His most recent job had been general manager of a glass plant in Wellsburg, West Virginia. Other founding members of the management team were James B. Russell, Benjamin M. Hildreth, and Otto Jaeger. Hildreth and Russell had worked at Hobbs plant, and Russell had also worked at a Pittsburgh glass works. German-born Otto Jaeger had worked at the Hobbs works as head of the engraving department. Former Ohio governor Charles Foster, son of the city of Fostoria's namesake, was added to this group of glass industry veterans on the board of directors.

The company hired Henry Humphreville to be plant manager. Humphreville was from the nation's other center of glassmaking innovation: Pittsburg. He had also worked at Brady's Riverside Glass Company in Wellsburg. Many of the employees hired for the startup were from the Wheeling area. At least 20 people from Bellaire, Ohio, joined the new company. This included experienced glass men such as Henry Crimmel and his brother Jacob, Hayes O’Neal, and Deacon Scroggins. Their work experience included glassmaking at the Belmont Glass Company (in Bellaire) and at Wheeling's Hobbs, Brockunier and Company.

Early products

The company advertised as a manufacturer of pressed glassware. Specialties were candle stands, candelabras, and banquet lamps. The first piece of glass pressed at the plant was a salt dip, pattern number 93. Another early pattern was called Cascade. This pattern looked like a swirl, and was very popular. It was used for candelabras and ink wells. It was also used for tableware such as containers for sugar, cream, and butter. This was the first tableware pattern made, and it continued through the years under different names.

The company had many talented designers. Among them was, Charles E. Beam, who was the head of the company's mold shop and eventually added to the board of directors. Beam's specialty was designing dishes with animals as the covers. Another talented designer was Martin (company president), who patented the Cascade ink well (called an inkstand) and a paper weight with swirl sides.

Another pattern for the company was called Virginia, and it was introduced around Christmas in 1888. This pattern was quickly stolen (or "pirated") by a rival company. Fostoria Glass copied the copy, and named this so-called new pattern Captain Kidd. Eventually this same Virginia/Captain Kidd pattern was also called Foster or Foster Block in honor of Charles Foster. An advertisement for the Captain Kidd pattern featured a butter dish, spoon dish, a sugar bowel, and a creamer.

Fostoria's Valencia pattern, number 205, is often called Artichoke because of the shape of the overlapping leaves on the bottom half of the glassware. This pattern was advertised in China, Glass and Lamps magazine in early 1891.

A pattern made in Fostoria that is popular with collectors is called Victoria. A wide variety of products were made using this pattern. This is the only pattern that was patented by the company. Fostoria Glass had employees who were from the glassmaking region of France. The Victoria pattern appears "almost identical" to a French company's pattern. When the company moved to Moundsville, all of the molds for this pattern mysteriously disappeared.

Move to Moundsville

Unfortunately for the area glass factories, Northwest Ohio's gas boom was short lived. Gas shortages started occurring during the winter of 1890–91. During April 1891, Fostoria Glass executives decided to move to Moundsville, West Virginia, because of the availability of coal as a fuel for the plant—and $10,000 cash (equivalent to $339,111 in 2023) offered by the community. The move was announced in September 1891. The Fostoria plant was sold to a group of investors led by Fostoria Glass executive Otto Jaeger, and his new company was named Seneca Glass Company.

In early December, the move to Moundsville was delayed by a temporary restraining order. Several members of the Crimmel family, who owned stock in the company, filed suit. The Crimmels, who were also employees of the company, claimed shareholders should have been consulted for the move. The attempt to stop the move was unsuccessful, and the restraining order was lifted a short time later. The Fostoria Glass Company moved by the end of December 1891, and the Seneca Glass Company began operations January 1892.

In addition to the $10,000 cash incentive, the company was also offered a 10-year supply of coal at a low price. Its first Moundsville furnace had a capacity of 14 pots. Coal was not used directly as a fuel for the furnace. Instead, the furnace burned coal gas made from the local supply of coal. About 60 workers from the Fostoria glass works moved with the company to the Moundsville location.

Moundsville operations

In 1899, the company became associated with the National Glass Company, which was a corporate trust. Co-founder Lucien Martin left the firm in 1901 to work in Pittsburgh for National Glass. Another co-founder, William Brady, also moved to the Pittsburg firm a short time later. Despite the association, Fostoria Glass Company did not become part of the National Glass Company.

William A. B. Dalzell joined the company as general manager in 1901. Dalzell was from Pittsburgh, and his initial experience in the glass industry was with Pittsburgh’s Adams and Company. The Dalzell brothers had been involved with the glass business as owners and management in West Virginia and Ohio. In 1899, he worked for National Glass Company, and from there he had joined the Fostoria Glass Company. Also joining the firm from Dalzell's Ohio plant was Calvin B. Roe, who had been a bookkeeper and plant superintendent. Dalzell quickly ascended to Vice President. Under Dalzell’s leadership, the Fostoria Glass Company gained a national reputation. Dalzell served as president and/or chairman from 1902 until his unexpected death in 1928.

In 1903, the company added a three-story brick building that housed a 14-pot furnace. This was thought to make it the largest independent glass plant in the United States. It meant that Fostoria Glass was operating with three large furnaces. By 1904, the company had 800 employees. Products made as of 1906 included decorated lamps, globes, shades, blown and pressed tableware, high grade lead blown tumblers, stemware, and novelties. At that time, it was said that the company "makes so many lines of glassware, all so perfectly, and markets its output so successfully to all classes of buyers, that no name is better known to all classes of trade."

Moundsville Products

Fostoria was considered one of the top producers of elegant glass. Yet, Fostoria glassware is also found on lists of Depression glass. The company had over 1,000 patterns, including many designed by artist George Sakier. An example of a glass pattern design by Sakier is the Colony pattern 2412. This pattern was produced in crystal from the 1930s until 1983. It was reissued as Maypole in the 1980s using colored glass. Patterns can be a style of glass, an etching on the glass, or a cutting on the glass. Some of the most successful Fostoria patterns were American, Kashmir, June, Trojan, and Versailles. One pattern that should be easy for historians to remember is pattern 1861. The pattern was named Lincoln, and 1861 is the year Abraham Lincoln became President of the United States. The pattern was used for pressed tableware. It was pictured on the front page of the Crockery and Glass Journal on January 4, 1912.

In 1915, Fostoria introduced its American pattern (pattern number 2056). This glass pattern was used for stemware and tableware, and continued to be produced until 1988. Described as "block geometric", its appearance was very different from other patterns when it was introduced. Most glass made with the American pattern was produced using Fostoria's high-quality crystal formula. American became Fostoria's most famous pattern. Management around this time was still led by is W. A. B. Dalzell as company president. Vice president was C. B. Roe, and A. C. Scroggins, Jr. was the secretary and treasurer. W. S. Brady was still listed as on the board of directors.

In 1924, the company became the first glass manufacturer to produce complete dinner sets in crystalware. In 1925, the company introduced dinnerware in colors. A national advertising campaign was started in 1926 to promote the complete dinnerware sets. Fostoria was also a major contributor to the creation of the bridal registry. Clear and pastel dinner sets became very popular, although expensive. This led to low cost dinner sets being made by injecting molten glass into an automated pressing mold. The product often had minor flaws, so "lacy" patterns were often included in the mold, or etched onto the glass, to hide imperfections.

Among the etching patterns introduced by Fostoria during the 1920s were June, Versailles, and Trojan. The June pattern, which was made from 1928 to 1951, was etched on stemware and tableware. It is one of the rare patterns that can be dated based on color of the glass. The Versailles pattern, made from 1928 to 1943, was another etching pattern. The etchings were mostly on plates and dishes. The glass product with the etching was made in many colors. The etching pattern called Trojan was made from 1929 to 1943. The Trojan etchings were mostly on plates and dishes. Original glass colors were rose and topaz. Gold tint was used in some of the last years of production. By 1928, Fostoria was the largest producer of handmade glass in the nation.

During the Great Depression the company made glassware for the higher and lower cost segments of the market. Two popular Fostoria etching patterns were Navarre and Chintz. Navarre was made from 1937 until 1980. Some of the pieces were etched onto the Baroque glass pattern, but others were on more modern glass patterns. The product was originally made in crystal, but later on a few pieces with color. The Baroque glass pattern was made by Fostoria from 1937 to 1965, and used for stemware and many types of tableware. The Chintz pattern was made from 1940 to 1973. This etching pattern is a drawing of branches leaves and flowers, and was usually on the Baroque glass pattern. The Colony pattern discussed earlier was introduced around this time. Another long-lived glass pattern, Century, was introduced in 1949 and made until 1982. It was used for stemware and tableware. Advertising during the 1940s included photos in the Ladies Home Journal.

Production peaked in 1950 when Fostoria's 1,000 employees manufactured over 8 million pieces of glass and crystal. A combination of outstanding products and national advertising helped the company become the largest manufacturer of handmade glassware in the United States. Beginning with President Dwight D. Eisenhower, every American president through Ronald Reagan had glassware made by Fostoria. Long-lived patterns introduced during the 1950s included Rose, Wedding Ring, and Jamestown. Rose was a cutting on stemware and tableware, and it was produced from 1951 to 1973. Wedding Ring was a decoration on stemware and tableware that was produced from 1953 to 1975. Jamestown was a glass pattern for stemware and tableware, and was used for numerous products from 1958 to 1982. The glass used was crystal and seven colors of glass: amber, blue, green, pink, amethyst, brown, and ruby. Among Jamestown stemware, ruby is valued higher than other colors by collectors. Among the milk glass patterns, Vintage was used for tableware and a few types of stemware from 1958 to 1965.

In the 1960s and 1970s, the company's marketing campaign expanded to include boutiques and display rooms within jewelry and department stores. In addition, Fostoria published its own consumer direct magazine, "Creating with Crystal" during this time. The Woodland glass pattern, not to be confused with the Woodland etching from the 1920s, was introduced in 1975 and made until 1981.

Decline

Changing dinnerware preferences and foreign competition made profitability difficult for the company during the 1970s. In 1983, Fostoria sold its factory to Lancaster Colony Corporation of Columbus, Ohio. The Fostoria Glass factory was shut down permanently on February 28, 1986. At the time, Kenneth B. Dalzell, the fourth generation of Dalzells at Fostoria Glass, was head of Fostoria operations. Dalzell purchased Viking Glass company of New Martinsville, West Virginia in April 1987, and renamed the company Dalzell-Viking. Fostoria inventory and molds were sold. The American, Baroque, and Coin patterns were therefore produced by others, including Dalzell-Viking. Some of this glassware produced at Dalzell-Viking was made by former Fostoria employees using Fostoria molds—making it difficult to differentiate from glassware made at the Fostoria plant.

Notes

Footnotes

- The Hobbs glass works, located in Ohio County's South Wheeling, West Virginia, was renamed numerous times over a period of about 60 years. Some of the names were Barnes & Hobbs; Hobbs & Barnes; Hobbs, Brockunier & Company; and Hobbs Glass Company.

- Bellaire is located in the Ohio coal belt, and therefore had a fuel source for local factories. By 1881, Bellaire had 15 glass factories, and was known as "Glass City".

- An example of the importance of waterways can be observed in February 1912. It was reported that because of ice on the Ohio River, 600 barrels of glassware from the Fostoria Class Company were waiting shipment at the Moundsville warf.

- A pot was essentially a measure of a glass plant's capacity. Each ceramic pot was located inside the furnace. The pot contained molten glass created by melting a batch of ingredients that typically included sand, soda, and lime. Stationed around each pot was a team of laborers that extracted the molten glass and began the process of making the glass product.

- The Crimmels, O'Neal, and Scroggins were mentioned in a Bellaire newspaper article. Henry and Jacob Crimmel were "key craftsmen in the early period of the company" and both had worked at Belmont Glass Company in Bellaire and Hobbs, Brockunier and Company in Wheeling. Crimmel family recipes for glass were used in the early days of the Fostoria Glass Company.

- One of Beam's creations that is "highly-prized" by today's collectors is a dish with a dolphin covering. Beam received a patent in 1890 for a glass mold that would enable pieces of chandeliers and candelabras to have small holes.

- Murray discusses Martin and his patents. Martin received the patent for the ink well in 1890. He patented the paper weight in 1891.

- Murray discusses the Virginia pattern, and identifies it as pattern number 140. He also shows an advertisement for the Virginia pattern in an 1889 edition of the Crockery and Glass Journal. Long and Seate do not identify this pattern, but list a Virginia plate etching as pattern 267 that was made from 1923 to 1929. They also list a Virginia glass pattern, number 2977, that was made from 1978 to 1986.

- Sources do not always agree on the number of pots for the first furnace. Rider says 16 pots. Lucht say 14 pots. A trade magazine describing the firm in 1912 mentioned a 14-pot furnace, but did not mention one with 16-pots.

- Three Dalzell brothers (Andrew, James, and William) and a banker from Pittsburg founded the Dalzell Brothers and Gilmore Glass Company in Wellsburg, West Virginia during 1883. In 1888 (after the death of Andrew Dalzell) they received incentives to move their company to Findlay, Ohio. The company name was changed to Dalzell, Gilmore and Leighton, after well-known glassmaker William Leighton Jr. joined the firm from the Hobbs Glass works.

- In the 1960s, collectors began being interested in the inexpensive versions of glass made during the Great Depression, and the term "Depression glass" was born. The term Depression Glass eventually began to be used for glass made beyond the Great Depression years, including years from 1925 through the 1970s. By the 1990s, the phrase "elegant glassware of the Depression" was being used to describe the better quality glass made at the same time as Depression glass. Thus, some of the patterns made by Fostoria using crystal glass are listed in books about Depression glass.

- Etching refers to using acid to alter the surface of glass. Engraving or cutting glass refers to using a tool to carve into the glass.

- Long and Seate list the Colony pattern (number 2412) as manufactured from 1940 to 1973. Schroy says the pattern was produced from the 1930s to 1983.

Citations

- ^ United States Department of Commerce, Bureau of Foreign and Domestic Commerce 1917, pp. 12–13

- ^ "South Wheeling Glass Works". Wheeling Daily Intelligencer. 1873-12-12. p. 3.

- ^ Fones-Wolf 2007, pp. 85–86

- Skrabec 2007, p. 73

- "Hobbs Brockunier Glass, Wheeling, WV 1886". Ohio County Public Library. Retrieved 2013-11-24.

- McKelvey 1903, p. 79

- Revi 1964, p. 69

- "Around the Glass and Lamp Factories (right column, bottom of page)". Crockery and Glass Journal. Whittemore and Jaques, Inc. 1912-02-15.

- United States Department of Commerce, Bureau of Foreign and Domestic Commerce 1917, p. 11

- Weeks 1884, p. 43 harvnb error: no target: CITEREFWeeks1884 (help)

- C.E. Frazier (1921-03-01). "The Operation of Lehrs". The Glass Industry. New York: Glass Industry Publishing, Inc.

- United States Department of Commerce, Bureau of Foreign and Domestic Commerce 1917, p. 36

- Paquette 2002, pp. 24–25

- Paquette 2002, p. 26

- "O-I Retiree's Quest to Clear up History of Glass Industry Develops into Book". Toledo Blade. 2002-09-24. p. online web page.

By 1880, Pittsburgh would be the center of glassmaking, with 44 factories, a number that northwest Ohio would top in the next two decades, mostly because of the oil-and-gas boom that began in northwest Ohio.

- Paquette 2002, p. 179

- ^ Paquette 2002, p. 180

- United States Department of Commerce, Bureau of Foreign and Domestic Commerce 1917, p. 67

- United States Department of Commerce, Bureau of Foreign and Domestic Commerce 1917, pp. 71–74

- ^ Murray 1992, p. 40

- "Otto Jaeger - Founder of Fostoria, Seneca, and Bonita Art Glass". Ohio County Public Library. Retrieved 2018-05-07.

- Murray 1992, p. 41

- Venable et al. 2000, p. 174

- Murray 1992, pp. 61–62

- Paquette 2002, p. 248

- Murray 1992, p. 39

- Murray 1992, pp. 43–44

- Murray 1992, p. 42

- ^ Murray 1992, p. 45

- US patent 442,599, "Glass-mold", issued 1890-12-16.

- US patent 19,953, "Inkstand", issued 1890-07-01.

- US patent 444,647, "Paper Weight", issued 1891-01-13.

- ^ Murray 1992, pp. 46–47

- Long & Seate 2003, pp. 181–182

- ^ Lechner & Lechner 1998, p. 67

- Murray 1992, p. 56

- Murray 1992, pp. 48–49

- Murray 1992, pp. 59–60

- Paquette 2002, p. 181

- Paquette 2002, p. 182

- "(No title, lower right corner of page 22)". Paint, Oil and Drug Review. Chicago: D. Van Ness Person. 1891-12-16.

- Murray 1992, p. 59

- ^ Rider & Grubber 2011, p. 48 harvnb error: no target: CITEREFRiderGrubber2011 (help)

- ^ Lucht 2011, p. 7 harvnb error: no target: CITEREFLucht2011 (help)

- "Still Expanding". Crockery and Glass Journal. New York: Whittemore and Jaques, Inc. 1912-01-11.

- Fones-Wolf 2007, p. 87

- ^ Fones-Wolf 2007, pp. 93–94

- Lechner & Lechner 1998, p. 68

- ^ Paquette 2002, p. 65

- Paquette 2002, pp. 61–62

- ^ Paquette 2002, p. 183

- "News from the Glass Factories (next page)". Glass and Pottery World. Chicago: Porter, Taylor and Company. 1903-04-01. Retrieved 2018-04-30.

- "Notes from the Glass Factories (next page)". Glass and Pottery World. Chicago: Porter, Taylor and Company. 1903-09-01.

- "Glimpses of Glass Makers". Glass and Pottery World. Chicago: Porter, Taylor and Company. 1904-08-01. Retrieved 2018-04-30.

- Fostoria Glass Company (1906-01-01). "Fostoria Glass Company advertisement on page 39". Glass and Pottery World. Chicago: Porter, Taylor and Company.

- Fostoria Glass Company (1906-05-01). "Glimpses of Glass Houses". Glass and Pottery World. Chicago: Porter, Taylor and Company.

- ^ Prisant 2003, p. 93

- ^ Kovel & Kovel 1991, p. 3

- Kovel & Kovel 1991, p. 13

- ^ Schroy & Warman 2013, p. 124

- "Corning Museum of Glass - Acid Etching". Corning Museum of Glass. Retrieved 2018-05-28.

- "The Fitzwilliam Museum: Techniques of Glass Engraving". University of Cambridge. Retrieved 2018-05-28.

- "The New York Crockery and Glass District(2nd page, right column)". Crockery and Glass Journal. Whittemore and Jaques, Inc. 1912-03-07.

- "Crockery and Glass Journal (front page), Fostoria Quality Excels". Crockery and Glass Journal. Whittemore and Jaques, Inc. 1912-01-04.

- ^ Sullivan 2010, p. 188

- Schroy & Meyer 2017, p. 37

- Long & Seate 2003, pp. 6–8

- "Fostoria Glass Co". Moody's Manual of Railroads and Corporation Securities 1916 Vol. III. New York: Moody Publishing Company. 1916. Retrieved 2008-05-11.

- ^ Schramm 2004, Ch. 4 of e-book

- Long & Seate 2003, pp. 92–93

- Kovel & Kovel 1991, p. 48

- Kovel & Kovel 1991, pp. 86–87

- Kovel & Kovel 1991, p. 85

- Kovel & Kovel 1991, p. 58

- Long & Seate 2003, pp. 16–18

- Kovel & Kovel 1991, p. 26

- Long & Seate 2003, p. 53

- Long & Seate 2003, p. 46

- "Yours, for a toast to charm (advertisement)". Ladies' Home Journal. Philadelphia, PA: The Curtis Publishing Company. April 1948.

- Long & Seate 2003, p. 141

- Long & Seate 2003, pp. 90–91

- Long & Seate 2003, p. 181

- Rinker 1997, p. 97

- Long & Seate 2003, pp. 188–189

- Rinker 1997, p. 71

- "". American Glass Review. Commoner Publishing Company. 1988.

References

- Fones-Wolf, Ken (2007). Glass towns: industry, labor and political economy in Appalachia, 1890–1930s. Urbana, IL: University of Illinois Press. ISBN 978-0-252-03131-1. OCLC 69792081.

{{cite book}}: Invalid|ref=harv(help) - Kovel, Ralph M.; Kovel, Terry H. (1991). Kovels' Depression Glass & American Dinnerware Price List. New York: Crown Publishers. p. 250. ISBN 978-0-51758-444-6.

{{cite book}}: Invalid|ref=harv(help) - Lechner, Mildred; Lechner, Ralph (1998). The World of Salt Shakers: Antique & Art Glass Value Guide, Volume 3. Paducah, KY: Collector Books. p. 311. ISBN 978-1-57432-065-7.

{{cite book}}: Invalid|ref=harv(help) - Long, Milbra; Seate, Emily (2003). The Fostoria Value Guide. Paducah, KY: Collector Books. p. 206. ISBN 978-1-57432-583-6. OCLC 229317585.

{{cite book}}: Invalid|ref=harv(help) - McKelvey, Alexander T. (1903). Centennial History of Belmont county, Ohio and Representative Citizens. Chicago: Biographical Publishing Company. p. 833. OCLC 318390043.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Murray, Melvin L. (1992). Fostoria, Ohio Glass II. Fostoria, OH: M. L. Murray. p. 184. OCLC 27036061.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Paquette, Jack K. (2002). Blowpipes, Northwest Ohio Glassmaking in the Gas Boom of the 1880s. Xlibris Corp. p. 559. ISBN 1-4010-4790-4. OCLC 50932436.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Prisant, Carol (2003). Antiques Roadshow Collectibles: The Complete Guide to Collecting 20th Century Toys, Glassware, Costume Jewelry, Memorabilia, Ceramics, and More. New York: Workman Publishing. p. 589. ISBN 0-7611-2887-5.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Revi, Albert Christian (1964). American Pressed Glass and Figure Bottles. New York: Nelson. OCLC 965803.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Rinker, Harry L. (1997). Stemware of the 20th Century: The Top 200 Patterns. New York: House of Collectables. p. 195. ISBN 978-0-67660-084-1.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Schramm, Robert W. (2004). Moundsville. Charleston, South Carolina: Arcadia. ISBN 978-0-73851-735-3. OCLC 630552674.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Schroy, Ellen Tischbein; Warman (2013). Warman's Depression Glass Field Guide 2017: Values and Identification. Iola, WI: KP/F+W Media. p. 511. ISBN 978-1-44023-456-9. OCLC 1011912525.

{{cite book}}: Invalid|ref=harv(help) - Schroy, Ellen Tischbein; Meyer, Pam (2017). Warman's Depression Glass Handbook 2017: Identification, Values, Pattern Guide. Iola, WI: Krause Publications. p. 320. ISBN 978-1-44024-813-9. OCLC 1011859939.

{{cite book}}: Invalid|ref=harv(help) - Skrabec, Quentin R. (2007). Michael Owens and the Glass Industry. Gretna, LA: Pelican Publishing. OCLC 137341537.

{{cite book}}: Invalid|ref=harv(help) - Skrabec, Quentin R. (2011). Edward Drummond Libbey, American glassmaker. Jefferson, NC: McFarland. ISBN 978-0-78648-548-2. OCLC 753968484.

{{cite book}}: Invalid|ref=harv(help) - Sullivan, Amy (2010). Schroeder's Antiques Price Guide. Padacuh, KY: Collector Books. p. 607. ISBN 978-1-57432-632-1. OCLC 433147612.

{{cite book}}: Invalid|ref=harv(help) - United States Department of Commerce, Bureau of Foreign and Domestic Commerce (1917). The Glass Industry. Report on the Cost of Production of Glass in the United States. Washington: Government Printing Office. OCLC 5705310.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Venable, Charles L.; Jenkins, Tom; Denker, Ellen P.; Grier, Katherine C.; Harrison, Stephen G. (2000). China and Glass in America, 1880-1980: from Tabletop to TV Tray. Dallas: Dallas Museum of Art. ISBN 978-0-81096-692-5. OCLC 905439701.

{{cite book}}: Invalid|ref=harv(help) - Weeks, Joseph Dame; United States Census Office (1884). Report on the Manufacture of Glass. Washington: Government Printing Office. p. 1152. OCLC 2123984.

{{cite book}}: Invalid|ref=harv(help)

Further reading

- Bones, Frances (1999). Fostoria Glassware, 1887-1982: Identification and Values: 95 Years of Glassmaking. Paducah, KY: Collector Books. p. 446. ISBN 978-1-57432-108-1. OCLC 41878453.

{{cite book}}: Invalid|ref=harv(help) - Kerr, Ann (1994). Fostoria: an Identification and Value Guide of Pressed, Blown & Hand Molded Shapes. Paducah, KY: Collector Books. p. 360. ISBN 978-0-89145-726-8. OCLC 1003180297.

{{cite book}}: Invalid|ref=harv(help) - Piña, Leslie (2006). Fostoria American: line 2056. A Schiffer Book for Collectors. Atglen, PA: Schiffer Pub. p. 160. ISBN 978-0-76432-469-7. OCLC 76827604.

{{cite book}}: Invalid|ref=harv(help) - Long, Milbra; Seate, Emily (2008). Fostoria Stemware: The Crystal for America. Paducah, KY: Collector Books. p. 268. ISBN 978-1-57432-583-6. OCLC 229317585.

{{cite book}}: Invalid|ref=harv(help) - Weatherman, Hazel M. (1972). Fostoria: Its First Fifty Years. Springfield, MO: The Weathermans. p. 320. ISBN 978-0-91307-402-2. OCLC 410096.

{{cite book}}: Invalid|ref=harv(help) - Williams, Juanita L. (2004). Fostoria Glass: Scarce, Unique, and Whimsies. Atglen, PA: Schiffer Pub. p. 256. ISBN 978-0-76431-974-7. OCLC 55209418.

{{cite book}}: Invalid|ref=harv(help)

See also

External links

- Fostoria Glass Society

- Fostoria Ohio Glass Association

- National Depression Glass Association - Fostoria advertisements

- YouTube Video - Fostoria Glass

- Glassmaking companies of the United States

- Drinkware

- Defunct glassmaking companies

- Defunct manufacturing companies of the United States

- Defunct companies based in Ohio

- Defunct companies based in West Virginia

- Fostoria, Ohio

- Manufacturing companies based in Ohio

- Manufacturing companies based in West Virginia

- American companies established in 1887

- Manufacturing companies established in 1887

- Manufacturing companies disestablished in 1986

- 1887 establishments in Ohio

- 1986 disestablishments in West Virginia