This is an old revision of this page, as edited by Light current (talk | contribs) at 21:29, 1 August 2005 (added heading 'Operation'). The present address (URL) is a permanent link to this revision, which may differ significantly from the current revision.

Revision as of 21:29, 1 August 2005 by Light current (talk | contribs) (added heading 'Operation')(diff) ← Previous revision | Latest revision (diff) | Newer revision → (diff)

A relay is an electrical switch that opens and closes automatically under control of another electrical circuit. It can therefore be considered, in a broad sense, to be a form of electrical amplifier. In the original form, the switch is operated by an electromagnet to open or close one or many sets of contacts. It was invented by Joseph Henry in 1835.

These contacts can be either normally-open, normally-closed, or change-over contacts.

- Normally-open contacts disconnect the circuit until the relay is activated.

- Normally-closed contacts connect the circuit until the relay is activated.

- Change-over contacts control two circuits: one that is normally connected and one that is normally disconnected. Activating the relay flips the connections, disconnecting the normally-connected circuit and connecting the normally-disconnected circuit.

Operation

When a current flows through the coil, the resulting magnetic field attracts an armature that is mechanically linked to a moving contact. The movement either makes or breaks a connection with a fixed contact. When the current is switched off, the armature is usually returned by a spring to its resting position, although latching relays exist that require operation of a second coil to reset the contact position.

By analogy with the functions of the original electromagnetic device, a solid-state relay operates a thyristor or other solid-state switching device with a transformer or light-emitting diode to trigger it.

Relays may also be operated by heat where a coil heats a bi-metal strip to open contacts, or where a solder pot melts, releasing a spring to operate contacts. Such heat-activated relays are commonly used for motor circuit protection.

Applications

Relays are used:

- to control a high-voltage circuit with a low-voltage signal, as in some types of modems,

- to control a high-current circuit with a low-current signal, as in the starter solenoid of an automobile,

- to detect and isolate faults on transmission and distribution lines by opening and closing circuit breakers (protection relays),

- to isolate the controlling circuit from the controlled circuit when the two are at different potentials, for example when controlling a mains-powered device from a low-voltage switch. The latter is often applied to control office lighting as the low voltage wires are easily installed in partitions, which may be often moved as needs change. They may also be controlled by room occupancy detectors in an effort to conserve energy,

- to perform logic functions. For example, the boolean AND function is realised by connecting relay contacts in series, the OR function by connecting contacts in parallel. Due to the failure modes of a relay compared with a semiconductor, they are widely used in safety critical logic, such as the control panels of radioactive waste handling machinery.

- exceptionally, to generate sound. The clicking sounds of a relay were likely the inspiration for the early telegraph, which rather than producing tones (as is heard on radiotelegraph), only clicks were generated. A relay can also be made into a buzzer by wiring up the coil in series with the normally-closed contacts. When a current is applied to the relay, it opens the contacts that provide current to the coil, causing the current to stop flowing and the contacts to close again. This cycle repeats continuously, causing the relay to buzz at an audible frequency. This can be further improved into an electric bell by extending the moving contact so it can repeatedly strike a bell.

Types of relay

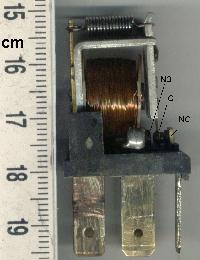

- A changeover relay has one moving contact (common or C) and two fixed contacts. One of these is Normally Closed (NC) when the relay is switched off, and the other is Normally Open (NO). Switching the relay on causes the normally open contact to close and the normally closed contact to open.

- A latching relay is mechanically arranged so that the armature can rest in either of two positions. There are two coils that pull the armature in opposite directions, so the relay can be switched to one position or the other and then left in that state indefinitely. This type of relay has the advantage that it consumes power only for an instant, while it is being switched, and it retains its last setting across a power outage. (Some common relays may be wired to electrically latch, which offers no power saving but does ensure that the relay returns to a known state during and after a power outage.)

- A reed relay has two, usually normally open, contacts inside a vacuum or inert gas filled glass tube. This protects the contacts against atmospheric corrosion. The two contacts are closed by magnetism from a coil around the glass tube, or a permanent magnet moved towards it. See also: reed switch.

- A mercury wetted relay is a form of reed relay in which the contacts are wetted with mercury. Such relays are used to switch low-voltage signals (one volt or less), or for high-speed counting and timing applications where the mercury eliminated contact bounce. Mercury wetted relays are position-sensitive and must be mounted vertically to work properly. Because of the toxicity and expense of liquid mercury, these relays are rarely specified for new equipment. See also mercury switch.

- A machine tool relay is a type standardized for industrial control of machine tools, transfer machines, and other seqential control. They are characterized by a large number of contacts (sometimes extendable in the field) which are easily converted from normally-open to normally-closed status, easily replaceable coils, and a form factor that allows compactly installing many relays in a control panel. Although such relays once were the backbone of automation in such industries as automobile assembly, the programmable logic controller mostly displaced the machine tool relay from sequential control applications.

- A contactor is a very heavy-duty relay used for switching electric motors and lighting loads. Such devices are often used for motor starters, and may be built up with overload protection devices attached.

- A Buchholz relay is a safety device sensing the accumulation of gas in large oil-filled transformers, which will alarm on slow accumulation of gas or shut down the transformer if gas is produced rapidly in the transformer oil.

Relay application considerations

Selection of an appropriate relay for a particular application requires evaluation of many different factors:

- Number and type of contacts - normally open, normally closed, changeover (double-throw)

- Rating of contacts - small relays switch a few amperes, large contactors are rated for up to 3000 amperes, alternating or direct current

- Voltage rating of contacts - typical control relays rated 300 VAC or 600 VAC, automotive types to 50 VDC, special high-voltage relays to about 15,000 V

- Coil voltage - machine-tool relays usually 24 VAC or 120 VAC, relays for switchgear may have 125 V or 250 VDC coils, "sensitive" relays operate on a few milliamperes

- Package/enclosure - open, touch-safe, double-voltage for isolation between circuits, explosion proof, outdoor, oil-splashresistant

- Mounting - sockets, rail mount, panel mount, through-panel mount, enclosure for mounting on walls or equipment

- Switching time - where high speed is required

- "Dry" contacts - when switching very low level signals, special contact materials may be needed such as gold-plated contacts

- Contact protection - suppress arcing in very inductive circuits

- Coil protection - suppress the surge voltage produced when switching the coil current.

- Isolation between coil circuit and contacts

- Aerospace or radiation-resistant testing, special quality assurance

- Accessories such as timers, auxiliary contacts, pilot lamps, test buttons

- Regulatory approvals

Protection relay

A protection relay is a complex electromechanical apparatus, often with more than one coil, designed to calculate operating conditions on an electrical circuit and trip circuit breakers when a fault was found. Unlike switching type relays with fixed and usually ill-defined operating voltage thresholds and operating times, protection relays had well-established, selectable, time/current (or other operating parameter) curves. Such relays were very elaborate, using arrays of induction disks, shaded-pole magnets, operating and restraint coils, solenoid-type operators, telephone-relay style contacts, and phase-shifting networks to allow the relay to respond to such conditions as over-current, over-voltage, reverse power flow, over- and under- frequency, and even distance relays that would trip for faults up to a certain distance away from a substation but not beyond that point. An important transmission line or generator unit would have had cubicles dedicated to protection, with a score of individual electromechanical devices.

Design and theory of these protective devices is an important part of the education of a electrical engineer who specializes in power systems. Today these devices are nearly entirely replaced (in new designs) with microprocessor-based instruments (numerical relays) that emulate their electromechanical ancestors with great precision and convenience in application. By combining several functions in one case, numerical relays also save capital cost and maintenance cost over electromechanical relays. However, due to their very long life span, tens of thousands of these "silent sentinels" are still protecting transmission lines and electrical apparatus all over the world.

See also:

Relay is also the name of a series of medium-altitude satellites; the first was launched in 1962.

References

Westinghouse Corporation, Applied Protective Relaying, 1976, Westinghouse Corporation, no ISBN, Library of Congress card no. 76-8060 - a standard reference on electromechanical protection relays (out of print - current edition published by ABB)

Terrell Croft and Wilford Summers (ed), American Electricans' Handbook, Eleventh Edition, McGraw Hill, New York (1987) ISBN 0070139326

External links

Many manfacturers of relays exist. Some commonly used relays are made by the following companies:

Categories: