This is an old revision of this page, as edited by Christian75 (talk | contribs) at 20:11, 21 January 2012 (clean up, removed stub tag using AWB (7852)). The present address (URL) is a permanent link to this revision, which may differ significantly from the current revision.

Revision as of 20:11, 21 January 2012 by Christian75 (talk | contribs) (clean up, removed stub tag using AWB (7852))(diff) ← Previous revision | Latest revision (diff) | Newer revision → (diff)

| |

| Names | |

|---|---|

| IUPAC name Bis(sulfanylidene)tungsten | |

| Systematic IUPAC name Dithioxotungsten | |

| Other names

Tungsten(IV) sulfide Tungstenite | |

| Identifiers | |

| CAS Number | |

| 3D model (JSmol) | |

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.032.027 |

| PubChem CID | |

| CompTox Dashboard (EPA) | |

InChI

| |

SMILES

| |

| Properties | |

| Chemical formula | WS2 |

| Molar mass | 247.98 g/mol |

| Appearance | blue-gray powder |

| Density | 7.5 g/cm, solid |

| Melting point | 1250 °C decomp. |

| Structure | |

| Crystal structure | Molybdenite |

| Coordination geometry | Trigonal prismatic (W) Pyramidal (S) |

| Related compounds | |

| Other anions | Tungsten(IV) oxide |

| Other cations | Molybdenum disulfide |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C , 100 kPa).

| |

Tungsten(IV) sulfide is the chemical compound with the formula WS2. It occurs naturally as the rare mineral called tungstenite. This material is a component of certain catalysts used for hydrodesulfurization and hydrodenitrification.

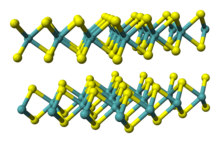

WS2 adopts a layered structure related to MoS2, with W atoms situated in trigonal prismatic coordination sphere. Owing to this layered structure, WS2 forms inorganic nanotubes, which were discovered on example of WS2 in 1992.

Properties

Bulk WS2 forms dark gray hexagonal crystals with a layered structure. They are not chemically active and can only be dissolved by a mixture of nitric and hydrofluoric acids. When burned in oxygen-containing atmosphere, WS2 converts to tungsten trioxide. When heated in absence of oxygen, WS2 does not melt but decomposes to tungsten and sulfur at 1250 °C.

Synthesis

WS2 is produced by a number of methods:

- Hydrothermal synthesis

- Gas phase reaction of H2S or H2S/Ar mixture with tungsten metal

- Reduction of ammonium tetrathiotungstate ((NH4)2WS4) at ~1300 °C in a flow of hydrogen gas

- Direct decomposition of various tetraalkylammonium tetrathiotungstate precursors in inert gas atmosphere.

- Microwave treatment of a solution of tungstic acid, elemental sulfur and monoethanolamine.

- Heating WS3 in absence of oxygen (otherwise the product is tungsten trioxide).

- Melting a mixture of tungsten trioxide, potassium carbonate and sulfur.

Uses

Nanostructured WS2 finds application as hydrogen and lithium storage material, as material for solid-state secondary lithium battery cathodes; as a component of batteries and other electrochemical devices; as a dry lubricant; and as catalyst in hydrodesulfurization of crude oil. WS2 also catalyses production of carbon monoxide

- CO2 + H2 → CO + H2O

bringing the reaction yield to the level above 99.9%.

Nanotubes

Tungsten disulfide is the first material which was found to form inorganic nanotubes, in 1992. This ability is related to the layered structure of WS2, and macroscopic amounts of WS2 have been produced by the methods mentioned above. Apart from scientific interest, these nanotubes are studied for potential applications. The addition of WS2 nanotubes to epoxy resin improves adhesion, fracture toughness and strain energy release rate. The wear of the nanotubes-reinforced epoxy is eight times lower than that of pure epoxy. WS2 nanotubes were embedded into a poly(methyl methacrylate) (PMMA) nanofiber matrix via electrospinning. The nanotubes were well dispersed and aligned along fiber axis. The enhanced stiffness and toughness of PMMA fiber meshes by means of inorganic nanotubes addition may have potential uses as impact-absorbing materials, e.g. for ballistic vests.

WS2 nanotubes are hollow and can be filled with another material, to preserve or guide it to a desired location, or to generate new properties in the filler material which is confined within a nanometer-scale diameter. To this goal, inorganic nanotube hybrids were made by filling WS2 nanotubes with molten lead, antimony or bithmuth iodide salt by a capillary wetting process, resulting in PbI2@WS2, SbI3@WS2 or BiI3@WS2 core-shell nanotubes.

References

- ^ Mary Eagleson (1994). Concise encyclopedia chemistry. Walter de Gruyter. p. 1129. ISBN 978-3-11-011451-5. Retrieved 6 November 2011.

- ^ Tenne R, Margulis L, Genut M, Hodes G (1992). "Polyhedral and cylindrical structures of tungsten disulphide". Nature. 360 (6403): 444–446. doi:10.1038/360444a0.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Panigrahi, Pravas Kumar; Pathak, Amita (2008). "Microwave-assisted synthesis of WS2 nanowires through tetrathiotungstate precursors". Sci. Technol. Adv. Mater. 9 (4): 045008. doi:10.1088/1468-6996/9/4/045008.

{{cite journal}}:|format=requires|url=(help)CS1 maint: multiple names: authors list (link) - ^ Erik Lassner; Wolf-Dieter Schubert (1999). Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds. Springer. pp. 374–. ISBN 978-0-306-45053-2. Retrieved 6 November 2011.

- E. Zohar, S. Baruch, M. Shneider, H. Dodiu, S. Kenig, D.H. Wagner, A. Zak, A. Moshkovith, L. Rapoport and R. Tenne (2011). "The Mechanical and Tribological Properties of Epoxy Nanocomposites with WS2 Nanotubes". Sensors & Transducers Journal. 12 (Special Issue): 53–65.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - C. S. Reddy, A. Zak and E. Zussman (2011). "WS2 nanotubes embedded in PMMA nanofibers as energy absorptive material". J. Mater. Chem. 21 (40): 16086–16093. doi:10.1039/C1JM12700D.

- Physorg.news – Nano-Armor: Protecting the Soldiers of Tomorrow

- R. Kreizman, A. N. Enyashin, F. L. Deepak, A. Albu-Yaron, R. Popovitz-Biro, G. Seifert and R. Tenne (2010). "Synthesis of Core-Shell Inorganic Nanotubes". Adv. Funct. Mater. 20 (15): 2459–2468. doi:10.1002/adfm.201000490.

{{cite journal}}: CS1 maint: multiple names: authors list (link)

| Tungsten compounds | |||||

|---|---|---|---|---|---|

| Tungsten(0) | |||||

| Tungsten(II) | |||||

| Tungsten(III) | |||||

| Tungsten(IV) | |||||

| Tungsten(V) | |||||

| Tungsten(VI) |

| ||||