| Argus 140/150 hp 6-cylinder | |

|---|---|

| |

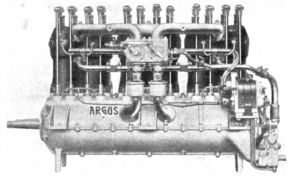

| Argus 140/150 hp 6-cylinder aircraft engine, intake side | |

| Type | Piston inline aero engine |

| National origin | Germany |

| Manufacturer | Argus Motoren |

| First run | c.1913 |

| Major applications | Sikorsky Ilya Muromets Kievsky No 128 |

| Developed from | Argus As I, Argus 115 hp |

| Developed into | Argus As II |

The Argus 140/150 hp 6-cylinder aircraft engine from 1913 was a six-cylinder, water cooled inline engine built by the German Argus Motoren company from 1913 to 1914.

The engine design evolved from earlier four- and six-cylinder Argus engines and was produced in a 140/150 hp and a 120/130 hp variant with cylinder dimensions of 140 mm × 140 mm (5.5 in × 5.5 in) and 130 mm × 140 mm (5.1 in × 5.5 in) bore and stroke respectively. It was used in some German prewar racing aircraft and, most notably, also powered some of the Sikorsky Ilya Muromets aircraft.

The engine design however was relatively short lived and was succeeded already in 1914 by a new line-up of completely redesigned six-cylinder engines ranging from 120 to 200 hp, of which the 120 hp Argus As II became the most well known.

Design and development

The first mentioning of the 150 hp six-cylinder Argus engine being offered in the Jeannin-Stahltaube can be found in early 1913. The engine had the same 140 mm (5.5 in) bore and stroke as the older 100 hp four-cylinder Argus engine and was said to develop up to 150 hp (110 kW) at 1,400 rpm.

Compared with the preceding Argus six-cylinder engines once again the external components have been rearranged. Besides that the design of the engine remained largely similar to the preceding Argus engines.

The cylinders were of cast iron, cast in pairs of two cylinders, with the cooling jackets integral in the casting. There were two overhead valves per cylinder, which were operated via pushrods and rocker arms from the camshaft on the left side of the engine. The intake valves were oriented to the center of each cylinder pair, and their intake ducts were conjoined within the casting into a single external port facing to the left side of the engine.

Two Cudell-G.A.-carburettors were placed centrally on the left side of the engine in close proximity to each other. A heating jacket, integrated into the coolant circulation, enclosed both carburettors, which fed separately into the two intake pipes of the intake manifold. The intake manifold was made out of cast aluminum and consisted of two separate intake pipes, which fed into single distribution pipe, which then connected to all three cylinder pairs.

The pistons were made of cast iron and had two piston rings. Each cylinder pair was fixated to the crankcase by six bolts. The cylinders were axially offset to the crankshaft, which was supported by two inner plain bearings and two outer ball bearings.

The crankcase was made of aluminum and cast in separate upper and lower half parts, with the upper half having six mounting arms cast into it. The engine case was divided into three separate chambers by internal walls at the inner crankshaft bearings, with each chamber having a separate breather on the right hand side. Compared to the earlier 115 hp six-cylinder Argus the engine case had been slightly redesigned, with most notably the pedestals being elongated to accommodate for the additional height of the oil- and water pump assembly.

The centrifugal water pump has been moved to the lower right at the control side of the engine, mounted together with the oil pump on a transverse shaft, which was driven by helical gears from the crankshaft end. The water pump fed the coolant to the water cooled cylinders as well as to the carburettor's heating jacket from the left side. Lubrication was done by a combination of splash lubrication and additional forced lubrication of the plain bearings with fresh oil fed by the oil pump.

The two magnetos were mounted with their shafts in parallel to the engine, with one magneto placed on either side at the control end. The magnetos were driven via spur gears from the camshaft gear and from the crankshaft via an intermediate idler gear respectively.

Variants

- Argus 120/130 hp six-cylinder

- (1913-1914), 120-130 hp, 130 mm × 140 mm (5.1 in × 5.5 in) bore and stroke

- Argus 140/150 hp six-cylinder

- (1913-1914), 140-150 hp, 140 mm × 140 mm (5.5 in × 5.5 in) bore and stroke

Applications

- Aviatik P.14 (Argus 120/130 hp, e.g. Aviatik biplane of Willy Trück in German South West Africa)

- Jeannin Stahltaube (e.g. Argus 120/130 hp, Prinz-Heinrich-Flug 1914, No. 24 with pilot René Freindt)

- Sikorsky Ilya Muromets No 128 (two Argus 140 hp and two Argus 125 hp engines)

Specifications (Argus 140/150 hp)

Data from Huth.

General characteristics

- Type: six-cylinder, water-cooled in-line piston engine

- Bore: 140 mm (5.51 in)

- Stroke: 140 mm (5.51 in)

- Displacement: 12.9 L (790 cu in)

- Dry weight: 250 kg (551 lb)

Components

- Valvetrain: Cam-in-block, OHV

- Cooling system: Water-cooled

Performance

- Power output: 150 hp (110 kW) at 1,400 rpm

See also

Related development

Related lists

References

Notes

- ^ Joachimczyk, 1914, pp. 538-540

- ^ Khajrulin 2018, p. 40

- Deutsche Luftfahrer-Zeitschrift, issue 2/1913, p. 37

- ^ Flugsport, issue 7/1914, pp. 278-281

- ^ Huth, 1914, p. 188

- Jane, 1913. p. 8c

- Zeitschrift für Flugtechnik und Motorluftschiffahrt, issue 12/1914, p. IX

- Deutsche Luftfahrer-Zeitschrift, issue 7/1914, p. 158

- Béjeuhr, 1914, p. 243, Note: The cylinder dimensions can be inferred by the formula L = 10.5 V (see v. Mises, 1914, p. 192) for estimated power L (listed as 117.1 hp) and displacement V

Bibliography

- Joachimczyk, Alfred Marcel (1914). "Neuere Deutsche Flugmotoren". Der Motorwagen, XVII. Jahrgang, 1914 (in German). Berlin: Krayn: 538–540. OCLC 4551189.

- "Der 150 PS Sechszylinder Argus-Flugmotor". Flugsport (in German). Jahrgang 1914 (7). Frankfurt am Main: Redaktion und Verlag Flugsport: 278–281. 1914.

- Huth, Fritz (1914). Motoren für Flugzeuge und Luftschiffe (in German). Berlin: R. C. Schmidt & co. p. 188. OCLC 11492610.

- Khajrulin, M.A. (2018). Legendarnyj "Ilja Muromets". Pervyj tjazhelyj bombardirovschik (in Russian). Moscow: Jauza. pp. 40–45. ISBN 978-5-04-091056-4.

- Jane, Fred T. (1913). Jane's all the world's aircraft, 1913 : a reprint of the 1913 edition of All the world's air-craft. New York: Arco Publishing Co., 1969. pp. 8c. OCLC 943875.

- "Einige neuere Flugzeugkonstruktionen". Deutsche Luftfahrer-Zeitschrift (in German). 17 (2). Berlin: Klasing & Co.: 36–37 1913. OCLC 29889214.

- "Teilnehmer am Prinz-Heinrich-Flug 1914". Deutsche Luftfahrer-Zeitschrift (in German). 18 (7). Berlin: Klasing & Co.: 158 1914. OCLC 29889214.

- Béjeuhr, Paul (1914). "Prinz-Heinrich-Flug 1914". Deutsche Luftfahrer-Zeitschrift (in German). 18 (11). Berlin: Klasing & Co.: 243–252. OCLC 29889214.

- v. Mises, R. (1914). "Die Ergebnisse des Prinz Heinrich-Fluges 1914". Zeitschrift für Flugtechnik und Motorluftschiffahrt (in German). 5 (12): 188–192. OCLC 1606129.

- "Neueste Fernflüge mit Argus 6 Cyl.-Motoren". Zeitschrift für Flugtechnik und Motorluftschiffahrt (in German). 5 (12): IX. June 27, 1914. OCLC 1606129.

- Angle, Glenn Dale (1921). Airplane Engine Encyclopedia: An Alphabetically Arranged Compilation Of All Available Data On The World's Airplane Engines. Otterbein Press. pp. 51-52. OL 23525261M.

| Argus aircraft engines | |

|---|---|

| Piston engines | |

| Pulse jet | |

| This aircraft engine article is missing some (or all) of its specifications. If you have a source, you can help Misplaced Pages by adding them. |