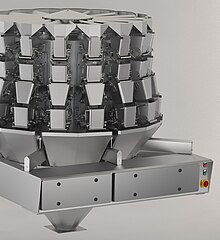

A multihead weigher is a fast, accurate and reliable weighing machine, used in packing both food and non-food products.

History

The multihead weigher was invented and developed by Ishida in the 1970s and launched into the food industry across the world.

Today this kind of machine, thanks to its high speed and accuracy, has achieved widespread adoption in the packaging industry and is produced worldwide by a number of manufacturers. Some manufacturers offer complete packaging lines, integrating the multihead weigher with other packaging machinery ranging from bagmakers (including Vertical Form Fill and Seal bagmakers) to traysealers and inspection systems. The latter include checkweighers and X-ray inspection systems.

How multihead weighing works

A ‘typical target’ weight per pack might be 100 grams of a product. The product is fed to the top of the multihead weigher where it is dispersed to the pool hoppers. Each pool hopper drops the product into a weigh hopper beneath it as soon as the weigh hopper becomes empty.

The weigher’s computer determines the weight of product in each individual weigh hopper and identifies which combination contains the weight closest to the target weight of 100g. The multihead weigher opens all the hoppers of this combination and the product falls, via a discharge chute, into a bagmaker or, alternatively, into a distribution system which places the product, for example, into trays.

Dispersion is normally by gravity, vibration or centrifugal force, while feeding can be driven by vibration, gravity, belts, or screw systems.

An extra layer of hoppers (‘booster hoppers’) can be added to store product which has been weighed in the weigh hoppers but not used in a weighment, thus increasing the number of suitable combinations available to the computer and so increasing speed and accuracy.

How multihead weighing can help a business

Multihead weighing can help in the following ways:

Filling bags

The range of bags which can be filled using multihead weighers is immense. At one end of the scale are large catering packs of many kilogrammes. At the other are small bags of crisps which can be handled at high speed and efficiency.

Mix-weighing

Products containing up to eight components can be mixed on a multihead weigher, very accurately at high speeds. The weigher is divided into sections, each with its own infeed. For example, a breakfast cereal containing hazelnuts and dried fruit plus two relatively cheap ingredients, could be weighed on a multihead with say eight heads devoted to each of the more expensive components and four heads to each of the other two. This would ensure high weighing speed while ensuring that overfilling of the expensive ingredients was negligible.

Placing into trays

A well-engineered distribution system enables you to combine the speed and accuracy of multihead weighing with precise, splash-free delivery of product into trays.

Applications

Multihead weighers were used initially for weighing certain vegetables. Their use expanded exponentially in the 1970s and 1980s when they were applied to the rapid weighing of snacks and confectionery into bags. What cherry tomatoes and crisps had in common was that they flowed easily through the machine and into the pack, with no more encouragement than gravity and a moderate level of vibration of the feeders. Since then, the accuracy and relative speed have been extended to many products which would in the early days of the technology have been seen as difficult to handle.

Sticky products

Fresh meat and fish, whether in a sauce or not, poultry and cheese (including grated cheese) can be moved along by using belts or screw feeders rather than vibration.

Granules and powders

While free-flowing, fine-grained powders can be weighed more cheaply by other means (such as cut-gate or linear weighers, or volumetric feeders), granules such as coffee granules and products such as loose tea can be weighed on today’s multiheads.

Fragile products

Weighers with more shallow angles of descent and various cushioned inserts have made it possible to pack delicate and brittle items such as hand-made chocolates and gourmet biscuits. These are often paired with baggers or other packaging systems designed to handle fragile products.

Complex products

Using mix-weighing combined with a distribution system tailored to deliver separate components into a tray, a ready meal can be assembled with just the right quantities of, say, rice, meat and vegetables in the appropriate compartments.

References

- Pulido-Rojano, Alexander (October 21–23, 2015). A multiobjective approach for optimization of the multihead weighing process. IEEE-IESM 2015. Seville. pp. 426–434. Retrieved 8 January 2018.

- Evans, Ferguson (30 September 2008). The Rise of the Japanese Specialist Manufacturer: Leading Medium-Sized Enterprises. Palgrave Macmillan. p. 121. ISBN 978-0-230-59495-1.

- "Ishida company profile". Packaging International. Retrieved 6 March 2014.

- "Ishida company history". Ishida (company). Retrieved 6 March 2014.

- "Ishida product description". Heat and Control, Inc. Retrieved 6 March 2014.

- Force Measurement Panel (2010). A Guide to Dynamic Weighing for Industry. London: The Institute of Measurement and Control. 22-28. (Downloadable free from www.npl.co.uk/instmc-wfmp)

- Ohlson Packaging (2020). Multi-head weighers (http://ohlsonpack.com/product/multi-head-weigher-and-counter/)

- Yam, K. L., "Encyclopedia of Packaging Technology", John Wiley & Sons, 2009, ISBN 978-0-470-08704-6