| |

The railway factory of the Ganz company (1880—1959: Ganz Wagon- and Machine Factory, 1959—1988: Ganz–MÁVAG Locomotive, Wagon- and Machine Factory) The railway factory of the Ganz company (1880—1959: Ganz Wagon- and Machine Factory, 1959—1988: Ganz–MÁVAG Locomotive, Wagon- and Machine Factory)/ Budapest, Kőbányai út 19-33. / | |

| Formerly |

|

|---|---|

| Company type |

|

| Industry | Transport Metallurgy |

| Founded | 1844 in Buda, Kingdom of Hungary |

| Founders | Ábrahám Ganz |

| Defunct | 1989; 35 years ago (1989) |

| Fate | Sold in 1989 to diverse companies that used the name 'Ganz'for their own enterprises |

| Headquarters | Buda, Hungary |

| Area served | Worldwide |

| Key people | List |

| Products | Trams Trains Ships Electric generators |

| Owner | Ábrahám Ganz and his family (1845–1947) State of Hungary (1947–1949) |

| Subsidiaries |

|

| Website | ganz-holding.hu |

The Ganz Machinery Works Holding is a Hungarian holding company. Its products are related to rail transport, power generation, and water supply, among other industries.

The original Ganz Works or Ganz (Hungarian: Ganz vállalatok or Ganz Művek, Ganz companies, formerly Ganz and Partner Iron Mill and Machine Factory) operated between 1845 and 1949 in Budapest, Hungary. It was named after Ábrahám Ganz, the founder and manager of the company. Ganz is probably best known for the manufacture of tramcars, but was also a pioneer in the application of three-phase alternating current to electric railways.

Ganz also made ships (through its Ganz Danubius division), bridge steel structures (Ganz Acélszerkezet) and high-voltage equipment (Ganz Transelektro). In the early 20th century the company experienced its heyday and became the third-largest industrial enterprise in the Kingdom of Hungary after the Manfréd Weiss Steel and Metal Works and the MÁVAG company.

Since 1989, various parts of Ganz have been taken over by other companies.

History

The company was founded by Ábrahám Ganz in 1844. He was invited to Pest, Hungary, by Count István Széchenyi and became the casting master at the Roller Mill Plant (referred to as Hengermalom in Hungarian). In 1854 he began manufacturing hard cast railroad wheels in his own plant founded in 1844. The management of the steam mill paid a share of the profit to Ganz. This enabled him to buy, in 1844, land and a house for 4500 Forints in Víziváros, Buda castle district. Abraham Ganz built his own foundry on this site and started to work there with seven assistants. They made mostly casting products for the needs of the people of the city. In 1845, he bought the neighbouring site and expanded his foundry with a cupola furnace. He gave his brother, Henrik a job as a clerk, because of the growing administration work. He made a profit in the first year, and his factory grew, even though he had not yet engaged in mass production. In 1846, at the third Hungarian Industrywork Exhibition (Magyar Iparmű Kiállítás), he introduced his stoves to the public. He won the silver medal of the exhibition committee and the bronze medaille from Archduke Joseph, Palatine of Hungary.

During the Hungarian Revolution of 1848 the foundry made ten cannons and many cannonballs for the Hungarian army. Because of this, the Military Court of Austria impeached him. He got seven weeks in prison as penalty, but because of his Swiss citizenship he was acquitted of the charge.

Ganz recognized that, to develop his factory, he had to make products that were mass-produced. In 1846 the Pest-Vác railway line was built. At that time, European foundries made wrought iron rims for spoked wagon wheels by pouring the casts in shapes in sand, and leaving them to cool down. He successfully developed a railway wheel casting technology; it was the new method of "crust-casting" to produce cheap yet sturdy iron railway wheels, which greatly contributed to the rapid railway development in Central Europe. 86,074 pieces of hard cast wheels had been sold to 59 European railway companies until 1866. Consequently, this factory played an important role in building the infrastructure of the Hungarian Kingdom and the Austro-Hungarian Empire. At this time the agricultural machines, steam locomotives, pumps and the railway carriages were the main products. At the beginning of the 20th century, 60 to 80% of the factory's products were sold for export.

After the death of Abraham Ganz, the heirs entrusted the management of the factory to his direct colleagues at Ganz Művek: Antal Eichleter, Ulrik Keller and Andreas Mechwart, which then took the name Ganz & Co. The Ganz family sold the company, which consisted of five departments, and in April 1869 it was transformed into a joint-stock company, and continued its operations under the name of "Ganz és Társa vasontöde és Gépgyár Rt." (Ganz & Partners Iron Foundry and Machine Factory Co.) The technical director was András Mechwart, under whose direction Ganz became one of the most important groups of machine building companies in the Austro-Hungarian Monarchy after 1869.

At the end of the 19th century, the products of the Ganz and Partner Iron Mill and Machine Factory (hereinafter referred to as Ganz Works) promoted the expansion of alternating-current power transmissions.

Prominent engineers

Prominent engineers at Ganz works included András Mechwart, Károly Zipernowsky, Miksa Déri, Ottó Titusz Bláthy, Kálmán Kandó, György Jendrassik and Ernő Wilczek.

Revolution in the milling industry

The invention of the modern industrial mill (the roller mill ) – by András Mechwart in 1874 – guaranteed a solid technological superiority and revolutionized the world's milling industry. Budapest's milling industry grow the second largest in the world, behind the American Minneapolis. The Hungarian grain export increased by 66% within some years.

Power plants, generators turbines and transformers

In 1878, the company's general manager András Mechwart founded the Department of Electrical Engineering headed by Károly Zipernowsky. Engineers Miksa Déri and Ottó Bláthy also worked at the department producing direct-current machines and arc lamps.

In 1878, the company began producing equipment for electric lighting and, by 1883, had installed over fifty systems in Austria-Hungary. Their AC systems used arc and incandescent lamps, generators, and other equipment.

Generators

The first turbo generators were water turbines which drove electric generators. The first Hungarian water turbine was designed by engineers of the Ganz Works in 1866. Mass production of dynamo generators started in 1883.

The missing link of a full Voltage Sensitive/Voltage Intensive (VSVI) system was the reliable alternating current constant voltage generator. Therefore, the invention of the constant voltage generator by the Ganz Works in 1883 had a crucial role in the beginnings of industrial scale AC power generation, because only these type of generators can produce a stable output voltage, regardless of the actual load.

Transformers

In cooperation, Zipernovsky, Bláthy and Déri (known as the ZBD team) constructed and patented the transformer. The "transformer" was named by Ottó Titusz Bláthy. The three invented the first high efficiency, closed core shunt connection transformer. They also invented the modern power distribution system: Instead of a series of connections they connected supply transformers in parallel to the main line.

The transformer patents described two basic principles. Loads were to be connected in parallel, not in series as had been the general practice until 1885. Additionally, the inventors described the closed armature as an essential part of the transformer. Both factors assisted the stabilisation of voltage under varying load, and allowed definition of standard voltages for distribution and loads. The parallel connection and efficient closed core made construction of electrical distribution systems technically and economically feasible.

The Ganz Works built the first transformers using iron plating of enamelled mild iron wire, and started to use laminated cores to eliminate eddy currents

AC Power stations

In 1886, the ZBD engineers designed, and the company supplied, electrical equipment for the world's first power station to use AC generators to power a parallel connected common electrical network. This was the Italian steam-powered Rome-Cerchi power plant.

Following the introduction of the transformer, the Ganz Works changed over to production of alternating-current equipment. For instance, Rome's electricity was supplied by hydroelectric plant and long-distance energy transfer.

- Ganz Transelektro power plant and power distribution products

-

Ganz Transformers in december 1886

Ganz Transformers in december 1886

-

construction of a Ganz water turbo generator (1886)

construction of a Ganz water turbo generator (1886)

-

PSM V56 D0433 direct connected electric railway generator (1899)

PSM V56 D0433 direct connected electric railway generator (1899)

-

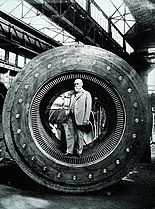

Ottó Bláthy in the armature of a turbo generator (1904)

Ottó Bláthy in the armature of a turbo generator (1904)

-

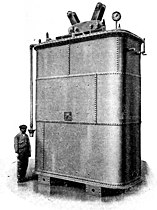

Ganz 21.000 kW Transformer (1911, weight: 38t)

Ganz 21.000 kW Transformer (1911, weight: 38t)

-

A generator assembly hall of the Ganz Works (1922)

A generator assembly hall of the Ganz Works (1922)

-

Alternators in a hydroelectric station on the Murghab River.

Alternators in a hydroelectric station on the Murghab River.

-

Generator in Zwevegem, West Flanders, Belgium

Generator in Zwevegem, West Flanders, Belgium

Electricity meters

The first mass-produced kilowatt-hour meter (electricity meter), based on Hungarian Ottó Bláthy's patent and named after him, was presented by the Ganz Works at the Frankfurt Fair in the autumn of 1889, and the company was marketing the first induction kilowatt-hour meter by the end of the year. These were the first alternating-current wattmeters, known by the name of Bláthy-meters.

Industrial refrigerators and air conditioners

In 1894, Hungarian inventor and industrialist István Röck started to manufacture a large industrial ammonia refrigerator (together with the Esslingen Machine Works) which was powered by Ganz electric compressors. At the 1896 Millennium Exhibition, Röck and the Esslingen Machine Works presented a 6-tonne capacity artificial ice producing plant. In 1906, the first large Hungarian cold store (with a capacity of 3,000 tonnes, the largest in Europe) opened in Tóth Kálmán Street, Budapest, the machine was manufactured by the Ganz Works. Until nationalisation after the Second World War, large-scale industrial refrigerator production in Hungary was in the hands of Röck and Ganz Works.

The contract between Ganz and Egypt in the 1930s played a key role in the development of cooling equipment: railcars delivered to Egypt were equipped with air-conditioning cooling systems. The collective of the Ganz factory (machine designers: Gábor Hollerung, Rezső Oláh, István Pfeifer, Prónai) designed and built the 3-cylinder, 20 kW compressors with freon refrigerant, air condenser and evaporator. The machine could also be converted to heat pump operation.

ICE engines and vehicles

The beginning of gas engine manufacturing in Hungary is linked to Donát Bánki and János Csonka but it is not clear that they ever worked for Ganz.

Ganz produced engines whose designs were licensed to Western European partners, notably in the United Kingdom and Italy.

- Timeline

- 1889 the first four-stroke gas engine was built by the Ganz factory

- 1893 the manufacture of paraffin and petrol fuelled engine with carburetor

- 1898 the manufacture of engines with the Bánki water injection system

- 1908 the introduction of a new petrol engine type, the series Am

- 1913 the manufacture of Büssing petrol engines for trucks

- 1914–18 the manufacture of fighter plane engines

- 1916 the manufacture of petrol engines, type Fiat

- 1920 the modification of petrol engines for suction gas operation

- 1924 György Jendrassik started his engine development activity

- 1928 the first railway diesel engine was completed, according to the plans of Ganz-Jendrassik

- 1929 the first export delivery of a railway engine using the system of Ganz-Jendrassik

- 1934 there was an engine reliability World Competition in the USSR where the Ganz engine achieved the best fuel consumption in its category

- 1939 Scale model of Ganz Ac Electric locomotive exhibited at the Italy Pavilion of the New York World's Fair

- 1939–42 construction of the Jendrassik Cs-1 turboprop engine

- 1944 the first application of the engine type XII JV 170/240 in a motor-train set

- 1953 modernisationon of the diesel engine system Ganz-Jendrassik

- 1959 the union of the Ganz factory and the MÁVAG company, establishing Ganz-MÁVAG

Railways

Steam motors

The Ganz Company started to construct steam locomotives and steam railcars from the 1860s. Between 1901 and 1908, Ganz Works of Budapest and de Dion-Bouton of Paris collaborated to build a number of railcars for the Hungarian State Railways together with units with de Dion-Bouton boilers, Ganz steam motors and equipments, and Raba carriages built by the Raba Hungarian Wagon and Machine Factory in Győr. In 1908, the Borzsavölgyi Gazdasági Vasút (BGV), a narrow-gauge railway in Carpathian Ruthenia (today's Ukraine), purchased five railcars from Ganz and four railcars from the Hungarian Royal State Railway Machine Factory with de Dion-Bouton boilers. The Ganz company started to export steam motor railcars to the United Kingdom, Italy, Canada, Japan, Russia and Bulgaria.

The World's first electrified main railway line in Italy

Main articles: FS Class E.430 and FS Class E.360The Ganz Works, having identified the significance of induction motors and synchronous motors, commissioned Kálmán Kandó to develop them. In 1894, Hungarian engineer Kálmán Kandó developed high-voltage three-phase AC motors and generators for electric locomotives. The first-ever electric rail vehicle manufactured by Ganz Works was a 6 HP pit locomotive with direct current traction system. The first Ganz made asynchronous rail vehicles (altogether 2 pieces) were supplied in 1898 to Évian-les-Bains (France) with a 37 HP asynchronous traction system. The Ganz Works won the tender for electrification of the Valtellina Railway in Italy in 1897. Under the management, and on the basis of plans from Kálmán Kandó, three phase electric power at 3 kV and 15 Hz was fed through two upper wires and the rails.

The electricity was produced in a dedicated power station and the system operated for thirty years from 1902. Italian railways were the first in the world to introduce electric traction for the entire length of a main line rather than just a short stretch. The 106 km Valtellina line was opened on 4 September 1902, designed by Kandó and a team from the Ganz works. The voltage was significantly higher than used earlier and it required new designs for electric motors and switching devices. The three-phase two-wire system was used on several railways in Northern Italy and became known as "the Italian system". Kandó was invited in 1905 to undertake the management of Società Italiana Westinghouse and led the development of several Italian electric locomotives.

Invention of the Phase Converter

In 1918, Kandó invented and developed the rotary phase converter, enabling electric locomotives to use three-phase motors whilst supplied via a single overhead wire, carrying the simple industrial frequency (50 Hz) single phase AC of the high-voltage national networks. After World War I, at the Ganz Works, Kálmán Kandó constructed a single-phase electric railway system using 16 kV at 50 Hz. A similar system, but using 15 kV at 16.7 Hz, later became widely used in Europe. The main attribute of Kandó's 50 Hz system was that it was fed by the normal power network, so dedicated railway power stations became unnecessary. Because of the early death of Kálmán Kandó, László Verebélÿ continued the work for the Hungarian State Railways (MÁV).

- Ganz Rail rolling stock

-

The first steam railcar built by Ganz and de Dion-Bouton

-

Ganz AC electric locomotive prototype (1901 Valtellina, Italy)

Ganz AC electric locomotive prototype (1901 Valtellina, Italy)

-

Electric locomotive RA 361 (later FS Class E.360) by Ganz for the Valtellina line, 1904

Electric locomotive RA 361 (later FS Class E.360) by Ganz for the Valtellina line, 1904

-

The first locomotive with a phase converter was Kando's V50 locomotive (only for demonstration and testing purposes)

The first locomotive with a phase converter was Kando's V50 locomotive (only for demonstration and testing purposes)

-

Árpád Diesel railbus in 1937

Árpád Diesel railbus in 1937

-

Ganz train on the Ferrocarriles Patagónicos railway in Argentina (1945)

Ganz train on the Ferrocarriles Patagónicos railway in Argentina (1945)

-

Ganz diesel railcar on Septemvri-Dobrinishte narrow gauge line, Bulgaria, 1950-1963

Ganz diesel railcar on Septemvri-Dobrinishte narrow gauge line, Bulgaria, 1950-1963

-

A series V63 Ganz-MÁVAG electric locomotive of Hungarian State Railways

A series V63 Ganz-MÁVAG electric locomotive of Hungarian State Railways

-

Tranz Metro EM class Ganz-MÁVAG unit in service in the Hutt Valley, New Zealand

Tranz Metro EM class Ganz-MÁVAG unit in service in the Hutt Valley, New Zealand

-

Metre gauge Ganz-MÁVAG trainset of Hellenic Railways Organisation (OSE) at Tripoli, Greece

Metre gauge Ganz-MÁVAG trainset of Hellenic Railways Organisation (OSE) at Tripoli, Greece

-

Ganz-MÁVAG CSMG tram for the Budapest tram (2007)

Ganz-MÁVAG CSMG tram for the Budapest tram (2007)

Ganz-MÁVAG rail rolling stock

Main article: Ganz-MÁVAG

In 1959 Ganz merged with the MÁVAG company and was renamed Ganz-MÁVAG. In 1976 Ganz-Mávag supplied ten standard gauge 3-car diesel trainset to the Hellenic Railways Organisation (OSE), designated as Class AA-91 and four metre gauge 4-car trainsets, designated as Class A-6451. In 1981/82 Ganz-Mávag supplied to OSE 11 B-B diesel-hydraulic DHM7-9 locomotives, designated as class A-251. Finally, in 1983, OSE bought eleven 3-car metre gauge trainsets, designated as Class A-6461. All these locomotives and trainsets have been withdrawn with the exception of one standard and one metre gauge trainset.

In 1982/83 Ganz-Mávag supplied an order for electric multiple units to New Zealand Railways Corporation for Wellington suburban services. The order was made in 1979, and was for 44 powered units and 44 trailer units, see New Zealand EM class electric multiple unit.

Ganz-MÁVAG Trams

Ganz-MÁVAG delivered 29 trams (2 car sets) to Alexandria, Egypt from 1985 to 1986.

Shipbuilding, Ganz - Danubius

In 1911, the Ganz Company merged with the Danubius shipbuilding company, which was the largest shipbuilding company in Hungary. From 1911, the unified company adopted the "Ganz–Danubius" brand name. In the beginning of the 20th century the company had 19 shipyards on the Danube and the Adriatic Sea in the city of Rijeka and Pula. As Ganz Danubius, the company became involved in shipbuilding before, and during, World War I. Ganz was responsible for building the dreadnought SMS Szent István, all of the Novara-class cruisers, and built diesel-electric U-boats at its shipyard in Budapest, for final assembly at Fiume. Several U-boats of the U-XXIX class, U-XXX class, U-XXXI class and U-XXXII class were completed, A number of other types were laid down, but remained incomplete at the war's end. By the end of the First World War, 116 naval vessels had been built by The Ganz-Danubius company. The company also produces transatlantic ocean liners for passenger lines Trieste - New York, Trieste - Montevideo, as a reflection of already formed wave of mass migration from Central Europe to America.

- Ganz–Danubius ships and submarines

-

The back of the SM U-29 submarine during assembly (24 April 1916)

The back of the SM U-29 submarine during assembly (24 April 1916)

-

The battle-damaged SMS Novara (1913) after a victorious naval battle

The battle-damaged SMS Novara (1913) after a victorious naval battle

-

Austro-Hungarian built dreadnought class battleship SMS Szent István at Pula (military dock)

Austro-Hungarian built dreadnought class battleship SMS Szent István at Pula (military dock)

- construction of SMS Szent István battleship in the Ganz Danubius shipyard in Rijeka (filmed 1912)

Aircraft

Main article: UFAGThe first Hungarian "aeroplane factory" ( UFAG ) was founded by the Ganz Company and Weiss-Manfréd Works in 1912. During World War I, the company made many types of Albatros and Fokker fighter planes.

Before 1919, the company built ocean liners, dreadnought type battleships and submarines, power plants, automobiles and many types of fighter aircraft.

The world's first turboprop engine was the Jendrassik Cs-1 designed by the Hungarian mechanical engineer György Jendrassik. It was built and tested in the Ganz factory in Budapest between 1939 and 1942. It was planned to be fitted to the Varga RMI-1 X/H twin-engined reconnaissance bomber designed by László Varga in 1940, but the program was cancelled. Jendrassik had also designed a small-scale 75 kW turboprop in 1937.

After World War II

In 1947, the Ganz Works was nationalised and in 1949 it became independent and six big companies came into existence, including the Ganz Transformer Factory. In 1959, Ganz Wagon and Machine Factory merged with the MÁVAG Locomotive and Machine Factory under the name of Ganz-MÁVAG Locomotive, Wagon and Machine Works. Of the products of the Works, outstanding results were shown in the field of the manufacture of diesel railcars and multiple units. Traditional products included tramcars as well, and customers included the tramway network of Budapest. In the meantime the Foundry workshop was closed down.

In 1974, the locomotive and wagon Works were merged under the name of Railway Vehicle Factory and then the machine construction branch went through significant development. The production of industrial and apartment house lifts became a new branch. Ganz-MÁVAG took over a lot of smaller plants in the 1960s and 1970s and their product range was extended. Among other things, they increased their bridge-building capacity. They made iron structures for several Tisza bridges, for the Erzsébet Bridge in Budapest, for public road bridges in Yugoslavia and for several industrial halls.

The Ganz Shipyard experienced its most productive times during the four decades following nationalisation. In the course of this period 1100 ship units were produced, the number of completed seagoing ships was 240 and that of floating cranes was 663. As a result of the great economic and social crises of the 1980s, Ganz-MÁVAG had to be reorganised. The company was transformed into seven independent Works and three joint ventures.

Ganz since 1989

In 1989, the British company Telfos Holdings gained a majority of the shares in Ganz Railway Vehicle Factory Co. Ltd. and the name of the company was changed to Ganz-Hunslet Co. Ltd. In the course of 1991 and 1992, the Austrian company Jenbacher Werke obtained 100% of the company's shares and consequently the railway vehicle factory is now a member of the international railway vehicle manufacturing group, Jenbacher Transport Systeme. At present, the Ganz Electric Works, under the name of Ganz-Ansaldo is a member of the Italian industrial giant, AnsaldoBreda. The Ganz Works were transformed into holdings. Ganz-Danubius was wound up in 1994. The Ganz Electric Meter Factory in Gödöllő became the member of the international Schlumberger group.

In 2006, the power transmission and distribution sectors of Ganz Transelektro were acquired by Crompton Greaves, but still doing business under the Ganz brand name, while the unit dealing with electric traction (propulsion and control systems for electric vehicles) was acquired by Škoda Transportation and is now a part of Škoda Electric.

Now the plant is operated by a new investor as a tenant, Ganz Transformer Motor and Manufacturing Ltd., after the previous owner was unable to finance the production.

Timeline

1991: Joint Venture with Italian Ansaldo named Ganz Ansaldo Ltd.

1994: Air-cooled turbogenerator from 20 up to 70MVA

1998: Development of double-cage induction motor for twin-drives first on the world

2000: Acquisition by Tranelektro Group under name of Ganz-Transelektro

2001: Developed 1MW ExN Non-sparking gasturbine starter motors for GE

2002: First transformer in the world for 123 kV with ester liquid

2006: Became a Part of Crompton Greaves Ltd as CG Electric Systerms Hungary

2010: Start of manufacturing Safety Class 3&4 motors for Nuclear Power Plants

2018: Developing VFD-driven Increased Safety LVAC motors for driving OEM pumps used in Oil&gas fields

2020: Establishment of Ganz Transformer Motor and Generator Ltd., Ganz brand back in Hungarian ownership

Divisions

Source:

Transformer division

The Transformer division specializes in the design, manufacture and testing of substation transformers, generation transformers, auxiliary transformers, mobile transformers and traction transformers from 20 to 600 MVA (1000 MVA for autotransformers) from 52 to 800 kV.

Rotating machines division

The production of three-phase, alternating current induction motors began in the factory in 1894. Through the 90's Ganz has developed more advanced motors with decreased total weight, increased efficiency and low noise levels in order to satisfy the actual needs of the market and all conditions of the industrial application and to conform to IEC, NEMA, ATEX and EAC standards.

GIS Service Division

GIS Service division performs onsite works like maintenance, inspection, modification, overhaul, extensions on former GANZ and other brands of switchgears. The activity is mainly focused on the existing substations and equipment.

References

- About us at Ganz Holding (19 Mar 2023)

- About us, Ganz-holding.hu

- Mikulas Teich; Roy Porter; Bo Gustafsson (1996). The Industrial Revolution in National Context: Europe and the USA. Cambridge University Press. p. 280. ISBN 9780521409407.

- Guarnieri, M. (2013). "Who Invented the Transformer?". IEEE Industrial Electronics Magazine. 7 (4): 56–59. doi:10.1109/MIE.2013.2283834. S2CID 27936000.

- Hughes, Thomas P. (1993). Networks of Power: Electrification in Western Society, 1880-1930. Baltimore: The Johns Hopkins University Press. pp. 95–96. ISBN 978-0-8018-2873-7. Retrieved Sep 9, 2009.

- http://www.sze.hu/~mgergo/EnergiatudatosEpulettervezes/2013_1_feladat/ErosErika/V%EDzenergia%20hasznos%EDt%E1s%20szigetk%F6zi%20szemmel%20EL%D5AD%C1SANYAG.pdf

- American Society for Engineering Education (1995). Proceedings, Part 2. p. 1848.

- Robert L. Libbey (1991). A Handbook of Circuit Math for Technical Engineers. CRC Press. p. 22. ISBN 9780849374005.

- "Bláthy, Ottó Titusz". Retrieved 20 December 2016.

- Electrical Society of Cornell University (1896). Proceedings of the Electrical Society of Cornell University. Andrus & Church. p. 39.

- "Ottó Bláthy, Miksa Déri, Károly Zipernowsky". IEC Techline. Archived from the original on September 30, 2007. Retrieved Apr 16, 2010.

- Hungarian Inventors and their Inventions Archived 2012-03-22 at the Wayback Machine

- Eugenii Katz. "Blathy". Clarkson University. Archived from the original on June 25, 2008. Retrieved 2009-08-04.

- The development and heyday of mechanical science (Hungarian) Link

- The development and heyday of mechanical science (Hungarian) Link

- Railroad Gazette – Volume 37 – Page 296 (printed in 1904)

- Modern Machinery – Volumes 19–20 – Page 206 (Printed in 1906)

- John Robertson Dunlap, Arthur Van Vlissingen, John Michael Carmody: Factory and Industrial Management – Volume 33 – Page 1003 (printed in 1907

- Duffy (2003), p. 120-121.

- ^ Hungarian Patent Office. "Kálmán Kandó (1869–1931)". www.mszh.hu. Archived from the original on 2010-10-08. Retrieved 2008-08-10.

- ^ "Kalman Kando". Retrieved 2011-10-26.

- "Kalman Kando". Archived from the original on 2012-07-12. Retrieved 2009-12-05.

- Duffy, Michael C. (2003). Electric Railways 1880–1990. IET. p. 137. ISBN 9780852968055.

- "Ganz and Tungsram – the 20th century". Electric History. EnergoSolar.com. 2007. Archived from the original on 6 January 2009. Retrieved 20 December 2016.

- "Archived copy" (PDF). Archived from the original (PDF) on 2015-01-10. Retrieved 2015-01-10.

{{cite web}}: CS1 maint: archived copy as title (link) - History of Ganz Danubius

- R.H. Gibson, Maurice Prendergast (2002). The German Submarine War 1914–1918. Periscope Publishing Ltd. p. 386. ISBN 9781904381082.

- http://www.gwpda.org/naval/ahsubs.htm Sieche article on KuK U-Boats

- Iván Boldizsár: NHQ; the New Hungarian Quarterly, Volume 16, Issue 2; Volume 16, Issues 59–60, p. 128

- Hungarian Technical Abstracts: Magyar Műszaki Lapszemle, Volumes 10–13, p. 41

- Iván T. Berend: Case Studies on Modern European Economy: Entrepreneurship, Inventions, and Institutions, p. 151

- Ganz is now CG Archived 2011-03-10 at the Wayback Machine Retrieved 2009-11-28.

- info@lundegaard.cz, Lundegaard – e-business solutions provider, www.lundegaard.cz. "Česká verze – ŠKODA TRANSPORTATION a.s." Archived from the original on 13 April 2008. Retrieved 20 December 2016.

{{cite web}}:|first=has generic name (help)CS1 maint: multiple names: authors list (link) - "Production resumes at the Ganz factory – Ganz Group". 8 September 2020. Retrieved 2021-03-23.

- "About us – Ganz Group". Retrieved 2021-03-23.

- "Ganz Group". Retrieved 2021-03-23.

- "Transformer Division – Ganz Group". Retrieved 2021-03-23.

- "Rotating Machines Division – Ganz Group". Retrieved 2021-03-23.

- "GIS Service Division – Ganz Group". Retrieved 2021-03-23.

External links

- Official website

– Ganz Machinery Works Holding, current company

– Ganz Machinery Works Holding, current company - A photo of a Ganz railcar of Hungarian State Railways c1936

- A withdrawn Ganz-Mavag DMU at Mendoza, Argentina

- Ganz Transelektro Ltd's page in English Archived 2011-03-10 at the Wayback Machine

- Ganz Danubius homepage

- Ganz Works

- Rolling stock manufacturers of Hungary

- Hungarian brands

- Tram manufacturers

- Companies of Austria-Hungary

- Motor vehicle manufacturers of Austria-Hungary

- Shipbuilding companies of Austria-Hungary

- Manufacturing companies established in 1844

- 1844 establishments in the Austrian Empire

- Electrical engineering companies

- Avantha Group