| This article needs additional citations for verification. Please help improve this article by adding citations to reliable sources. Unsourced material may be challenged and removed. Find sources: "Plate glass" – news · newspapers · books · scholar · JSTOR (October 2022) (Learn how and when to remove this message) |

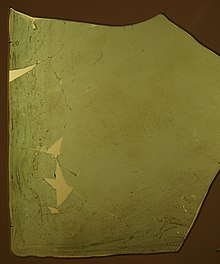

Plate glass, flat glass or sheet glass is a type of glass, initially produced in plane form, commonly used for windows, glass doors, transparent walls, and windscreens. For modern architectural and automotive applications, the flat glass is sometimes bent after production of the plane sheet. Flat glass stands in contrast to container glass (used for bottles, jars, cups) and glass fibre (used for thermal insulation, in fibreglass composites, and for optical communication).

Flat glass has a higher magnesium oxide and sodium oxide content than container glass, and a lower silica, calcium oxide, and aluminium oxide content. From the lower soluble oxide content comes the better chemical durability of container glass against water, which is required especially for storage of beverages and food.

Most flat glass is soda–lime glass, produced by the float glass process (1950s). Other processes for making flat glass include:

- Broad sheet method (13th century)

- Window crown glass technique (14th century)

- Blown plate method (17th century)

- Plate polishing (17th century)

- Cylinder blown sheet method

- Machine drawn cylinder sheet method (early 20th century)

- Rolling (rolled plate glass, figure rolled glass) (19th century)

- Fourcault process (1900s)

- Float glass (1950s)

- Overflow downdraw method (1960s)

The term plate glass universities is used in the United Kingdom to describe a group – or generation – of universities (in an acknowledgement of the term red brick universities, used for an older generation of establishments).

Quality and damage

Scratches can occur on sheet of glass from accidental causes. In glass trade terminology these include "block reek" produced in polishing, "runner-cut" or “over/under grind” caused by edge grinding, or a "sleek" or hairline scratch, as well as "crush" or "rub" on the surface.

See also

References

- "High temperature glass melt property database for process modeling"; Eds.: Thomas P. Seward III and Terese Vascott; The American Ceramic Society, Westerville, Ohio, 2005, ISBN 1-57498-225-7

- Ron Hanifan Concise Dictionary of Engineering: A Guide to the Language 2014 3319078399 "Scratches occur on sheet glass in all degrees from various accidental causes. Block reek is a chain-line scratch produced in polishing. A runner-cut is a curved scratch caused by grinding. An over/under grind is an imperfection on the edge. A sleek is a hairline scratch. A crush or rub is a surface ..."