This is an old revision of this page, as edited by 186.22.30.243 (talk) at 20:40, 8 July 2011 (→Fuel). The present address (URL) is a permanent link to this revision, which may differ significantly from the current revision.

Revision as of 20:40, 8 July 2011 by 186.22.30.243 (talk) (→Fuel)(diff) ← Previous revision | Latest revision (diff) | Newer revision → (diff)

| |||

| Names | |||

|---|---|---|---|

| Systematic IUPAC name Methoxymethane | |||

| Other names

Demeon Dimethyl oxide | |||

| Identifiers | |||

| CAS Number | |||

| 3D model (JSmol) | |||

| Abbreviations | DME | ||

| Beilstein Reference | 1730743 | ||

| ChEBI | |||

| ChEMBL | |||

| ChemSpider | |||

| ECHA InfoCard | 100.003.696 | ||

| EC Number |

| ||

| KEGG | |||

| MeSH | Dimethyl+ether | ||

| PubChem CID | |||

| RTECS number |

| ||

| UNII | |||

| UN number | 1033 | ||

| CompTox Dashboard (EPA) | |||

InChI

| |||

SMILES

| |||

| Properties | |||

| Chemical formula | C2H6O | ||

| Molar mass | 46.069 g·mol | ||

| Appearance | Colourless gas | ||

| Odor | Typical | ||

| Density | 1.97 mg cm | ||

| Melting point | −141 °C; −222 °F; 132 K | ||

| Boiling point | −24 °C; −11 °F; 249 K | ||

| Solubility in water | 71 g dm (at 20 °C) | ||

| log P | 0.022 | ||

| Vapor pressure | >100 kPa | ||

| Dipole moment | 1.30 D | ||

| Thermochemistry | |||

| Heat capacity (C) | 65.57 J K mol | ||

| Std enthalpy of formation (ΔfH298) |

-184.1 kJ mol | ||

| Std enthalpy of combustion (ΔcH298) |

-1.4604 MJ mol | ||

| Hazards | |||

| GHS labelling: | |||

| Pictograms |

| ||

| Signal word | Danger | ||

| Hazard statements | H220 | ||

| Precautionary statements | P210, P410+P403 | ||

| NFPA 704 (fire diamond) |

| ||

| Flash point | -41 °C | ||

| Explosive limits | 27% | ||

| Related compounds | |||

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C , 100 kPa).

| |||

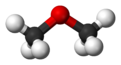

Dimethyl ether (DME) is the organic compound with the formula CH3OCH3. The simplest ether, it is a colourless gas that is a useful precursor to other organic compounds and an aerosol propellant. When combusted, DME produces minimal NOx and CO, though HC and soot formation is significant. DME can act as a clean fuel when burned in engines properly optimized for DME.

Production

Today DME is primarily produced by converting hydrocarbons sourced from natural gas or coal via gasification to synthesis gas (syngas). Synthesis gas is then converted into methanol in the presence of catalyst (usually copper-based), with subsequent methanol dehydration in the presence of a different catalyst (for example, silica-alumina) resulting in the production of DME. As described this is a two-step (indirect synthesis) process that starts with methanol synthesis and ends with DME synthesis (methanol dehydration). The same process can be conducted using organic waste or biomass. Approximately 50,000 tons were produced in 1985 in Western Europe using the methanol dehydration process. Alternatively, DME can be produced through direct synthesis, using a dual catalyst system that permits both methanol synthesis and dehydration in the same process unit, with no methanol isolation and purification, a procedure that by eliminating the intermediate methanol synthesis stage, the licensors claim promises efficiency advantages and cost benefits.

Both the one-step and two-step processes above are commercially available. Currently, there is more widespread application of the two-step process since it is relatively simple and start-up costs are relatively low. It is worth mentioning that there is a developing one-step liquid-phase process.

Applications

The largest use of DME is currently (2010) as substitute for propane in LPG used as fuel in household and industry. The largest use of DME for this purpose is in China. DME has two other primary applications: as a propellant in aerosol canisters, and as a precursor to dimethyl sulfate. As an aerosol propellant, DME is useful as a somewhat polar solvent. It can also be used as a refrigerant.

Feedstock

Several thousand tons of DME are consumed annually for the production of the methylating agent, dimethyl sulfate, which entails its reaction with sulfur trioxide:

- CH3OCH3 + SO3 → (CH3O)2SO2

DME can also be converted into acetic acid using carbonylation technology related to the Monsanto acetic acid process:

- (CH3)2O + 2 CO + H2O → 2 CH3CO2H

Laboratory reagent and solvent

DME is a low-temperature solvent and extraction agent, applicable to specialised laboratory procedures. Its usefulness is limited by its low boiling point (−23 °C), but the same property facilitates its removal from reaction mixtures. DME is the precursor to the useful alkylating agent, trimethyloxonium tetrafluoroborate.

Fuel

DME is a promising fuel in diesel engines, petrol engines (30% DME / 70% LPG), and gas turbines owing to its high cetane number, which is 55, compared to diesel's, which is 40–53. Only moderate modification are needed to convert a diesel engine to burn DME. The simplicity of this short carbon chain compound leads during combustion to very low emissions of particulate matter, NOx, CO. For these reasons as well as being sulfur-free, DME meets even the most stringent emission regulations in Europe (EURO5), U.S. (U.S. 2010), and Japan (2009 Japan). Mobil is using DME in their methanol to gasoline process.

DME is being developed as a synthetic second generation biofuel (BioDME), which can be manufactured from lignocellulosic biomass. Currently the EU is considering BioDME in its potential biofuel mix in 2030; the Volvo Group is the coordinator for the European Community Seventh Framework Programme project BioDME where Chemrec's BioDME pilot plant based on black liquor gasification is nearing completion in Piteå, Sweden.

The image below illustrates some of processes from various raw materials to DME.

In 2009 a team of university students from Denmark won the Urban Concept/Internal Combustion class at the European Shell Eco Marathon (The Shell Eco Marathon is an unofficial World Championship for mileage) with a vehicle running on 100% DME. The vehicle drove 589 km/liter, fuel equivalent to gasoline with a 50 ccm 2-stroke engine operating by the Diesel principle. As well as winning they beat the old standing record of 306 km/liter, set by the same team in 2007

Refrigerant

DME is also gaining popularity as a refrigerant with ASHRAE refrigerant designation R-E170. DME is also used in refrigerant blends with e.g. butane and propene.

Treating warts

A mixture of DME and propane is used in an over-the-counter device to treat warts, by freezing them.

Safety

Unlike other alkyl ethers, DME resists autoxidation. DME is also relatively non-toxic, although it is highly flammable.

References

- "dimethyl ether - PubChem Public Chemical Database". The PubChem Project. USA: National Center for Biotechnology Information.

- ^ Dimethyl Ether Technology and Markets 07/08-S3 Report, ChemSystems, December 2008.

- ^ Manfred Müller, Ute Hübsch, “Dimethyl Ether” in Ullmann’s Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2005.

- P.S. Sai Prasad et al., Fuel Processing Technology, 2008, 89, 1281.

- Air Products Technology Offerings

- IDA Fact Sheet DME/LPG Blends 2010 v1

- demeon.com, Akzo Nobel DME

- T. J. Curphey (1988). "Trimethyloxonium tetrafluoroborate". Organic Syntheses; Collected Volumes, vol. 6, p. 1019.

- nycomb.se, Nycomb Chemicals company

- http://www.topsoe.com/site.nsf/all/BBNN-5PNJ3F?OpenDocument topsoe.com

- http://www.japantransport.com/conferences/2006/03/dme_detailed_information.pdf, Conference on the Development and Promotion of Environmentally Friendly Heavy Duty Vehicles such as DME Trucks, Washington DC, March 17, 2006

- http://www.biodme.eu/

- Biofuels in the European Union, 2006

- http://www.volvo.com/group/global/en-gb/newsmedia/pressreleases/NewsItemPage.htm?channelId=2184&ItemID=47984&sl=en-gb

- http://www.volvo.com/group/global/en-gb/volvo+group/ourvalues/environment/renewable_fuels/biodme/biodme.htm

- Chemrec press release September 9, 2010

- The Danish Ecocar Team - List of achievements

- http://www.mecanica.pub.ro/frigo-eco/R404A_DME.pdf 101110

- http://www.ashrae.org/technology/page/1933#et ASHRAE list of refrigerants

- "A Pharmacist's Guide to OTC Therapy: OTC Treatments for Warts". July 2006.

- http://www.fda.gov/cdrh/pdf3/K030838.pdf