This is an old revision of this page, as edited by Mr.Z-man (talk | contribs) at 15:05, 29 May 2015 (correct some things and incorporate the draft I started, but never finished). The present address (URL) is a permanent link to this revision, which may differ significantly from the current revision.

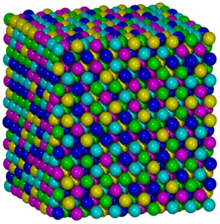

Revision as of 15:05, 29 May 2015 by Mr.Z-man (talk | contribs) (correct some things and incorporate the draft I started, but never finished)(diff) ← Previous revision | Latest revision (diff) | Newer revision → (diff)High-entropy alloys (HEAs) are a class of multi-component alloys composed of 5 or more principal constituent elements each with a concentration between 5 and 35 atomic %. The defining feature of HEAs over other complex alloys is that they consist entirely or primarily of a simple solid solution phase, thus having a high entropy of mixing.

HEAs have been described in the literature that have better strength-to-weight ratios, fracture toughness, tensile strength, high-temperature strength, or corrosion resistance than similar conventional alloys.

Early development

Although HEAs were described as early as 1996, significant research interest did not develop until after independent 2004 papers by Jien-Wei Yeh and Brian Cantor, with Yeh's first paper on the topic published 2 months sooner. Yeh also coined the term "high-entropy alloy" when he attributed the high configurational entropy as the mechanism stabilizing the solid solution phase. Cantor, not knowing of Yeh's work, did not describe his alloy as a "high entropy" alloy, but the base alloy he developed, equiatomic FeCrMnNiCo, has been the subject of considerable work in the field.

Definition

There is no universally agreed-upon definition of a HEA. Yeh originally defined HEAs as alloys containing at least 5 elements with concentrations between 5 and 35 atomic percent. Later research however, suggested that this definition may be inadequate. Otto et al. suggested that only alloys that form a solid solution with no intermetallic phases should be considered true high-entropy alloys, as the formation of ordered phases decreases the entropy of the system. Some authors have described 4-component alloys as high-entropy alloys while others have suggested that alloys meeting the other requirements of HEAs, but with only 2–4 elements or a mixing entropy between R and 1.5R should be considered "medium-entropy" alloys.

Alloy design

In conventional alloy design, one primary element such as iron, copper, or aluminum is chosen for its properties. Then, small amounts of additional elements are added to improve or add properties. Even among binary alloy systems, there are few common cases of both elements being used in nearly-equal proportions such as Pb-Sn solders. Therefore, much is known from experimental results about phases near the edges of binary phase diagrams and the corners of ternary phase diagrams and much less is known about phases near the centers. In higher-order (4+ components) systems that cannot be easily represented on a 2-dimensional phase diagram, virtually nothing is known.

Phase formation

Gibbs' phase rule, , can be used to determine an upper bound on the number of phases that will form in an equilibrium system. In his 2004 paper, Cantor created a 20-component alloy containing 5 at% of Mn, Cr, Fe, Co, Ni, Cu, Ag, W, Mo, Nb, Al, Cd, Sn, Pb, Bi, Zn, Ge, Si, Sb, and Mg. At constant pressure, the phase rule would allow for up to 21 phases at equilibrium, but far fewer actually formed. The predominant phase was a face-centered cubic solid solution phase, containing mainly Fe, Ni, Cr, Co, and Mn. From that result, the FeCrMnNiCo alloy, which forms only a solid solution phase, was developed.

The Hume-Rothery rules have historically been applied to determine whether a mixture will form a solid solution. Research into high-entropy alloys has found that in multi-component systems, these rules tend to be relaxed slightly. In particular, the rule that solvent and solute elements must have the same crystal structure does not seem to apply, as Fe, Ni, Cr, Co, and Mn have 4 different crystal structures as pure elements (and when the elements are present in equal concentrations, there can be no meaningful distinction between "solvent" and "solute" elements).

Thermodynamic mechanisms

The multi-component alloys Yeh developed also consisted mostly or entirely of solid solution phases, contrary to what had been expected from earlier work in multi-component systems, primarily in the field of metallic glasses. Yeh attributed this result to the high configurational, or mixing, entropy of a random solid solution containing numerous elements. Because , and the phase with the lowest Gibbs free energy of formation (ΔG) will be the phase formed at equilibrium, increasing ΔS (entropy) will increase the likelihood of a phase being stable. The mixing entropy for a random ideal solid solution can be calculated by:

where R is the ideal gas constant, N is the number of components, and ci is the atomic fraction of component i. From this it can be seen that alloys in which the components are present in equal proportions will have the highest entropy, and adding additional elements will increase the entropy. A 5 component, equiatomic alloy will have a mixing entropy of 1.61R.

| Parameter | Design guideline |

|---|---|

| ∆Smix | Maximized |

| ∆Hmix | > -10 and < 5 kJ/mol |

| Ω | ≥ 1.1 |

| δ | ≤ 6.6% |

| VEC | ≥ 8 for fcc, <6.87 for bcc |

However entropy alone is not sufficient to stabilize the solid solution phase in every system. The enthalpy of mixing (ΔH), must also be taken into account. This can be calculated using:

where is the binary enthalpy of mixing for A and B. Zhang et al. found, empirically, that in order to form a complete solid solution, ΔHmix should be between -10 and 5 kJ/mol. In addition, Otto et al. found that if the alloy contains any pair of elements that tend to form ordered compounds in their binary system, a multi-component alloy containing them is also likely to form ordered compounds.

Both of the thermodynamic parameters can be combined into a single, unitless parameter Ω:

where Tm is the average melting point of the elements in the alloy. Ω should be greater than or equal to 1.1 to promote solid solution development.

Kinetic mechanisms

The atomic radii of the components must also be similar in order to form a solid solution. Zhang et al. proposed a parameter δ representing the difference in atomic radii:

where ri is the atomic radius of element i and . Formation of a solid solution phase requires a δ≤6.6%, but some alloys with 4%<δ≤6.6% do form intermetallics.

Other properties

For those alloys that do form solid solutions, an additional empirical parameter has been proposed to predict the crystal structure that will form. If the average valence electron concentration (VEC) of the alloy is ≥8, the alloy will form a face-centered cubic (fcc) lattice. If the average VEC is <6.87, it will form a body-centered cubic (bcc) lattice. For values in between, it will form a mixture of fcc and bcc. VEC has also been used to predict the formation of σ-phase intermetallics (which are generally brittle and undesirable) in chromium and vanadium-containing HEAs.

Synthesis

High entropy alloys are mostly produced using distinct methods that depend on the initial phase - starting either from a liquid, solid, or gas state.

- Most HEAs have been produced using liquid-phase methods include arc melting, induction melting, and Bridgman solidification.

- Solid-state processing is generally done by mechanical alloying using a high-energy ball mill. This method produces powders that can then be processed using conventional powder metallurgy methods or spark plasma sintering. This method allows for alloys to be produced that would be difficult or impossible to produce using casting, such as AlLiMgScTi, in which the melting points of the constituent elements has a range of nearly 1500 °C.

- Gas-phase processing includes processes such as sputtering or molecular beam epitaxy (MBE), which can be used to carefully control different elemental compositions to get high entropy metallic or ceramic films.

Other HEAs have been produced by thermal spray, laser cladding, and electrodeposition.

Properties and potential uses

HEAs, because of their high form-ability and strength combined with low density, are expected to replace superalloys in energy sectors and aero-space applications. Because HEAs are a cocktail of metallic elements, a wide range of materials can be produced which can serve future requirements at a lower cost with superior mechanical properties.

Recent research has also indicated that magnetic properties of high entropy alloys could also be promising.

References

- ^ Tsai, Ming-Hung; Yeh, Jien-Wei (30 April 2014). "High-Entropy Alloys: A Critical Review". Materials Research Letters. 2 (3): 107–123. doi:10.1080/21663831.2014.912690.

- Wang, Shaoqing (13 December 2013). "Atomic Structure Modeling of Multi-Principal-Element Alloys by the Principle of Maximum Entropy". Entropy. 15 (12): 5536–5548. doi:10.3390/e15125536.

{{cite journal}}: CS1 maint: unflagged free DOI (link) - ^ Zhang, Yong; Zuo, Ting Ting; Tang, Zhi; Gao, Michael C.; Dahmen, Karin A.; Liaw, Peter K.; Lu, Zhao Ping (April 2014). "Microstructures and properties of high-entropy alloys". Progress in Materials Science. 61: 1–93. doi:10.1016/j.pmatsci.2013.10.001.

- Huang KH, Yeh JW. A study on multicomponent alloy systems containing equal-mole elements . Hsinchu: National Tsing Hua University; 1996.

- ^ Yeh, J.-W. (May 2004). "Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes". Advanced Engineering Materials. 6 (5): 299–303. doi:10.1002/adem.200300567.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Cantor, B. (July 2004). "Microstructural development in equiatomic multicomponent alloys". Materials Science and Engineering: A. 375–377: 213–218. doi:10.1016/j.msea.2003.10.257.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Otto, F. (April 2013). "Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys". Acta Materialia. 61 (7): 2628–2638. doi:10.1016/j.actamat.2013.01.042.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Zou, Yu (February 2014). "Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy". Acta Materialia. 65: 85–97. doi:10.1016/j.actamat.2013.11.049.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Middleburgh, S.C. (June 2014). "Segregation and migration of species in the CrCoFeNi high entropy alloy". Journal of Alloys and Compounds. 599: 179–182. doi:10.1016/j.jallcom.2014.01.135.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Gali, A. (August 2013). "Tensile properties of high- and medium-entropy alloys". Intermetallics. 39: 74–78. doi:10.1016/j.intermet.2013.03.018.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Miracle, Daniel (10 January 2014). "Exploration and Development of High Entropy Alloys for Structural Applications". Entropy. 16 (1): 494–525. doi:10.3390/e16010494.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help)CS1 maint: unflagged free DOI (link) - Greer, A. Lindsay (25 December 1993). "Confusion by design". Nature. 366 (6453): 303–304. doi:10.1038/366303a0.

- ^ Zhang, Y. (June 2008). "Solid-Solution Phase Formation Rules for Multi-component Alloys". Advanced Engineering Materials. 10 (6): 534–538. doi:10.1002/adem.200700240.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Takeuchi, Akira (2005). "Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element". Materials Transactions. 46 (12): 2817–2829. doi:10.2320/matertrans.46.2817.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Guo, Sheng (2011). "Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys". Journal of Applied Physics. 109 (10): 103505. doi:10.1063/1.3587228.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Tsai, Ming-Hung; Tsai, Kun-Yo; Tsai, Che-Wei; Lee, Chi; Juan, Chien-Chang; Yeh, Jien-Wei (20 August 2013). "Criterion for Sigma Phase Formation in Cr- and V-Containing High-Entropy Alloys". Materials Research Letters. 1 (4): 207–212. doi:10.1080/21663831.2013.831382.

- Youssef, Khaled M.; Zaddach, Alexander J.; Niu, Changning; Irving, Douglas L.; Koch, Carl C. (9 December 2014). "A Novel Low-Density, High-Hardness, High-entropy Alloy with Close-packed Single-phase Nanocrystalline Structures". Materials Research Letters. 3 (2): 95–99. doi:10.1080/21663831.2014.985855.

- Ji, Wei; Wang, Weimin; Wang, Hao; Zhang, Jinyong; Wang, Yucheng; Zhang, Fan; Fu, Zhengyi (January 2015). "Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering". Intermetallics. 56: 24–27. doi:10.1016/j.intermet.2014.08.008.

- Yao, Chen-Zhong; Zhang, Peng; Liu, Meng; Li, Gao-Ren; Ye, Jian-Qing; Liu, Peng; Tong, Ye-Xiang (November 2008). "Electrochemical preparation and magnetic study of Bi–Fe–Co–Ni–Mn high entropy alloy". Electrochimica Acta. 53 (28): 8359–8365. doi:10.1016/j.electacta.2008.06.036.

- Zhang et.al (Scientific Reports Volume: 3 Published: MAR 15 2013,DOI: 10.1038/srep01455)

, can be used to determine an upper bound on the number of phases that will form in an equilibrium system. In his 2004 paper, Cantor created a 20-component alloy containing 5 at% of Mn, Cr, Fe, Co, Ni, Cu, Ag, W, Mo, Nb, Al, Cd, Sn, Pb, Bi, Zn, Ge, Si, Sb, and Mg. At constant pressure, the phase rule would allow for up to 21 phases at equilibrium, but far fewer actually formed. The predominant phase was a

, can be used to determine an upper bound on the number of phases that will form in an equilibrium system. In his 2004 paper, Cantor created a 20-component alloy containing 5 at% of Mn, Cr, Fe, Co, Ni, Cu, Ag, W, Mo, Nb, Al, Cd, Sn, Pb, Bi, Zn, Ge, Si, Sb, and Mg. At constant pressure, the phase rule would allow for up to 21 phases at equilibrium, but far fewer actually formed. The predominant phase was a  , and the phase with the lowest

, and the phase with the lowest

is the binary enthalpy of mixing for A and B. Zhang et al. found, empirically, that in order to form a complete solid solution, ΔHmix should be between -10 and 5 kJ/mol. In addition, Otto et al. found that if the alloy contains any pair of elements that tend to form ordered compounds in their binary system, a multi-component alloy containing them is also likely to form ordered compounds.

is the binary enthalpy of mixing for A and B. Zhang et al. found, empirically, that in order to form a complete solid solution, ΔHmix should be between -10 and 5 kJ/mol. In addition, Otto et al. found that if the alloy contains any pair of elements that tend to form ordered compounds in their binary system, a multi-component alloy containing them is also likely to form ordered compounds.

. Formation of a solid solution phase requires a δ≤6.6%, but some alloys with 4%<δ≤6.6% do form intermetallics.

. Formation of a solid solution phase requires a δ≤6.6%, but some alloys with 4%<δ≤6.6% do form intermetallics.